Abstract

The aim of this study was to improve the quality and nutritional value of Barbari bread using sourdough and whole wheat-barley flour. To optimize the fermentation condition, the effect of sourdough content (15–30%), temperature (30–45 °C), and time (30–120 min) of fermentation on Barbari bread characteristics (specific volume, porosity, textural characteristics, phytic acid and sensory properties) were investigated. The optimal conditions obtained by the model for the production of Barbari bread were found 30.00% sourdough, 39.39 °C temperature, and 55.81 min fermentation time. Under optimal condition, the overall acceptance, hardness, gumminess, chewability, volume, porosity, and phytic acid were 3.63, 38.58 N, 24.61 N, 193.50 N/mm, 1.69%, 17.71%, and 0.151%, respectively, which was consistent with experimental data. The phytic acid content significantly decreased by increasing sourdough and fermentation time, which resulted in the highest content of zinc and iron content.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Bread is the basis of the daily diet in many countries and continues to be the most widely consumed food for many populations because of its inexpensive cost, easy preparation, pleasant taste, and high nutritious value as a source of energy, protein, and fiber [1]. Wheat flour is the main ingredient of the bread and creates the specific structure of dough when it comes into contact with water. As a result, wheat flour is the only flour of cereal, which provides the exclusive quality of sha** the structure and appearance of bread and other bakery products. Different investigations have been conducted to improve bread quality and nutrition [2,3,4,5].

Barbari is a type of yeast-leavened traditional bread of Iran produced by baking in special ovens and under defined conditions of mass consisting of wheat white flour with 67.5 to 95% extraction rates, water, sourdough, and small amount of other ingredients such as salt and sugar. Although refined white flour has many nutritional benefits, it may be contributed to mineral deficiencies over time due to its phytic acid content and associated with different problems, such as allergies, cardiovascular diseases, type 2 diabetes, and some cancers at the high level of consumption [1]. In contrast, diets rich in whole grain foods are suggested for their health beneficial effects and to help protect against chronic diseases, as well as body weight management [6].

Whole flours are more nutritious than white flours because they retain the bran and germ fractions of the grain that are separated from the endosperm during the milling and refining process. The bran contributes diverse nutrients, including dietary fiber, vitamins, minerals, polyphenolic compounds, and antioxidants, so bread making with whole flour as a principal ingredient in place of refined flour will be richer in these nutrients and phytochemicals [7]. However, the structure of cereal whole grains makes them resistant to digestion due to their cell walls and the dense particles which are digested slowly or in some cases remain largely undigested in the small intestine and passes into the colon where it fermented by the present bacteria [8]. Therefore, it is preferred to use mixed whole flours for special baked products to retain the desirable characteristics and obtain enhanced value grain-based foods.

Sourdough, as one of the most ancient cereal fermentations, is a complex biological ecosystem in which spontaneous fermentation occurs based on lactic acid and the alcoholic fermentation of flour and water. The main functions of sourdough fermentation depends on both the fermentation conditions, and bacterial sources, are to leaven the dough, which results in the production of a gaseous ecosystem, and development of porous crumb structure, organic acids, and many other functional compounds which has various favorable influences on bread quality, digestibility, and flavor [9]. Moreover, the influence of microflora composition and fermentation conditions for phytate degradation is fully recognized [10].

The use of bran and whole grain flour changes dough rheology and causes difficulties in manufacturing bread. Moreover, substituting whole wheat or other cereal flours for white refined wheat flour will give less volume, more compact texture and will cause changes in flavor, and color. Therefore, the aim of the present study was to improve the quality characteristics, and nutritional value using sourdough and whole wheat-barley flours. Moreover, the dough process depends on both the microflora composition and fermentation conditions; hence, the influence of the controlled fermentation condition of sourdough to enhance the quality and sensory attributes of the composite wheat-barley Barbari bread was evaluated. Main parameters of optimization were sourdough content, temperature and time of fermentation.

