Abstract

Coronavirus Pandemic is the current biggest challenge against humanity. Apart from the personal health issues and higher mortality by the coronavirus, recent research works have also reported the environmental impacts of the pandemic. The review aims to analyze the current status of face masks and personal protective equipment littering and subsequent environmental impact in terms of microplastic and microfiber pollution. Recent researches in this domain are collected from the leading databases with relevant keywords and critically analyzed. The review results report a multi-fold increment in the usage of personal protective equipment, particularly face masks after the pandemic. Mismanagement of these items leads them to reach the marine environment through a variety of transportation. The results show a significant amount of increment in plastic and pandemic-related littering after the pandemic. The systematic review shows that the use of synthetic fibers in disposable personal protective equipment and masks leads to release of fibers that can add-on to microfiber pollution. The results are also true in the case of reusable masks as the repeated laundry and disinfection methods release a significantly higher amount of microfibers. Only very few studies have addressed the release of microfiber from the mask, and no studies have reported the impact of personal protective equipment. The worldwide mass adaptation and improper disposal of these materials increase the seriousness of the problem multiple folds. These findings suggest the immediate requirement of critical analysis of the pandemic-related littering and microfiber release characteristics. The research also urges the need for the implementation of an environmental management plan as a mitigation strategy around the globe.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Microplastic pollution is a rising concern among environmentalists due to its huge impact on the environment as well as biota. The researchers have witnessed the microplastic contamination in different environmental compartments including hydrosphere, lithosphere, biosphere, and atmosphere (Eriksen et al. 2013; Castañeda et al. 2014; Gasperi et al. 2015; Sanchez-Vidal et al. 2018; Absher et al., 2018; Kaya et al. 2018; Liu et al. 2018; Liu et al. 2019; Ambrosini et al. 2019; Chen et al. 2019). Around 18.75% (1.5 million tons) of total plastics (8 million tons) entering the marine environment were microplastics (Bird 2019). However, unlike macroplastics, the traceability and removal of microplastics are tedious. The higher level of contamination elevates the risks associated with the microplastics. Microplastics were found in different land-based (Selonen et al. 2019; Zhao et al. 2016) as well as water-based living organisms (Cauwenberghe et al. 2016) and medicinal animals (Lu et al. 2016; Lusher et al. 2015; Wang et al. 2019; Tiwari et al. 2019; Ambrosini et al. 2019). Moreover, the link between the type of apparel being used and the polymers found in contaminated regions confirms the role of synthetic textiles in microplastic pollution (Browne et al. 2011; Sanchez-Vidal et al. 2018). In addition to this, the detachment of microfibers from the textile materials has also been reported. The microfiber shedding behavior of textile materials was analyzed in the dry state (wearing) (De Falco et al. 2020; Cai et al. 2021) as well as the wet state (domestic laundry) (Browne et al. 2011; Napper and Thompson 2016; Kelly et al. 2019). Domestic laundering of textiles has been realized as the major cause of microfiber shedding from synthetic textiles. Researchers have pointed out that the increased production and consumption of synthetic textiles due to fast fashion trends are the key accelerators of the contribution of synthetic textiles in microplastic pollution (Ellen MacArthur Foundation 2017). Besides, the rapid disposal of garments due to shorter trend cycles also increases the seriousness as the textile materials can get degraded or fragmented due to aging and exposure to sunlight (Laitala et al. 2018; Henry et al. 2019).

In this context, recently, the use of single-use personal protective equipment (PPE) that includes masks, face shields, gloves, and other protective items has reached its peak due to the rapid spread of Coronavirus (COVID-19). The increased production and consumption of single-use PPEs result in increased as well as unsafe disposal that ends up in the environment. The management of these wastes got complicated with the sudden increment. It has been estimated that switching from single-use masks to reusable masks can reduce plastic wastes by 60,000 tons in a single year (E &T editorial, 2021). Researchers have reported the existence of PPE along coastal sides where masks were found abundantly (87.7%) followed by face shields (6.5%) (De-la-Torre et al. 2021). These should be addressed properly as the surgical masks are generally made of synthetic polymers which can harm the environment (Aragaw 2020). The noticeable impact associated with the increased consumption and disposal of single-use PPE is that it can ultimately increase microfiber pollution in the environment. Researchers have reported the microfiber release behavior of surgical masks during usage and in the disposed state (Aragaw 2020; Chen et al. 2021; Shen et al. 2021). Researchers have also witnessed the release of fibers from the non-woven layer of surgical masks (Chen et al. 2021). With a significant level of microplastic emission issues with the disposable masks, researchers have estimated that a range of 72–31,200 tons of microplastics add up to the ocean in 2020 due to the increased use of surgical masks (2.4–52 billion pieces) (Saliu et al. 2021). The situation should be given even more attention when disposable masks can also act as pollutant carriers (Anastopoulos and Pashalidis 2021). Moreover, disposable masks were found to release heavy metals in addition to micro- and nanoparticles (Swansea University 2021). The microplastic release behavior of masks needs to be analyzed with greater importance as this possesses the risk of inhalation of microfibers (Li et al. 2021). Like single-use disposable masks, reusable masks should also be given equal importance in the case of microplastic issues. Reusable masks do undergo disinfectant processes that can cause the release of fibers which is very similar to the microfiber shedding of textiles during washing (Shruti et al. 2020). The existing complications with microplastic pollution got a greater concern with the increased consumption and disposal of PPEs, more specifically masks. Being a potential pollutant, these PPEs should be handled properly amidst the pandemic to avoid long-term effects. Hence, this paper aims to analyze the environmental impact of PPEs, single-use surgical masks, and reuse face masks. In specific, the review consolidates the potential impact of these articles on the microplastic and microfiber release to the environment. This review process was performed in June 2021 and is carried out in the Department of Fashion Technology at PSG College of Technology (Coimbatore, India).

Materials and methods

The study involves a critical analysis of the literature that is focused on the area of plastic and microplastic pollution impact of COVID-19 related PPEs. Science direct, the American Chemical Society, and Springer database have been used for collecting research works that are done in this domain. Google Scholar and Researchgate were used to access the works which are inaccessible in the mentioned platforms. For the literature collection, specific keywords such as COVID-19, Personal Protective Equipment, Face masks, COVID-19 littering were used. Further, the research works were narrowed down to environmental pollution, microplastic pollution, and microfiber pollution. After narrowing it down, 32 articles were selected based on their direct relevance to the current research. The collected articles were consolidated based on their scope and finding and then analyzed to derive the key findings and the research gap. Moreover, other relevant researches on microfiber pollution due to textile materials and their impacts were also discussed to provide basic support for a better understanding of the issue and its origin.

Results and discussion

PPE and face masks usage in COVID 19

The second wave of COVID-19 created a higher awareness among the general public to use personal protective equipment (PPE). A personal protective kit is typically used by health professionals to avoid infection and disease transmission. Hence, these materials are primarily developed for single-use purposes (Patel et al. 2017). As the high rate of human transmission of COVID-19 is reported through respiratory transmissions, presently general public was insisted to wear face masks in public places by their national governments (Kwak and An 2021). The use of face masks is one of the precautionary measures to protect the person-to-person transmission of COVID-19 and so a sudden increase in the consumption of face masks is noted worldwide. World Health Organization (WHO) reported a worldwide requirement of 89 million surgical masks per month in this pandemic and a 40% increment in the disposal PPE production (WHO 2020a, b). Recent research works also intimated a huge surge in global mask production. Adyel (2020) reported a 12% increment in China’s mask production in February 2020 than the previous year. At this post lockdown, by adhering to the WHO norms, if people use disposable masks daily, the consumption will rise to 129 billion face masks and 65 billion gloves per month (Prata et al. 2020). Due to the large quantity of general public consumption, the masks are disposed of in the environment without proper care. Improper disposal of even 1% of the masks used in the world will develop 10 million masks per month and that can induce 30,000–40,000 kg of plastic into the environment (WWF 2020).

