Abstract

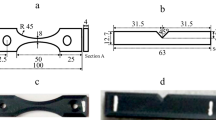

Based on the building principle of additive manufacturing, printing orientation mainly determines the tribological properties of joint prostheses. In this study, we created a polyether-ether-ketone (PEEK) joint prosthesis using fused filament fabrication and investigated the effects of printing orientation on its tribological properties using a pin-on-plate tribometer in 25% newborn calf serum. An ultrahigh molecular weight polyethylene transfer film is formed on the surface of PEEK due to the mechanical capture of wear debris by the 3D-printed groove morphology, which is significantly impacted by the printing orientation of PEEK. When the printing orientation was parallel to the sliding direction of friction, the number and size of the transfer film increased due to higher steady stress. This transfer film protected the matrix and reduced the friction coefficient and wear rate of friction pairs by 39.13% and 74.33%, respectively. Furthermore, our findings provide a novel perspective regarding the role of printing orientation in designing knee prostheses, facilitating its practical applications.

Graphic abstract

Similar content being viewed by others

References

Gullbrand SE, Ashinsky B, Bonnevie ED (2018) Long-term mechanical function and integration of an implanted tissue-engineered intervertebral disc. Transl Med Sci 10(468):eaau0670. https://doi.org/10.1126/scitranslmed.aau0670

Yang ML, Yang LY, Peng SP et al (2023) Laser additive manufacturing of zinc: formation quality, texture, and cell behavior. Bio-Des Manuf 6(2):103–120. https://doi.org/10.1007/s42242-022-00216-0

Zhang A, Chen H, Liu Y et al (2021) Customized reconstructive prosthesis design based on topological optimization to treat severe proximal tibia defect. Bio-Des Manuf 4(1):87–99. https://doi.org/10.1007/s42242-020-00102-7

Cheng KY, Gopal V, Mcnallan M et al (2019) Enhanced tribocorrosion resistance of hard ceramic coated Ti–6Al–4V alloy for hip implant application: in-vitro simulation study. Acs Biomater Sci Eng 5(9):4817–4824. https://doi.org/10.1021/acsbiomaterials.9b00609

Bandyopadhyay A, Shivaram A, Isik M (2019) Additively manufactured calcium phosphate reinforced CoCrMo alloy: bio-tribological and biocompatibility evaluation for load-bearing implants. Addit Manuf 28:312–324. https://doi.org/10.1016/j.addma.2019.04.020

Xu HD, Zhang DK, Chen K (2019) Taper fretting behavior of PEEK artificial hip joint. Tribol Int 137:30–38. https://doi.org/10.1016/j.triboint.2019.04.027

Han XT, Sharma N, Xu ZQ et al (2019) An in vitro study of osteoblast response on fused-filament fabrication 3D printed PEEK for dental and cranio-maxillofacial implants. J Clin Med 8(6):771. https://doi.org/10.3390/jcm8060771

Liu G, Zhang LG, Li GT et al (2019) Tuning the tribofilm nanostructures of polymer-on-metal joint replacements for simultaneously enhancing anti-wear performance and corrosion resistance. Acta Biomater 87:285–295. https://doi.org/10.1016/j.actbio.2019.01.038

Oladapo BI, Zahedi SA, Ismail SO et al (2021) 3D printing of PEEK–cHAp scaffold for medical bone implant. Bio-Des Manuf 4(1):44–59. https://doi.org/10.1007/s42242-020-00098-0

Lin ZB, Yue HQ, Gao BZ (2020) Enhancing tribological characteristics of PEEK by using PTFE composite as a sacrificial tribofilm-generating part in a novel dual-pins-on-disk tribometer. Wear 460–461:203472. https://doi.org/10.1016/j.wear.2020.203472

Zhang YH, Wei T, Yu Z et al (2018) Continuous carbon fiber/crosslinkable poly(ether ether ketone) laminated composites with outstanding mechanical properties, robust solvent resistance and excellent thermal stability. Compos Sci Technol 165:148–153. https://doi.org/10.1016/j.compscitech.2018.06.020

Li YD, Jia H, Cui XH et al (2022) Bending properties, compression properties, biocompatibility and bioactivity of sulfonated carbon fibers/PEEK composites with graphene oxide coating. Appl Surf Sci 575:151774. https://doi.org/10.1016/j.apsusc.2021.151774

Zheng JB, Zhao HY, Dong EC et al (2021) Additively-manufactured PEEK/HA porous scaffolds with highly-controllable mechanical properties and excellent biocompatibility. Sci Eng C Mater Biol Appl 128:112333. https://doi.org/10.1016/j.msec.2021.112333

