Abstract

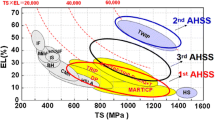

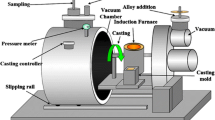

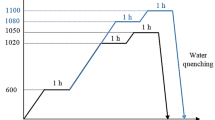

Certain medium-manganese (6–12 wt% Mn) steels can be heat-treated to produce single-phase (austenite) or multi-phase (ferrite, austenite, bainite, martensite, and/or iron carbide) microstructures. With the proper amount of silicon and aluminum, both transformation-induced plasticity (TRIP) and/or twinning-induced plasticity (TWIP) can be the active deformation mechanism. In this study, two steel heats with compositions of Fe–7.53Mn–2.01Al–1.94Si–0.74C and Fe–7.71Mn–1.57Al–1.51Si–0.50C were investigated. The lower-carbon steel had a wider heat treating range but did not achieve as high of a hardness as the higher-carbon steel. Multi-phase microstructures were produced in both of these steels, and the multi-phase microstructures had higher yield strength compared to single-phase (austenite) microstructures. A high iron and manganese content skull adhered to the sides of the furnace after induction melting. This skull was difficult to remove from the furnace lining.

Similar content being viewed by others

References

Hadfield, R., British patent No. 200 (1883).

S. Lee, B.C. De Cooman, Annealing temperature dependence of the tensile behavior of 10 pct Mn multi-phase TWIP-TRIP steel. Metall. Mater. Trans. A 45, 6039–6052 (2014). https://doi.org/10.1007/s11661-014-2540-6

H. Aydin, I.-H. Jung, E. Essadiqi, S. Yue, Twinning and trip** in 10% Mn steels. Mater. Sci. Eng. A 591, 90–96 (2014). https://doi.org/10.1016/j.msae.2013.10.088

S. Lee, K. Lee, B.C. De Cooman, Observation of the TWIP+TRIP plasticity-enhancement mechanism in Al-added 6 Wt Pct medium Mn steel. Metall Mater Trans A 46A, 2356–2363 (2015). https://doi.org/10.1007/s11661-015-2854-z

C.-Y. Lee, J. Jeong, J. Han, S.-J. Lee, S. Lee, Y.-K. Lee, Coupled strengthening in a medium manganese lightweight steel with an inhomogenously grain structure of austenite. Acta Mater. 84, 1–8 (2015). https://doi.org/10.1016/j.actamat.2014.10.032

S. Lee, B.C. De Cooman, Tensile behavior of intercritically annealed ultra-fine grained 8% Mn multi-phase steel. Steel Res. Int. 86(10), 1170–1178 (2015). https://doi.org/10.1002/srin.201500038

S. Lee, W. Woo, B.C. De Cooman, Analysis of the tensile behavior of 12 pct Mn multi-phase (α+γ) TWIP+TRIP steel by neutron diffraction. Metall. Mater. Trans. A 47A, 2016–2125 (2016). https://doi.org/10.1007/s11661-016-3407-9

B. Hu, H. Luo, F. Yang, H. Dong, Recent progress in medium-Mn steels made with new designing strategies, a review. J. Mater. Sci. Technol. 33, 1457–1464 (2017). https://doi.org/10.1016/j.jmst.2017.06.017

S. Yan, T. Liang, Z. Wang, B. Yan, T. Li, X. Liu, Novel 1.4 GPa strength medium-Mn steel with uncompromised high ductility. Mater. Sci. Eng. A 773, 138732 (2020). https://doi.org/10.1016/j.msea.2019.138732

T.W.J. Kwok, K.M. Rahman, X. Xu, I. Bantounas, J.F. Kelleher, S. Dasari, T. Alam, Design of a high strength, high ductility 12 wt% Mn medium manganese steel with hierarchical deformation behavior. Mater. Sci. Eng. A 782, 139258 (2020). https://doi.org/10.1016/j.msea.2020.139258

T.W.J. Kwok, P. Gong, X. Xu, J. Nutter, W.M. Rainforth, D. Dye, Microstructure evolution and tensile behaviour of a cold rolled 8 wt% Mn medium manganese steel. Metall. Mater. Trans. A 53, 597–609 (2021)

