Abstract

Optimization of machining parameters like cutting speed, feed, and depth of cut is one of the extensively studied fields in the past two decades. While researchers agree optimization of these parameters is essential, there is no conscience as to what the objective of the optimization should be. The studies consider production cost, production time, surface finish, among others, as the objective of parameter optimization, but there are very few studies that consider the manufacturer prescribed tool life as the criteria for parament optimization. Among the methods that do consider tool life as an optimization objective, very few are closed-loop systems and these systems are facing challenges to generalizing when the application changes or the machining material changes or the tool geometry changes. Considering this, a novel image feedback using a convolution neural network-based method combined with principles of fuzzy logic is used to optimize machining parameters. Since the system is based on online feedback from the images of the inserts, it can be used for different materials, and the system is invariant to the different tool geometries and grades as the decisions are based on the wear mechanisms detected. The hybrid system is validated through experimentation for the turning application, but the methodology can be easily adapted for other machining applications.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

In the past decades, the optimization of machining parameters like cutting speed, feed, and depth of cut are extensively studied [2. In Sect. 3, the methodology is proposed starting with the overview followed by the basic concepts used in the system. In Sect. 4, the case study and the results are demonstrated. Finally, the further development needs in the full implementation of the system and the conclusions are given in Sect. 5.

2 Literature review

In this section, we first discuss the start of art technologies, followed by the different objectives for optimization and deficiencies of these systems. Finally, we explore the different prediction models used in the prediction.

Lan et al. [3] developed a system to maximize the tool life using fuzzy logic. This system optimizes the cutting speed, feed, and depth of cut using fuzzy rules, but there is no feedback loop in this system. Schultheiss et al. [32] studied the possibility of using a previously used tool for secondary machining operations. The authors in this study propose using alternatively left and right-hand cutters for using both sides of the nose. Haber et al. [12] developed a closed-loop fuzzy controller with an optimizer; this controller optimizes the feed rate based on force signals to achieve better tool life in drilling applications. The study also identified the need to tune fuzzy controllers using feedback. Bhushan [33] discussed the identification of significant combinations of critical machining parameters to achieve improvements in tool life and power consumption. The study takes an experimental approach to identify these significant combinations. Zhang et al. [34] Proposed an objective function to minimize the energy consumption; this objective function accounts for the stochastic nature of tool wear with other machining parameters. Finally, the authors arrive at the best combination to achieve better energy consumption. Shi et al. [35], in their study, established the relation between tool wear and power consumption. Ribeiro et al. [36], in their system, analyzed and optimized the machining parameters with the surface finish as the objective using an experimental approach. Moshat et al. [37] pointed to the popularity of Taguchi methodology when it comes to parameter optimization. The study proposed a hybrid Principle Component Analysis and Taguchi methodology to solve the optimization problem. Thepsonthi et al. [7] developed a multiobjective particle swarm optimization-based model for obtaining burr-free surface features along with the tool life. Yan et al. [20] proposed a multiobjective optimizer that considered production rate, cutting quality and energy consumption; the right cutting conditions are determined using weighted grey relational analysis. Ramesh et al. [19] investigated the optimal cutting parameters for better surface finish and better tool life using grey relation analysis and techniques for order preferences by similarity to ideal solution method. El-Hossainy et al. [38] introduced an optimizer using LINGO software; the software was optimizing different objective functions, and one of them is tool life. The system considered cutting speed, feed, and depth of cut as independent variables.

Surface finish [9, 39,40,41,42,43] is one of the primary objectives to optimize the machining parameters where inputs to prediction models are cutting speed, feed, and depth of cut, among others, and the model is expected to predict the surface finish. The drawbacks of using surface finish as an objective function are discussed in the previous section. The effects of various parameters on power consumption [42] are also studied extensively to provide the best working parameters that consume the least power. Often studies quote sustainable manufacturing while optimizing power consumption, but the studies do not consider the environmental impacts of the carbide ore extraction, supply chain, and how will improved tool life impact these aspects; there is a need for more holistic optimization when it comes to power consumption and sustainable manufacturing. Cycle time or production time [4] and Manufacturing cost [44, 45] are also a common objective to optimize the cutting parameters. Other than the above-mentioned objectives, some studies have also considered cutting force or load on machine [42] and material removal rate [46] as the objective to optimize the machining parameters. A complete review of different optimization objectives can be found in the study done by Rana et al. [47].

The machining parameter optimization objectives mentioned in the previous paragraphs are essential as they affect machining quality and production cost. On the other hand, if surface finish, power consumption, and production cost are considered without considering tool life, the manufacturers run the risk of underutilizing the tool or, in the worst-case, end up using the wrong tool, which drives up the tooling cost. Therefore, there is a need for a system that can optimize the tool life. In the context of optimized tool life, if the other desired outcomes like surface finish, production time, and cost are not achieved, the tool selection is wrong and has to be changed in consultation with tooling engineers.

