Abstract

Micropatterned structures have applications in microchips, circuit board designs, microfluidics, evaporator/condenser coils, microelectronics, metasurfaces, and other functional devices. Conventional microfabrication techniques include lithography, vapor deposition, and laser writing. However, these methods have slow processing rates, complex requirements, or costly procedures. As a result, it is challenging to fabricate micropatterned structures onto large-scale surfaces with high production rates and resolution features. Thus, this study focuses on a non-conventional, mask-free micropatterning technique that combines bottom-up 3D printing capable of processing multiple materials and top-down wet etching for selective elimination of sacrificial material. The unique 3D printing, multiphase direct ink writing (MDIW), utilizes various polymer and nanoparticle systems as feedstocks for depositing lamellar structures containing 32–128 sublayers of varying compositions (i.e., wet etchable sacrificial ink and ultraviolet-curable patterning ink). The rapid phase transformation of photosensitive ink (i.e., epoxy and boron nitride (BN)) into solidified features enables “micro-confinement” of the sacrificial ink (i.e., polyethyleneimine). Subsequently, wet etching can locally and selectively dissolve sacrificial polymers by solvent diffusion and polymer dissolution at the polymer–solvent interface. The parameter control (i.e., ink rheology, polymer–polymer interdiffusion, layer multiplication, phase transformation, and solvent-polymer interactions) can precisely tune the lamellar-groove transition, thus forming desirable surfaces or internal microstructures. Microgrooves with a resolution of ≈ 55–170 µm were fabricated by selective wet etching via isopropanol with an etching rate of ≈ 7–11 µg/s. Our hybrid approach, which combines bottom-up 3D printing and top-down wet etching, facilitates surface micropatterning and demonstrates the massive potential of distributing boron nitride nanoparticles for dissipating thermal energies. The micropatterns displayed a thermal conductivity of ≈ 0.2 W/mK for 25wt.% BN with an enhancement of heat dissipation by ≈ 11 °C via confinement of coolants. With production scalability, operation simplicity, and multimaterial compatibility, our 3D-printed micropatterning shows broader applications in nanoparticle assembly, drug delivery, optical lenses, intelligent microbots, and morphing objects.

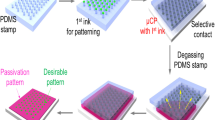

Graphical Abstract

This technique combines multiphase direct ink writing (MDIW) 3D printing and wet etching capable of micropatterning for thermal management applications.

Similar content being viewed by others

References

Wooh S, Yoon H, Jung J-H et al (2013) Efficient light harvesting with micropatterned 3d pyramidal photoanodes in dye-sensitized solar cells. Adv Mater 25:3111–3116. https://doi.org/10.1002/adma.201300085

Feng W, Chai Y, Forth J et al (2019) Harnessing liquid-in-liquid printing and micropatterned substrates to fabricate 3-dimensional all-liquid fluidic devices. Nat Commun 10:1095. https://doi.org/10.1038/s41467-019-09042-y

Han B, Huang Y, Li R et al (2014) Bio-inspired networks for optoelectronic applications. Nat Commun 5:5674. https://doi.org/10.1038/ncomms6674

Kim M, Brown DK, Brand O (2020) Nanofabrication for all-soft and high-density electronic devices based on liquid metal. Nat Commun 11:1002. https://doi.org/10.1038/s41467-020-14814-y

Quist AP, Oscarsson S (2010) Micropatterned surfaces: techniques and applications in cell biology. Expert Opin Drug Discov 5:569–581. https://doi.org/10.1517/17460441.2010.489606

Jambhulkar S, Liu S, Vala P et al (2021) Aligned Ti3 C2 Tx MXene for 3D micropatterning via additive manufacturing. ACS Nano 15:12057–12068. https://doi.org/10.1021/acsnano.1c03388

Hou C, Yang W, Kimura H et al (2023) Boosted lithium storage performance by local build-in electric field derived by oxygen vacancies in 3D holey N-doped carbon structure decorated with molybdenum dioxide. J Mater Sci Technol 142:185–195. https://doi.org/10.1016/j.jmst.2022.10.007

