Highlights

-

Bottlenecks for develo** polymer based electromagnetic interference (EMI) shielding composites are proposed and inner reasons are discussed

-

Possible directions to break through bottlenecks are raised and recent advances in such directions are introduced.

-

Development trends in the future are foreseen to provide theoretical basis and technical guidance for development of polymer based EMI shielding composites.

Abstract

The rapid development of aerospace weapons and equipment, wireless base stations and 5G communication technologies has put forward newer and higher requirements for the comprehensive performances of polymer-based electromagnetic interference (EMI) shielding composites. However, most of currently prepared polymer-based EMI shielding composites are still difficult to combine high performance and multi-functionality. In response to this, based on the research works of relevant researchers as well as our research group, three possible directions to break through the above bottlenecks are proposed, including construction of efficient conductive networks, optimization of multi-interfaces for lightweight and multifunction compatibility design. The future development trends in three directions are prospected, and it is hoped to provide certain theoretical basis and technical guidance for the preparation, research and development of polymer-based EMI shielding composites.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The rapid development of aerospace weapons and equipment, wireless base stations and 5G communication technologies has led to the upgrading of electronic equipments and components toward high frequency, high power, high density and high integration, which inevitably brings problems such as electromagnetic radiation and electromagnetic interference (EMI), seriously affecting the normal operation of electronic equipments and components, safe transmission of information, as well as human health [1,2,3]. The EMI shielding materials can effectively protect electronic equipments and their environment, prevent electromagnetic information leakage, cut off propagation paths of electromagnetic waves and suppress radiation and interference of electromagnetic waves. It is one of the most important technical means to solve the problem of electromagnetic radiation and electromagnetic pollution [4, 5]. With the development of new generation of electronic equipment in the direction of intelligence, portability and wearability, higher requirements are also placed on the lightweight, flexibility, thermal conductivity and mechanical properties of EMI shielding materials. Therefore, the research and development of novel high-performance and multi-functional EMI shielding composites with excellent comprehensive properties have urgent theoretical significance and practical application value for the design and expansion of materials in fields related to aerospace, wearable electronic devices and artificial intelligence [6,7,8].

Polymer-based EMI shielding composites are gradually replacing traditional metal-based EMI shielding materials because of their lightweight, high specific strength, corrosion resistance, easy processing, and excellent EMI shielding performances. The shielding effects of polymer-based EMI shielding composites on electromagnetic waves are mainly realized by introducing electrically/magnetically conductive fillers into the polymer matrix to form the electrically/magnetically conductive network [9, 10]. At present, most of the polymer-based EMI shielding composites are prepared by solution blending, melt blending, in situ polymerization, etc. In these methods, the polymer matrix and functional fillers are directly mixed, and the functional fillers in the composites are randomly distributed in the entire polymer matrix. It is not conducive to the efficient construction of the electrically/magnetically conductive network, resulting in very limited EMI shielding ability [11]. To achieve the desired EMI shielding effectiveness (EMI SE), large amount of electrically/magnetically conductive fillers are usually required [12]. However, high filling of functional fillers will seriously affect the processability and mechanical properties of polymer-based EMI shielding composites. Researchers have improved the compatibility and dispersion of electrically/magnetically conductive fillers in polymer matrix by functionalization via covalent bonds or non-covalent bonds, but the improvement in electrical conductivity (σ) and EMI SE is still relatively limited [13, 14]. Especially in aerospace, wearable electronic devices, artificial intelligence and other fields, not only excellent EMI shielding performance and mechanical properties are required, lightweight and multi-functionality are also the key technical indicators [15, 16]. However, most of the currently prepared polymer-based EMI shielding composites are difficult to meet all these requirements.