Feng S, Liu C, Sue HJ (2022) Preparation of PEEK/MWCNT nanocomposites via MWCNT-induced interfacial crystallization mediated compatibilization. Compos Sci Technol 221:109298. https://doi.org/10.1016/j.compscitech.2022.109298

Wang ZQ, Ni J, Gao DR (2018) Combined effect of the use of carbon fiber and seawater and the molecular structure on the tribological behavior of polymer materials. Friction 6(2):183–194. https://doi.org/10.1007/s40544-017-0164-8

Chamberlain KA, Rankin KS, Briscoe A et al (2017) Wear properties of poly-ether-ether-ketone bearing combinations under zero and cross shear kinematics in total knee arthroplasty. J Biomed Mater Res B 107(2):445–453. https://doi.org/10.1002/JBM.B.34136

Liang YN, Gao DR, Zhao JH (2020) Tribological properties of friction pair between 316L stainless steel and CF/PEEK with nonsmooth surface under seawater lubrication. Tribol Trans 63(4):658–671. https://doi.org/10.1080/10402004.2020.1734704

Kandemir G, Smith S, Joyce TJ (2019) Wear behaviour of CFR PEEK articulated against CoCr under varying contact stresses: low wear of CFR PEEK negated by wear of the CoCr counterface. J Mech Behav Biomed 97:117–125. https://doi.org/10.1016/j.jmbbm.2019.05.022

East RH, Briscoe A, Unsworth A (2015) Wear of PEEK-OPTIMA® and PEEK-OPTIMA®-wear performance articulating against highly cross-linked polyethylene. Proc Inst Mech Eng Part H J Eng Med 229(3):187–193. https://doi.org/10.1177/0954411915576353

Scholes SC, Unsworth A (2019) Wear studies on the likely performance of CFR-PEEK/CoCrMo for use as artificial joint bearing materials. J Mater Sci Mater Med 20(1):163–170. https://doi.org/10.1007/s10856-008-3558-3

Cowie RM, Pallem NM, Jennings LM et al (2020) Third body wear of UHMWPE-on-PEEK-OPTIMA™. Materials 13(6):1264. https://doi.org/10.3390/ma13061264

Cowie RM, Briscoe A, Fisher J et al (2019) Wear and friction of UHMWPE-on-PEEK OPTIMA™. J Mech Behav Biomed 89:65–71. https://doi.org/10.1016/j.jmbbm.2018.09.021

Brockett CL, Carbone S, Fisher J et al (2017) PEEK and CFR-PEEK as alternative bearing materials to UHMWPE in a fixed bearing total knee replacement: an experimental wear study. Wear 374–375:86–91. https://doi.org/10.1016/j.wear.2016.12.010

Cowie RM, Briscoe A, Fisher J et al (2016) PEEK-OPTIMA™ as an alternative to cobalt chrome in the femoral component of total knee replacement: a preliminary study. Proc Inst Mech Eng Part H J Eng Med 230(11):1008–1015. https://doi.org/10.1177/0954411916667410

Zhang T, Liu HT, Zhang DK et al (2019) Mechanical and wear properties of polyetheretherketone composites filled with basalt fibres. Sci Eng Compos Mater 26(4):317–326. https://doi.org/10.1515/secm-2019-0016

Li Z, Haddouti E, Welle K et al (2020) The effects of biomaterial implant wear debris on osteoblasts. Front Cell Dev Biol 8:352. https://doi.org/10.3389/fcell.2020.00352

Yan Z, Tian XX, Zhu JY et al (2018) Metformin suppresses UHMWPE particle-induced osteolysis in the mouse calvaria by promoting polarization of macrophages to an anti-inflammatory phenotype. Mol Med 24(1):20. https://doi.org/10.1186/s10020-018-0013-x

Yuan T, Terkawi MA, Onodera T et al (2020) Blockade of XCL1/lymphotactin ameliorates severity of periprosthetic osteolysis triggered by polyethylene-particles. Front Immunol 11:1720. https://doi.org/10.3389/fimmu.2020.01720

Rafiee M, Farahani R, Therriault D (2020) Multi-material 3D and 4D printing: a survey. Adv Sci 7(12):1902307. https://doi.org/10.1002/advs.201902307

Kim JY, Kim WJ, Kim GH (2020) Scaffold with micro/nanoscale topographical cues fabricated using E-field-assisted 3D printing combined with plasma-etching for enhancing myoblast alignment and differentiation. Appl Surf Sci 509:145404. https://doi.org/10.1016/j.apsusc.2020.145404

Redondo E, Pumera M (2021) Fully metallic copper 3D-printed electrodes via sintering for electrocatalytic biosensing. Appl Mater Today 25:101253. https://doi.org/10.1016/j.apmt.2021.101253

