Abstract

The purpose of this study is to develop a natural gas simulation model for costs optimization. The main focus of the model is on the transmission system since its imbalance leads to the penalties which must be paid by the suppliers. The total nominated amount of natural gas (the gas injected into the transmission system) must be consumed (withdrawn from the system) in order for the system to be in balance. In practice, this is not the case since it is very hard to accurately predict the future hourly consumption (in order to make a nomination) and certain deviations appear which leads to the imbalance. However, this problem could be solved by introducing a special electromotor valve which would be placed at the beginning of the distribution system and control the accumulation of the system. To test this solution, a simulation model was created using Arena Simulation tool. Data for the simulation model are collected by the natural gas distributor and consist of natural gas consumption and nomination values for one measuring-reduction station on the hourly basis. Thus, the final dataset includes 8.754 records. The separate As-Is and To-Be models for seven (summer) months were made and the results were compared. The simulation experiment shows that the positive rebalancing energy would be reduced by 32%, and the negative one by 34%. The created model can serve as a good initial step for the analysis of the justification of investment in the implementation of a technical solution that would manage the accumulation of the distribution system.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Supply chains are formal or informal creations of relationships and activities between business subjects who, in their interactions, bring a product and/or a service to the end customer. The natural gas supply chain, in the physical sense, is a complex energetic system in which five basic participants can be identified—the natural gas producer, natural gas transporter, along with gas storage, natural gas distributer and the consumer of natural gas. With the aim of liberalizing and de-monopolizing (separating the physical infrastructure from the market) the energy market, and the natural gas market along with it, special companies dealing with energy were introduced. These companies perform the job of traders and suppliers of individual market categories with the usage of the aforementioned technological infrastructure. In such conditions, it is necessary to define special rules of behavior for all the participants in the energy, i.e., natural gas sector. The participants of the entire supply chain in the natural gas sector are organized into so-called balance groups in order to synchronize the system according to the mater of material, energetic, financial, information flows and the flows of legal conduct. The rules of the organization of the natural gas market [19] define the balance group as an “interest association of participants in the natural gas market, organized on a commercial basis, primarily for the purpose of balancing and optimizing the balancing costs, for which the leader of the balance group is responsible.”

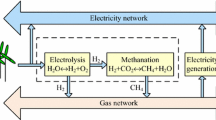

Figure 1 shows the natural gas supply chain, its physical flow from production to the end-customer, as well as the main participants on the Croatian gas market.

The current system of natural gas supply in the Republic of Croatia (which acquired its regulatory legacy from the European Union) functions on the balancing principle. The main task of the balance group leader is to ensure that the total nominated amount of gas injected into the transmission system (from own production, import or underground gas storage) is extracted by the distributor. However, seeing as how it is relatively difficult to precisely estimate the total amount of natural gas needed for the following gas day, an imbalance of the transmission system emerges, whether it is because of a surplus of the nominated amount which was not withdrawn, or a deficit of the nominated amount compared to the one withdrawn from the system. Because of the imbalance of the transmission system, the balance group leaders are penalized, since they are the ones who caused the imbalance above the limits allowed. The balance group leaders will charge that amount to the suppliers who withdrawn more or less natural gas from the nominated amount. Šebalj et al. [20] have, based on the data on household consumption and the nominations given by the Croatian supplier/distributor of natural gas, showed the difference between the nominations and real consumption in various time frames. They concluded that the difference is increased by narrowing the timeframe.

Even though technical systems for production, storage, transmission and distribution are usually firmly defined and standardized systems, due to the dynamic of their functioning, they still have a limited possibility of adaptation which can be used for balancing. The first such possibility is the limited flexibility of the transmission system which can endure relatively high loads in relation to the foreseen stable states (pressure of 50, or 75 bar). The second possibility is the eventual flexibility of the distribution system. Given that the owners of distribution systems are responsible for the development and maintenance of the distribution network, their current under-capacity running can also be seen from the data of the usage of capacities of the larger distributors, which enables them to consider using the reserves in regard to the acceptance of errors in the over-nominated gas amounts. Such a possibility is particularly interesting to vertically integrated energy companies (which are owners of distribution systems and function as suppliers on the natural gas market).