Mu Q, Liu R, Kimura H et al (2023) Supramolecular self-assembly synthesis of hemoglobin-like amorphous CoP@N, P-doped carbon composites enable ultralong stable cycling under high-current density for lithium-ion battery anodes. Adv Compos Hybrid Mater 6:23. https://doi.org/10.1007/s42114-022-00607-y

Yang W, Peng D, Kimura H et al (2022) Honeycomb-like nitrogen-doped porous carbon decorated with Co3O4 nanoparticles for superior electrochemical performance pseudo-capacitive lithium storage and supercapacitors. Adv Compos Hybrid Mater 5:3146–3157. https://doi.org/10.1007/s42114-022-00556-6

Li F, Li Q, Kimura H et al (2023) Morphology controllable urchin-shaped bimetallic nickel-cobalt oxide/carbon composites with enhanced electromagnetic wave absorption performance. J Mater Sci Technol 148:250–259. https://doi.org/10.1016/j.jmst.2022.12.003

Dang C, Mu Q, **e X et al (2022) Recent progress in cathode catalyst for nonaqueous lithium oxygen batteries: a review. Adv Compos Hybrid Mater 5:606–626. https://doi.org/10.1007/s42114-022-00500-8

Ma Y, Hou C, Kimura H et al (2023) Recent advances in the application of carbon-based electrode materials for high-performance zinc ion capacitors: a mini review. Adv Compos Hybrid Mater 6:59. https://doi.org/10.1007/s42114-023-00636-1

Barad H-N, Kwon H, Alarcón-Correa M, Fischer P (2021) Large area patterning of nanoparticles and nanostructures: current status and future prospects. ACS Nano 15:5861–5875. https://doi.org/10.1021/acsnano.0c09999

Kim Y, Kim T, Lee J et al (2021) Tailored graphene micropatterns by wafer-scale direct transfer for flexible chemical sensor platform. Adv Mater 33:2004827. https://doi.org/10.1002/adma.202004827

Topolniak I, Elert AM, Knigge X et al (2022) High-precision micropatterning of polydopamine by multiphoton lithography. Adv Mater 34:2109509. https://doi.org/10.1002/adma.202109509

Pfeiffer F, Felix NM, Neuber C et al (2007) Physical vapor deposition of molecular glass photoresists: a new route to chemically amplified patterning. Adv Funct Mater 17:2336–2342. https://doi.org/10.1002/adfm.200600717

Obst M, Arnauts G, Cruz AJ et al (2021) Chemical vapor deposition of ionic liquids for the fabrication of ionogel films and patterns. Angewandte Chemie Intl Edit 60:25668–25673. https://doi.org/10.1002/anie.202110022

Li P, Dou X, Schönherr H (2019) Micropatterning and nanopatterning with polymeric materials for advanced biointerface-controlled systems. Polym Int 68:1015–1032. https://doi.org/10.1002/pi.5770

Grzelczak M, Vermant J, Furst EM, Liz-Marzán LM (2010) Directed self-assembly of nanoparticles. ACS Nano 4:3591–3605. https://doi.org/10.1021/nn100869j

Yang GG, Choi HJ, Han KH et al (2022) Block copolymer nanopatterning for nonsemiconductor device applications. ACS Appl Mater Interfaces 14:12011–12037. https://doi.org/10.1021/acsami.1c22836

Kiruthika S, Radha B (2020) Direct Micromolding of bimetals and transparent conducting oxide using Metal−TOABr complexes as single-source precursors. ACS Omega 5:20739–20745. https://doi.org/10.1021/acsomega.0c00407

Jung W, Jang S, Cho S et al (2020) Recent progress in simple and cost-effective top-down lithography for ≈10 nm scale nanopatterns: from edge lithography to secondary sputtering lithography. Adv Mater 32:1907101. https://doi.org/10.1002/adma.201907101

Rogers JA, Lee HH (2008) Unconventional nanopatterning techniques and applications. John Wiley & Sons Inc, Hoboken, NJ, USA

Hosaka K, Tagami J, Nishitani Y et al (2007) Effect of wet vs. dry testing on the mechanical properties of hydrophilic self-etching primer polymers. Eur J Oral Sci 115:239–245. https://doi.org/10.1111/j.1600-0722.2007.00452.x