Our research group has been focusing our studies on the structural design and preparation of polymer-based EMI shielding composites. Based on multi-scale network structure design, functional filler–polymer matrix interface regulation and structure/function integration, a series of polymer-based EMI shielding composites have been prepared. The internal relationship between their microstructures and macroscopic properties is explored. This paper aims to put forward the research ideas and technical routes that can be taken in the future in view of the bottleneck problems in the field of polymer-based EMI shielding composites, ho** to provide certain theoretical basis and technical guidance for the preparation, research and development of polymer-based EMI shielding composites.

2 Possible Directions for Develo** Polymer-Based EMI Shielding Composites

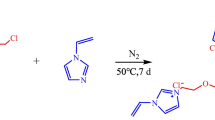

2.1 Construction of Efficient Conductive Networks

Polymer-based EMI shielding composites prepared by simple blending method are usually difficult to achieve excellent EMI shielding performance at low amount of conductive fillers [17, 18]. Gathering conductive fillers at the interfaces among the polymer particles through electrostatic interaction, or backfilling the polymer matrix into the constructed three-dimensional skeleton of conductive fillers, so as to achieve efficient overlap between the conductive fillers, forming more efficient and complete conductive networks, are the interesting ideas to realize excellent electrical conductivities and EMI shielding performances of polymer-based EMI shielding composites with relatively low amount of conductive fillers [19].

Electrostatic interaction forces can control the distribution state of nano-sized conductive fillers among polymer particles, enabling precise control of efficient three-dimensional conductive networks. By electrostatic attraction, negatively (positively) charged nano-sized conductive fillers selectively distribute on the surface of positively (negatively) charged polymer particles, rather than inside the entire polymer matrix, and precisely self-assemble to form efficient conductive network, Fig. 1a. By electrostatic repulsion, nano-sized conductive fillers with the same charges are squeezed out at interfaces between the polymer particles. By increasing the content of polymer particles or applying external force, the nano-sized conductive fillers are tightly packed at the interfaces, thereby forming the uniform and complete highly efficient conductive network, Fig. 1b. Sun et al. [22, 23].

Zhao et al. [24] prepared three-dimensional highly conductive MXene/reduced graphene oxide (rGO) aerogel frameworks with directionally porous structure by means of graphene oxide (GO)-assisted hydrothermal assembly and directional freeze-drying. Then, MXene/rGO/epoxy EMI shielding composites were prepared by backfilling epoxy resin by vacuum-assisted impregnation. When the volume fraction of MXene was 0.74 vol%, the σ and EMI SE of MXene/rGO/epoxy EMI shielding composites reached 695.9 S m−1 and 56 dB, respectively. Shen et al. [25] prepared the carbon skeleton with continuous structure by delignification and carbonization of natural wood and prepared wood-derived carbon/epoxy composites after backfilling epoxy resin. Results showed that when the carbon content was 7.0 vol%, the σ and EMI SE of the epoxy/wood-derived carbon composite were 12.5 S m−1 and 27.8 dB, respectively. In our previous research work, Gu et al. [26] prepared reduced graphene oxide (rGO)-MXene with honeycomb structure (rGMH) by combination of template (honeycomb made of aluminum oxide) induction and electrostatic self-assembly and backfilled epoxy resin to obtain rGMH/epoxy EMI shielding composites. Honeycomb structure has special hexagonal structure, i.e., a structure of cells with six sides, like the hive made by bees for holding their honey. On the one hand, its regular structure made the conductive fillers arrange in the orderly manner and overlap efficiently, so as to realize the construction of efficient conductive pathways. On the other hand, its hexagonal structure enabled electromagnetic waves to undergo multiple reflection, scattering and absorption processes, prolonging the transmission distance of electromagnetic waves in the composite materials and improving the EMI shielding performances. When the amounts of rGO and MXene were 1.2 wt% and 3.3 wt%, respectively, the σ and EMI SE of rGMH/epoxy EMI shielding composites were as high as 387.1 S m−1 and 55 dB, respectively, 2978 and 5 × those of the blended rGO-MXene/epoxy composites with the same amounts of fillers (σ and EMI SE were 0.13 S m−1 and 11 dB, respectively). In addition, Gu et al. [27] prepared silver platelets (AgPs)/rGO foam with spherical hollow structure by sol–gel templating method and backfilled epoxy resin to prepare AgPs/rGO/epoxy composites. Results showed that, benefiting from the construction of three-dimensional conductive networks, when the thickness was 3 mm and the volume fractions of rGO and AgPs were 0.44 vol% and 0.94 vol%, respectively, the EMI SE of AgPs/rGO/epoxy composites reached 58 dB at X-band.