A technical solution, in the form of a special electromotor valve, which could achieve the synchronization of the transmission system, would be set at the entry of the distribution system and would control the accumulation in it. Such a solution primarily has the aim of compensating for errors in nominations when they are a result of hard-to-predict (suddenly changing) variables of natural gas consumption and should be applied in a short time span. Good prognosis models for natural gas consumption (for instance, various machine learning methods or other mathematical and statistical models) and their consistent application still remain the primary demand made to the suppliers, i.e., balance group leaders. The overview of such methods can be found in the research conducted by Šebalj et al. [21]. In this paper, that potential technical solution will be tested by a computer simulation, more precisely by combination of discrete and continuous simulation.

The main research question is—can a technical solution, within the limits of allowable solutions in distribution system, compensate for the errors in nominations and minimize the balancing costs of the balance group?

The literature in which various simulation models were used, especially those which are discrete or continuous, and in the area of the transmission and distribution system of natural gas, is very limited. There are only a few papers relating to this method of analysis and testing of the natural gas supply chain. Even if there are papers related to the transmission system, they only relate to some part of it. The most complete simulation model, for the purpose of creating a program solution for decision-making in the natural gas business, was created by Romo et al. [17]. In their research, they showed the process of develo** and using a tool for decision-making during natural gas transmission, called GassOpt, used by the main Norwegian operator of the StatoilHydro transmission system, and it serves to optimize the transmission network. The basic variables used in this program solution are the total flow of gas, the flow of gas between different knots where the gas lines connect and the entry and exit pressure of each gas pipeline. Using the GassOpt application, the transmission system operator can control the flow of natural gas in the transmission system, make eventual reallocations of capacities, enable the reservations of transport capacities, long-term planning and investments, etc. An encompassing model of the gas pipeline system was developed also by Nimmanonda et al. [13]. They developed a computer simulation model of the gas transmission system which included natural gas properties, energy balance and the mass balance. The user can use the presented model to create a system of a natural gas pipelines, by choosing the properties of natural gas, pipe diameter and compressor capacity. Given that the consumption of natural gas varies in time, the dynamic simulation model was created also in order to show key variables of the gas pipeline system and give guidelines to users on how to manage the system in a correct way. Matko et al. [11] presented three different models of the natural gas system and, based on them, performed a simulation in order to see the deviation of those models from a real system. Eparu et al. [6] analyzed the dynamic flows transpiring in the natural gas transmission system in Romania. In order to gain the best possible insight into the processes, they created a simulation of the transmission system in the Simone simulator, the best-known numerical simulator used by the majority of European and Asian countries to manage the natural gas transmission network. They included pipelines, valves, regulators, compressor stations, gas sources, and consumers into their simulation. They concluded that the hourly, daily, and yearly household consumption, as well as the fluctuations in the industrial consumer supplying, are what influences gas flow dynamics the most. Several papers were also noted in which the combinations of discrete and continuous simulations were used. For instance, Kbah et al. [8], using a combination of a discrete and continuous simulation, created a model of an oil and natural gas supply chain in their paper. After setting the model and its validation in order to confirm concurrence with a real oil and natural gas supply chain, the “what-if” scenarios were analyzed. Lately, studies related to the natural gas supply chain models deals with different optimization models. For example, Becerra-Fernandez et al. [3, 4] used system dynamics modeling to present the natural gas supply chain in Colombia. The results allow them to compare the behavior of production and transport levels on the one side, and the behavior of the demand on the other side. That comparison helps to identify capacity levels to be developed taking into account implementation times and percentage of the coverage in the supply. The research conducted by Dara et al. [5] focuses on the optimization analysis of the natural gas supply chain performed on a Middle Eastern country. They have built the model which aims at maximizing the net profit of the gas network through optimum allocation of gas across the supply chain components. Zarei et al. [24] presented a mixed integer linear programming (MILP) model which minimizes total cost and optimizes gas flow between supply chain nodes through pipelines, location of facilities and pipeline routes. The model was applied to a real case study from Iran’s natural gas supply chain. A multi-simulation MILP model was developed by Zhang et al. [26]. Their model is based on Monte Carlo sampling and captures four seasons, three states of natural gas and four transport options. Arya and Honwad [1] researched another problem. For very long distances, natural gas is transported by the pipelines since they are the most economic and safe type of gas transportation. While flowing through the pipeline, gas pressure and energy are lost due to friction and elevation so the compressor stations must be installed. Their task is to maintain the pressure and flow of gas. The energy required for running compressors is obtained by a portion of the natural gas flowing through the station. Authors estimated that 3–5% of the transported gas is consumed by the compressors. So they developed a steady-state model which includes gas flow dynamics, compressor station characteristics and mass balance to minimize fuel consumption.