2 Materials and methods

2.1 Materials

The whole wheat flour (moisture: 12%, ash: 1.54%, protein: 15.74%, wet gluten: 25.50%, Fe: 32.47 mg kg−1, Zn: 25.21 mg kg−1, and phytic acid content: 1.40%) and whole barley flour (moisture: 8.63%, ash: 2.17%, protein: 12.13%, gluten: 0%, Fe: 54.19 mg kg−1, Zn: 38.14 mg kg−1, and phytic acid content: 0.39%) were prepared from Khorasan Industrial Gas company (Khorasan Industrial Gas, Iran). All chemicals were used in this study were purchased from Merck Company (Germany) and were of analytical grade.

2.2 Barbari bread production

First, whole wheat and whole barley flours were mixed in a ratio of 50:50, and then other ingredients were added. Sunflower oil (2%), salt (1%), sugar (5%), sourdough (15–30%), and an appropriate amount of water were used in the dough formulation. Sourdough with spontaneous fermentation was applied in the preparation of Barbari bread [11]. In the first step, dry ingredients (flour, sugar, and salt) were mixed in a blender bowl (made in Taiwan) for 10 min, and then the sourdough was added with some water and oil, and stirring was continued for 5 min. The blending of the dough continued in a spiral dough mixer (made in Taiwan). The dough was placed in a cabinet with a relative humidity of 85% at various temperatures (30–45 °C) for different times (30–120 min). Then, the dough was divided into 250 g portions, and after resting, each portion was shaped with a thickness of 10 mm. After resting, the bread was baked (250 °C for 10 min). In order to analyze quality parameters, the bread was cooled to room temperature for 1 h and placed in polyethylene bags.

2.3 Chemical composition

The chemical composition of the flour (moisture, total protein, gluten, and ash) was determined according to the American Association of Cereal Chemists (AACC) methods (AACC 2000).

2.4 Determination of zinc and iron

Atomic absorption spectrophotometer (GBC equipment, Australia) was used to measure Zinc (Zn) and iron (Fe) salts. 5 g of dried bread was placed in a flame and then put in the electric oven (550º C) and kept for 8 h. The bread ash was cooled in desiccators. Then, 2 mL of HCl (0.5 N) was added to the ash and heated. The digested samples were filtered through Whatman No. 41 filter paper. 0.1 N nitric acid was used in the final dilutions of the digested samples. The standard solutions of Zn and Fe elements were prepared, and standard curves were curved for each element by atomic absorption spectrophotometer [12].

2.5 Phytic acid concentration

Phytic acid content was measured via the spectrophotometry method. In summary, 5 g of sample was added to 100 ml of 1.2% HCl solution containing 10% sodium sulfate and placed on shaker for 24 h at room temperature (25 °C). Then, it was centrifuged at 5000 rpm for 40 min. 10 ml of supernatant containing the extracted phytic acid was removed and 5 ml of 0.6% HCl solution containing 5% sodium sulfate and 0.4% Fe (III) chloride added. The mixture was placed in a boiling water bath for 40 min until a precipitate formed. The ferric phytate precipitate was separated from the solution by centrifugation at 5000 rpm for 30 min. Then, 6 ml of a mixture of sulfuric acid and concentrated nitric acid (1: 1 v/v) was added. The solution was completely digested. 10 ml of distilled water was added to the digested solution, and heated for 30 min in a boiling water bath until the pyrophosphate was completely eliminated. Then, the solution was diluted and 15 ml of ammonium heptamolybdate solution was added. After 15 min of resting the solution, the adsorption of the sample was read at 420 nm and the amount of phytic acid was determined using a standard curve [13].

2.6 Properties of bread

2.6.1 Specific volume

The specific volume of bread was measured by the seed displacement method [14].

2.6.2 Crumb porosity

Porosity of bread crumb was measured by image processing method. The crumb bread image was captured with a scanner (resolution of 300 pixels) (Scanjet G2710 HP, china). After adjusting the threshold of the gray scale picture, pore area fractions were analyzed with ImageJ software. Before analysis, the pixel values were converted to distance units [15].

