Abstract

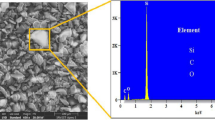

In this current research study, the holes are drilled in the hybrid composite reinforced with Ni–P-coated glass fiber (GF) and Al2O3 nanowires via abrasive water jet (AWJ) machining process. The input process parameters such as jet pressure, traverse speed, and concentration of abrasive on the delamination characteristic both at the inlet and at the exit sides of the drilled holes are investigated and optimized for the minimum delamination and fiber pullouts. The experiments are conducted using Taguchi’s L25 orthogonal arrays, and the input process parameters are optimized for lesser delamination at both sides together by grey relational analysis. From the experimental results, it is clear that the abrasive flow rate has significantly effect on the delamination characteristics followed by abrasive water jet pressure and the traverse speed. Grey relational technique is used for optimizing multiple responses (delamination at the inlet and exit) simultaneously. The morphological analysis was been carried out using scanning electron microscope (SEM) to determine the wall quality of the drilled holes. From the experimental analysis, it was found that the machined surfaces were free from delamination to an extent at optimized conditions (the mass flow rate of 350 gm/min, jet pressure of 3000 Bar and traverse speed of 800 mm/min, respectively), which leads to minimal delamination both at the entry and at exit side of the machined hole as compared with the holes drilled by conventional machining process.

Similar content being viewed by others

References

C. Dong, I.J. Davies, Flexural properties of E glass and TR50S carbon fiber reinforced epoxy hybrid composites. J. Mater. Eng. Perform. 22(1), 41–49 (2013). https://doi.org/10.1007/s11665-012-0247-7

J. Zhang, K. Chaisombat, S. He, C.H. Wang, Hybrid composite laminates reinforced with glass/carbon woven fabrics for lightweight load bearing structures. Mater. Design. 36, 75–80 (2012). https://doi.org/10.1016/j.matdes.2011.11.006

C.C. Tsao, H. Hocheng, The path towards delamination-free drilling of composite materials. J. Mater. Process. Technol. 167(2–3), 251–264 (2005). https://doi.org/10.1016/j.jmatprotec.2005.06.039

V.A. Phadnis, F. Makhdum, A. Roy, V.V. Silberschmidt, Experimental and numerical investigations in conventional and ultrasonically assisted drilling of CFRP laminate. Procedia Cirp. 1, 455–459 (2012). https://doi.org/10.1016/j.procir.2012.04.081

U. Heisel, T. Pfeifroth, Influence of point angle on drill hole quality and machining forces when drilling CFRP. Procedia Cirp. 1, 471–476 (2012). https://doi.org/10.1016/j.procir.2012.04.084

C.L. Tan, A.I. Azmi, N. Muhammad, Performance evaluations of carbon/glass hybrid polymer composites. Adv. Mater. Res. 980, 8–12 (2014)

H. Hocheng, C.C. Tsao, Comprehensive analysis of delamination in drilling of composite materials with various drill bits. J. Mater. Process. Tech. 140(1–3), 335–339 (2003). https://doi.org/10.1016/S0924-0136(03)00749-0

A.I. Azmi, R.J.T. Lin, D. Bhattacharyya, Machinability study of glass fibre-reinforced polymer composites during end milling. Int J. Adv. Manuf. Technol. 64(1–4), 247–261 (2013). https://doi.org/10.1007/s00170-012-4006-6

A. Alberdi, A. Suárez, T. Artaza, G.A. Escobar-Palafox, K. Ridgway, Composite cutting with abrasive water jet. Procedia Eng. 63, 421–429 (2013). https://doi.org/10.1016/j.proeng.2013.08.217

J. Wang, D.M. Guo, A predictive depth of penetration model for abrasive waterjet cutting of polymer matrix composites. J. Mater. Process. Tech. 121(2–3), 390–394 (2002). https://doi.org/10.1016/S0924-0136(01)01246-8

J. Wang, Abrasive waterjet machining of polymer matrix composites–cutting performance, erosive process and predictive models. Int. J. Adv. Manuf. Tech. 15(10), 757–768 (1999). https://doi.org/10.1007/s001700050129

H. Ho-Cheng, A failure analysis of water jet drilling in composite laminates. Int. J. Mach. Tools Manuf. 30(3), 423–429 (1990). https://doi.org/10.1016/0890-6955(90)90186-M

A.W. Momber, R. Kovacevic, Principles of abrasive water jet machining. Springer Science & Business Media. (2012). https://doi.org/10.1007/978-1-4471-1572-4

E. Huttunen-Saarivirta, F.H. Stott, V. Rohr, M. Schütze, Particle angularity effects on the elevated-temperature erosion–oxidation behaviour of aluminium diffusion coatings on 9% Cr steel. Wear 261(7–8), 746–759 (2006). https://doi.org/10.1016/j.wear.2006.01.014