In addition to modeling the natural gas supply chain, the use of discrete-event simulations has also been reported in papers related to other supply chains, such as bioenergy or electrical energy. For example, a somewhat similar simulation model, which has been developed in this paper, was made by Paulista et al. [14], but from the field of electrical energy. Using simulation software Ururau they analyzed the behavior of the consumption and generation of electrical energy in conjunction with other variables of the process. There were several papers in which simulation models from the wood industry were used. Prinz et al. [16] used discrete-event simulations to investigate how new vehicle types would affect the cost and energy efficiency of the entire wood chip supply chain. Mobini et al. [12] developed a discrete-event simulation model to evaluate the cost of delivered forest biomass in Canada. Pinho et al. [15] modeled a biomass supply chain using discrete-event simulation by the computer platform SIMEVENTS in order to predict future system behavior scenarios. Forest biomass supply chains in Finland and Germany have been the subject of research in paper written by Windisch et al. [22]. They used map** to clarify the business processes in the supply chain and then discrete-event simulation approach to estimate work time expenditure for organizational and managerial tasks. Windisch et al. [23] also used discrete-event simulation to measure the effects on wood supply chain productivity. They show that the information-based approach increased the productivity in terms of energy output of the supply chain. Zhang et al. [25] developed a simulation model, using Arena Simulation software, as a tool for supply chain management, especially for selection of the optimal biofuel facility location, logistics design and inventory management. Their model includes several supply chain activities, such as biomass harvesting/processing, transportation and storage.

The main goal of this research was to suggest a simulation model of the natural gas supply chain which will represent the basis for a technical solution in the distribution system that would compensate for the errors in natural gas nominations.

The paper is organized as follows: in Sect. 2 methodology is described, Sect. 3 represents the results of the simulation experiment, and Sect. 4 gives a conclusion and states the limitations of the research, as well as the suggestions for further research.

2 Methodology

The method of simulation was used to conduct this research. The simulation is an imitation of the operation of a real-world process or system over time [2]. It encompasses a collection of methods and applications to mimic the behavior of a real system, usually on a computer using appropriate software [9]. This research presented a computer simulation, i.e., the process of sha** and creating a computer model of a real or suggested system for the purpose of conducting numerical experiments for the better understanding of system behavior for the given set of conditions [9]. The same authors recommend precisely the computer simulations to study and analyze complex systems. According to Rossetti [18], the most important advantage of such modeling is that it possesses the ability to model the entire system and its complex inner relations and enables lower costs of conducting experiments on a model with the aim of making conclusions on how a real system might behave.

For the purpose of modeling the natural gas supply chain, this research will use a combination of discrete and continuous simulations, given that precisely this combination is recommended by several authors who used simulations in the area of supply chain management (for instance, [8, 10]). The discrete part of the simulation relates to the hourly consumption and nomination values, while the continuous part represents the flow of gas through the system.

In order to create the simulation model, the Arena Simulation is used, a commercial software used to develop and execute computer simulation models, developed by Rockwell Software. It uses the SIMAN simulation language through an environment which enables the creation of a model portrayed by a flowchart [18]. The Arena possesses the ability to verify the model, but it also contains tools which enable result validation.

Gas pressure in the distribution system will represent one of the performance metrics of the model. The simulation experiment will test the ability of the distribution system to function under certain pressure, by changing the amount of accumulated gas. If the system can normally function with an additional gas accumulation in the system itself without the gas pressure going below around 1.5 bar or above 3 bar of the allowed limits, it can be considered that the simulation experiment was successful. The other performance metric of the model will be the total amounts of positive and negative balancing energies and the accumulated amount in the distribution system. If it is shown that after a conducted simulation experiment, the total amount of balancing energy will be reduced in comparison with the current state, the model will be considered successful.

After defining the problem, and prior to the creation of the simulation model itself, it is necessary to create a conceptual model which serves as the basis for creating a simulation and which shows the functioning of the gas system after the introduction of the suggested technical solution. According to Rossetti [18], the aim of the conceptual model is to show a more detailed description of the system in order to be able to translate the model into a form that the computer can understand. Model creation should start with a simple conceptual model which shows the basic aspects and system behavior. After that, details which show additional system functionalities are gradually added. However, it is very important that the system complexity remains proportionate to the quality of available data and their validity needed to achieve research goals.