Puliyalil H, Cvelbar U (2016) Selective plasma etching of polymeric substrates for advanced applications. Nanomaterials 6:108. https://doi.org/10.3390/nano6060108

Kwak D, Lim JA, Kang B et al (2013) Self-organization of inkjet-printed organic semiconductor films prepared in inkjet-etched microwells. Adv Funct Mater 23:5224–5231. https://doi.org/10.1002/adfm.201300936

de Gans B-J, Hoeppener S, Schubert US (2006) Polymer-relief microstructures by inkjet etching. Adv Mater 18:910–914. https://doi.org/10.1002/adma.200502051

Bao B, Jiang J, Li F et al (2015) Fabrication of patterned concave microstructures by inkjet imprinting. Adv Funct Mater 25:3286–3294. https://doi.org/10.1002/adfm.201500908

de Beer MP, van der Laan HL, Cole MA et al (2019) Rapid, continuous additive manufacturing by volumetric polymerization inhibition patterning. Sci Adv 5:eaau8723. https://doi.org/10.1126/sciadv.aau8723

Jambhulkar S, Xu W, Ravichandran D et al (2020) Scalable alignment and selective deposition of nanoparticles for multifunctional sensor applications. Nano Lett 20:3199–3206. https://doi.org/10.1021/acs.nanolett.9b05245

Jambhulkar S, Xu W, Franklin R et al (2020) Integrating 3D printing and self-assembly for layered polymer/nanoparticle microstructures as high-performance sensors. J Mater Chem C 8:9495–9501. https://doi.org/10.1039/D0TC02660C

Ahn D, Stevens LM, Zhou K, Page ZA (2020) Rapid high-resolution visible light 3d printing. ACS Cent Sci 6:1555–1563. https://doi.org/10.1021/acscentsci.0c00929

Kelly BE, Bhattacharya I, Heidari H et al (2019) Volumetric additive manufacturing via tomographic reconstruction. Science 363:1075–1079. https://doi.org/10.1126/science.aau7114

Tumbleston JR, Shirvanyants D, Ermoshkin N et al (2015) Continuous liquid interface production of 3D objects. Science 347:1349–1352. https://doi.org/10.1126/science.aaa2397

Loke G, Yuan R, Rein M et al (2019) Structured multimaterial filaments for 3D printing of optoelectronics. Nat Commun 10:4010. https://doi.org/10.1038/s41467-019-11986-0

Coelho S, Baek J, Walsh J et al (2022) Direct-laser writing for subnanometer focusing and single-molecule imaging. Nat Commun 13:647. https://doi.org/10.1038/s41467-022-28219-6

Lewis JA (2006) Direct ink writing of 3D functional materials. Adv Funct Mater 16:2193–2204. https://doi.org/10.1002/adfm.200600434

Reiser A, Lindén M, Rohner P et al (2019) Multi-metal electrohydrodynamic redox 3D printing at the submicron scale. Nat Commun 10:1853. https://doi.org/10.1038/s41467-019-09827-1

Park J-U, Hardy M, Kang SJ et al (2007) High-resolution electrohydrodynamic jet printing Nature Mater 6:782–789. https://doi.org/10.1038/nmat1974

Jung W, Jung Y-H, Pikhitsa PV et al (2021) Three-dimensional nanoprinting via charged aerosol jets. Nature 592:54–59. https://doi.org/10.1038/s41586-021-03353-1

Su W, Cook BS, Fang Y, Tentzeris MM (2016) Fully inkjet-printed microfluidics: a solution to low-cost rapid three-dimensional microfluidics fabrication with numerous electrical and sensing applications. Sci Rep 6:35111. https://doi.org/10.1038/srep35111

Xu W, Jambhulkar S, Zhu Y et al (2021) 3D printing for polymer/particle-based processing: a review. ComposPart B: Eng 223:109102. https://doi.org/10.1016/j.compositesb.2021.109102

Xu W, Jambhulkar S, Ravichandran D et al (2021) 3D printing-enabled nanoparticle alignment: a review of mechanisms and applications. Small 17:2100817. https://doi.org/10.1002/smll.202100817

Elder B, Neupane R, Tokita E et al (2020) Nanomaterial patterning in 3D printing. Adv Mater 32:1907142. https://doi.org/10.1002/adma.201907142