C. Shao, W. Hui, Y. Zhang, X. Zhao, Y. Weng, Microstructure and mechanical properties of hot-rolled medium-Mn steel containing 3% aluminum. Mater. Sci. Eng. A 682, 44–53 (2017). https://doi.org/10.1016/j.msea.2016.11.036

B. Sun, F. Fazeli, C. Scott, N. Brodusch, R. Gauvin, The influence of silicon additions on the deformation behavior of austenite-ferrite duplex medium manganese steels. Acta Mater. 148, 249–262 (2018). https://doi.org/10.1016/j.actamat.2018.02.005

S.S. Sohn, B.-J. Lee, S. Lee, N.J. Kim, J.-H. Kwak, Effect of annealing temperature on microstructural modification and tensile properties in 0.35 C–3.5 Mn–5.8 Al lightweight steel. Acta Mater. 61, 5050–5066 (2013). https://doi.org/10.1016/j.actamat.2013.04.038

S.S. Sohn, B.-J. Lee, S. Lee, J.-H. Kwak, Effect of aluminum content on cracking phenomenon occurring during cold rolling of three ferrite-based lightweight steel. Acta Mater. 61, 5626–5635 (2013). https://doi.org/10.1016/j.actamat.2013.06.004

J.-B. Seol, D. Raabe, P. Choi, H.-S. Park, J.-H. Kwak, C.-G. Park, Direct evidence for the formation of ordered carbide in a ferrite-based low-density Fe–Mn–Al–C alloy studied by transmission electron microscopy and atom probe tomography. Scr. Mater. 68, 348–353 (2013). https://doi.org/10.1016/j.scriptamat.2012.08.013

L. Zhang, S. Song, C. Zhao, F. Yang, Y. Xu, S. Peng, Evolution of the microstructure and mechanical properties of an austenite-ferrite Fe–Mn–Al–C steel. Mater. Sci. Eng. A 643, 183–193 (2015). https://doi.org/10.1016/j.msea.2015.07.043

A. Saeed-Akbari, J. Imlau, U. Prahl, W. Bleck, Derivation and variation in composition-dependent stacking fault energy maps based on subregular solution model in high-manganese steels. Met. Trans. A. 40, 3072–3090 (2009)

J. Mahieu, J. Maki, B.C. De Cooman, S. Claessens, Phase transformation and mechanical properties of Si-free cmnal transformation-induced plasticity-aided steel. Metall. Mater. Trans. A 33A, 2573–2580 (2002)

Thermo-CalcTM, https://thermocalc.com/

B.C. De Cooman, Y. Estrin, S.K. Kim, Twinning-induced plasticity (TWIP) steels. Acta Mater. 142, 283–362 (2018). https://doi.org/10.1016/j.actamat.2017.06.046

Heraeus Electro-Nite, PosithermTM Multi-immersion Long Quartz Thermocouple, model IF, 10–68, type S, p. 13. https://www.heraeus.com/media/media/hen/media_hen/products_hen/copper/temperature_measurement_in_liquid_metal.pdf

ASTM E8/E8M—21. Standard Test Methods for Tension Testing of Metallic Materials. ASTM International, 100 Barr Harbor Drive. West Conshohocken, pp. 19428–2959 (2021) https://doi.org/10.1520/E0008_E0008M-16AE01

Acknowledgements

The authors would like to acknowledge the Virginia Tech Foundry Institute for Research and Education for providing the necessary materials and equipment to produce the steel alloys, Virginia Tech graduate students Corinne Wells and Josh Adelmann for performing the scanning electron microscopy, Josh Adelmann and Adrian Davila for performing the Thermo-CalcTM analysis, and **g Zhao for performing the X-ray diffraction measurements. This paper is an invited submission to IJMC selected from presentations at the 74th World Foundry Congress, held October 16 to 20, 2022, in Busan, Korea, and has been expanded from the original presentation.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

This paper is an invited submission to IJMC selected from presentations at the 74th World Foundry Congress, held October 16–20, 2022, in Busan, Korea, and has been expanded from the original presentation.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Druschitz, A.P., Seigler, A., Hall, O. et al. Cast Medium-Manganese FeMnAlSiC Steel. Inter Metalcast 17, 2413–2420 (2023). https://doi.org/10.1007/s40962-023-01000-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40962-023-01000-1