A conceptual model which describes the basic aspects and system behavior in more detail is shown below (Fig. 2).

2.1 Data

The input data needed to create a simulation model were received from a company performing the task of supplier and distributor of natural gas. The data relate to the household sector, for the period from January 1st to December 31st 2017 and encompass the information on actual consumption and nomination from all measuring-reduction stations of this company for every gas hour of the year (translating into a total of 8754 records). However, for the purpose of this research, the simulation model was created for just one measuring-reduction station with the maximum flow of natural gas (the greatest consumption by a household), with a capacity of 3 million kWh/day.

2.2 Simulation model

The simulation experiment starts with every gas hour given that the leaders of the balance groups are obligated to put in the nominations on an hourly level for the following gas day. This means that a total of 8754 entities (gas hours) will go through the simulation. It was originally imagined that the simulation be done on 12 separate models, one model per month, in order to ensure the highest possible accuracy of the received data. After the simulation starts, two attributes will be created every gas hour—consumption (aConsumption) and nomination (aNomination). Given that the two aforementioned attributes need to be simulated for every gas hour in this experiment, a mathematical function needs to be entered which will perform this task for their values. Within the Arena Simulation software, there is also the Input Analyzer tool which serves to analyze the input variables. All the 8754 entries (8754 gas hours in 2017) on consumption and nominations were copied into individual text files (.txt), for every month individually, and then imported into the Input Analyzer. In the Input Analyzer tool, a normal distribution is chosen for all input data, given the fact it is the most similar to real distribution of nomination and consumption. For the months of May, June, July, August and September, Input Analyzer did not provide satisfactory results and mathematical function values due to the difference distributions of hourly values of nomination and consumption being too low in those months. Those are summer months, when gas is not used for heating households and its consumption is significantly reduced in relation to the other months. Therefore, the simulation experiment will not be conducted for the aforementioned 5 months.

After the values received for consumption and nomination, the difference between these two values is calculated in order to make it possible to see, later on in the process, whether the nominated amount is larger than actual consumption or vice versa.

The consumers constantly consume natural gas so it is, therefore, injected from the transmission system into the distribution system over the measuring-reduction station and then it goes to the place of consumption. When the consumption reaches the nominated amount, the electromotor valve, placed behind the MRS, closes the flow of gas and the remaining amount is withdrawn from the accumulation in the distribution system. For instance, the leader of a balance group has nominated an amount of 1000 units for a gas hour. In that gas hour, households consume 1200 units. After 1000 units of gas enter the transmission system, the electromotor valve closes the flow and the remaining 200 units of gas will be withdrawn from the accumulation of the distribution system. However, prior to that, it is necessary to check whether the accumulated amount in the distribution system is sufficient to cover the difference and whether the pressure in the distribution system will fall below 1.5 bar after that, which is the lower limit until which the system can still function normally. If that is not the case, the electromotor valve is opened again and then the activation of positive balancing energy ensues, which will be paid, in the end, by the leaders of balance groups. In the opposite case, when the leader of the balance group nominated more gas than the households consume in an hour, the electromotor valve will open and inject the difference, up until the nominated amount, into the distribution system and, by doing so, will accumulate gas in the system itself and use it in cases when the consumption is larger than the nomination. However, in case the pressure in the distribution system rises to a maximum allowable limit of 3 bar, the electromotor valve closes and the remaining gas is taken from the transmission system as negative balancing energy. The implementation of the potential technical solution leads to the fact that balance group leaders do not have to pay penalties because the transmission system will only withdraw the nominated amount, and the difference between that and the consumed amount will be withdrawn from accumulation (if the amount of accumulation in the distribution system is sufficient).

The final appearance of the simulation model created in the Arena Simulation software is shown in Fig. 3.

For the stability of the model and getting the most accurate possible final results, the simulation experiment will be performed in 50 replications.

In the end, the procedure of model verification and validation was performed. Verification confirmed that the model is flawless and operates as it should. By running the model and tracking various parameters (consumption and nomination simulation, tracking the pressure in the gas pipeline system etc.) also meant performing the validation of the model and it was determined that the system faithfully represents the behavior of a real system. After the simulation, a comparison between the total simulated nomination and consumption and the real nomination and consumption was performed (based on the data available from 2017). The results are shown in Table 1. It is visible that the difference between simulated and real values was between 1.6 and 7.8%, which is satisfactory.