The parameter optimization study has used a variety of methodologies to achieve the desired objectives. ANN is one of the new methodologies used in the last decade [42]; this methodology establishes the nonlinear relations between the input variables and target variables. The relation later helps in the prediction of outcomes of using individual machining parameter combinations. The genetic algorithm [48] is also a commonly used methodology based on the basic principle of selection of the best solution to the optimization problem. Experimentation, which involves trying different parameters and determining the best paraments of the lot, is also a common approach; the Taguchi method [9] is used to design these experiments. In the experimentation approach, which forms the basis of the above-mentioned methodologies, there is no room for a closed-loop system, which can adjust the parameters based on the online feedback from the change in a machining environment. The experimental approaches are at best useful to generate machining parameters data for catalogs; even for these applications, the experiment is trying different combinations without reliable feedback. The findings of these approaches are also limited to the material they are experimenting with or the tool geometries that are used in the studies. If the material or the tool geometry or the tool coating grade changes, the assumptions make the generalization of the findings for a different material or tool impossible. Therefore, there is a need for a methodology that can arrive at the best machining parameters using reliable feedback.

The proposed system develops a feedback loop and a closed system by optimizing the parameters based on the wear condition of the tools. The wear on the cutting tool is unavoidable. There are, however, desired and undesired wear patterns. The desired wear morphologies must prevail for the full utilization of cutting tools (or normal wear curve). Abrasion wear is the removal of small fragments [49] from the tool, which relatively preserves the rake angles of the cutting tool, giving the best life designed by the manufacturer. The abrasion wear pattern is also termed as normal flank wear by the tooling engineers. The other wear mechanism is plastic deformation, which significantly changes the working angles [49] of the insert rendering it unfit for machining in a short cutting time, this type of tool wear is commonly seen while machining high melting point material at high cutting speeds. The adhesive wear pattern is the other commonly seen wear pattern in the cutting insert, where the material being cut adheres to the cutting edge and the rake face [49], this leads to change in cutting angles and poses a risk to smooth chip flow which makes the tool unfit for machining, Built-Up Edge (BUE) is the industrially used term for this kind of wear pattern. The undesired wear patterns also lead to imperfections such as chatter marks, edge fettering, poor surface finish among others these effect the quality standards. The pictorial examples of these imperfections can be seen in the study conducted by Mamledesai et al. [21]. Considering that the plastic deformation and adhesive wear patterns drastically reduce the usability of the cutting tools (or generate abnormal wear curves), tool manufacturers prescribe remedy actions to achieve abrasive wear pattern, which is the ideal wear pattern to realize the full life of the cutting tool. The remedy actions to achieve abrasion wear patterns are discussed later in Sects. 3.3.

Parameter optimization based on tool condition monitoring can be done using indirect and direct monitoring methods [50]. Indirect methods use data from one or more of vibration [51,52,53], sound [54], and force [52] sensors. On the other hand, direct methods rely on first-hand evidence, like images of tools [55]. While indirect methods are online systems and give information on real-time bases, they are less accurate and susceptible to noise when the systems are deployed in machine shop floors [56]. Indirect systems are also trained for predictions based on specific experimental data provided by the sensors, and the model needs to be retrained if any of the parameters in the experiment change. For example, if the vibration sensor-based model is trained for finishing geometry, the same model can’t be used if the geometry changes to roughing geometry as the vibration levels are higher for roughing geometry; the same can be implied for other indirect methods. Direct systems like vision-based systems are not real-time systems but are in process systems; they can be designed to work in between cycles [18] and tool change programs. Since direct systems are based on first-hand evidence, they present the advantage of higher accuracy. Also, the vision systems can be placed away from the metal cutting; this allows them not to interfere with machining operations. That is why vision systems have gained popularity in inspects [57], collision detection [15, 16], and other applications. Direct systems can also be trained to monitor wear morphologies, which have specific remedial actions to achieve desired wear morphology. These remedy actions are common to different tool geometries, coating grates and workpiece materials. The ability to work with wear morphologies allows the system to generalize the remedy rules for different applications. Considering the higher accuracy of direct methods, combined with the ability to generalize remedy rules, the computer vision-based direct method is selected to create a feedback loop for a closed machining parameter optimization system that can respond to change in tool condition.

The gap in continuous machining parameter optimization using reliable feedback in the context of tool life is an area with scarce publications. As is evident in the literature discussed in the previous paragraphs, the proposed system is designed to address this gap. The developed system is a combination of a Convolutional Neural Network (CNN) and Fuzzy Logic (FL) methodology. The previous studies use FL for tool condition monitoring [58, 59], but FL is not the best approach for feature recognition since the feature descriptions have to be hardcoded in terms of fuzzy rules, which takes a considerable amount of computational memory and also FL systems can't accommodate new situations not bound by the rules [60]. In this regard, CNN approaches are more accurate and also don’t require the feature definition stage [61]; this expedites the training process and also improves the ability to recognize a variety of wear morphologies. FL, however, is efficient in converting human knowledge into variables computers can understand [60]. The FL in the proposed methodology is used to model the expert and tool manufacturer’s troubleshooting knowledge. The proposed hybrid system uses CNN as the feedback and FL as the controller, which selects and adapts the machining parameter.