Though the disposable or surgical face masks that are made of synthetic non-woven materials were recommended to avoid the risk of infection (Feng et al. 2020; Potluri and Needham 2005; Aragaw 2020), WHO also approved tri-layered reusable cloth masks with higher filtration efficiency (WHO 2020a). The reusable masks that are commercially sold through retailers increased tremendously as the need for regular use increased after the lockdown. Amazon and Esty reported millions of cloth mask sales in the pandemic alone (Kavilanz 2020). A recent research report mentioned that the global reusable face mask industry will grow at a compound annual growth rate (CAGR) of 23.5% from 2020 to 2027 and reach a value of 7.08 billion USD by 2027 (Reusable Face Mask Market 2020). As far as the fiber contents are concerned, the disposable surgical masks are typically made of three layers. The first layer is the typical inner or skin contact layer that is made of cotton and cellulosic blends to absorb the sweat from the skin. The second layer or middle layer is mainly prepared with synthetic non-woven materials like polypropylene and polyester. It is used to filter or retain the aerosol particle, viruses, and other microorganisms from reaching the wearer. The outermost layer is hydrophobic synthetic material to restrict material and liquid passage, preferably made with nylon, polypropylene, and polyesters materials (WHO 2020b; Shruti et al. 2020). In the case of a reusable face mask, all the types of fibers were used without any regulations. Konda et al. (2020) reported that most of the masks in the commercial retail outlets contain a significant amount of synthetic fiber contents. The few common fibers used were 100% polyester, nylon, polyether-polyurea copolymer, spandex, cotton and polyester blends, and polyester/polyamide mix. These masks are also widely available with two to six layers to control the coughing and sneezing droplets (Konda et al. 2020). A recent study in the USA compared the mask usage of the US people in April 2020 and May 2020. The survey results showed that compared to April 2020 (61.9%), the cloth face mask usage increased to 76.4% in May 2020. The increment is mainly associated with native people compared to others and people above 65 years (Fisher et al. 2020).

Next to mask, the use of PPE also increased sharply due to the COVID-19 outbreak. Initially, the PPE kit is restricted to medical practitioners but during this pandemic, the usage increased exponentially. Polyethylene, polypropylene, polyvinyl chloride, polyurethane, polyacrylonitrile, polystyrene, and polycarbonate are the common synthetic fibers used in manufactured PPE products (Fadare and Okoffo 2020). All frontline workers who deal with COVID-19 patients, police personnel, cleaning workers, public government officials, and volunteers use PPE. Hence, the market was expected to grow with a CAGR of 13.5% and reach a value of 11.45 billion USD in 2023 (Research and Markets 2020). At the initial stage of COVID-19 in 2019, a severe shortage of PPE kits was noted in the countries like India and other Asian countries (Sharma et al. 2020). In March 2020, WHO also reported the risks associated with the global shortages of PPE and its impact on the health of frontline workers (WHO 2020b), and in later stage, through procurement from abroad and own production, countries have fulfilled their needs. In May 2020, the Indian union minister reported that India developed their PPE production capacity to the level of 0.45 million per day (Ojha 2020). Due to the shortage of PPE for the frontline workers, countries like the USA and Ireland were looking for different reuse methodologies to decontaminate the disposable PPE and facemask with different technologies (Rowan and Laffey 2020). As the global community fights against the COVID-19, the PPEs and face masks became the essential day-to-day requirements of the general public apart from the medical professional. The extreme use of the disposable PPEs recently alarmed the environmentalists regarding the mismanagement of these PPEs which cause serious plastic pollution. Imparting knowledge to the general public about the proper disposal method of the mask is a huge challenge in the pandemic. The plastic waste and business management head, World Wildlife Fund, mentioned that the goal is not to risk personal health and medical safety, however, educating the public in the proper management of used masks (Zoe Malin 2021). Before lockdown, the disposable masks were used by medical industry people and there was no problem, but after the pandemic lockdown, as the governments advised to use the mask, the general public adopted the same. It is safe to use against COVID-19 but they are not environmental-friendly as expected.

Environmental impact of PPE and masks

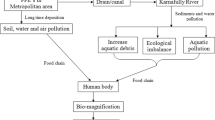

Though COVID-19 is a big threat to human life, it indirectly contributes to Sustainable Development Goals (SDG) due to the reduction of air pollution, greenhouse gas reduction, and other controlled activities (Silva et al. 2021). Everyday use of reusable and disposable masks becomes the new normal after the COVID-19 pandemic and the use of PPE also increased significantly as discussed earlier. As the PPE and masks are majorly produced from synthetic fiber material, it is also creating an impact like single-use plastics on the environment. In February 2020, the first concern on face mask pollution was given by the Oceans Asia foundation, which reported a large number of masks on the beaches of Hong Kong. It warned that the disposal of the mask will also end up in a situation like single-use plastics by impacting marine lives (Emily Chan 2020). A report released by Oceans Asia reported that around 1.5 billion disposable masks around the world had reached aquatic (sea) sources at the end of the year 2020. This approximately adds 6,500 tons of additional plastic wastes to the marine environment. The major difficulty comes in mask recycling than other plastics since they were made up of multiple plastics. An environmental simulation study showed that a single face mask can release up to 1,73,000 microfibers per day (Leyla Yvonne Ergil 2021). As the masks are mainly made of polypropylene, the microfibers from the medical-grade disposable face mask will take up to 450 years to decompose (Zoe Malin 2021).

Hence, to avoid contamination and to also regulate the pandemic wastes, WHO released a separate waste management protocol on a regional level based on sustainable approaches (WHO, 2020c). Several studies from all around the world reported the littering of used PPE materials and face mask in open and public places (Prata et al. 2020; Canning Clode et al. 2020; Ouhsine et al. 2020). It was also evident that due to higher consumption than other PPEs, the single-use masks are the most littered item in public places (Ammendolia et al. 2020; Okuku et al. 2021; Roberts et al. 2021). Detailed analysis on mask and PPE littering was reported recently by Roberts et al. (2021). The recent research analyzed the PPE and mask littering in eleven different countries using Litterati open-source data (Litterati 2020). The research was performed at different periods from March to October 2020, and the results are presented in Fig. 1. It reported the results at three stages of analysis namely, at emergency (E), at pandemic (P), and after general use recommended (M). From the time of emergency (Jan 2020) to pandemic (March 2020), no significant difference in the litter was noted concerning the PPE items like masks, gloves, and wipes. But after the announcement of the pandemic, the usage of all PPE increased. 0.2% to 2.4% increment in the gloves litters was noted in the pandemic, and similarly, the wipe litters increased from 0.2 to 0.6% in the pandemic and reduced to 0.4% in the post-pandemic. But due to the mass requirements, a gradual increase in the mask littering was noted from March 2020 to October 2020 to the level of 0.84% of total collected litter. Only for the mask littering, 84-fold increment was reported by the study. The research also showed prominent differences among the countries, where the UK showed a significant increment in littering during and post-pandemic, and the Netherlands did not show any differences except for gloves.