In order to answer the research question, it was also necessary to create a simulation model of the existing system (so-called As-Is model) and, by doing so, confirm whether the suggested solution can result in lower penalization costs due to a less frequent balancing energy activation (positive or negative). In order for the comparison between these two models to be as accurate and precise as possible, the same mathematical function value was put in for the aConsumption and aNomination attributes as is stated in the To-Be model. Unlike that model, in case the consumption of natural gas in a certain gas hour is larger than the nomination, the difference cannot be balanced out by accumulation, but the positive balancing energy must immediately be activated. Alternatively, when the nomination is higher than the consumption, the negative balancing energy will be activated, i.e., there will be an overtake of extra gas from the transmission system and it will not be possible to accumulate it in the distribution system.

This simulation model is shown in Fig. 4.

The parameters which will be noted in the simulation experiment are different for the As-Is and To-Be models. In the As-Is model, those will be the total amounts of positive and negative balancing energy, while for the To-Be model, the total amount of gas injected into the distribution system as accumulation will be taken as a parameter as well. That way, one can see whether the To-Be model will have an amount of activated balancing energy lower than the one in the As-Is model.

After defining the simulation model, a preliminary simulation run is performed. For both types of models (As-Is and To-Be), all 7 simulation models were initiated (for 7 months) in 50 replications per model and the pre-defined statistical indicators of the simulation were noted. In Tables 2 and 3, the results gained by simulation experiments are shown. In the results of the simulation experiment, for every value there is also the so-called half-width value shown.

The comparison of the results of this simulation experiment will be clarified in the following section.

3 Results and discussion

The research shown in this paper relates to the creation of a simulation model of the natural gas supply chain which would imitate a real system after the introduction of a suggested technical solution which would compensate for errors in nominations. Due to the nature of the research problem, the simulation combined discrete and continuous processes. The discrete processes represented the hourly consumption and nominations, while the continuous processes were tied to a flow of gas into the system or out of it. The simulation model was created gradually, starting from a declaration of key variables needed for the model to function (nomination and consumption) right up until adding the process modules and making decisions in places where there are branches in the process. After the end, the model was restarted and changed many times because the initial models did not faithfully represent the functioning of a real system. Therefore, the simulation model was upgraded until it satisfied validation. Validation was checked so that the difference between the total actual and total simulated amount of nominated and consumed gas was under 10% (between 1.6 and 7.8%).

After the simulation was performed, it was possible to make a comparison between the As-Is and To-Be model presented in Table 4.

It is visible from Table 4 that even with the introduction of the presented technical solution, deviations would still be present and the balancing energy would not be completely removed, but it would be drastically reduced. The greatest reduction would be present in October—70% lower positive balancing energy and more than 73% lower negative balancing energy. Looking at the total values of all observed models, the positive balancing energy would be reduced by almost 32%, and the negative balancing energy by 34%. The reason for such a large reduction in deviations lies precisely in the fact that the distribution system, by accumulating gas, should withstand that difference, while its pressure would be within the allowable limits. Table 3 shows also the average pressure of the distribution system after the simulation was performed. It was visible that the pressure was, on average, from 2.19 bars in January to 2.25 in February and December, which is a very small deviation from the 3 bars of pressure which is currently the maximum allowable pressure in the distribution system of the observed company.

This comparison shows that a technical solution can actually compensate for the errors that the leaders of balance groups make during nominations.

The model shown in this research would reduce the balancing of the transmission system by introducing the potential technical solution by over 30%. When talking about balancing, i.e., positive or negative balancing energy, in this case what is meant is the amount of gas necessary to take over/inject in order for that balancing to happen. Croatian Energy Market Operator (HROTE) uses its website to regularly publish monthly reports on trades on the trading platform, i.e., the sum of activated positive and negative balancing energy, which is the same as the multiplication of the amount of gas and the unit price of the balancing energy for every gas day in the month. Table 5 shows the data on the total amount of activated balancing energy and the total costs for 2017.

From Table 5, it is visible that the transmission system operator in 2017, for the purpose of balancing the transmission system, had to purchase gas for the value of over 28 million HRK (around 3.7 million euros) and, for the same reason, sell gas worth over 40 million HRK (around 5.3 million euros) on the trade platform. This means that the balance group leaders traded with the transmission system operator on the trade platform and bought gas for a value of over 40 million HRK because of the surplus of gas in the transmission system. On the other hand, due to a deficit of nominated gas, they sold 28 million HRK worth of gas to the transmission system operator. Given that the negative balancing energy sum is larger than the positive one, the balance group leaders, in 2017, had to pay HROTE the stated difference of 12 million HRK (around 1.6 million euros). The largest amount of balancing energy was, as is expected, activated in the winter months, especially in February and March, due to less stable consumption and harder predictions.