3 Hybrid Fuzzy controller with an image feedback system

The overview of the proposed fuzzy controller can be seen in Fig. 4. The proposed system is divided into the controller and the feedback sections. The feedback section consists of the wear classifiers that classify the type of wear on the tool and the approximates amount of wear on the tool. The type of wear, amount of wear, the component diameter, and spindle revolutions per minute (RPM) form the inputs to the controller; these are further elaborated in Sect. 3.1. The first step in the controller is the fuzzification, where the change in cutting speed, wear type, and lever of wear are converted to linguistic variables discussed in Sect. 3.2. In Sect. 3.3, the rule base, which forms the intelligence of the controller for remedial actions as suggested by tooling engineers and tool manufacturers, is developed. The output of the controller is a crisp number that is used to control the cutting speed of the machine. The output of the system is a remedial action to achieve the desired wear morphology that improves tool life. The process of relying on the evidence of wear morphology, amount of wear, and the initial machining parameters replicate the tooling engineer decision-making process when it comes to machining parameter optimization. The techniques of output inference and defuzzification are discussed in Sect. 3.4.

3.1 Inputs to controller

The controller uses four inputs diameter of the component, RPM, type of wear, and level of wear. The cutting speed (\({\mathrm{V}}_{\mathrm{c}}\)) in meters per minute is calculated using Eq. 1 [62], where D is the diameter of the component to be machined in millimeters, and N is RPM of the workpiece.

There have been many studies in wear type identification and wear amount estimation fields. Sun and Yeh [63] developed an image processing methodology that can recognize the type of wear, and the level of wear is estimated by accounting for the number of pixels in the wear region. Wu et al. [61] took a neural network approach to identify the type of wear pattern and used a minimum circumscribed rectangle to get the quantity of the wear. The proposed system uses a neural network approach to identify the type of wear automatically by capturing the images of the used tools, and the amount of wear is manually calculated. However, there are other technologies developed that can also automate the amount of wear calculation.

Neural networks are one of the most used methods in image recognition. The neural network allows for automatic feature extraction by learning the nuanced differences in the images. The images are manually classified into different wear categories and are used to training and validate the classification models. Once the training is complete, the model can automatically identify the different wear patterns by uploading the new images.

The CNN architectures use different layers which perform different actions on the images. The convolution layers, narrow down on the region of interest and create useful descriptions of the images which make them best suited to work with images [64]. The output of the convolution layers then passes through the pooling layer, which in the case of the proposed architecture is a max-pooling layer which reports the maximum value in the predefined image pixel neighborhood. Max pooling layers make the proposed architecture more robust against small translation in image pixel data [65]. The dense layers are the fully connected layers where each neuron is interacting with all the neurons of the previous layers [66]. The last dense layer has the same amount of neurons as the number of wear classes, the output of the layer is the network’s prediction for the image belonging to three classes. This is summarized in Eq. 2 where \({\mathrm{y}}_{\mathrm{p}}\) is the prediction of the model.

Activation functions are commonly used in the neural network to allow them to accommodate and learn non-linear functions [65], Rectified Linear Unit (ReLU) is commonly used in hidden layers of the network architectures as they return zero gradient value of negative nodes and the node value for positive inputs this improves the computation easy [67]. The softmax activation function is used in the final layer to represent probability distribution over different classes, which is a common practice in classifier architectures [65].

The parameters are where the intelligence of the layers are stored in terms of weights. These weights are fine-tuned by backpropagation in the training process. The model uses categorical cross-entropy as loss function [65] and ADAM as the optimizer for training and optimizing the weights [66]. More information about the training and optimization of neural network architectures can be found in [61, 65]–[68]. The proposed system uses the CNN architecture proposed in Table 1 to classify the wear type.

The amount of wear is manually demarcated on the images of the used tools; although the magnitude can also be automatically generated by technologies discussed in [61, 63, 69], and many other studies, this work is not replicated. The type of wear (\({\mathrm{y}}_{\mathrm{p}}\)), amount of wear in terms of micrometers, and cutting speed (\({\mathrm{V}}_{\mathrm{c}}\)) form the inputs to the fuzzy controller.

3.2 Fuzzification

There are two variables, type of wear \(\chi_{T}\) and the amount of wear \(\chi_{A}\) which form the input to the fuzzy systems. \({\mathcal{L}}_{{\text{T}}} { = }\left\{ {{\text{"BUE"}}, {\text{"Deformation"}}, {\text{"Normal"}} {\text{"wear"}}} \right\}\), and \({\mathcal{L}}_{{\text{A}}} { = }\left\{ {{\text{"Low"}}, {\text{"Medium"}}, {\text{"High"}}} \right\}\) are the family of linguistic values for the type of wear and amount of wear, respectively. LT is the label used from family \({\mathcal{L}}_{{\text{T}}}\) and LA is the label used from family \({\mathcal{L}}_{A}\) this is summarized by Eqs. 3 and 4.

The amount of wear has a trapezoidal membership function [70]; this is summarized in Eq. 5, where xa is the measured value of wear on the cutting tool in micrometers and p,q,r,s are the boundary values of the membership function. Similarly, for the type of wear, the membership function is singleton given in Eq. 6, where \({\mathrm{x}}_{0}= {\mathrm{y}}_{\mathrm{p}}\).