Analysis of the results of total litter per month for all countries analyzed. Vertical gray lines labeled “E”, “P” and “M” denote the month of the WHO declarations and guidance: E = emergency, P = pandemic, and M = general mask use recommended (Reprinted under Creative Commons License) (Roberts et al. 2021)

An analysis performed in two metropolitan cities namely Toronto, and Ontario found 43 out of 44 surveyed places polluted with PPE debris. Out of several PPE items surveyed, maximum debris of used gloves was found in the city (41%), in the large grocery store, and in residential locations. All the gloves found were made of synthetic materials. The higher prevalence of the gloves is associated with the public mindset about the safety against COVID-19 virus. As the virus remains inert on plastic surfaces (van Doremalen et al. 2020) hand wash was the best method to remove the viruses. Among the various locations verified, an average of 32% place showed the debris of face masks. The maximum amount of litter was found in hospital locations. In the case of mask type, the majority of the littered material noted was single use masks followed by reusable masks. Medical wipes were noted in around 27% of the surveyed areas (Ammendolia et al. 2021). The ecotoxicological effects of micro- and nanofiber debris from disposable face masks were reported by Kwak and An (2021). Researchers used earthworms and springtails to measure the ingestion rate of microfibers from the mask filters. The study results showed a rapid uptake of microfibers in earthworms and springtails. The presence of microfibers on those organisms confirmed the environmental impact of the face masks. It was also reported that the fragmentations of polypropylene fibers can also act as a heavy metal carrier and spoil the soil ecosystem.

The main issue in the face mask comes with the polypropylene content as it was used to protect the wearer from the body fluids and aerosol droplets. Polypropylene never degrades completely instead, it shrinks and converts into debris over years. Studies proposed the reusable mask as a potentially viable option to overcome the pollution related to disposable facemasks (Azyan Zafyrah Mohd Zahid 2020). A comparative study conducted by Environmental Science Center, Qatar University, compared the coastal littering in the west coast region of Qatar between November 2019 and July 2020. The results showed that after a lockdown in July 2020, the researchers reported a higher amount of PPE materials and disposable face masks as littered items than the 2019 study. Through FTIR analysis, they confirmed the presence of polypropylene in identified littered material and suggested that the disposal face mask, PPE are emerging environmental threats. They also reported that polypropylene will become the source of microplastic pollution in the ocean (Veerasingam et al. 2020). Other researchers reported the COVID-19 related littering in the Kenyan beaches. The study reported 0.43% of litters found are COVID-related PPEs and masks. Out of several beaches evaluated, urban beaches (Mkomani) were noted with 55.1% of COVID-litters than the remote beaches. Concerning the floating material survey in the sea range, the research did not find any COVID-related litter on the surface as the PPE items and disposal masks tend to sink into the bottom of the sea (Okuku et al. 2021). The analysis in Indonesia, also reported a similar trend of PPE debris on the coastal regions of Jakarta Bay. The previous study in April 2016 did not show any such kind of PPE debris; however, the study on June 2020 reported a PPE debris of 16% of the total debris collected. After the pandemic, more medical wastes including gloves, masks, etc., were found in the study. Out of which medical PPEs, masks (disposable) occupied a major percentage of 9.83% of debris (Cordova et al. 2021).

Several researchers reported the mismanaged wastes and their impact on pollution (Lebreton and Andrady 2019). They have predicted plastic pollution till 2060 and reported mismanaged wastes as the main source of 91% of the pollution. A recent study by Chowdhury et al. (2021) reported a face mask consumption prediction based on the population in the coastal regions and mask acceptance percentage by the respective country. Out of the countries measured, Asian countries consume 289.63 billion face masks annually than any other country. The study also reported a 65% and above mask acceptance percentage in Asian countries than other countries. When the mismanaged pollution was related due to the higher mask usage, Asian countries contribute much higher. The study reported that approximately 0.15–0.39 million tons of plastic debris enter the ocean yearly. In the case of COVID-related plastics wastes from the mask, the Asian countries contribute 1.51 million tons of waste. The researchers noticed that poor waste management in lower-income countries was the main reason. Other than this, common environmental issues like sewage treatment issues, recycling issues, carbon footprint issues, and other impacts are also associated with the PPE and related plastic items. The detailed information on the long-term effect and carbon footprints can be found elsewhere (Silva et al. 2021).

Due to the increased open-air and landfilling process, to avoid the potential environmental harm caused by PPEs, Aragaw and Mekonnen (2021) reported thermal pyrolysis as a potential method. In a study, researchers reported 75% conversion of PPE as bio-crude oil through the pyrolysis process. It is also reported that the surface littering washed off into the water bodies in several means and adds pollution to the aquatic environment. Initially, it disintegrates to macro-level debris and further to micro-level over time. The complete adoption of face mask usage by the global community increased the disposal of PPE and face mask. Studies showed that the COVID situation has brought an environmental disorder in both the terrestrial and aquatic environments (Aragaw 2020). Shruthi et al. (2020) reported the potential issues that arise from the mask that we use during the pandemic. Either it may be disposable or reusable, the researchers understand that they can cause higher microfiber emissions into freshwater systems, land, and the ocean. Since synthetic textiles cause a higher amount of microfiber shedding as reported by earlier researchers (Rathinamoorthy and Raja Balasaraswathi 2021; Napper and Thompson 2016; De Falco et al. 2019), the current recommendation for reusable masks also can contribute similarly to the marine pollution as they are also made of synthetic textiles. A virologist from the University of Cambridge mentioned that for the general public, the use of reusable cloth masks is perfectly safe and adequate. The experts also advise washing the reusable mask at above 60 degrees centigrade to kill any virus particles in non-medical circumstances (Emily Chan 2020; UNE 2020; AFNOR 2020). Other studies report that machine washing of the reusable mask is the better way to control the environmental impacts (in terms of carbon footprint and chemical release to sewage and marine) (Roberts et al. 2020). Figure 2 represents the distribution of various COVID-19 related PPE items (Fig. 2a) and mask types (Fig. 2b) as reported in the literature.

When the environmental impact of these face masks (reusable and disposable) in terms of plastics pollution has been analyzed, it is alarming that the reusable masks are also creating pollution but are comparatively lesser than the disposable mask. As per previous studies, machine washing synthetic textiles can cause higher microfiber shedding from fabric (Lant et al. 2020). Similarly, washing at higher temperatures, above 60 degrees will increase the amount of microfiber released per unit square of fabric with statistical significance (Yang et al. 2019; Zambrano et al. 2019). Hence, the use of a reusable face mask is also not completely safer in terms of plastic pollution is concerned. Further, the lifetime of the reusable masks is not standardized and it is essential to wear masks in day-to-day routine; hence, a higher number of repeated washes can contribute to a significant level of microfiber and microplastic pollution. A survey conducted in the UK reported that reusable masks reduce the environmental impact by about 95% (compared to single-use surgical masks), followed by a reusable mask with one-time use filters (60% reduction). The least impact was noted with the reusable mask with no filters whereas the face shield had a higher environmental impact. The study reported that disposable masks can cause 10 times higher pollution than reusable masks (Allison 2020). Though several researchers reported the recycling of disposable masks is difficult due to their multiple fiber types, few existing technologies were also suggested to disinfect, sterilize and reuse the disposable face masks. A review report by Rubio-Romero et al. (2020) evaluated the different cleaning methods like decontamination with ozone, Vaporized Hydrogen Peroxide, Low-Temperature Moist Heat, ultraviolet C radiation, and ultraviolet germicidal irradiation for their effectiveness on Filtering facepiece (FFP) respirators. However, no specific method for the decontamination and sterilization of disposable PPEs was detailed in this study. Figure 3 denotes the use of various COVID-19 related PPE items distributed at different locations as reported in the literature.