2.6.3 Texture analysis

The bread samples were cut into square pieces (30 × 30 mm). Texture Analyzer device (TA-XT Plus Texture Analyzer, England) was used to determine texture properties. Texture profile analysis (TPA) was conducted to determine texture properties (hardness, gumminess, and chewiness). The bread pieces were subjected to compression cycles using a cylindrical probe with a diameter of 75 mm at 1 mm/s rate to 50% of their original height [16, 17].

2.6.4 Sensory analysis

Sensory properties were investigated by 25 trained panelists (from the age range of 24 to 40 years) in the format of 5-point Hedonic Scale (5 = like extremely; 4 = like moderately; 3 = neither like nor dislike; 2 = dislike moderately; and 1 = dislike extremely). The panelists were advised to drink warm water between the two samples to omit the effect of each sample on the other. Overall acceptance as the major sensory parameter was applied for fermentation condition optimization [18].

2.6.5 Statistical analysis and optimization

RSMFootnote 1 (CCDFootnote 2) was used to estimate the effect of the variables (amount of sourdough (X1), temperature (X2) and fermentation time (X3)) on responses (Y) including (volume, hardness, gumminess, chewiness, and porosity), nutritional properties (phytate content, iron, and zinc) and sensory properties (acceptance) (Table 1). Face centered-CCD (FC-CCD) matrix was used to design experiments. Data were analyzed using Design Expert Software version 10.0.0 (Statsoft Inc, USA). Significant effect of F-test (P < 0.05), non-significant lack-of-fit test, and suitable correlation coefficient (R2) was considered to select the appropriate model. Chewiness, porosity, and overall acceptability of the bread were specified as maximum level and hardness, gumminess, and phytic acid were specified as minimum desirable. A verification experiment was performed in the experimental domain. All importance coefficients were considered 3. The amount of phytic acid content had higher degree of importance than other responses.

3 Results and discussion

The quadratic equation was used to fit the experimental data and predict the responses.

The significance of each equation was determined by analysis of variance (ANOVA) at 5% level.

In this relation, Y is the dependent variable (responses), b is the coefficient of the equation and X is the independent variable. Accordingly, the quadratic model was identified as the best model for fitting responses (Table 1). Table 2 presents the coefficients and correlation coefficient for the equation of each of the responses. Based on the equations related to each of the responses, it is possible to predict the responses based on the dependent variables.

3.1 Hardness

The results of this study showed that the hardness of bread was affected by the amount of sourdough, temperature, and fermentation time. The amount of sourdough and time had a significant effect on the hardness, while the fermentation time did not have a significant effect on this factor (Table 3). However, the interaction of temperature and time had a significant impact on bread hardness.

The hardness decreased with increasing amount of sourdough. Also, with increasing temperature from 30 to 37 °C, the amount of hardness decreased, and with increasing temperature, its value increased (Fig. 1A1).

Figure 1A2 shows the effect of temperature and time on bread hardness. The hardness of the bread significantly decreased by increasing the fermentation time from 30 to 75 min, but this decrease was not significant with increasing the time from 75 to 120 min.

These results were consistent with Ghiafe Davoodi et al. (2011) results [19]. The researchers stated that the lowest texture compaction and the highest elasticity were related to the samples with the longest fermentation time. In addition, in line with the effect of fermentation time on compaction, Qarooni et al. [20] stated that with increasing fermentation time, the number of gas cells increased, which was involved in reducing the compression of the bread texture and increasing the elasticity, although in this study the temperature and the amount of yeast were constant.

Robert et al. [21] investigated the effect of Lactobacillus plantarum and Leuconostoc mesentroids, and Leuconostoc citroeum primers during the bread making process from wheat sourdough by adding 2% bread yeast. Results of simultaneous fermentation of sourdough and Saccharomyces cerevisiae showed that in the presence of lactic acid bacteria (LAB), less ethanol but more glycerol was produced. The produced glycerol acts as a plasticizer or softener and increases the elasticity of the bread. Peighambardoust et al. [22] also showed that adding fresh and dry sourdough containing Lactobacillus reuteri to the dough resulted in bread with the highest compaction during storage. Siljeström et al. [23] reported that sourdough by affecting the activity of the alpha-amylase enzyme in flour reduces the hydrolysis of starch and limited release of low molecular weight dextrins, which increases the elasticity and softness of bread.