Ravichandran D, Xu W, Kakarla M et al (2021) Multiphase direct ink writing (MDIW) for multilayered polymer/nanoparticle composites. Additive Manuf 47:102322. https://doi.org/10.1016/j.addma.2021.102322

Xu W, Ravichandran D, Jambhulkar S et al (2021) Hierarchically structured composite fibers for real nanoscale manipulation of carbon nanotubes. Adv Funct Mater 31:2009311. https://doi.org/10.1002/adfm.202009311

Xu W, Franklin R, Ravichandran D et al (2022) Continuous nanoparticle patterning strategy in layer‐structured nanocomposite fibers. Adv Funct Mater 2204731. https://doi.org/10.1002/adfm.202204731

Rasul MG, Cheng M, Jiang Y et al (2022) Direct ink printing of PVdF composite polymer electrolytes with aligned BN Nanosheets for lithium-metal batteries. ACS Nanosci Au 2:297–306. https://doi.org/10.1021/acsnanoscienceau.1c00056

Tao Y, Kong F, Li Z et al (2021) A review on voids of 3D printed parts by fused filament fabrication. J Market Res 15:4860–4879. https://doi.org/10.1016/j.jmrt.2021.10.108

Guo H, Zhao H, Niu H et al (2021) Highly thermally conductive 3D printed graphene filled polymer composites for scalable thermal management applications. ACS Nano 15:6917–6928. https://doi.org/10.1021/acsnano.0c10768

Ravichandran D, Ahmed RJ, Banerjee R et al (2022) Multi-material 3D printing-enabled multilayers for smart actuation via magnetic and thermal stimuli. J Mater Chem C 10.1039.D2TC01109C. https://doi.org/10.1039/D2TC01109C

Grundke K, Michel S, Osterhold M (2000) Surface tension studies of additives in acrylic resin-based powder coatings using the Wilhelmy balance technique. Prog Org Coat 39:101–106. https://doi.org/10.1016/S0300-9440(00)00129-6

Bellettini IC, Eising R, Felippe AC et al (2015) Association of branched polyethylene imine with surfactants in aqueous solution. Quim Nova. https://doi.org/10.5935/0100-4042.20150085

Penfold J, Tucker I, Thomas RK et al (2007) The impact of electrolyte on the adsorption of sodium dodecyl sulfate/polyethyleneimine complexes at the air−solution interface. Langmuir 23:3690–3698. https://doi.org/10.1021/la063017p

Lee MY, Lee JH, Chung JW, Kwak S-Y (2018) Hydrophilic and positively charged polyethylenimine-functionalized mesoporous magnetic clusters for highly efficient removal of Pb(II) and Cr(VI) from wastewater. J Environ Manage 206:740–748. https://doi.org/10.1016/j.jenvman.2017.10.051

Uzal N, Ates N, Saki S et al (2017) Enhanced hydrophilicity and mechanical robustness of polysulfone nanofiber membranes by addition of polyethyleneimine and Al2O3 nanoparticles. Sep Purif Technol 187:118–126. https://doi.org/10.1016/j.seppur.2017.06.047

Wang T, Zhang G, Zhang B et al (2021) Oriented boron nitride nanosheet films for thermal management and electrical insulation in electrical and electronic equipment. ACS Appl Nano Mater 4:4153–4161. https://doi.org/10.1021/acsanm.1c00484

Han J, Du G, Gao W, Bai H (2019) An Anisotropically high thermal conductive boron nitride/epoxy composite based on nacre-mimetic 3D network. Adv Funct Mater 29:1900412. https://doi.org/10.1002/adfm.201900412

Pan D, Yang G, Abo-Dief HM et al (2022) Vertically Aligned silicon carbide nanowires/boron nitride cellulose aerogel networks enhanced thermal conductivity and electromagnetic absorbing of epoxy composites. Nano-Micro Lett 14:118. https://doi.org/10.1007/s40820-022-00863-z

Zhu Q, Zhao Y, Miao B et al (2022) Hydrothermally synthesized ZnO-RGO-PPy for water-borne epoxy nanocomposite coating with anticorrosive reinforcement. Prog Organic Coat 172:107153. https://doi.org/10.1016/j.porgcoat.2022.107153