The construction of high-efficiency conductive networks can improve the effective overlap between conductive fillers and further reduce the percolation threshold of composites. On the other hand, the fillers/polymer interfaces can be used more efficiently to enhance the reflection and reabsorption of electromagnetic waves between ordered structures and effectively improve the loss ability of electromagnetic waves. However, the polymer-based EMI shielding composites prepared based on the three-dimensional efficient conductive network only have weak electrostatic interaction or hydrogen bond interaction between the polymer matrix and the conductive fillers, resulting in poor mechanical properties and difficult to achieve practical application requirements. In the future research work, researchers can try to enhance the interaction between the two by means of chemical bonding through the optimal selection and combination design of polymer matrix and functional fillers, and improve the mechanical properties of composites. In addition, the construction of the three-dimensional conductive network endows the polymer-based EMI shielding composites with excellent electrical conductivity, and its EMI shielding mechanism is mostly based on reflection, which is easy to cause new EMI problems. The introduction of magnetic fillers and the construction of absorption-based microstructures to achieve absorption-based EMI shielding are also issues for researchers to consider.

2.2 Optimization of Multi-interfaces for Lightweight

The densities of polymer-based EMI shielding composites are significantly lower than those of traditional metal EMI shielding materials, but it is still difficult to meet the low density expectations required in fields such as aerospace [28, 29]. The density of composites can be effectively reduced by optimization of multi-interfaces, which is also a hopeful idea for the preparation of lightweight and high-performance polymer-based EMI shielding composites [30].

The optimization of multi-interfaces based on the porous structure can not only reduce the density of the composites, but also realize the multiple reflection and scattering loss of the electromagnetic waves, prolong the transmission paths of the electromagnetic waves and further improve the EMI shielding performances, Fig. 2. Zeng et al. [31] blended multi-walled carbon nanotubes (MWCNT) and waterborne polyurethane (WPU) solution to prepare lightweight MWCNT/WPU aerogels with anisotropic pore structure by freeze-drying technology. When the mass fraction of MWCNT was 76.2 wt%, the EMI SE of the MWCNT/WPU aerogel reached 50 dB and the density was only 126 mg cm−3. Lu et al. [32] prepared ultralight GO/lignin aerogels with oriented microporous structure by directional freeze-drying technology and then thermally reduced them to obtain rGO/lignin-derived carbon (rGO/LDC) EMI shielding composite aerogels. Benefiting from the establishment of the ordered porous structure, the rGO/LDC composite aerogel achieved the EMI SE of 49 dB at ultra-low density of 8 mg cm−3. In our previous research work, Gu et al. [33] used natural wood as template to obtain wood-derived porous carbon (WPC) skeletons with highly ordered internal pore structure through high-temperature carbonization and then prepared lightweight MXene aerogel/WPC EMI shielding composites by vacuum-assisted impregnation and freeze-drying. When the carbonization temperature was 1500 °C, the MXene aerogel/WPC EMI shielding composites achieved the EMI SE as high as 71 dB at low density of 0.197 g cm−3. Therefore, the construction of porous structures not only contributes to the realization of low-density and lightweight of composites, but also contributes to the effective multiple reflection and absorption of electromagnetic waves.

Aerogels prepared by optimization of multi-interfaces generally suffer from poor structural stability and relatively weak controllability on distribution of pore sizes, resulting in relatively poor mechanical properties and shielding stability of polymer-based EMI shielding composites. It is necessary to explore new preparation methods and routes, such as photolithography, microfluidics and additive manufacturing, to optimize and control the pore structure, shape and pore size distribution, and to realize the internal microstructure of polymer-based EMI shielding composites. In addition, how to introduce some reinforcing phases into the composites system to improve its structural stability without affecting EMI shielding performance is also a question worth considering.