The sample containing 30% sourdough, and fermented at 30 °C for 75 min had the lowest hardness value. In an appropriate fermentation condition, more uniform gas bubbles produce and distribute, and creates better elasticity and proper formability of the dough. This dough results in more uniform porous bread so that the hardness of bread decreases [24]. At 30% of the sourdough, which was the highest level, the lowest texture hardness was obtained. In lower amounts of sourdough, longer fermentation time was required to create a soft texture. Kochaki et al. [25] also showed that in the samples prepared with Lactobacillus plantarum and Lactobacillus sanferansis, the hardness of bread decreased along with the increase of fermentation time. Gianotti et al. [26] reported the acidity of sourdough increases with increment of fermentation time and changes gluten behavior, which is one of the most important reasons for modifying the rheology of dough and bread. Piazza and Masi [27] stated that due to the differences in hydrophilic properties of the ingredients produced during different processes of dough and bread preparation, their firmness would be significantly different.

3.2 Gumminess

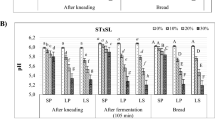

The amount of sourdough and time also had a significant effect on the gumminess of the breads and temperature did not have a significant effect on this response (Table 3). The effect of temperature–time interaction was significant.

As can be seen in Fig. 1B1, with increasing the amount of sourdough, the gumminess of the bread decreased and with increasing the temperature from 30 to 37 °C, the amount of gumminess decreased and then showed an increasing trend up to 40 °C.

Increasing the time from 30 to 75 min reduced the amount of gumminess, and increasing it to 120 min increased the gumminess value (Fig. 1B2).

3.3 Chewiness

All variables, sourdough, temperature, and time of fermentation, had a significant effect on the chewiness of the bread (Table 3). Also, their interactions had a considerable influence on this response (Table 3).

As shown in Fig. 1C1, with increasing the amount of sourdough, the chewiness decreased with a slight slope and with increasing the temperature from 30 to 37 °C, the amount of chewiness decreased (Fig. 1C2).

In lower amounts of sourdough or lower fermentation time and temperature, the chewiness ability increased, which could be due to the higher degree of hardness of the bread texture in these fermentation conditions. In general, the chewiness value depends on the elasticity and pores structure of the dough, the degree of swelling of the starch, and the enzymatic activity of the dough. If the fermentation process is not done enough, it lead to non-plasticization and bread elasticity reduces [28].

3.4 Porosity

According to Table 3 results, all three variables of sourdough, temperature, and time had a significant effect on bread porosity and none of them showed interaction with each other. The porosity of Barbari bread obtained from a mixture of whole barley flour and wheat was in the range of 11.19% to 18.65% (Fig. 2). The porosity of barley-wheat mixed flour bread was lower than wheat bread. Lower amount of gluten protein leads to weakening the gluten network in maintaining the gas during the fermentation process and decrease bread porosity.

By increasing the amount of sourdough from 15 to 22.50%, the porosity of bread increased, while by increment of sourdough from 22.50 to 30%, the variation in porosity continued with a lower slope. Also, with increasing temperature from 30 to 37 °C, the porosity increased, while with increment the temperature up to 45 °C, the porosity reduced (Fig. 2).

In general, higher porosity of the bread results in lower hardness of the bread. To increase porosity, gluten plays a major role in creating pores wall [29]. The trend of changes in porosity of bread was in line with changes in bread hardness. The results were consistent with the results presented by Clarke et al. [33].

3.5 Volume of bread

The results showed that the porosity was directly related to the specific volume (Table 3). By increment of sourdough, the bread volume increased (Fig. 3a). However, the increase of volume continued with a lower slope with increase of sourdough from 22.5 to 30%. With increasing the temperature, the bread volume increased and then decreased. The volume of bread enhanced with increasing fermentation time (Fig. 3b).

The increase in the specific volume of bread was produced by sourdough is attributed to the ability of the dough to expand and retain gases during the baking process (Karimi et al., 2012). The specific volume of wheat-barley bread was less than wheat flour. Shahsavan Tabrizi [30] also reported addition of soy flour to wheat flour significantly decreased the volume of bread.