The response (\(\mathfrak{R}\)) is divided into seven linguistic variables \(\mathcal{R}\). Where, \(\mathcal{R}\) = {Deformation High (DH), Deformation Medium (DM), Deformation Low (DL), Normal (N), BUE High (BH), BUE Medium (BM), BUE Low (BL)}. R is the label used from family \(\mathcal{R}\). The Gaussian membership function [70] for the response variable (\({\upmu }_{\mathrm{R}}\)) is given in Eq. 7, where c is the mean of the distribution, s is the standard deviation, and y is the output value. The mean of the linguistic response variables is dependent on the initial cutting speeds. The Gaussian membership is carefully chosen because we can easily control the distribution with two parameters compared to four in the trapezoidal membership function.

3.3 Rules

The rules for the fuzzy controller are developed using the knowledge base of troubleshooting guides from different tool manufacturers. The different statements extracted from troubleshooting guides are given in Table 2. The troubleshooting guides only suggest the overall remedy actions, but the magnitude of change in cutting speed or the feed rate is the skills developed by tooling engineers over time and experience; these skills are captured in the fuzzy rules.

Based on the information from the knowledge base and the tooling engineer’s skills, the fuzzy rules (\({\mathcal{H}}^{i}\)) are developed, the basic fuzzy rule is given by Eq. 8. The different linguistic values of LT, LA, and R for rule i are summarized in Table 3. The fuzzy rules model the expert statement; for example, rule 1 states that if the wear type is “BUE” and wear amount is “High” then increase the cutting speed by “BH,” where “BH” can be a percentage increase from initial cutting speed.

3.4 Inference and defuzzification

Mamdani-Assilan fuzzy inference method is used for fuzzy inference. This method is suitable for the application at hand as it can work with the conjunctive interpretation of fuzzy rules in the canonical form given in Eq. 8 [70]. The conjunctive “AND” is interpreted as the minimum (\(\wedge\)) [70]. The inference results from each rule are finally added using maximum (\(\vee\)) operation [70]. The final inference value \({\upmu }_{{{\text{R}}^{*} }} \left( {\text{y}} \right)\), which gives the area under all the triggered rules is given in Eq. 9.

The defuzzification is done using the center of gravity (COG) method [70] where the crisp number for the new cutting speed \({\text{y}}_{{{\text{new}}}}\) is returned by the controller. The COG of the aggregate area of all the rules represented by Eq. 9 is calculated using Eq. 10. \({\text{y}}_{{{\text{new}}}}\) is the new cutting speed used for the new machining cycle, which is influenced by initial cutting speed, type of wear, and amount of wear detected on the tool used in the previous cycle.

The fuzzy controller developed can only work with the cutting speed. Similarly, the fuzzy controllers can be developed for other machining parameters like feed rate and depth of cut. Cutting speed was considered as there is a consensus among the previous studies that the cutting speed is one of the most influential factors when it comes to tool life [73]74.

4 Case study

The purpose of this case study is to demonstrate the ability of the hybrid system to take remedy actions based on the wear morphology detected from the images of the cutting tools, and to demonstrate the positive effects of those remedy actions. Proving the effectiveness of the magnitude of changes (response) and the limits of linguistic variables is beyond the scope of the case study, and there is a need for more research in this direction.

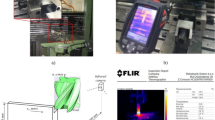

The case study started with the training and deployment of wear classification CNN. For the training, first, the images of used TNMG, CNMG and uncoated High Speed steel cutting tools that have BUE, deformation, and normal wear patterns are acquired using a GigE DFK 33GP006 image sensor with TCL 3520 5MP lens with a 35 mm focal length; the setup can be seen in Fig. 5. The examples of images from different categories can be seen in Fig. 6. The image sensor has a resolution of 2592 * 1955. The neural network models were built and trained in the Intel Core i5 processor using the Tensorflow backend and Keras higher level package. For the wear classification model, a total of 207 images were used to train the model discussed in Table 1, and 89 images were used for validation of the model. The images, when captured, were of different sizes but were resized to 200*200*3 RGB images using the EBImage [75] package.

The confusion matrix of wear type classification model’s predictions on the validation data set is shown in Table 4. The model has 86.52 percent accuracy and 0.3752 loss on the validation data set. The confusion matrix illustrates that the model performed reasonably well in identifying the wear patterns; the numbers in the diagonal of Table 4 are the correct predictions.

The wear classification model is then deployed using a Graphical user interface (GUI). The GUI asks the user to upload the image of the used tool, and the output is the type of wear, this is manually fed to the fuzzy controller. The examples of the deployed GUI can be seen in Fig. 7.

The amount of wear can be automatically measured using various technologies discussed in Sect. 3.1; however, in the proposed system, the measurement is done manually using commercially available IC Measure software [28]. The software uses image processing techniques. The calibration process prescribed by the makers were followed before measurement. Since the software is the intellectual property of the company further details are not shared by the makers. The examples of the measurements can be seen in Fig. 8.

The boundary values used to define the amount of wear trapezoidal membership function (p,q,r,s) are summarized in Table 5. These values are used with Eq. 5 to generate the membership functions for high, medium, and low linguistic variables as shown in Fig. 9b; similarly, the membership function for the type of wear is shown in Fig. 9a. The c and s values used to define the response linguistic variable’s Gaussian membership functions are summarized in Table 6.

For the fuzzy controller evaluation, Micro-Mark mini-lathe 7 × 16 is used for machining. The tools used are uncoated high-speed steel tools. The workpiece material is Stainless steel 304. The cutting speed was monitored by recording the diameter of the component and the RPM (measured using REED instruments R7050 photo tachometer and counter). The standard operating procedure in Table 7 was followed for collecting the data; the steps are repeated after every cut of 78 mm.