Li X, Zhao S, Hu W et al (2019) Robust superhydrophobic surface with excellent adhesive properties based on benzoxazine/epoxy/mesoporous SiO2. Appl Surf Sci 481:374–378. https://doi.org/10.1016/j.apsusc.2019.03.114

Hu W, Huang J, Zhang X et al (2020) A mechanically robust and reversibly wettable benzoxazine/epoxy/mesoporous TiO2 coating for oil/water separation. Appl Surf Sci 507:145168. https://doi.org/10.1016/j.apsusc.2019.145168

Ardebili H, Zhang J, Pecht MG (2019) Characterization of encapsulant properties. In: Encapsulation Technologies for Electronic Applications. Elsevier, pp 221–258. https://doi.org/10.1016/B978-0-12-811978-5.00006-7

Miller-Chou BA, Koenig JL (2003) A review of polymer dissolution. Prog Polym Sci 28:1223–1270. https://doi.org/10.1016/S0079-6700(03)00045-5

Schaffner M, Rühs PA, Coulter F et al (2017) 3D printing of bacteria into functional complex materials. Sci Adv 3:eaao6804. https://doi.org/10.1126/sciadv.aao6804

Zhao S, Siqueira G, Drdova S et al (2020) Additive manufacturing of silica aerogels. Nature 584:387–392. https://doi.org/10.1038/s41586-020-2594-0

Cheng M, Ramasubramanian A, Rasul MG et al (2021) Direct ink writing of polymer composite electrolytes with enhanced thermal conductivities. Adv Funct Mater 31:2006683. https://doi.org/10.1002/adfm.202006683

Shen K, Ding J, Yang S (2018) 3D printing quasi-solid-state asymmetric micro-supercapacitors with ultrahigh areal energy density. Adv Energy Mater 8:1800408. https://doi.org/10.1002/aenm.201800408

Yirmibesoglu OD, Simonsen LE, Manson R et al (2021) Multi-material direct ink writing of photocurable elastomeric foams. Commun Mater 2:82. https://doi.org/10.1038/s43246-021-00186-3

Yuk H, Lu B, Lin S et al (2020) 3D printing of conducting polymers. Nat Commun 11:1604. https://doi.org/10.1038/s41467-020-15316-7

Saadi MASR, Maguire A, Pottackal NT et al (2022) Direct ink writing: a 3D printing technology for diverse materials. Adv Mater 34:2108855. https://doi.org/10.1002/adma.202108855

Agassant J-F, Demay Y (2022) Investigation of the polymer coextrusion process: a review. Polymers 14:1309. https://doi.org/10.3390/polym14071309

Lu B, Zhang H, Maazouz A, Lamnawar K (2021) Interfacial phenomena in multi-micro-/nanolayered polymer coextrusion: a review of fundamental and engineering aspects. Polymers 13:417. https://doi.org/10.3390/polym13030417

Cortés A, Cosola A, Sangermano M et al (2021) DLP 4D-printing of remotely, modularly, and selectively controllable shape memory polymer nanocomposites embedding carbon nanotubes. Adv Funct Mater 31:2106774. https://doi.org/10.1002/adfm.202106774

Guerra V, Wan C, Degirmenci V et al (2018) 2D boron nitride nanosheets (BNNS) prepared by high-pressure homogenisation: structure and morphology. Nanoscale 10:19469–19477. https://doi.org/10.1039/C8NR06429F

Lin Z, Liu Y, Raghavan S et al (2013) Magnetic alignment of hexagonal boron nitride platelets in polymer matrix: toward high performance anisotropic polymer composites for electronic encapsulation. ACS Appl Mater Interfaces 5:7633–7640. https://doi.org/10.1021/am401939z

Han G, Zhang D, Kong C et al (2022) Flexible, thermostable and flame-resistant epoxy-based thermally conductive layered films with aligned ionic liquid-wrapped boron nitride nanosheets via cyclic layer-by-layer blade-casting. Chem Eng J 437:135482. https://doi.org/10.1016/j.cej.2022.135482

Zhong B, Zou J, An L et al (2019) The effects of the hexagonal boron nitride nanoflake properties on the thermal conductivity of hexagonal boron nitride nanoflake/silicone rubber composites. Composites Part A Appl Sci Manuf 127:105629. https://doi.org/10.1016/j.compositesa.2019.105629