J. Wang, D.M. Guo, A predictive depth of penetration model for abrasive water jet cutting of polymer matrix composites. J. Mater. Process. Tech. 121(2–3), 390–394 (2002)

D.K. Shanmugam, T. Nguyen, J. Wang, A study of delamination on graphite/epoxy composites in abrasive waterjet machining. Compos. Part A Appl. S. 39(6), 923–929 (2008)

M.A. Azmir, A.K. Ahsan, A study of abrasive water jet machining process on glass/epoxy composite laminate. J. Mater. Process. Tech. 209(20), 6168–6173 (2009). https://doi.org/10.1016/j.jmatprotec.2009.08.011

G. Anand, N. Alagumurthi, K. Palanikumar, N. Venkateshwaran, R. Elansezhain, Influence of drilling process parameters on hybrid vinyl ester composite. Mater. Manuf. Process. 33(12), 1299–1305 (2018). https://doi.org/10.1080/10426914.2018.1453161

D.K. Shanmugam, S.H. Masood, An investigation on kerf characteristics in abrasive waterjet cutting of layered composites. J. Mater. Process. Tech. 209(8), 3887–3893 (2009). https://doi.org/10.1016/j.jmatprotec.2008.09.001

J. Wang, A machinability study of polymer matrix composites using abrasive waterjet cutting technology. J. Mater. Process. Technol. 94(1), 30–35 (1999). https://doi.org/10.1016/S0924-0136(98)00443-9

M.A. Azmir, A.K. Ahsan, Investigation on glass/epoxy composite surfaces machined by abrasive water jet machining. J. Mater. Process. Technol. 198(1–3), 122–128 (2008). https://doi.org/10.1016/j.jmatprotec.2007.07.014

N. Yuvaraj, M. Pradeep Kumar, Multiresponse optimization of abrasive water jet cutting process parameters using TOPSIS approach. Mater. Manuf. Process. 30(7), 882–889 (2015). https://doi.org/10.1080/10426914.2014.994763

G. Anand, N. Alagumurthi, R. Elansezhian, K. Palanikumar, N. Venkateshwaran, Investigation of drilling parameters on hybrid polymer composites using grey relational analysis, regression, fuzzy logic, and ANN models. J. Braz. Soc. Mech. Sci. Eng. 40(4), 214 (2018)

G. Anand, N. Alagumurthi, R. Elansezhian, N. Venkateshwaran, Ni-P coated glass Fiber/Al2O3 nanowire reinforced vinyl ester composite. Polymer Korea 41(3), 443–451 (2017). https://doi.org/10.7317/pk.2017.41.3.443

D.K. Shanmugam, T. Nguyen, J. Wang, A study of delamination on graphite/epoxy composites in abrasive waterjet machining. Compos. A Appl. Sci. Manuf. 39(6), 923–929 (2008)

Y. Kuo, T. Yang, G.-W. Huang, The use of grey relational analysis in solving multiple attribute decision-making problems. Comput. Ind. Eng. 55(1), 80–93 (2008)

C.P. Fung, Manufacturing process optimization for wear property of fiber-reinforced polybutylene terephthalate composites with grey relational analysis. Wear 254(3–4), 298–306 (2003). https://doi.org/10.1016/S0043-1648(03)00013-9

P.D. Unde, M.D. Gayakwad, N.G. Patil, R.S. Pawade, D.G. Thakur, P.K. Brahmankar, Experimental investigations into abrasive waterjet machining of carbon fiber reinforced plastic. J. Compos. (2015). https://doi.org/10.1155/2015/971596

N. Yuvaraj, P. Kumar, in Performance and Surface Evaluation Characteristics on Cryogenic-Assisted Abrasive Water Jet Machining of AISI D2 Steel. Non-Conventional Machining in Modern Manufacturing Systems (IGI Global, 2019), pp. 202–231

Unde, P. D.; Ghodke, R; Investigations of delamination in GFRP material cutting using abrasive water jet machining. Fourth International Conference on Advances in Mechanical, Aeronautical and Production Techniques—MAPT 2015, 2015, pp. 6–9

M.M.W. Irnia, A.I. Azmi, C.C. Lee, A.F. Mansor, Kerf taper and delamination damage minimization of FRP hybrid composites under abrasive water-jet machining. Int. J. Adv. Manuf. Technol 94(5–8), 1727–1744 (2018). https://doi.org/10.1007/s00170-016-9669-y

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The author(s) declare that there is no conflict of interest with respect to the project and the research paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Anand, G., Perumal, S.V., Yuvaraj, N. et al. Influence of Abrasive Water Jet Machining Parameters on Hybrid Polymer Composite. J. Inst. Eng. India Ser. C 102, 713–722 (2021). https://doi.org/10.1007/s40032-021-00672-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40032-021-00672-0