The data is collected for four cutting edges; the result of the experiment is shown in Appendix 1 and summarized in Fig. 10. Tool 1 and Tool 3 are initiated with abnormally low (23 m/min) and high (39 m/min) cutting speeds, respectively, which generated BUE and Deformation. The use of tools is stopped when the undesired wear patterns are detected. The life for Tool 1 and Tool 2 in terms of contract length is 312 mm and 234 mm, respectively. When the undesired wear patterns are detected, the fuzzy controller suggested the change in cutting speed; when the suggestion is used while machining with Tool 2 and Tool 4, the tool life improved by more than 100 percent, as shown in Fig. 10.

Consolidated results from the experimental data presented in Appendix 1

The study illustrates the ability of the system to detect different wear morphologies and take remedy actions by changing the cutting speed to achieve the desired wear patterns and, in this process, achieve better tool life. The system can work with different materials and tool geometries as the remedy actions are based on the wear morphologies. The system was evaluated on a manual lathe, which did not allow for the control of feed rate.

The study considered cutting speed as the optimizing parameter as it has maximum impact on the tool life [73], 74]. To further advance the scope of this study the fuzzy controller will have to modified to be a multiple output optimization fuzzy controller as discussed in the study done by Rodic [76]. Similar fuzzy rules, as discussed in Sect. 3.3, will have to be developed for remedy actions that involve controlling feed rates and depth of cut based on the remedial actions prescribed for different wear patterns. The future work will be bidirectional. One, towards including a wider range of undesired wear patterns other than BUE and Deformation like chip**, crater wear, among others, which require us to control other machining parameters like feed rate and depth pf cut as part of remedy actions. Second, There is also a need to make the system completely automatic by integrating the outputs of the wear classification model, wear amount measurement tool with the input to the controller, this process in the proposed study is done manually.

5 Conclusion

Machining parameter optimization is one of the extensively studied fields of manufacturing, with the objective of optimization being different. The proposed system uses the theory of wear mechanism to optimize the machining parameters. The objective of the study is to get the desired wear pattern when undesired wear patterns are detected to achieve better tool life. This problem is divided into two sections first, the detection of wear mechanism and level of wear, and in the second section, these detections are used as signals to trigger fuzzy rules, which change the machining parameter to obtain the desired wear pattern in the next cutting edge. The system uses CNN for the detection of wear mechanisms. The fuzzy controller uses the output of wear classifier, amount of wear, and current state of machining parameters as input to suggest changes to the machining parameters for the next cutting edge. The case study developed illustrates that when the suggested changes are incorporated, the tool life can be improved by 100 percent. Since the system is dependent on the wear morphology as feedback to the deployed parameters, the system is not limited by the working material or tool geometries.

References

**ao Q, Li C, Yi Q, Wang Q. (2017) An industrial data based investigation into effects of process parameters on cutting power and energy efficiency. IEEE international conference on automation science and engineering, vol. 2017-Augus, pp 1481–1486, https://doi.org/10.1109/COASE.2017.8256313.

Diyaley S, Chakraborty S (2019) Metaheuristics-based parametric optimization of multi-pass turning process: a comparative analysis. Opsearch 57(2):414–437. https://doi.org/10.1007/s12597-019-00420-0

Lan TS, Chuang KC, Chen YM (2018) Optimization of machining parameters using fuzzy Taguchi method for reducing tool wear. Appl Sci (Switzerland). https://doi.org/10.3390/app8071011

Quiza Sardiñas R, Rivas Santana M, Alfonso Brindis E (2006) Genetic algorithm-based multi-objective optimization of cutting parameters in turning processes. Eng Appl Art Intell 19(2):127–133. https://doi.org/10.1016/j.engappai.2005.06.007

Hashmi K, Graham ID, Mills B (2000) Fuzzy logic based data selection for the drilling process. J Mater Process Technol 108(1):55–61. https://doi.org/10.1016/S0924-0136(00)00597-5

Ghani JA, Rizal M, Nuawi MZ, Ghazali MJ, Haron CHC (2011) Monitoring online cutting tool wear using low-cost technique and user-friendly GUI. Wear 271(9–10):2619–2624. https://doi.org/10.1016/j.wear.2011.01.038

Thepsonthi T (2014) An integrated toolpath and process parameter optimization for high-performance micro-milling process of Ti–6Al–4V titanium alloy. Int J Adv Manuf Technol 75:57–75. https://doi.org/10.1007/s00170-014-6102-2

Shankar NVS, Chandu KS, Kumar NP, Sankar HR, (2018) Process parameter optimization for minimizing vibrations and surface roughness during turning en19 steel using coated carbide tool,” 3rd International conference on advances in materials and manufacturing applications, vol 24, p 410, https://doi.org/10.1016/j.matpr.2020.04.387.