Du M-X, Yuan Y-F, Zhang J-M, Liu C-Y (2022) Hydrogen-bonding interactions in polymer–organic solvent mixtures. Macromolecules 55:4578–4588. https://doi.org/10.1021/acs.macromol.2c00799

Chan TC, Li HT, Li KY (2015) Effects of shapes of solute molecules on diffusion: a study of dependences on solute size, solvent, and temperature. J Phys Chem B 119:15718–15728. https://doi.org/10.1021/acs.jpcb.5b10550

P. Gall T, Lasky RC, Kramer EJ, (1990) Case II diffusion: effect of solvent molecule size. Polymer 31:1491–1499. https://doi.org/10.1016/0032-3861(90)90156-S

Kleiman M, Ryu KA, Esser-Kahn AP (2016) Determination of factors influencing the wet etching of polydimethylsiloxane using tetra- n -butylammonium fluoride. Macromol Chem Phys 217:284–291. https://doi.org/10.1002/macp.201500225

Razali M, Didaskalou C, Kim JF et al (2017) Exploring and exploiting the effect of solvent treatment in membrane separations. ACS Appl Mater Interfaces 9:11279–11289. https://doi.org/10.1021/acsami.7b01879

Jasso-Gastinel CF (2017) Gradients in homopolymers, blends, and copolymers. In: Modification of Polymer Properties. Elsevier, pp 185–210

Baij L, Hermans JJ, Keune K, Iedema PD (2018) Time-dependent ATR-FTIR spectroscopic studies on solvent diffusion and film swelling in oil paint model systems. Macromolecules 51:7134–7144. https://doi.org/10.1021/acs.macromol.8b00890

Harter JR, Palmer TS, Greaney PA (2020) Predicting mesoscale spectral thermal conductivity using advanced deterministic phonon transport techniques. In: Advances in Heat Transfer. Elsevier, pp 335–488

Yan H, Dai X, Ruan K et al (2021) Flexible thermally conductive and electrically insulating silicone rubber composite films with BNNS@Al2O3 fillers. Adv Compos Hybrid Mater 4:36–50. https://doi.org/10.1007/s42114-021-00208-1

Clausi M, Zahid M, Shayganpour A, Bayer IS (2022) Polyimide foam composites with nano-boron nitride (BN) and silicon carbide (SiC) for latent heat storage. Adv Compos Hybrid Mater 5:798–812. https://doi.org/10.1007/s42114-022-00426-1

Sohel Murshed SM, Nieto de Castro CA (2017) A critical review of traditional and emerging techniques and fluids for electronics cooling. Renew Sustain Energy Rev 78:821–833. https://doi.org/10.1016/j.rser.2017.04.112

Pastukhov VG, Maidanik YuF, Vershinin CV, Korukov MA (2003) Miniature loop heat pipes for electronics cooling. Appl Therm Eng 23:1125–1135. https://doi.org/10.1016/S1359-4311(03)00046-2

Acknowledgements

We would like to thank Dr. D. Bhate from 3DX research for the use of the Keyence 3D Optical profilometer at ASU. We thank Dr. B. Kwon for providing help to use the hot disk at ASU.

Funding

We acknowledge the financial support from the NSF EAGER (Award Abstract #1902172), NSF CAREER (Award #2145895), ONR NEPTUNE (N00014-22–1-2105), AFOSR (FA9550-22–1-0263), BSF (2020102), and ACS PRF (#62371-ND10).

Author information

Authors and Affiliations

Contributions

S. Jambhulkar and K. Song conceptualized and designed a research objective; S. Jambhulkar performed experiments, analyzed results, performed theoretical calculations, and drafted manuscript; D. Ravichandran designed MDIW 3D printing setup and performed fluidic simulation; V. Thippanna, and D. Patil assisted with experiments of 3D printing. All authors reviewed the final manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Jambhulkar, S., Ravichandran, D., Thippanna, V. et al. A multimaterial 3D printing-assisted micropatterning for heat dissipation applications. Adv Compos Hybrid Mater 6, 93 (2023). https://doi.org/10.1007/s42114-023-00672-x

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s42114-023-00672-x