The literature indicated a higher amount of face mask littering all around the world compared to other PPEs. The mass adaptation of facemask usage after the pandemic was reported as the major reason for higher consumption. In the case of disposal, inadequate knowledge of individuals and poor waste management practices of the nations were reported as potential sources of environmental littering. Due to the synthetic fibers content and non-woven structures, the disposed surgical masks quickly interact with sewage paths or river streams, or seawater and releases microfiber. Studies often reported that the use of reusable face masks reduces the environmental impact to a significant level. However, without proper regulation, similar to a disposable mask, the repeated use, and laundering of the reusable mask is also capable of releasing microfibers.

Microfiber/microplastic release from face masks

Microfiber emission from these PPEs and face masks is one of the significant environmental impacts of these products. Single-use disposable masks are being used widely in this pandemic and results in huge disposal. The microfibers/microplastics releases from the PPEs were witnessed by few researchers and specifically the microplastic release behavior of the masks as the masks are dominant among others in the PPEs used. The morphology of the layers can be responsible for the microfiber release. In the case of a disposable surgical mask, the inner and outer layer of the mask is made of randomly arranged fibers that are intertwined without proper fixation. This accelerates the slippage of fibers under external force (Shen et al. 2021).

Saliu et al. (2021) have evaluated the potential of disposable surgical masks to emit microplastics after being disposed of. To replicate the weathered masks, artificial aging has been done with ultraviolet (UV) irradiation. Moreover, the artificial seawater surroundings with mechanical agitation were also made to simulate real-time conditions. Researchers compared different types of commercially available surgical masks sourced from different vendors. The microfiber release from the mask under the simulated conditions reported a maximum of 173,000 microfibers/day whereas the average release is around 135,000 microfibers/day. The combined mechanical and chemical degradation leads to the formation of microplastics. However, in the sea, mechanical degradation dominates over chemical degradation because of the abrasion induced by the sediments. To validate the reliability of laboratory-scale aging simulation in real time, the masks that are collected from the beaches were compared with the experimentally aged masks and found with the same morphological and chemical degradation (Sailu et al. 2021). Similarly, the other researcher mimicked the real deterioration conditions of surgical masks in the aquatic environment by applying simulated shear stress. This revealed that the masks could release thousands of microplastic particles even when subjected to low-level shear energy densities (Morgana et al. 2021).

The change in the physio-chemical properties of the disposable masks under UV weathering leads to the breaking down of masks into microplastic particles that can have a severe impact on the environment. Researchers have reported changes in the chemical composition, chain structure, and reduction in the mechanical strength of the masks after being exposed to UV radiations. UV radiations can provide energy which leads to the breakage of C–C and C–H bonds and forms alkoxy and peroxyl radicals. This causes chain scission. This decrease in molecular weight over UV weathering leads to a decrease in the mechanical strength of the mask layers. The surface analysis has reported that exposure to UV radiation causes fiber fracture which results in the formation of fiber fragments. Among all layers, the middle layer which is the melt-blown cloth is made of polypropylene and is the most vulnerable to the UV radiation which releases polypropylene microfibers. Since the melt-blown layer is made of fibers of a smaller diameter than the outer and inner layer fibers, the increased fiber breakage was noted after the UV exposure and it results in rapid microfiber release. They have also reported 1.5 million microplastic particles to be released from the single mask due to UV weathering which can increase up to 16 million particles while considering the abrasion in the presence of sand. However, the exceeding UV weathering over 36 h have not shown any significant impact of abrasion of sand (Wang et al. 2021). Similarly, the other researcher reported the microfiber release from the mask under two months of natural exposure. The aging under natural conditions showed a significant increment (25,000 times) in the microfiber release. The increased release in aged masks was attributed to the fact that aging makes the material more fragile. The SEM analysis of the aged masks shows obvious fracture marks and destruction of nodes. The failure of binding the fibers in the structure results in aging and leads to the release of fibers. Moreover, while considering the length of the fibers, aged masks release shorter fibers than normal masks (Shen et al. 2021).

In line with this, a study reported the new as well as used masks for microfiber release and noted a significant increase in the microfiber release from the used mask than the new mask (new mask—183.00 ± 78.42 particles/piece; used mask—1246.62 ± 403.50 particles/piece). The presence of loosely bound fibers is the reason for the microfiber release in the case of new masks whereas abrasion during usage and aging was the major reason for the increased release of microfibers in the case of used masks. The actions like adjusting, folding, pulling during the wear phase can cause mechanical deformation of the structure which results in fiber breakage (Chen et al. 2021). This can be related to the finding of the previous researcher who reported abrasion of sediments in the sea that accelerates fragmentation and release of microfibers from the surgical masks (Saliu et al. 2021). It has to be noted that the microfiber release ability of the surgical masks could not be related to the material quality and function which is evident from the results of the findings where a correlation was not found between microfiber release and price of the mask (Chen et al. 2021).

In addition to the microplastic release in the disposal stage due to degradation and abrasion, the researchers have reported microfiber emission while wearing masks. This possesses the risk of direct inhalation of microplastic particles by the wearer. Masks are potential enough to prevent the inhalation of microplastics suspended in the atmosphere. However, the prolonged use of these masks can result in the inhalation of microplastics originated from the mask itself. The release characteristics of microfiber/plastic particles from different masks including N95 respirators, surgical masks, cotton masks, fashion masks, non-woven masks, activated carbon masks were reported by Li et al. (2021). With breathing simulation, the researchers have witnessed the risk of inhalation of microplastics. Initially, wearing masks for a lesser duration helps in preventing inhalation of atmospheric microplastics which is evident from the results showing higher microplastic particles in the specimen without masks compared to the specimen wearing a mask for 2 h. However, the prolonged wearing of a mask increases the microplastics inhalation than not wearing a mask. When compared to the case of not wearing a mask, wearing masks such as activated carbon mask, surgical mask, cotton mask, fashion mask, and non-woven mask increases microfibers inhalation by 1.17, 0.16, 0.40, 0.54, 0.04 times, respectively, over 720 h of wearing. The higher fiber release with the activated carbon mask is linked to the inferior quality materials (Li et al. 2021).

These studies clearly show that masks are emerging as one of the greatest contributors to microplastic pollution. The different layers of the masks are prone to release microplastics and fibers. Generally, the outer and the inner layer of the masks were made of spun-bond non-woven whereas the middle layer will be of melt-spun non-woven which acts as a filter (Dharmaraj et al. 2021). The spun-bonded structure will have a random arrangement of fibers that are held together by nodes which can provide strength. This intertwinement of fibers without proper fixation (like yarns in fabrics) leads to fiber release from the inner and outer layers of the mask. Moreover, the nodes can get fractured over a period of time when exposed to external actions that lead to easy detachment of fibers (Shen et al. 2021). Whereas, the middle melt-blown layer is highly sensitive to UV radiation, which can release polypropylene microfibers while exposed to UV lights (Wang et al. 2021). The non-woven structure is mainly used in these PPEs to reduce product costs. As yarn production and fabric manufacturing steps are eliminated, the product cost reduces significantly. Further, as they tend to be disposed of after single use, the fibers are bonded in such a way that they cannot withstand much strength. In both melt-blown and spun-bonded fabric, the fibers were randomly bonded throughout the structure. The physical, as well as chemical changes in the structure of these non-woven layers when exposed to different environments, causes the release of microfibers from the structure. Figure 4 illustrates the structure and composition along with the microfiber release potential of different layers of disposable masks.