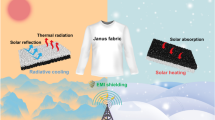

2.3 Multifunction Compatibility Design

At present, most research works mainly focus on the improvement in EMI SE of polymer-based EMI shielding composites. The rapid development of modern electronic technology has put forward newer and higher requirements for polymer-based EMI shielding composites. In addition to ensuring its excellent EMI shielding performance, it also needs to have good flexibility, thermal conductivity, self-heating performance and mechanical properties [34, 35]. By introducing multifunctional fillers and constructing the layered structure, it is feasible to realize the multifunctional compatibility design of polymer-based EMI shielding composites [36, 37].

The layered structure design can concentrate functional fillers in one or more layers, effectively increase the relative concentration of functional fillers and realize the optimal design and combination of various function of different functional fillers, Fig. 3. Zhou et al. [38] prepared multifunctional multilayered MXene/CNF/BC composite films by repeatedly spraying MXene/CNF on bacterial cellulose (BC), which was encapsulated with silicone to impart excellent hydrophobicity and solvent resistance. When sprayed with 200 layers of MXene/CNF, the EMI SE of the composite films was as high as 60 dB. In addition, due to the excellent electrical conductivity, extremely strong light absorption and localized surface plasmon resonance (LSPR) effect of MXene, the corresponding composite films had excellent low-voltage driven Joule heating and good photosensitive heating. The dense layered structure and strong interfacial interaction also endowed the composite films with high mechanical strength (> 250 MPa) and good toughness (> 20 MJ cm−3). In our previous research work, Gu et al. [39] used the facile and efficient two-step vacuum-assisted filtration, hot pressing method to prepare flexible and strong double-layered MXene/silver nanowires-aramid nanofibers (MXene/AgNW-ANF) EMI shielding composite films. The MXene/AgNW-ANF composite film had excellent EMI shielding performance (σ and EMI SE up to 3725.6 S cm−1 and 80 dB, respectively), excellent Joule heating performance (heating temperature of the composite film up to 110 °C under the low applied voltage of 2.5 V) and mechanical properties (tensile strength up to 235.9 MPa). In addition, Gu et al. [ W. Cao, C. Ma, S. Tan, M. Ma, P. Wan et al., Ultrathin and flexible CNTs/MXene/cellulose nanofibrils composite paper for electromagnetic interference shielding. Nano-Micro. Lett. 11, 72 (2019). https://doi.org/10.1007/s40820-019-0304-y Y. Chen, P. Potschke, J. Pionteck, B. Voit, H. Qi, Multifunctional cellulose/rGO/Fe3O4 composite aerogels for electromagnetic interference shielding. ACS Appl. Mater. Interfaces 12(19), 22088–22098 (2020). https://doi.org/10.1021/acsami.9b23052 Z. Chen, C. Xu, C. Ma, W. Ren, H.M. Cheng, Lightweight and flexible graphene foam composites for high-performance electromagnetic interference shielding. Adv. Mater. 