4 Conclusion and policy implications

The basic purpose of this paper was to create a natural gas simulation model in order to test a solution which would compensate for the mistakes in nominations, i.e., predictions of natural gas consumption. The transmission system must be in balance, which means that the amount of gas injected into the system (nominated gas) and the amount of gas withdrawn from the system (consumed gas) must be the same. Since it is very hard to accurately predict the nominated amount, the transmission system is often in imbalance and the cost of this imbalance is paid by the suppliers. This problem could be solved by the special electromotor valve that would be placed at the beginning of the distribution system and would control the accumulation in the system. In case there is a surplus in the transmission system (because the amount nominated is larger than the one consumed), that surplus would accumulate in the distribution system. In the other case, if the consumption would be larger than nomination, in case the distribution system has the sufficient amount accumulated, the difference would be extracted precisely from it. In order to test this type of solution, the computer simulation was conducted.

The software Arena Simulation was used to make the simulation model and the input data which served to set various mathematical functions was the data on consumption and nominations given by a company which is a supplier and distributor of natural gas. The data show information for the household sector in 2017, and the simulation itself was done on the example of one measuring-reduction station with the greatest gas consumption. Thus, the dataset consisted of 8754 records. In order to be able to compare the simulation experiment results, the seven separate As-Is and To-Be models were created and the information about the positive and negative balancing energy activated was noted, as well as the total accumulation of the distribution system for individual months. The results showed that by introducing the suggested solution, the positive balancing energy would be reduced by 32%, and the negative one by 34%, while the average pressure in the distribution system would be a satisfying 2.23 bar.

Given that the simulation model was created based on the available data from 2017 for the household sector, for the purpose of future research it is planned to acquire the data for the commercial sector as well and, by doing so, expand the model. Also, the model can be expanded to other measuring-reduction stations which the observed company has in its jurisdiction. That way, there would be an encompassing model for the entire distribution area and a comparison of results could be done for every exit from the transmission system. Also, the assumption is that distribution areas in the Republic of Croatia differ by their characteristics and the characteristics of their consumers. Therefore, it is planned to gather the data from other suppliers and/or distributors and see whether the introduction of this technical solution in those distribution systems would also significantly reduce the activation of the balancing energy.

The benefits of implementing such a technical solution can be manifold. Since this solution, in combination with advanced methods of predicting future consumption (e.g., using machine learning methods), would increase the accuracy of nominations, the need to activate balancing energy would be reduced and the transport and distribution system would be more in balance. The result is lower amounts of penalties currently paid by suppliers due to incorrect predictions of nominated natural gas quantities. The simulation model developed in this paper showed that distribution system can accumulate this additional amount of gas and withstand the potential pressure increase since it is currently under capacitated. This simulation model can serve as a good initial step to analyze the justification of an investment into the implementation of the technical solution. Currently, the largest limitation of this suggested solution is in the legal framework which does not allow interventions of this type on the gas system. However, there is another potential problem. The accumulation of gas in the distribution system will only be accepted by those distributers who are, at the same time, suppliers. Why would a distributor accept to accumulate gas in his own system for some other supplier (who is in his own distribution area)? The only benefit here would be had by the supplier because, in case of error, he would not have to pay for balancing, but the distributor would have to invest further action to take care of the implemented technical solution, track the system functions, etc.

As was already stated, for the final implementation of the suggested solution, it is necessary to, first and foremost, create the legal framework. The greatest benefit will be had by the companies who are both distributors and suppliers of natural gas. Assuming, of course, they can pay for the investment into the solution in the first place.

Availability of data and materials

Not applicable.

Code availability

Not applicable.