Risks with reusable masks

With the increased demand for face masks due to the rapid spread of the infection, the habit of reusing the masks has been increased. Though different methods of disinfection process are being adapted, simple washing, washing with detergents, disinfection with UV exposure, disinfection with air blower, disinfection with alcohol, disinfection with sunlight are the common methods (Li et al. 2021; Shen et al. 2021). These methods of disinfection can have a significant impact on microfiber emissions. Researchers have quantified the microfiber release from the masks treated with alcohol and detergent solutions. The results reported that the used mask releases significantly more microfibers irrespective of the method of disinfection. While considering the method of disinfection, simple washing with ultrapure water was noted to release lesser fibers which is then followed by disinfection with alcohol and the use of detergents. The use of detergent can cause more fiber fracture as well as dissolution of nodes in the non-woven structure which results in loss of fiber bondage and enhances more fiber release (Shen et al. 2021). Similarly, the other researcher analyzed the microfiber inhalation risks of different types of masks after the disinfection process. They have been exposed to UV irradiation, alcohol disinfection, air blower disinfection, washing in running water, sunlight disinfection processes. The results reported that these disinfection processes increase the risk of inhalation of microfibers while wearing. Alcohol disinfection technique showed a higher level of microfibers for all the types of masks (N95 respirator, surgical mask, cotton masks, fashion masks, non-woven masks, activated carbon masks). They have also reported that alcohol damages the structure of the mask which facilitates the fiber release. Since simple washing in running water showed lesser fiber release, researchers suggested following the practice of simple washing and gentle indoor drying to reduce the risk of inhalation of microfibers (Li et al. 2021). Moreover, while considering cloth masks, the most common habit will be simple washing. In such cases, the release of microfibers is obvious as like the microfiber shedding from synthetic textiles during washing. Besides the release of microfibers during washing, it also weakens the fabrics that lead to rapid disposal and also increased microfiber release in the disposal stage. This shows that the reusable masks need to be evaluated for microfiber release during machine laundering as well as hand laundering. Moreover, their microfiber release after disposal (after multiple washes) should also be measured (Shruti et al. 2020).

Researchers have reported microfiber release from the mask during different stages. Microfiber release was noted with new masks, re-used masks, disposed masks (Chen et al. 2021; Li et al. 2021; Shen et al. 2021; Wang et al. 2021; Saliu et al.2021). The release of microfibers from the new and re-used masks has increased the possibility of microfibers directly reach human beings through inhalation (Li et al. 2021). The effect of these microfibers on human beings was not analyzed systematically. However, another team of researchers analyzed the release of microfibers from the melt-blown layer of the masks and reported their effect on soil species. They have noticed inhibition of reproduction and stunted growth in springtails whereas earthworms were noted with decreased intracellular esterase activity (Kwak and An 2021). Figure 5 illustrates the various pathways a PPE or mask can take to pollute the different environments.

Besides microplastic particles, researchers have reported the leaching of other chemical pollutants. Sullivan et al. (2021) studied the organic and inorganic materials from disposable surgical masks. Seven different brands of masks were reported to leach micro- and nano-level polymeric particles including fibers along with leachable inorganic and organic chemicals. Researchers reported lead, cadmium, antimony, and copper in the leachates of masks (Sullivan et al., 2021). When the sorption characteristics of disposable surgical masks were studied against the dye molecules, it was noted that the surgical masks are capable of carrying dye molecules including Methylene Blue, Crystal Violet, and Malachite Green in the aquatic environment (Anastopoulos and Pashalidis 2021). This pollutant carrying characteristic will be more harmful in micro-size where the surface to volume ratio is higher. Table 1 consolidates the existing literature’s method of analysis, with identified shortcomings at COVID-waste, microfiber release, environmental impacts and mitigation stages.

Microplastics/fibers from other sanitary products

In addition to masks, a few other protective types of equipment such as gloves and wet wipes are also being in use. These products are also contributing to microplastic pollution similar to masks. Researchers have considered nitrile gloves and latex gloves for microplastic release. The microplastic emission was measured by allowing the gloves to leach for 5 h in ultrapure water. The leachates were found to have polyamide, polystyrene, polypropylene, polyethylene terephthalate, and other indistinguishable polymers. Though the research was done to identify the contamination due to the use of gloves during microplastic analysis, the results reveal the potential of gloves, which are widely used in this pandemic, to release microplastics (Witzig et al. 2020). Another study reported microplastic emissions from the wet wipes that are commonly being used in the household for maintaining hygiene. Microfiber release of wet wipes under different conditions (wet state wipes exposed to water; dried state wipes exposed to water; wet state wipes exposed to dry abrasion; dry state wipes exposed to dry abrasion) were measured by representing different usage and disposal ways. Their results reported the release of polyester fibers from the wet wipes which are confirmed by the FTIR analysis. Moreover, among different conditions, exposing wet state wipes in water releases more fibers followed by exposing dried state wipes in water (Lee et al. 2021). To support the potential impact of these non-woven wipes as microplastic pollutants, researchers have reported microfibers in the deep-sea sediment to replicate those in wet wipes and other sanitary products. The spectra, shape, and size analysis of the fibers reveals that these fibers are originated from sanitary products (Briain et al. 2020). With the increased use of these personal care products in pandemics (Litterati 2020), their contribution to microplastic pollution is also noted to increase.

Proposed mitigation strategies

Being an environmental threatening issue, the microfiber pollution associated with disposable masks should be addressed properly and tackled. From the analysis of the literature, the review result suggests the scope of mitigation strategies in the following aspects:

-

As the researchers have reported different quantities of microfiber release from different types of masks (Li et al. 2021) as well as the different layers of masks (Shen et al. 2021; Wang et al. 2021), it is clear that the characteristics of masks influence the microfiber release. Hence, the effect of inherent textile properties of the non-woven (fiber type, weight per unit area, thickness, etc.) and production properties (manufacturing method) on the microfiber release should be analyzed. The optimization of the manufacturing parameters of the masks can reduce the microfiber release.

-

Studies have reported that the microfiber release from the masks get increased when they are exposed to natural weathering (Shen et al. 2021), seawater (Sailu et al. 2021), water currents (Morgana et al. 2021), and other environmental conditions. Hence, the proper waste management system should be developed which can potentially restrict the masks to end up in such an environment. Consumers should be educated about the safe disposal of these single-use surgical masks.

-

Though the proper disposal method can effectively reduce the microfiber release into the environment, the cycle can be completed only if the wastes are reprocessed effectively (Circular economy). In this aspect, either higher quality raw materials should be used or options for recycling of non-woven fabrics that are being used in the masks should be explored. Recently, Aragaw and Mekonnen (2021) have reported the potential of these masks to be converted into oil. Their thermoplastic behavior supports the conversion through the pyrolysis process. However, a more effective and simplest way of recycling these non-woven wastes should be developed as the quantity of waste is very high and they should be processed economically.

-

In addition to this, to properly manage this risk of higher usage of PPEs as a whole, the implementation of an Environmental Management Plan (EMP) will be thoughtful. While bringing down the usage of masks and PPEs is a solution to control the spread of the disease, there should be proper EMP that can reduce or mitigate the adverse impact on the environment. However, implementing such strategies on a large scale (either nationwide or state-wide) has its disadvantages including implementation difficulties and associated costs. Knowledge of all the stakeholders (manufacturer, general public, and governments) associated with the usage and production of PPEs is the key factor for such initiatives. The general public should be sensitized about the PPEs and microfiber pollution associated with it as equally as the importance of PPEs usage in the pandemic. A proper and separate waste management system for the safer disposal of these PPEs is the need of the hour requirement.