The results obtained in this study were consistent with the reports provided by other researchers in this field. Sarfaraz et al. [31] and Corsetti et al. [32] reported that the specific volume of bread increased by adding sourdough [31, 32]. Clarke et al. [28] presented similar results on increasing the specific volume of sourdough bread compared to chemically acidified bread and non-sourdough bread [33]. They reported production of exopolysaccharides and increasing arabinoxylan solubility were the main reasons of specific volume increase of bread containing sourdough.

In the samples with the highest percentage of sourdough, the specific volume significantly decreased with increasing fermentation time. But the volume increased with increasing fermentation time for bread contained low level of sourdough. According to the obtained results, fermentation time can be reduced by increasing the sourdough or the fermentation temperature. Significant reduction in the specific volume of bread by excessively increasing the amount of sourdough, fermentation temperature, or time is attributed to the reduction of gas storage capacity by the gluten network in these conditions. The production of organic acids increases with increasing fermentation time. Lower pH causes the activity of flour proteases, gluten proteolysis, weakening of the gluten network and finally reducing the gas storage capacity [34].

3.6 Phytic acid

As shown in Table 3, the fermentation temperature had a significant effect on the phytic acid content of bread. In addition, the influence of interaction between the amount of sourdough and time on the amount of phytic acid was significant.

By increasing the amount of sourdough from 15 to 22.5%, the amount of phytic acid in the bread decreased (Fig. 4a). Also, by increment of the fermentation temperature, a decreasing trend in the amount of phytic acid was observed. Increasing the fermentation time reduced the phytic acid content of the bread (Fig. 4b).

The time increasing along with low amounts of sourdough resulted in phytic acid reduction. Also, with increasing temperature in low amounts of sourdough, the amount of phytic acid decreased and in high amounts of sourdough, this trend reversed. It suggests the interaction of the sourdough effect with both temperature and time factors. Therefore, the lowest amount of phytic acid was obtained, about 22.5% sourdough, due to the temperature-sourdough interaction. In general, the presence of sourdough significantly reduced phytic acid content. The results were consistent with previous researches [35, 36]. In a similar study, using sourdough containing Lactobacillus plantarum and Lactobacillus ruteri (10, 20 and 30%) and appropriate fermentation time (40 min) significantly reduced the amount of phytic acid. They obtained the lowest phytic acid content (49.63 mg per 100 g) by adding sourdough containing Lactobacillus plantarum at a replacement level of 30% (highest replacement level) [37]. The greatest reduction in phytic acid content occurs in the bread-making process during the fermentation stage. Therefore, fermentation for more time and higher temperature or higher amount of sourdough results in a lower amount of phytic acid.

Mirshahidi et al. [28] also reported that the fermentation time, yeast content, and baking method had a significant effect on the amount of phytic acid of bread. Fermentation is the most important step to reduce phytic acid, which can reduce this substance by 31 to 85%. This decrease is due to the increased phytase activity of flour and the phytase activity of LAB strains. The reduction of phytic acid was intensified by the use of 30% sourdough due to the decrease in pH and approach to the optimal pH of phytase activity [37].

3.7 Overall acceptance

Among the main effects of independent variables, only time had a significant effect on the overall acceptance of the bread. The square of temperature and time also showed a significant effect on the overall acceptance of bread (Table 3).

As shown in Fig. 5a, by increasing the temperature from 30 to 37 °C, the overall acceptance of bread increased slightly and it decreased with increasing temperature from 37 to 45 °C. Regarding the amount of sourdough used in bread production and its effect on overall acceptance, as shown in Fig. 5b, with increasing the amount of sourdough from 15 to 22%, no significant change in overall acceptance was observed, but with increasing the amount to 30%, overall acceptance slightly increased. The overall acceptance improved as the fermentation time increased (Fig. 5b), which was probably related to the formation of more aromatic and texture-producing compounds and better chewability.