Sarỳkaya M, Dilipak H, Gezgin A (2015) Optimization of the process parameters for surface roughness and tool life in face milling using the Taguchi analysis. Materiali in Tehnologije 49(1):139–147

Morkun V, Morkun N, Tron V, Paraniuk D, Sulyma T (2020) Adaptive control of drilling by identifying parameters of object model under nonstationarity conditions Volodymyr. Min Miner Depos 14(1):100–106

Haber RE, Gajate A, Liang SY, Haber-Haber R, Del Toro RM (2011) An optimal fuzzy controller for a high-performance drilling process implemented over an industrial network. Int J Innov Comput Inform Control 7(3):1481–1498

Haber RE, Del Toro RM, Gajate A (2010) Optimal fuzzy control system using the cross-entropy method. A case study of a drilling process. Inf Sci 180(14):2777–2792. https://doi.org/10.1016/j.ins.2010.03.030

Haber RE, Alique JR, Alique A, Hernández J, Uribe-Etxebarria R (2003) Embedded fuzzy-control system for machining processes: results of a case study. Comput Ind 50(3):353–366. https://doi.org/10.1016/S0166-3615(03)00022-8

Ren Q, Balazinski M, Baron L, Jemielniak K, Botez R, Achiche S (2014) Type-2 fuzzy tool condition monitoring system based on acoustic emission in micromilling. Inf Sci 255:121–134. https://doi.org/10.1016/j.ins.2013.06.010

Ahmad R, Tichadou S, Hascoet JY (2013) 3D safe and intelligent trajectory generation for multi-axis machine tools using machine vision. Int J Comput Integr Manuf 26(4):365–385. https://doi.org/10.1080/0951192X.2012.717720

Ahmad R, Tichadou S (2010) Integration of vision based image processing for multi-axis CNC machine tool safe and efficient trajectory generation and collision avoidance. J Mach Eng 10(4):53–65

Ahmad R, Tichadou S, Hascoet JY (2017) A knowledge-based intelligent decision system for production planning. Int J Adv Manuf Technol 89(5–8):1717–1729. https://doi.org/10.1007/s00170-016-9214-z

Siddhpura A, Paurobally R (2013) A review of flank wear prediction methods for tool condition monitoring in a turning process. Int J Adv Manuf Technol 65(1–4):371–393. https://doi.org/10.1007/s00170-012-4177-1

Ramesh S, Viswanathan R, Ambika S (2016) Measurement and optimization of surface roughness and tool wear via grey relational analysis, TOPSIS and RSA techniques. Measurement 78:63–72. https://doi.org/10.1016/j.measurement.2015.09.036

Yan J, Li L (2013) Multi-objective optimization of milling parameters e the trade-offs between energy, production rate and cutting quality. J Clean Prod 52:462–471. https://doi.org/10.1016/j.jclepro.2013.02.030

Mamledesai H, Soriano MA, Ahmad R (2020) A qualitative tool condition monitoring framework using convolution neural network and transfer learning. Appl Sci 10(20):7298. https://doi.org/10.3390/app10207298

Astakhov V, Paulo Davim J (2008) Machining. Springer, London

Oguamanam DCD, Raafat H, Taboun SM (1994) A machine vision system for wear monitoring and breakage detection of single-point cutting tools. Comput Ind Eng 26(3):575–598. https://doi.org/10.1016/0360-8352(94)90052-3

Taegutec, “Taegutec catalog trouble shooting.” http://netpmcomp.pl/cms/wp-content/uploads/2015/05/taegutec_i_grades_en1.pdf (Accessed Jun. 18, 2020).

Tungaloy, “User’s guide - Technical reference.” https://www.tungaloy.com/wp-content/uploads/GC_2018-2019_EE.pdf (Accessed Jun. 18, 2020).

Sandvik, “Wear on cutting edges.” https://www.sandvik.coromant.com/en-gb/knowledge/materials/pages/wear-on-cutting-edges.aspx#:~:text=Crater wear on the, is amplified by cutting speed. (Accessed Jun. 18, 2020).

Varela-Santos S, Melin P (2021) A new approach for classifying coronavirus COVID-19 based on its manifestation on chest X-rays using texture features and neural networks. Inf Sci 545:403–414. https://doi.org/10.1016/j.ins.2020.09.041

Imagesource, “IC Measure software.” https://www.theimagingsource.com/products/software/end-user-software/ic-measure/ (Accessed Jun. 15, 2020).

Bernal E, Castillo O, Soria J, Valdez F (2019) Optimization of fuzzy controller using galactic swarm optimization with type-2 fuzzy dynamic parameter adjustment. Axioms 8(1):26. https://doi.org/10.3390/axioms8010026

Castillo O, Cervantes L, Soria J, Sanchez M, Castro JR (2016) A generalized type-2 fuzzy granular approach with applications to aerospace. Inf Sci 354:165–177. https://doi.org/10.1016/j.ins.2016.03.001

Ontiveros-Robles E, Melin P, Castillo O (2018) Comparative analysis of noise robustness of type 2 fuzzy logic controllers. Kybernetika https://doi.org/10.14736/kyb-2018-1-0175.