-

Implementation of laws related to the environmental impacts of such disposable items is another important way to regulate the manufacturers, retailers, and users. Similar initiatives were already implemented in various countries in controlling the microfiber shedding from the apparel fabrics with synthetic textiles (New York Assembly Bill A01549, 2018). Whereas, a law implemented in the California state is mandated the use of microfiber filtering systems in all synthetic textile manufacturing industries, associated laundry, and effluent treatment facilities (AB 1292019). Though no common laws were made in Europe, several nations in Europe implemented their own regulations to restrict microfiber pollution from textiles (Report to the Legislature on the Findings of the Synthetic Microfiber Working Group 2019). However, no such regulation was found on disposable PPEs. These types of initiatives should be taken either worldwide or nationwide by considering COVID-19 related disposable PPEs.

Research gap in microfiber release from PPEs

From the literature, it is evident that the PPEs and masks that are being widely used for the protection against virus transmission also have negative impacts on the environment. Researchers have reported PPE littering in beaches and oceans. Moreover, these materials are the potential source of microplastics in the environment. While the researchers are focusing on macro plastic pollution associated with the PPEs, only a few research works addressed microplastic pollution.

Researchers have reported microfiber release in the aquatic environment by exposing them to distilled water, detergent solution, seawater, and UV exposure (Sailu et al. 2021; Wang et al. 2021; Shen et al. 2021) and quantified the microfiber release. However, the microfiber release in the dry state, that is, during wearing or from the masks that are ended up in landfills were not explored. Though researchers reported mechanical deformation during the wearing phase of the masks (Chen et al. 2021), the microfiber release during the usage phase was not detailed. With the threatening of microfiber inhalation by the wearer (Li et al. 2021), the microfiber release of different layers of the masks in a dry state during wearing has to be investigated. Most of the studies addressed the microfiber release of single-use disposable masks whereas in the case of reusable masks, the effect of disinfectant processes on microfiber release was analyzed (Li et al. 2021; Shen et al. 2021). However, the reusable masks in the market are made from different materials with 6 to 7 layers. Hence, the microfiber release of different layers of reusable masks due to the disinfectant process should be detailed. The microfiber release of cloth masks during laundry has to be given more importance because domestic laundry of textile materials was noted as the important source of microfiber pollution (Browne et al. 2011; Napper and Thompson 2016). Researchers reported that the disinfectant process can affect the microfiber release behavior of masks; however, the microfiber release during the process of disinfection is not taken into account. As far as disposal is concerned, disposable and reusable masks need to be tested for their microfiber release in soil, normal water (river currents), and also in the seawater condition, as most of the mismanaged PPE ends up in the aquatic system. The analysis of microfiber release from the masks has to be made in these aspects also to get an insight on the microfiber emission behavior of masks. Though masks were identified as the most commonly used PPEs, others like gloves, head covers, and gowns, are also being used widely. Hence, the exploration of microfiber release from these products should not be exempted.

Conclusion

The increased awareness on COVID-19 related safety measures significantly increased the usage and disposal of PPEs which includes face masks, gloves, and others. This study shows a significant increase in the littering of these PPEs on seashores and landfills in post-pandemic. It is also very clear that the awareness on safe disposal of these products and proper waste management system is lacking among the public. The initial research on the microplastic issue associated with these disposable PPEs has already begun; however, very few studies alone reported the magnitude of the issue. This review elucidates the research gap in the area of microfiber pollution associated with the PPEs. Considering the number of PPE and masks (reusable or disposable) used per day during this pandemic, the impact of the usage will result in a huge deposit of microfibers and microplastics in the land and aquatic system. This study points to the necessity of future research in this domain. Focused research on the impact of disposable, reusable masks, microfiber release behavior of masks in different lifecycle stages, and more attention should also be paid to PPEs other than masks. The implementation of nationwide or state-wide environmental management plans will be a potential option to create awareness among the public and to have effective waste management.

References

AB 129 (2019) California legislature, https://leginfo.legislature.ca.gov/faces/billTextClient.xhtml?bill_id=201920200AB129. Accessed 08 Jan 2022

AFNOR (2020) AFNOR SPEC S76–001 Barrier masks. Guide to minimum requirements,test methods, preparation and use for mass manufactured and homemade masks.Associationfrançaise de Normalisation AFNOR. https://iv.revistalocal.es/wp-content/uploads/AFNORSpec-S76-001-MascarillasDeProteccion.pdf.

Absher TM, Ferreira SL, KernY Ferreira AL, Christo SW, Ando RA (2019) Incidence and identification of microfibers in ocean waters in Admiralty Bay, Antarctica. Environ Sci Pollut Res 26:292–298. https://doi.org/10.1007/s11356-018-3509-6

Adyel TM (2020) Accumulation of plastic waste during COVID-19. Science 369(6509):1314–1315. https://doi.org/10.1126/science.abd9925

Allison AL, Dempster EA, Bawn M, Arredondo MC, Chau C, Chandler K, Dobrijevic D, Aparasi TD, Hailes HC, Lettieri P, Liu C, Medda F, Michie S, Miodownik M, Munro B, Purkiss D, Ward JM (2021) The impact and effectiveness of the general public wearing masks to reduce the spread of pandemics in the UK: a multidisciplinary comparison of single-use masks versus reusable face masks. UCL Open Eviron. 3. https://doi.org/10.14324/111.444/ucloe.000022

Amato-Lourenço LF, Galvão LS, Weger LA, Hiemstra PS, Vijiver MG, Mauad T (2020) An emerging class of air pollutants: potential effects of microplastics to respiratory human health? Sci Total Environ 749:141676. https://doi.org/10.1016/j.scitotenv.2020.141676

Ambrosini R, Azzoni RS, Pittino F, Diolaiuti G, Franzetti A, Parolini M (2019) First evidence of microplastic contamination in the supraglacial debris of an alpine glacier. Environ Pollut 253:297–301. https://doi.org/10.1016/j.envpol.2019.07.005

Ammendolia J, Saturno J, Brooks AL, Jacobs S, Jambeck JR (2021) An emerging source of plastic pollution: environmental presence of plastic personal protective equipment (PPE) debris related to COVID-19 in a metropolitan city. Environ Pollut 269:116160. https://doi.org/10.1016/j.envpol.2020.116160

Anastopoulos I, Pashalidis I (2021) Single-use surgical face masks, as a potential source of microplastics: Do they act as pollutant carriers? J Mol Liq 326:115247. https://doi.org/10.1016/j.molliq.2020.115247

Aragaw TA (2020) Surgical face masks as a potential source for microplastic pollution in the COVID-19 scenario. Mar Pollut Bull 159:111517. https://doi.org/10.1016/j.marpolbul.2020.111517

Aragaw TA, Mekonnen BA (2021) Current plastics pollution threats due to COVID-19 and its possible mitigation techniques: a waste-to-energy conversion via Pyrolysis. Environ Syst Res 10:8. https://doi.org/10.1186/s40068-020-00217-x

Zahid AZM (2020) Consider reusable face mask to reducepollution threat, https://www.nst.com.my/opinion/letters/2020/08/617325/consider-reusable-face-mask-reduce-pollution-threat

Bird S (2019) Synthetic Fibers in Clothing Contribute to Pollution, https://www.indianaenvironmentalreporter.org/posts/synthetic-fibers-in-clothing-contribute-to-pollution (Accessed on 15 May 2021)

Boucher J, Friot D (2017) Primary Microplastics in the oceans: a global evaluation of sources. IUCN, Gland, Switzerland. https://doi.org/10.2305/IUCN.CH.2017.01

Briain O, Mendes ARM, McCarron S, Healy MG, Morrison L (2020) The role of wet wipes and sanitary towels as a source of white microplastic fibres in the marine environment. Water Res 182:116021. https://doi.org/10.1016/j.watres.2020.116021

Browne MA, Crump P, Niven SJ, Teuten E, Tonkin A, Galloway T, Thompson R (2011) Accumulation of Microplastic on Shorelines Worldwide: Sources and Sinks. Environ Sci Technol 45:9175–9179. https://doi.org/10.1021/es201811s

