Abstract

Experiments on splitting and curling collapse of square sandwich metal tubes with aluminum foam core under axial low-velocity impact are conducted in this paper. Experimental details are described including geometric and test parameters of specimens. Deformation modes and load–displacement curves are obtained through experiment. Analytical solution of quasi-static splitting and curling steady load can be used to predict steady load of square sandwich tube under axial low-velocity impact based on the similarity of quasi-static and low-velocity impact deformation modes.

Similar content being viewed by others

References

Talebi S, Sadighi M, Aghdam MM, Mirbagheri SMH (2017) Micro–macro analysis of closed-cell aluminum foam with crushing behavior subjected to dynamic loadings. Mater Today Commun 13:170–177

Mahdi KM, Vahid B (2016) Bending and buckling analysis of corrugated composite sandwich plates. J Braz Soc Mech Sci 38(8):2571–2588

Zhang JX, Guo HY, Du JL, Yuan H, Qin QH (2021) Splitting and curling collapse of metal foam core square sandwich metal tubes: Experimental and theoretical investigations. Thin Wall Struct 169:108346

Yuen SCK, Altenhof W, Opperman CJ, Nurick GN (2013) Axial splitting of circular tubes by means of blast load. Int J Impact Eng 53:17–28

Dai LP, Pan YS, Wang AW (2018) Study of the energy absorption performance of an axial splitting component for anchor bolts under static loading. Tunn Undergr Space Technol 81:176–186

Dai LP, **ao YH, Pan YS, Guo JL (2020) Mechanical behavior and factors influencing axial splitting energy absorbers and optimized application for rock bolts. Tunn Undergr Space Technol 102:103427

Guan WY, Gao GJ, Yu Y, Zhuo TY (2020) Theoretical, experimental and numerical investigations on the energy absorption of splitting multiple circular tubes under impact loading. Thin Wall Struct 155:106916

Huang X, Lu G, Yu TX (2002) On the axial splitting and curling of circular metal tubes. Int J Mech Sci 44:2369–2391

Li J, Gao GJ, Yu Y, Guan WY (2019) Experimental and numerical study on splitting process of circular steel tube with enhanced crashworthiness performance. Thin Wall Struct 145:106406

Niknejad A, Rezaei B, Liaghat GH (2013) Empty circular metal tubes in the splitting process – theoretical and experimental studies. Thin Wall Struct 72:48–60

Huang X, Lu G, Yu TX (2002) Energy absorption in splitting square metal tubes. Thin Wall Struct 40:153165

Huang X, Lu G, Yu TX (2006) Collapse of square metal tubes in splitting and curling mode. Proc Inst Mech Eng C J Mech Eng Sci 220:1–13

Lu G, Ong LS, Wang B, Ng HW (1994) An experimental study on tearing energy in splitting square metal tubes. Int J Mech Sci 36:1087–1097

Kostazos PK, Lykakos SSA, Kyritsis PAE, Manolakos DE (2021) Quasi-static axial crushing of multi-walled (spiral) aluminium tubes fabricated by roll bending: Experimental and numerical investigation. Thin Wall Struct 159:107237

Tak SK, Iqbal MA (2021) Axial compression behaviour of thin-walled metallic tubes under quasi-static and dynamic loading. Thin Wall Struct 159:107261

Deng XL, Qin SA, Huang JL (2021) Energy absorption characteristics of axially varying thickness lateral corrugated tubes under axial impact loading. Thin Wall Struct 163:107721

Sadighi A, Eyvazian A, Asgari M, Hamouda AM (2019) A novel axially half corrugated thin-walled tube for energy absorption under Axial loading. Thin Wall Struct 145:106418

Zhang JX, Ye Y, Zhu YQ, Yuan H, Qin QH, Wang TJ (2020) On axial splitting and curling behaviour of circular sandwich metal tubes with metal foam core. Int J Solids Struct 202:111–125

Zhang JX, Ye Y, Li JF, Zhu YQ, Yuan H, Qin QH, Zhao MD (2021) Dynamic collapse of circular metal foam core sandwich tubes in splitting and curling mode. Thin Wall Struct 161:107464

Djamaluddin F, Abdullah S, Ariffin AK, Nopiah ZM (2015) Optimization of foam-filled double circular tubes under axial and oblique impact loading conditions. Thin Wall Struct 87:1–11

Kılıçaslan C (2015) Numerical crushing analysis of aluminum foam-filled corrugated single- and double-circular tubes subjected to axial impact loading. Thin Wall Struct 96:82–94