25(9), 1296–1300 (2013). https://doi.org/10.1002/adma.201204196 W. Chen, L.X. Liu, H.B. Zhang, Z.Z. Yu, Flexible, transparent, and conductive Ti3C2Tx MXene-silver nanowire films with smart acoustic sensitivity for high-performance electromagnetic interference shielding. ACS Nano 14(12), 16643–16653 (2020). https://doi.org/10.1021/acsnano.0c01635 M.A.F. Shahzad, C.B. Hatter, B. Anasori, S.M. Hong, C.M. Koo et al., Electromagnetic interference shielding with 2D transition metal carbides (MXenes). Science 353(6304), 1137–1140 (2016). https://doi.org/10.1126/science.aag2421 G. Cao, S. Cai, H. Zhang, Y. Tian, High-performance conductive adhesives based on water-soluble resins for printed circuits, flexible conductive films, and electromagnetic interference shielding devices. Adv. Compos. Hybrid Mater. (2022). https://doi.org/10.1007/s42114-021-00402-1 Y. Han, K. Ruan, J. Gu. Janus, (BNNS/ANF)-(AgNWs/ANF) thermal conductivity composite films with superior electromagnetic interference shielding and Joule heat performances. Nano Res. 15, 4747–4755 (2022). https://doi.org/10.1007/s12274-022-4159-z C. Liang, Z. Gu, Y. Zhang, Z. Ma, H. Qiu et al., Structural design strategies of polymer matrix composites for electromagnetic interference shielding: a review. Nano-Micro Lett. 13, 181 (2021). https://doi.org/10.1007/s40820-021-00707-2 T.W. Lee, S.E. Lee, Y.G. Jeong, Highly effective electromagnetic interference shielding materials based on silver nanowire/cellulose papers. ACS Appl. Mater. Interfaces 8(20), 13123–13132 (2016). https://doi.org/10.1021/acsami.6b02218 H. Zhu, Y. Yang, A. Sheng, H. Duan, G. Zhao et al., Layered structural design of flexible waterborne polyurethane conductive film for excellent electromagnetic interference shielding and low microwave reflectivity. Appl. Surf. Sci. 469, 1–9 (2019). https://doi.org/10.1016/j.apsusc.2018.11.007 P. Song, B. Liu, H. Qiu, X. Shi, D. Cao et al., MXenes for polymer matrix electromagnetic interference shielding composites: a review. Compos. Commun. 24, 100653 (2021). https://doi.org/10.1016/j.coco.2021.100653 Y.J. Wan, X.M. Li, P.L. Zhu, R. Sun, C.P. Wong et al., Lightweight, flexible MXene/polymer film with simultaneously excellent mechanical property and high-performance electromagnetic interference shielding. Compos. Part A Appl. Sci. Manuf. 130, 105764 (2020). https://doi.org/10.1016/j.compositesa.2020.105764 H. Abbasi, M. Antunes, J.I. Velasco, Recent advances in carbon-based polymer nanocomposites for electromagnetic interference shielding. Prog. Mater. Sci. 103, 319–373 (2019). https://doi.org/10.1016/j.pmatsci.2019.02.003 M.S. Cao, Y.Z. Cai, P. He, J.C. Shu, W.Q. Cao et al., 2D MXenes: electromagnetic property for microwave absorption and electromagnetic interference shielding. Chem. Eng. J. 359, 1265–1302 (2019). https://doi.org/10.1016/j.cej.2018.11.051 Z. Fan, H. He, J. Yu, L. Liu, Y. Liu et al., Lightweight three-dimensional cellular MXene film for superior energy storage and electromagnetic interference shielding. ACS Appl. Energ. Mater. 3(9), 8171–8178 (2020). https://doi.org/10.1021/acsaem.0c01650 P. Hu, J. Lyu, C. Fu, W.B. Gong, J. Liao et al., Multifunctional aramid nanofiber/carbon nanotube hybrid aerogel films. ACS Nano 14(1), 688–697 (2020). https://doi.org/10.1021/acsnano.9b07459 H. Wei, M. Wang, W. Zheng, Z. Jiang, Y. Huang, 2D Ti3C2Tx MXene/aramid nanofibers composite films prepared via a simple filtration method with excellent mechanical and electromagnetic interference shielding properties. Ceram. Int. 46(5), 6199–6204 (2020). https://doi.org/10.1016/j.ceramint.2019.11.087 Y. Xu, Y. Yang, D.X. Yan, H. Duan, G. Zhao et al., Gradient structure design of flexible waterborne polyurethane conductive films for ultraefficient electromagnetic shielding with low reflection