Cai Y, Mitrano DM, Hufenus R, Nowack B (2021) Formation of fiber fragments during abrasion of polyester textiles. Environ Sci Technol 55:8009. https://doi.org/10.1021/acs.est.1c00650

Canning-Clode J, Sepúlveda P, AlmeidaS MJ (2020) Will COVID-19 containment and treatment measures drive shifts in marine litter pollution? Front Mar Sci 7:691. https://doi.org/10.3389/fmars.2020.00691

Castañeda RA, Avlijas S, Simard MA, Ricciardi A (2014) Microplastic pollution in St. Lawrence River sediments. Can J Fish Aquat Sci 71:1761–1771. https://doi.org/10.1139/cjfas-2014-0281

Cauwenberghe LV, Claessens M, Vandegehuchte MB, Janssen CR (2015) Microplastics are taken up by mussels (Mytilus edulis) and lugworms (Arenicola marina) living in natural habitats. Environ Pollut 199:10–17. https://doi.org/10.1016/j.envpol.2015.01.008

Chen X, Chen X, Liu Q, Zhao Q, **ong X, Wu C (2021) Used disposable face masks are significant sources of microplastics to environment. Environ Pollut 285:117485. https://doi.org/10.1016/j.envpol.2021.117485

Chen Y, LengY LX, Wang J (2019) Microplastic pollution in vegetable farmlands of suburb Wuhan, central China. Environ Pollut 257:113449. https://doi.org/10.1016/j.envpol.2019.113449

Chowdhury H, Chowdhury T, Sait SM (2021) Estimating marine plastic pollution from COVID-19 face masks incoastal regions. Mar Pollut Bull 168:112419. https://doi.org/10.1016/j.marpolbul.2021.112419

Conti GO, Ferrante M, Banni M, Favara C, Nicolosi I, Cristaldi A, Fiore M, Zuccarello P (2020) Micro- and nono-plastics in Edible fruits and vegetables. The first diet risks assessment for the general population. Environ Res 187:109677. https://doi.org/10.1016/j.envres.2020.109677

Cordova MR, Nurhati IS, Riani E, Nurhasanah, Iswari MY (2021) Unprecedented plastic-made personal protective equipment (PPE) debris in river outlets into Jakarta Bay during COVID-19 pandemic. Chemosphere 268:129360. https://doi.org/10.1016/j.chemosphere.2020.129360

Cox KD, Covernton GA, Davies HL, Dower JF, Juanes F, Dudas SE (2019) Human Consumption of Microplastics. Environ Sci Technol 53:7068–7074. https://doi.org/10.1021/acs.est.9b01517

Ergil LY (2021) Plastic pollution pandemic: Seeking solutions for mask-trash dilemma, https://www.dailysabah.com/life/environment/plastic-pollution-pandemic-seeking-solutions-for-mask-trash-dilemma

De Falco F, Di Pace E, Cocca M, Avella M (2019) The contribution of washing processes of synthetic clothes to microplastic pollution. Sci Rep 9:6633. https://doi.org/10.1038/s41598-019-43023-x

De Falco F, Cocca M, Avella M, Thompson RC (2020) Microfiber release to water, via laundering, and to air, via everyday use: a comparison between polyester clothing with differing textile parameters. Environ Sci Technol 54(6): 3288–3296. https://doi.org/10.1021/acs.est.9b06892

De-la-Torre GE, Rakib MRJ, Pizarro-Ortega CI, Dioses-Salinas DC (2021) Occurrence of personal protective equipment (PPE) associated with the COVID – 19 pandemic along the coast of Lima. Peru Sci Total Environ 774:145774. https://doi.org/10.1016/j.scitotenv.2021.145774

Dharmaraj S, Ashokkumar V, Hariharan S, Manibharathi A, Show PL, Chong CT, Ngamcharussrivichai C (2021) The COVID-19 pandemic face mask waste: a blooming threat to the marine environment. Chemosphere 272:129601. https://doi.org/10.1016/j.chemosphere.2021.129601

Diaz-Basantes M, Conesa JA, Fullana A (2020) Microplastics in honey, beer, milk and refreshments in ecuador as emerging contaminants. Sustainability 12:5514. https://doi.org/10.3390/su12145514

Dong C, Chen C, Chen Y, Chen H, Lee J, Lin C (2020) Polystyrene microplastic particles: in vitro pulmonary toxicity assessment. J Hazard Mater 385:121575. https://doi.org/10.1016/j.jhazmat.2019.121575

E & T Editorial Staff (2021) Disposable masks leak microplastics and other pollutants in water, https://eandt.theiet.org/content/articles/2021/05/disposable-masks-leak-microplastics-and-other-pollutants-in-water/. Accessed 25 June 2021

Ellen MacArthur Foundation (2017) A new textiles economy: redesigning fashion’s future, http://www.ellenmacarthurfoundation.org/publications. Accessed 15 Apr 2020

Chan E (2020) Disposable face masks and gloves are a plastics nightmare—but what’s the solution?,https://www.vogue.in/culture-and-living/content/disposable-face-masks-gloves-plastic-ocean-waste-environment

Eriksen M, Mason S, Wilson S, Box C, Zellers A, Edwards W, Farley H, Amato S (2013) Microplastic pollution in the surface waters of the Laurentian Great Lakes. Mar Pollut Bull 77:177–182. https://doi.org/10.1016/j.marpolbul.2013.10.007

Fadare OO, Okoffo ED (2020) Covid-19 facemasks: a potential source of microplastic fibers in the environment. Sci Total Environ 737:140279. https://doi.org/10.1016/j.scitotenv.2020.140279

Feng S, Shen C, **a N, Song W, Fan M, Cowling BJ (2020) Rational use of face masks in the COVID-19 pandemic. Lancet Respir Med 8(5):434–436. https://doi.org/10.1016/S2213-2600(20)30134-X

Fisher KA, Barile JP, Guerin RJ, Esschert KLV, Jeffers A, Tian LH, Garcia-Williams A, Gurbaxani B, Thompson WW, Prue CE (2020) Factors associated with cloth face covering use among adults during the COVID-19 pandemic — United States, April and May 2020. Morb MortalWkly Rep 69:933–937. https://doi.org/10.15585/mmwr.mm6928e3

Gasperi J, Dris R, Mirande-Bred C, Mandin C, Langlois V, Tassin B (2015) First overview of microplastics in indoor and outdoor air. 15thEuChemMS International Conference on Chemistry and the Environment, https://hal.archives-ouvertes.fr/hal-01195546/

Goodman KE, Hare JT, Khamis ZI, Hua T, Sang QA (2021) Exposure of human lung cells to Polystyrene Microplastics significantly retards cell proliferation and triggers morphological changes. Chem Res Toxicol 34:1069–1081. https://doi.org/10.1021/acs.chemrestox.0c00486

Henry B, Laitala K, Klepp IG (2019) Microfibres from apparel and home textiles: prospects for includingmicroplastics in environmental sustainability assessment. Sci Total Environ 652:483–494. https://doi.org/10.1016/j.scitotenv.2018.10.166

Hossain SM, Sobhan F, Uddin MN, Sharifuzzaman SM, Chowdhury SR, Sarker S, Chowdhury MSN (2019) Microplastics in fishes from the Norther Bay of Bengal. Sci Total Environ 690:821–830. https://doi.org/10.1016/j.scitotenv.2019.07.065

Jemec A, Horvat P, Kunej U, Bele M, Kržan A (2016) Uptake and effects of microplastic textile fibers on freshwater crustacean Daphnia magna. Environ Pollut 219:201–209. https://doi.org/10.1016/j.envpol.2016.10.037

Karami A, Golieskardi A, Choo CK, Larat V, Galloway TS, Salamatinia B (2017) The presence of microplastics in commercial salts from different countries. Sci Rep 7:46173. https://doi.org/10.1038/srep46173

Kavilanz P (2020) Etsy’s on Fire as Reusable Face Mask Sales Surge. https://edition.cnn.com/2020/08/07/business/etsy-face-mask-market/index.html.