Schultheiss F, Zhou J, Gröntoft E, Ståhl JE (2013) Sustainable machining through increasing the cutting tool utilization. J Clean Prod 59:298–307. https://doi.org/10.1016/j.jclepro.2013.06.058

Bhushan RK (2013) Optimization of cutting parameters for minimizing power consumption and maximizing tool life during machining of Al alloy SiC particle composites. J Clean Prod 39:242–254. https://doi.org/10.1016/j.jclepro.2012.08.008

Zhang X, Yu T, Dai Y, Qu S, Zhao J (2019) 2020, “Energy consumption considering tool wear and optimization of cutting parameters in micro milling process.” Int J Mech Sci 178(November):105628. https://doi.org/10.1016/j.ijmecsci.2020.105628

Shi KN, Zhang DH, Liu N, Wang SB, Ren JX, Wang SL (2018) A novel energy consumption model for milling process considering tool wear progression. J Clean Prod 184:152–159. https://doi.org/10.1016/j.jclepro.2018.02.239

Ribeiro J, Lopes H, Queijo L, Figueiredo D (2017) Optimization of cutting parameters to minimize the surface roughness in the end milling process using the Taguchi method. Period Polytechn Mech Eng 61(1):30–35. https://doi.org/10.3311/PPme.9114

Moshat S, Datta S, Bandyopadhyay A, Pal PK (2010) Optimization of CNC end milling process parameters using PCA-based Taguchi method. Int J Eng Sci Tech 2(1):92–102

El-Hossainy TM, El-Zoghby AA, Badr MA, Maalawi KY, Nasr MF (2010) Cutting parameter optimization when machining different materials. Mater Manuf Process 25(10):1101–1114. https://doi.org/10.1080/10426914.2010.480998

Ahilan C, Kumanan S, Sivakumaran N, Edwin Raja Dhas J (2013) Modeling and prediction of machining quality in CNC turning process using intelligent hybrid decision making tools. Appl Soft Comput J 13(3):1543–1551. https://doi.org/10.1016/j.asoc.2012.03.071

Kuo WF and Lee CH, (2019) “Machining parameters selection for high speed processing,” 2019 International conference on engineering, science, and industrial applications, ICESI 2019, pp 1–6, https://doi.org/10.1109/ICESI.2019.8862997.

Khare SK, Agarwal S (2017) Optimization of machining parameters in turning of AISI 4340 steel under cryogenic condition using Taguchi technique. Proced CIRP 63:610–614. https://doi.org/10.1016/j.procir.2017.03.166

Solarte-Pardo B, Hidalgo D, Yeh SS (2019) Cutting insert and parameter optimization for turning based on artificial neural networks and a genetic algorithm. Appl Sci (Switzerland) 9(3):479. https://doi.org/10.3390/app9030479

Karayel D (2009) Prediction and control of surface roughness in CNC lathe using artificial neural network. J Mater Process Technol 209(7):3125–3137. https://doi.org/10.1016/j.jmatprotec.2008.07.023

Chen MC, Tsai DM (1996) A simulated annealing approach for optimization of multi-pass turning operations. Int J Prod Res 34(10):2803–2825. https://doi.org/10.1080/00207549608905060

Onwubolu GC, Kumalo T (2001) Optimization of multipass turning operations with genetic algorithms. Int J Prod Res 39(16):3727–3745. https://doi.org/10.1080/00207540110056153

Yang SH, Natarajan U (2010) Multi-objective optimization of cutting parameters in turning process using differential evolution and non-dominated sorting genetic algorithm-II approaches. Int J Adv Manuf Technol 49(5–8):773–784. https://doi.org/10.1007/s00170-009-2404-1

Rana PB, Patel JL, Lalwani DI (2019) Parametric optimization of turning process using evolutionary optimization techniques—a review (2000–2016). https://doi.org/10.1007/978-981-13-1595-4

Wang X, Da ZJ, Balaji AK, Jawahir IS (2002) Performance-based optimal selection of cutting conditions and cutting tools in multipass turning operations using genetic algorithms. Int J Prod Res 40(9):2053–2065. https://doi.org/10.1080/00207540210128279

Trent EM (1984) Metal Cutting, 2nd edn. Butterworths & Co (Publishers) Ltd., London

Nguyen V, Malchodi T, Dinar M, Melkote SN, Mishra A, Rajagopalan S (2019) An IoT architecture for automated machining process control: a case study of tool life enhancement in turning operations. Smart Sustain Manufact Syst 3(2):20190017. https://doi.org/10.1520/ssms20190017

Wu TY, Lei KW (2019) Prediction of surface roughness in milling process using vibration signal analysis and artificial neural network. Int J Adv Manuf Technol 102(1–4):305–314. https://doi.org/10.1007/s00170-018-3176-2

Kene AP, Choudhury SK (2019) Analytical modeling of tool health monitoring system using multiple sensor data fusion approach in hard machining. Measurement 145:118–129. https://doi.org/10.1016/j.measurement.2019.05.062

Khorasani AM, Yazdi MRS (2017) Development of a dynamic surface roughness monitoring system based on artificial neural networks (ANN) in milling operation. Int J Adv Manuf Technol 93(1–4):141–151. https://doi.org/10.1007/s00170-015-7922-4

da Silva RHL, da Silva MB, Hassui A (2016) A probabilistic neural network applied in monitoring tool wear in the end milling operation via acoustic emission and cutting power signals. Mach Sci Technol 20:386–405

Dai Y, Zhu K (2017) 2018, “A machine vision system for micro-milling tool condition monitoring.” Precis Eng 52(May):183–191. https://doi.org/10.1016/j.precisioneng.2017.12.006