References

Arya AK, Honwad S (2016) Modeling, simulation, and optimization of a high-pressure cross-country natural gas pipeline: application of an ant colony optimization technique. J Pipeline Syst Eng Pract 7(1):04015008

Banks J, Carson J, Nelson B, Nicol D (2004) Discrete-event system simulation, 4th edn. Prentice Hall, Hoboken

Becerra-Fernandez M, Cosenz F, Dyner I (2020) Modeling the natural gas supply chain for sustainable growth policy. Energy 205:118018

Becerra-Fernandez M, La Rotta ECG, Cosenz F, Rezonzew ID (2018) Demand and supply model for the natural gas supply chain in Colombia. In: Li et al (eds) 18th annual Asia simulation conference (AsiaSim). Kyoto, Japan, pp 220–231

Dara S, Abdulaqader H, Al Wahed Y, Berrouk AS (2020) Countrywide optimization of natural gas supply chain: from wells to consumers. Energy 196:117125

Eparu C, Radulescu R, Stoica D (2013) The dynamic simulation of the natural gas transportation. Ovidius Univ Ann Chem 24:83–97

HROTE (2019). Balancing energy. https://www.hrote.hr/energijauravnotezenja-109. Accessed 28 Jan 2020

Kbah Z, Erdil N, Aqlan F (2016) Analysis of oil and gas supply chain using continuous-time discrete-event simulation. In: Proceedings of the 2016 industrial and systems engineering research conference. Anaheim

Kelton W, Sadowski R, Sturrock D (2007) Simulation with arena, 4th edn. McGraw-Hill, New York

Lee Y, Cho M, Kim S, Kim Y (2002) Supply chain simulation with discrete continuous combined modeling. Comput Ind Eng 43:375–392

Matko D, Geiger G, Gregoritza W (2000) Pipeline simulation techniques. Math Comput Simul 52:211–230

Mobini M, Sowlati T, Sokhansanj Sh (2011) Forest biomass supply logistics for a power plant using the discrete-event simulation approach. Appl Energy 88:1241–1250

Nimmanonda P, Uraikul V, Chan C, Tontiwachwuthikul P (2004) Computer aided simulation model for natural gas pipeline network system operations. Ind Eng Chem Res 43:990–1002

Paulista CR, Peixoto TA, de Assis Rangel JJ (2019) Modeling and discrete event simulation in industrial systems considering consumption and electrical energy generation. J Clean Prod 224:864–880

Pinho TM, Coelho JP, Moreira AP, Boaventura-Cunha J (2016) Modelling a biomass supply chain through discrete-event simulation. IFAC-PapersOnLine 49(2):84–89

Prinz E, Vaatainen K, Laitila J, Sikanen L, Asikainen A (2019) Analysis of energy efficiency of forest chip supply systems using discrete-event simulation. Appl Energy 235:1369–1380

Romo F, Tomasgard A, Hellemo L, Fodstad M, Haukelidsaeter Eidesen B, Pedersen B (2009) Optimizing the Norwegian natural gas production and transport. Interfaces 39:46–56

Rossetti M (2016) Simulation modeling and arena, 2nd edn. Wiley, Hoboken

Rules of the organization of the natural gas market (Official Gazette 50/18.)

Šebalj D, Mesarić J, Dujak D (2018) Analysis of natural gas trading system in Croatia: a preliminary research. In: Soliman, Khalid S (ed) Proceedings of the 32nd international business information management association conference (IBIMA). International Business Information Management Association (IBIMA), Seville, Spain, pp 1524–1535

Šebalj D, Mesarić J, Dujak D (2019) Analysis of methods and techniques for prediction of natural gas consumption: a literature review. J Inf Organ Sci 43:99–117

Windisch J, Röser D, Mola-Yudego B, Sikanen L, Asikainen A (2013) Business process map** and discrete-event simulation of two forest biomass supply chains. Biomass Bioenerg 56:370–381

Windisch J, Väätäinen K, Anttila P, Nivala M, Laitila J, Asikainen A, Sikanen L (2015) Discrete-event simulation of an information-based raw material allocation process for increasing the efficiency of an energy wood supply chain. Appl Energy 149:315–325

Zarei J, Amin-Naseri MR (2019) An integrated optimization model for natural gas supply chain. Energy 185:1114–1130

Zhang F, Johnson DM, Johnson MA (2012) Development of a simulation model of biomass supply chain for biofuel production. Renew Energy 44:380–391

Zhang H, Liang Y, Liao Q, Chen J, Zhang W, Long Y, Qian C (2019) Optimal design and operation for supply chain system of multi-state natural gas under uncertainties of demand and purchase price. Comput Ind Eng 131:115–130

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

Not applicable.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Šebalj, D. Simulation model of natural gas supply chain in a function of costs optimization: the case of Croatia. SN Appl. Sci. 4, 18 (2022). https://doi.org/10.1007/s42452-021-04901-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s42452-021-04901-0