Basgul C, Thieringer FM, Kurtz SM (2021) Heat transfer-based non-isothermal healing model for the interfacial bonding strength of fused filament fabricated polyetheretherketone. Addit Manuf 46:102097. https://doi.org/10.1016/j.addma.2021.102097

Doyle SE, Snow F, Duchi S (2021) 3D printed multiphasic scaffolds for osteochondral repair: challenges and opportunities. Int J Mol Sci 22(22):12420. https://doi.org/10.3390/ijms222212420

Zhiani Hervan S, Altnkaynak A, Parlar Z (2021) Hardness, friction and wear characteristics of 3D-printed PLA polymer. Proc Inst Mech Eng Part J J Eng Tribol 235(8):1590–1598. https://doi.org/10.1177/1350650120966407

Aziz R, UI Haq MI, Raina A (2020) Effect of surface texturing on friction behaviour of 3D printed polylactic acid (PLA). Polym Test 85:106434. https://doi.org/10.1016/j.polymertesting.2020.106434

Luo M, Huang SY, Man ZY et al (2022) Tribological behaviour of fused deposition modelling printed short carbon fibre reinforced nylon composites with surface textures under dry and water lubricated conditions. Friction 10(12):2045–2058. https://doi.org/10.1007/s40544-021-0574-5

Shang QB, Yu AB, Wu JZ et al (2017) Influence of heat affected zone on tribological properties of CuSn6 bronze laser dimple textured surface. Tribol Int 105:158–165. https://doi.org/10.1016/j.triboint.2016.10.008

Li WW, Meng L, Wang L et al (2016) Surface modification of ultra-high molecular weight polyethylene fibers by chromic acid. Surf Interface Anal 48(12):1316–1319. https://doi.org/10.1002/sia.6040

Zhu L, Dikin DA, Percec S et al (2021) Improving interlayer adhesion of poly(p-phenylene terephthalamide)(PPTA)/ultra-high-molecular-weight polyethylene (UHMWPE) laminates prepared by plasma treatment and hot pressing technique. Polymers 13(16):2600. https://doi.org/10.3390/polym13162600

Klapperich C, Graham J, Pruitt L et al (1999) Failure of a metal-on-metal total hip arthroplasty from progressive osteolysis. J Arthroplast 14(7):877–881. https://doi.org/10.1016/S0883-5403(99)90042-6

Murali R, Frcpa M, Bonar F et al (2008) Osteolysis in third-generation alumina ceramic-on-ceramic hip bearings with severe im**ement and titanium metallosis. J Arthroplast 23(8):13–19. https://doi.org/10.1016/j.arth.2007.10.020

Sarraf M, Rezvani Ghomi E, Alipour S et al (2022) A state-of-the-art review of the fabrication and characteristics of titanium and its alloys for biomedical applications. Bio-Des Manuf 5(2):371–395. https://doi.org/10.1007/s42242-021-00170-3

Eger M, Hiram-Bab S, Liron T et al (2018) Mechanism and prevention of titanium particle-induced inflammation and osteolysis. Front Immunol 9:2963. https://doi.org/10.3389/fimmu.2018.02963

Acknowledgements

This study was supported by the following funds: (1) National Key R&D Program of China (No. 2018YFE0207900); (2) Program for Innovation Team of Shaanxi Province (No. 2023-CX-TD-17); (3) Program of the National Natural Science Foundation of China (No. 51835010); (4) Key R&D Program of Guangdong Province (No. 2018B090906001); (5) Natural Science Basic Research Program of Shaanxi Province (No. 2022JQ-378); (6) China Postdoctoral Science Foundation (No. 2020M683458); (7) Fundamental Research Funds for the Central Universities; (8) Youth Innovation Team of Shaanxi Universities.

Author information

Authors and Affiliations

Contributions

YL contributed to conceptualization, methodology, data curation and writing-original draft; JBZ contributed to conceptualization, methodology and investigation; CNS contributed to conceptualization, validation and formal analysis; DCL contributed to funding acquisition and administration, and reviewed the initial versions of the manuscript. All authors have read and approved the final manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Ethical approval

This article does not contain any studies with human or animal subjects performed by any of the authors.

Data availability

The data used to support the findings of this study are available from the corresponding author upon request.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Li, Y., Zheng, J., Sun, C. et al. Transfer film effects induced by 3D-printed polyether-ether-ketone with excellent tribological properties for joint prosthesis. Bio-des. Manuf. 7, 43–56 (2024). https://doi.org/10.1007/s42242-023-00258-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42242-023-00258-y