Hou Q, Sun J, Huang P (2019) A novel algorithm for tool wear online inspection based on machine vision. Int J Adv Manuf Technol 101(9–12):2415–2423. https://doi.org/10.1007/s00170-018-3080-9

Martinez P, Ahmad R, Al-Hussein M (2019) Real-time visual detection and correction of automatic screw operations in dimpled light-gauge steel framing with pre-drilled pilot holes. Proced Manuf 34:798–803. https://doi.org/10.1016/j.promfg.2019.06.204

Gajate A, Haber R, Del Toro R, Vega P, Bustillo A (2012) Tool wear monitoring using neuro-fuzzy techniques: a comparative study in a turning process. J Intell Manuf 23(3):869–882. https://doi.org/10.1007/s10845-010-0443-y

Brezak D, Majetic D, Udiljak T, Kasac J (2010) Tool wear estimation using an analytic fuzzy classifier and support vector machines. J Intell Manuf 23(3):797–809. https://doi.org/10.1007/s10845-010-0436-x

Mohd Adnan MRH, Sarkheyli A, Mohd Zain A, Haron H (2013) Fuzzy logic for modeling machining process: a review. Art Intell Rev 43(3):345–379. https://doi.org/10.1007/s10462-012-9381-8

Wu X, Liu Y, Zhou X, Mou A (2019) Automatic identification of tool wear based on convolutional neural network in face milling process. Sensors (Basel, Switzerland) 19(18):3817. https://doi.org/10.3390/s19183817

Rao KV (2000) Manufacturing science and technology : manufacturing processes and machine tools, 2nd edn. New Age International Ltd, New Delhi, p 230

Sun WH, Yeh SS (2018) Using the machine vision method to develop an on-machine insert condition monitoring system for computer numerical control turning machine tools. Materials 11(10):1977. https://doi.org/10.3390/ma11101977

Traore BB, Kamsu-Foguem B, Tangara F (2018) Deep convolution neural network for image recognition. Eco Inform 48(October):257–268. https://doi.org/10.1016/j.ecoinf.2018.10.002

Goodfellow I, Bengio Y, Courville A (2016) Deep learning. MIT Press, Cambridge

Kingma DP, Ba JL (2015) Adam: a method for Stochastic Optimization. ICLR 2015:1–15

Ahila Priyadharshini R, Arivazhagan S, Arun M, Mirnalini A (2019) Maize leaf disease classification using deep convolutional neural networks. Neural Comput Appl 31(12):8887–8895. https://doi.org/10.1007/s00521-019-04228-3

Soriano MA, Khan F, Ahmad R (2020) Two-axis accelerometer calibration and non-linear correction using neural networks: design, optimization, and experimental evaluation. IEEE Trans Instrum Meas 69:6787–6794. https://doi.org/10.1109/tim.2020.2978568

Uros Z, Franc C, Edi K (2009) Adaptive network based inference system for estimation of flank wear in end-milling. J Mater Process Technol 209(3):1504–1511. https://doi.org/10.1016/j.jmatprotec.2008.04.002

Prokopowicz P, Czerniak J, Mikolajewski D, Apiecionek L, Slezak D (2017) Theory and applications of ordered fuzzy numbers. Springer International Publishing, Cham

Iscar, “Insert wear solutions.” https://www.iscar.com/Products.aspx/CountryId/1/ProductId/12343 (Accessed Jul. 09, 2020).

Kennametal, “Tooling wear: Which type is robbing your productivity.” http://chronicle.kennametal.com/tooling-wear-which-type-is-robbing-your-productivity/ (Accessed Jun. 18, 2020).

Altin A, Nalbant M, Taskesen A (2007) The effects of cutting speed on tool wear and tool life when machining Inconel 718 with ceramic tools. Mater Des 28(9):2518–2522. https://doi.org/10.1016/j.matdes.2006.09.004

Arsecularatne JA, Zhang LC, Montross C (2006) Wear and tool life of tungsten carbide, PCBN and PCD cutting tools. Int J Mach Tools Manuf 46(5):482–491. https://doi.org/10.1016/j.ijmachtools.2005.07.015

Pau G, Fuchs F, Sklyar O, Boutros M, Huber W (2010) EBImage–-an R package for image processing with applications to cellular phenotypes. Bioinformatics 26:979–981. https://doi.org/10.1093/bioinformatics/btq046

Rodic D, Gostimirovic M, Madic M, Sekulic M, Aleksic A (2020) Fuzzy model-based optimal energy control during the electrical discharge machining. Neural Comput Appl 32(22):17011–17026. https://doi.org/10.1007/s00521-020-04909-4

Acknowledgements

We express our gratitude to the Minister of Economic Development, Trade, and Tourism for funding this project through Major Innovation Funds. The authors also would like to acknowledge the NSERC (Grant Nos. NSERC RGPIN-2017-04516 and NSERC CRDPJ 537378-18) for further funding this project.

Funding

The authors have not disclosed any funding.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix 1

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Mamledesai, H., Zheng, Y. & Ahmad, R. Teaching machines to optimizing machining parameters: using independent fuzzy logic controller and image data. SN Appl. Sci. 4, 107 (2022). https://doi.org/10.1007/s42452-022-04987-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s42452-022-04987-0