3.8 Optimization of fermentation conditions

The purpose of fermentation is to produce bread with the desired aroma and texture and a significant reduction in phytic acid. The results showed optimal production conditions obtained if the concentration of sourdough, fermentation temperature, and time were 30%, 39.39 °C and 55.81 min, respectively (Table 4). In the optimal sample, gumminess, chewiness, volume, porosity, and phytic acid were 24.61 N, 193.50 N/mm, 1.69%, 17.71%, and 0.15%, respectively. After optimization, a validation test was performed to confirm the optimized point, the results of which were close to the predicted data (Table 5).

3.9 Iron and zinc content

The results of iron and zinc amount (Table 1) showed that the amount of iron was related to fermentation condition. The amount of iron was observed between 1.21 and 3.15 mg/100 g. The results showed that with increasing the amount of sourdough and fermentation time, the amount of iron increased. The highest amount of iron was obtained in the sample with the longest fermentation time and 22.5% sourdough. As the fermentation time decreased, the measured iron content decreased. Lopez et al. [38] compared the effects of different kinds of bread fermentation on mineral bioavailability. They stated that sourdough enhanced iron and zinc absorption [38].

The amount of zinc in Barbari bread samples prepared from whole wheat and barley flour ranged from 1.27 to 2.29 mg per 100 g, which was much higher than the values by Gargari et al. [39] 0.73 mg /100 g) and Najafi et al. [40] (1.9 mg/100 g) and Hojati et al. [41] (0.591 mg/100 g) were reported. As mentioned, the amount of iron and zinc in the bread samples of barley flour and whole wheat flour was positively affected by the time and temperature of fermentation or the amount of sourdough. Increasing the fermentation time reduced the amount of phytic acid and increased the bioavailability of minerals and the nutritional value of bread. In addition, the bran in whole wheat and barley flour increases iron and zinc in bread [39].

4 Conclusion

Results of this study revealed that the optimal fermentation condition for whole barley-wheat flour Barbari bread was 30.00% sourdough, 39.39 °C temperature, and 55.81 min fermentation time, which the overall acceptance, hardness, hardness, chewability, volume, porosity, and phytic acid were 3.63, 38.58 N, 24.61 N, 193.50 N/mm, 1.69%, 17.71%, and 0.151%, respectively. In optimum condition, phytic acid content noticeably decreased, which resulted in the highest content of zinc and iron content. All fermentation conditions (the sourdough content and fermentation temperature and time) parameters had a significant effect (p < 0.05) on the quality of bread.

Availability of data and materials

All data generated or analyzed during this study are available from the corresponding author on reasonable request.

Notes

Response Surface Methodology.

Central Composite Design.

References

Kourkouta L, Koukourikos K, Iliadis C, Ouzounakis P, Monios A, Tsaloglidou A (2017) Bread and health. J Pharmacy Pharmacol 5(11):2328–2150

Hosseininezhad M, Abedfar A (2018) A study on the qualitative characteristics and microbial survival of lactobacillus acidophilus and bacillus coagulans in probiotic bread. Res Innov Food Sci Technol 7(3):337–352

Hosseininezhad M, Anvari H, Zhiani M, Abedfar AA (2017) Evaluating the effect of inulin supplementary on the sensory and textural properties of prebiotic bread (Taftoon). Res Innov Food Sci Technol 6(2):185–198

Wang Y, Trani A, Knaapila A, Hietala S, Coda R, Katina K, Maina NH (2020) The effect of in situ produced dextran on flavour and texture perception of wholegrain sorghum bread. Food Hydrocolloids 105913

Sahraiyan B, Sheikholeslami Z, Karimi M (2020) Development of a Novel Edible Surface coating made by Lepidium Sativum seed gum and comparison of its effect with traditional glazes of sorghum gluten-free bread. Res Innov Food Sci Technol 8(4):405–414

Angioloni A, Collar C (2012) Effects of pressure treatment of hydrated oat, finger millet and sorghum flours on the quality and nutritional properties of composite wheat breads. J Cereal Sci 56(3):713–719

Seal CJ, Courtin CM, Venema K, de Vries J (2021) Health benefits of whole grain: effects on dietary carbohydrate quality, the gut microbiome, and consequences of processing. Compr Rev Food Sci Food Saf 20(3):2742–2768