Dirgantara T, Jusuf A, Kurniati EO, Gunawan L, Putra IS (2018) Crashworthiness analysis of foam–filled square column considering strain rate effect of the foam. Thin Wall Struct 129:365–380

Wang YJ, Zhang ZJ, Xue XW, Zhou J, Song ZX (2021) Axial and lateral crushing performance of plate-lattice filled square sandwich tubes. Compos Struct 274:114404

Chen HC, Zhang Y, Lin JM, Zhang F, Wang YX, Yan XL (2021) Crushing responses and optimization of novel sandwich columns. Compos Struct 263:113682

Deng XL, Liu WY (2019) Experimental and numerical investigation of a novel sandwich sinusoidal lateral corrugated tubular structure under axial compression. Int J Mech Sci 151:274–287

Deng XL, Liu WY (2019) Multi-objective optimization of thin-walled sandwich tubes with lateral corrugated tubes in the middle for energy absorption. Thin Wall Struct 137:303–317

Hou YB, Zhang Y, Yan XL, Lai XM, Lin JM (2021) Crushing behaviors of the thin-wall sandwich column under axial load. Thin Wall Struct 159:107229

Liu WY, Lin ZQ, He JY, Wang NL, Deng XL (2016) Crushing behavior and multi-objective optimization on the crashworthiness of sandwich structure with star-shaped tube in the center. Thin Wall Struct 108:205–214

Zhu XJ, Zheng J, **ong C, Yin JH, Deng HY, Zou YC, Song SJ (2021) Compression responses of composite corrugated sandwich square tube: Experimental and numerical investigation. Thin Wall Struct 169:108440

Wang SL, Zhang M, Wang Y, Huang ZL, Fang Y (2021) Experimental studies on quasi-static axial crushing of additively-manufactured PLA random honeycomb-filled double circular tubes. Compos Struct 261:113553

Yin HF, Wen GL, Hou SJ, Chen K (2011) Crushing analysis and multiobjective crashworthiness optimization of honeycomb-filled single and bitubular polygonal tubes. Mater Des 32:4449–4460

Zhang ZH, Liu ST, Tang ZL (2010) Crashworthiness investigation of kagome honeycomb sandwich cylindrical column under axial crushing loads. Thin Wall Struct 48:9–18

Acknowledgements

The authors are grateful for their financial support through NSFC (11872291), the Fundamental Research Funds for the Central Universities (lzujbky-2021-kb03), the State Key Laboratory of Automotive Safety and Energy under Project No. KFY2202, and Foundation of State Key Laboratory of Automotive Simulation and Control (20210206).

Author information

Authors and Affiliations

Corresponding author

Additional information

Technical Editor: João Marciano Laredo dos Reis.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix 1: Analytical model of steady load of quasi-static splitting and curling collapse of square sandwich metal tubes with aluminum foam core [3]

Appendix 1: Analytical model of steady load of quasi-static splitting and curling collapse of square sandwich metal tubes with aluminum foam core [3]

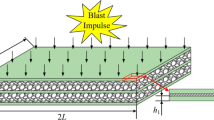

As shown in Fig.

10, in the steady deformation stage, the plastic curling deformation of inner and outer tubes happens and the metal foam core is compressed.

For the outer tube, from the conservation of energy,

where \(M_{20} = \frac{{\sigma_{t} b_{2} H^{2} }}{4}\), \(R_{2} = \frac{{H\left( {b_{2} + H} \right)}}{{4H_{1} }}\left[ {\frac{\sin \alpha + \mu \cos \alpha - \mu }{{\sin \left( {\alpha - \beta_{2} } \right) + \mu \cos \left( {\alpha - \beta_{2} - \mu } \right)}} - 1} \right].\)

Terms on the right of the equal sign are the rates of bending energy and tearing energy of the outer tube, respectively.

For the inner tube, from the energy conservation,

where \(M_{10} = \frac{{\sigma_{t} b_{1} H^{2} }}{4}\), \(R_{1}^{\prime } = R_{2} + c + H.\)

Terms on the right of the equal sign are the rates of bending energy, tearing energy and friction energy of the inner tube, respectively.

The metal foam is compressed until densification strain, and the rate of energy dissipated in the foam compression is

From the conservation of energy,

Thus,

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Guo, H., Zhang, J., Li, J. et al. Splitting and curling collapse of square sandwich metal tube with aluminum foam core under axial low-velocity impact. J Braz. Soc. Mech. Sci. Eng. 44, 514 (2022). https://doi.org/10.1007/s40430-022-03840-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40430-022-03840-0