characteristic. ACS Appl. Mater. Interfaces 10(22), 19143–19152 (2018). https://doi.org/10.1021/acsami.8b05129 L. Wang, Z. Ma, Y. Zhang, L. Chen, D. Cao et al., Polymer-based EMI shielding composites with 3D conductive networks: a mini-review. SusMat 1(3), 413–431 (2021). https://doi.org/10.1002/sus2.21 R. Sun, H.B. Zhang, J. Liu, X. **e, R. Yang et al., Highly conductive transition metal carbide/carbonitride (MXene)@polystyrene nanocomposites fabricated by electrostatic assembly for highly efficient electromagnetic interference shielding. Adv. Funct. Mater. 27(45), 1702807 (2017). https://doi.org/10.1002/adfm.201702807 J.Q. Luo, S. Zhao, H.B. Zhang, Z. Deng, L. Li et al., Flexible, stretchable and electrically conductive MXene/natural rubber nanocomposite films for efficient electromagnetic interference shielding. Compos. Sci. Technol. 182, 107754 (2019). https://doi.org/10.1016/j.compscitech.2019.107754 P. Song, B. Liu, C. Liang, K. Ruan, H. Qiu et al., Lightweight, flexible cellulose-derived carbon aerogel@reduced graphene oxide/PDMS composites with outstanding EMI shielding performances and excellent thermal conductivities. Nano-Micro Lett. 13, 91 (2021). https://doi.org/10.1007/s40820-021-00624-4 Y. Zhang, Z. Ma, K. Ruan, J. Gu, Flexible Ti3C2Tx/(aramid nanofiber/PVA) composite films for superior electromagnetic interference shielding. Research 2022, 1–12 (2022) S. Zhao, H.B. Zhang, J.Q. Luo, Q.W. Wang, B. Xu et al., Highly electrically conductive three-dimensional Ti3C2Tx MXene/reduced graphene oxide hybrid aerogels with excellent electromagnetic interference shielding performances. ACS Nano 12(11), 11193–11202 (2018). https://doi.org/10.1021/acsnano.8b05739 Z.M. Shen, J.C. Feng, Preparation of thermally conductive polymer composites with good electromagnetic interference shielding efficiency based on natural wood-derived carbon scaffolds. ACS Sustain. Chem. Eng. 7(6), 6259–6266 (2019). https://doi.org/10.1021/acssuschemeng.8b06661 P. Song, H. Qiu, L. Wang, X. Liu, Y. Zhang et al., Honeycomb structural rGO-MXene/epoxy nanocomposites for superior electromagnetic interference shielding performance. Sustain. Mater. Technol. 24, e00153 (2020). https://doi.org/10.1016/j.susmat.2020.e00153 C. Liang, P. Song, H. Qiu, Y. Zhang, X. Ma et al., Constructing interconnected spherical hollow conductive networks in silver platelets/reduced graphene oxide foam/epoxy nanocomposites for superior electromagnetic interference shielding effectiveness. Nanoscale 11(46), 22590–22598 (2019). https://doi.org/10.1039/C9NR06022G J. Yang, X. Liao, G. Wang, J. Chen, F. Guo et al., Gradient structure design of lightweight and flexible silicone rubber nanocomposite foam for efficient electromagnetic interference shielding. Chem. Eng. J. 390, 124589 (2020). https://doi.org/10.1016/j.cej.2020.124589 Z. Fan, D. Wang, Y. Yuan, Y. Wang, Z. Cheng et al., A lightweight and conductive MXene/graphene hybrid foam for superior electromagnetic interference shielding. Chem. Eng. J. 381, 122696 (2020). https://doi.org/10.1016/j.cej.2019.122696 Y. Zhang, Y. Yan, H. Qiu, Z. Ma, K. Ruan et al., A mini-review of MXene porous films: preparation, mechanism and application. J. Mater. Sci. Technol. 103, 42–49 (2022). https://doi.org/10.1016/j.jmst.2021.08.001 Z. Zeng, H. **, M. Chen, W. Li, L. Zhou et al., Lightweight and anisotropic porous MWCNT/WPU composites for ultrahigh performance electromagnetic interference shielding. Adv. Funct. Mater. 