Mishra S, Hardacre A, Monro J (2012) Food structure and carbohydrate digestibility. Carbohydr Compr Stud Glycobiol Glycotechnol 289–316

Abedfar A, Hosseininezhad M, Sadeghi A, Raeisi M, Feizy J (2018) Investigation on “spontaneous fermentation” and the productivity of microbial exopolysaccharides by Lactobacillus plantarum and Pediococcus pentosaceus isolated from wheat bran sourdough. LWT 96:686–693

Reale A, Konietzny U, Coppola R, Sorrentino E, Greiner R (2007) The importance of lactic acid bacteria for phytate degradation during cereal dough fermentation. J Agric Food Chem 55(8):2993–2997

Naji-Tabasi S, Shahidi Noghabi M, Hosseininezhad M, Zamani H, Hejrani T (2020) Use of sourdough containing Lactobacillus plantarum and traditional sourdough to improve the quality and shelf life of Barbari bread based on mixed whole flour. J Innov Food Sci Technol. In Press, https://doi.org/10.30495/JFST.2021.1916953.1689

Oury F-X, Leenhardt F, Remesy C, Chanliaud E, Duperrier B, Balfourier F, Charmet G (2006) Genetic variability and stability of grain magnesium, zinc and iron concentrations in bread wheat. Euro J Agron 25(2):177–185

ISIRI (2013) Institute of Standards and Industrial Research of Iran. Wheat - Wheat bran used for humans, ISIRI No. 17028. [In Persian]

Akbarian M, Mohebbi M, Koocheki A, Milani E, Khalilian Movahhed M (2020) The Evaluation of Xanthan Gum addition on the characteristics of local sweet bread (Kichi) and the use of image processing to the assessment of its microstructural properties. Res Innov Food Sci Technol 9(3):237–254

Naji-Tabasi S, Mohebbi M (2015) Evaluation of cress seed gum and xanthan gum effect on macrostructure properties of gluten-free bread by image processing. J Food Meas Charact 9(1):110–119

Sadeghi A, Shahidi F, Mortazavi A, Mahallati MN (2008) Evaluation of Lactobacillus sanfransicencis (ATCC 14917) and Lactobacillus plantarum (ATCC 43332) effects on Iranian Barbari bread shelf life. African J Biotechnol 7(18)

Zolfaghari M, Ardebili SMS, Asadi GH, Larijani K (2015) evaluating the effects of sourdough, bakery yeast and sodium bicarbonate on texture, volatile compounds and staling of barbari bread. Hacettepe J Biol Chem 43(4):283–293

Serka S, Getahun D, Abegaz K (2019) Formulation and sensory acceptability of flat bread from kocho with broad bean (Vicia faba L.) and quality protein maize (Zea mays) flours. J Food Process Technol 10(9)

Ghiafeh DM, Sahraiyan B, Naghipour B (2011) Effect of final fermentation time on barbari bread quality by addition of sodium stearoyl 2 lactilate. Gorgan, Iran: Conference on optimization of production, distribution and consumption in the Food Industry

Qarooni J (1989) The Handbook of Arabic Bread Production. Kuwait Flour Mills & Bakeries Company

Robert H, Gabriel V, Lefebvre D, Rabier P, Vayssier Y, Fontagné-Faucher C (2006) Study of the behaviour of Lactobacillus plantarum and Leuconostoc starters during a complete wheat sourdough breadmaking process. LWT-Food Sci Technol 39(3):256–265

Peyghambardoust S, Golshan TA, Khorasanchi N, Hejazi M, Rafat S (2010) Comparing the effects of fresh and dried sourdough on the sensory characteristics and staling of pan bread

Siljeström M, Björck I, Eliasson A-C, Lönner C, Nyman M, Asp N-G (1988) Effects on polysaccharides during baking and storage of bread—in vitro and in vivo studies. Cereal Chem 65(1):1–8

Naghipour F, Mazaheri Tehrani M, Sahraiyan B, Sheikholeslami Z, Soleimani M (2013) Replacing eggs with soy flour and mixing with wheat flour with wheat germ for oil cake production. Iranian J Nutr Sci Food Technol 8(2):211–220

Kochaki A, Sadeghi A, Hahidi FS, Mortazavi A, Nasiri M (2009) Sourdough effect on reduction of Barbari bread staling. J Water Soil Sci 13(47):37–46

Gianotti A, Vannini L, Gobbetti M, Corsetti A, Gardini F, Guerzoni ME (1997) Modelling of the activity of selected starters during sourdough fermentation. Food microbiol 14(4):327–337

Piazza L, Masi P (1995), Moisture redistribution throughout the bread loaf during staling and its effects on mechanical properties. Cereal chemistry (USA)

Mirshahidi M, Maghsoudlou Y, Khomeiri M, Ghorbani M (2010) The effect of yeast and the fermentation time on the phytic acid content and sensory properties of Barbari bread in Gorgan. EJFPP 2(1):15–26

Kamel BS (1987) Bread firmness measurement with emphasis on Baker compressimeter. Cereal Foods World 32(7):472–476

Shahsavan Tabrizi A (2013) The effect of soy flour on sensory properties, porosity and color of bread by image processing method. National Conference on Passive Defense in Agriculture. In: National Conference on Passive Defense in Agriculture: Iran.

Sarfaraz A, Azizi M, Esfahani ZH, Torshizi MK, Zafari A (2008) Interaction between lactic acid bacteria and baker’s yeast in liquid sourdough fermentation. Iranian J Nutr Sci Food Technol 3(2):73–80

Corsetti A, Gobbetti M, De Marco B, Balestrieri F, Paoletti F, Russi L, Rossi J (2000) Combined effect of sourdough lactic acid bacteria and additives on bread firmness and staling. J Agric Food Chem 48(7):3044–3051

Clarke CI, Arendt EK (2005) A review of the application of sourdough technology to wheat breads. Adv Food Nutr Res 49(1):137–161

Khorasanchi N, Peighambardoust S, Hejazi M, Rafat S (2013) Application of L. plantarum (ATCC 1058) and L. reuteri (ATCC 1655) as starter cultures in sourdough preparation

Arshadinezhad S, Azizi MH, Hamidi EZ (2005) Effect of different fermentation condition on phytic acid content of Barbari bread dough. Food Sci Technol 2(5):1–12

Beigmohammadi N, Karami M, Beigmohammadi F, Etminan AR (2016) Comparison of phytic acid content of traditional Lavash bread prepared from bakery’s yeast and sour dough and investigation of texture during fermentation. Food Sci Technol 14(64):190–179

Didar Z, Khodaparast MH (2011) Effect of different lactic acid bacteria on phytic acid content and quality of whole wheat toast bread

Lopez HW, Duclos V, Coudray C, Krespine V, Feillet-Coudray C, Messager A, Demigné C, Rémésy C (2003) Making bread with sourdough improves mineral bioavailability from reconstituted whole wheat flour in rats. Nutrition 19(6):524–530

Gargari B, Mahboob S, Razavieh S (2007) Content of phytic acid and its mole ratio to zinc in flour and breads consumed in Tabriz, Iran. Food Chem 100(3):1115–1119

Najafi MA, Rezaei K, Safari M, Razavi SH (2012) Use of sourdough to reduce phytic acid and improve zinc bioavailability of a traditional flat bread (sangak) from Iran. Food Sci Biotechnol 21(1):51–57

Hojati M, Jahangiri AR, Najafi MA (2015) Evaluation of phytic acid and zinc content in breads produced in Ahwaz. Food Sci Technol 12(47):9–19

Acknowledgements

The authors are thankful to the laboratories of the Research Institute of Food Science and Technology, Mashhad, Iran for their support to conduct the research work.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they do not have any conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Naji-Tabasi, S., Shahidi-Noghabi, M. & Hosseininezhad, M. Improving the quality of traditional Iranian bread by using sourdough and optimizing the fermentation conditions. SN Appl. Sci. 4, 148 (2022). https://doi.org/10.1007/s42452-022-05034-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s42452-022-05034-8