26(2), 303–310 (2016). https://doi.org/10.1002/adfm.201503579 Z. Zeng, C. Wang, Y. Zhang, P. Wang, S.I.S. Shahabadi et al., Ultralight and highly elastic graphene/lignin-derived carbon nanocomposite aerogels with ultrahigh electromagnetic interference shielding performance. ACS Appl. Mater. Interfaces 10(9), 8205–8213 (2018). https://doi.org/10.1021/acsami.7b19427 C. Liang, H. Qiu, P. Song, X. Shi, J. Kong et al., Ultra-light MXene aerogel/wood-derived porous carbon composites with wall-like “mortar/brick” structures for electromagnetic interference shielding. Sci. Bull. 65(8), 616–622 (2020). https://doi.org/10.1016/j.scib.2020.02.009 T.B. Ma, H. Ma, K.P. Ruan, X.T. Shi, H. Qiu et al., Thermally conductive poly(lactic acid) composites with superior electromagnetic shielding performances via 3D printing technology. Chinese J. Polym. Sci. 40(3), 248–255 (2022). https://doi.org/10.1007/s10118-022-2673-9 Q. Gao, Y. Pan, G. Zheng, C. Liu, C. Shen et al., Flexible multilayered MXene/thermoplastic polyurethane films with excellent electromagnetic interference shielding, thermal conductivity, and management performances. Adv. Compos. Hybrid Mater. 4(2), 274–285 (2021). https://doi.org/10.1007/s42114-021-00221-4 Y. Guo, H. Qiu, K. Ruan, S. Wang, Y. Zhang et al., Flexible and insulating silicone rubber composites with sandwich structure for thermal management and electromagnetic interference shielding. Compos. Sci. Technol. 219, 109253 (2022). https://doi.org/10.1016/j.compscitech.2021.109253 Y. Zhang, K. Ruan, J. Gu, Flexible sandwich-structured electromagnetic interference shielding nanocomposite films with excellent thermal conductivities. Small 17(42), 2101951 (2021). https://doi.org/10.1002/smll.202101951 Z. Zhou, Q. Song, B. Huang, S. Feng, C. Lu, Facile fabrication of densely packed Ti3C2 MXene/nanocellulose composite films for enhancing electromagnetic interference shielding and electro-/photothermal performance. ACS Nano 15(7), 12405–12417 (2021). https://doi.org/10.1021/acsnano.1c04526 Z. Ma, S. Kang, J. Ma, L. Shao, Y. Zhang et al., Ultraflexible and mechanically strong double-layered aramid nanofiber-Ti3C2Tx MXene/silver nanowire nanocomposite papers for high-performance electromagnetic interference shielding. ACS Nano 14(7), 8368–8382 (2020). https://doi.org/10.1021/acsnano.0c02401 Z. Ma, X. **ang, L. Shao, Y. Zhang, J. Gu, Multifunctional wearable silver nanowire decorated leather nanocomposites for joule heating electromagnetic interference shielding and piezoresistive sensing. Angew. Chem. Int. Ed. (2022). https://doi.org/10.1002/anie.202200705References

Acknowledgements

The authors are grateful for the supports from the National Natural Science Foundation of China (U21A2093). Y.L. Zhang would like to thank the Innovation Foundation for Doctor Dissertation of Northwestern Polytechnical University (CX2021107). This work is also financially supported by Polymer Electromagnetic Functional Materials Innovation Team of Shaanxi Sanqin Scholars.

Funding

Open access funding provided by Shanghai Jiao Tong University.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Zhang, Y., Gu, J. A Perspective for Develo** Polymer-Based Electromagnetic Interference Shielding Composites. Nano-Micro Lett. 14, 89 (2022). https://doi.org/10.1007/s40820-022-00843-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40820-022-00843-3