Kaya AT, Yurtsever M, Bayraktar SÇ (2018) Ubiquitous exposure to microfiber pollution in the air. Eur Phys J Plus133:488.https://doi.org/10.1140/epjp/i2018-12372-7

Kelly M, Lant NJ, Kurr M, Burgess JG (2019) Importance of Water-Volume on the Release of Microplastic Fibers from Laundry. Environ Sci Technol 53:11735–11744. https://doi.org/10.1021/acs.est.9b03022

Konda A, Prakash A, Moss GA, Schmoldt M, Grant GD, Guha S (2020) Aerosol filtration efficiency of common fabrics used in respiratory cloth masks. ACS Nano 14:6339–6347. https://doi.org/10.1021/acsnano.0c03252

Kwak J, An Y (2021) Post COVID-19 pandemic: Biofragmentation and soil ecotoxicological effects of microplastics derived from face masks. J HazardMater 416:126169. https://doi.org/10.1016/Fj.jhazmat.2021.126169

Laitala K, Klepp IG, Henry B (2018) Does Use Matter? Comparison of Environmental Impacts of Clothing Based on Fiber Type. Sustainability 10:2524. https://doi.org/10.3390/su10072524

Lant NJ, Hayward AS, Peththawadu MMD, Sheridan KJ, Dean JR (2020) Microfiber release from real soiled consumer laundry and the impact of fabric care products and washing conditions. PLoS ONE 15(6):e0233332. https://doi.org/10.1371/journal.pone.0233332

Lebreton L, Andrady A (2019) Future scenarios of global plastic waste generation and disposal. Palgrave Commun 5:6. https://doi.org/10.1057/s41599-018-0212-7

Lee J, Jeong S, Chae K (2021) Discharge of microplastics fibres from wet wipes in aquatic and solid environments under different release conditions. Sci Total Environ 784:147144. https://doi.org/10.1016/j.scitotenv.2021.147144

Lee H, Kunz A, Shim WJ, Walther BA (2019) Microplastic contamination of table salts from Taiwan, including a global review. Sci Rep 9:10145. https://doi.org/10.1038/s41598-019-46417-z

Li L, Zhao X, Li Z, Song K (2021) COVID-19: Performance study of microplastic inhalation risk posed by wearing masks. J Hazard Mater 411:124655. https://doi.org/10.1016/j.jhazmat.2020.124955

Litterati. Litterati Open Data, (2020) <https://opendata.litterati.org/>

Liu M, Lu S, Song Y, Lei L, Hu J, Lv W, Zhou W, Cao C, Shi H, Yang X, He D (2018) Microplastic and mesoplastic pollution in farmland soils in suburbs of Shanghai, China. Environ Pollut 242:855–862. https://doi.org/10.1016/j.envpol.2018.07.051

Liu K, Wang X, Fang T, Xu P, Zhu L, Li D (2019) Source and potential risk assessment of suspended atmospheric microplastics in Shanghai. Sci Total Environ 675:462–471. https://doi.org/10.1016/j.scitotenv.2019.04.110

Lu S, Qiu R, Hu J, Li X, Chen Y, Zhang X, Cao C, Shi H, **e B, Wu W, He D (2019) Prevalence of microplastics in animal-based traditional medicinal materials: Widespread pollution in terrestrial environments. Sci Total Environ 709:136214. https://doi.org/10.1016/j.scitotenv.2019.136214

Lusher A, Tirelli V, O’Connor I, Officer R (2015) Microplastics in Arctic polar waters: the first reported values of particles in surface and sub-surface samples. Sci Rep 5:14947. https://doi.org/10.1038/srep14947

Malin Z (2021) How to reduce face mask pollution, according to experts, https://www.nbcnews.com/shop**/eco-friendly/eco-friendly-face-mask-n1264810

Morgana S, Casentini B, Amalfitano S (2021) Uncovering the Release of Micro/nanoplastics from Disposable Face Masks at Times of COVID-19. J Hazard Mater 419:126507. https://doi.org/10.1016/j.jhazmat.2021.126507

Muniasamy GK, Guevara FP, Martinez IE, Shruti VC (2020) Branded milks – Are they immune from microplastics contamination? Sci Total Environ 714:136823. https://doi.org/10.1016/j.scitotenv.2020.136823

Napper IE, Thompson RC (2016) Release of synthetic microplastic plastic fibres from domestic washing machines: Effects of fabric type and washing conditions. Mar Pollut Bull 112:39–45. https://doi.org/10.1016/j.marpolbul.2016.09.025

New York Assembly Bill A01549 (2018) Environmental conservation law, in relation to requiring additional labels on certain microfiber clothing, https://assembly.state.ny.us/leg/?default_fld=&bn=A01549&term=2019&Summary=Y&Actions=Y&Text=Y&Committee%26nbspVotes=Y&Floor%26nbspVotes=Y.. Accessed 08 Jan 2022

Ojha S (2020) India now manufactures 4.5 lakh PPE suits a day in the fight against Covid-19, https://www.livemint.com/news/india/india-now-manufactures-4-5-lakh-ppe-suits-a-day-in-the-fight-against-covid-19-11589951566951.html

Okuku E, Kiteresi L, Owato G, Otieno K, Mwalugha C, Mbuche M, Gwada B, Nelson A, Chepkemboi P, Achieng Q, Wanjeri V, Ndwiga J, Mulupi L, Omire J (2021) The impacts of COVID-19 pandemic on marine litter pollution along the Kenyan Coast: A synthesis after 100 days following the first reported casein Kenya. Mar Pollut Bull 162:111840. https://doi.org/10.1016/j.marpolbul.2020.111840

Ouhsine O, Ouigmane A, Layati E, Aba B, Isaifan R, Berkani M (2020) Impact of COVID-19 in the qualitative and quantitative aspect of household solid waste. Glob J Environ Sci Manag 6:41–52. https://doi.org/10.22034/GJESM.2019.06.SI.05

Patel A, Alessandro D, Maryann M, Ireland KJ, Burel WG, Wencil EB, Rasmussen SA (2017) Personal protective equipment supply chain: lessons learned from recent public health emergency responses. Health Secur 15:e244–e252. https://doi.org/10.1089/hs.2016.0129

Potluri P, Needham P (2005) Technical textiles for protection. In: Scott RA (ed) Technical textiles for protection. Elsevier, Netherlands, pp 151–175

Prata JC, Silva ALP, Walker TR, Duarte AC, Rocha-Santos T (2020) COVID-19 pandemic repercussions on the use and management of plastics. Environ Sci Technol 54:e7760–e7765. https://doi.org/10.1021/acs.est.0c02178

Quinn B, Crawford CB (2017) Microplastic Pollutants. Elsevier, Netherlands. https://doi.org/10.1016/C2015-0-04315-5

Ragusa A, Svelato A, Santacroce C, Catalano P, Notarstefano V, Carnevali O, Pap F, Rongioletti MCA, Baiocco F, Draghi S, D’Amore E, Rinaldo D, Matta M, Giorgini E (2021) Plasticenta: First Evidence of microplastics in human placenta. Environ Int 146:106274. https://doi.org/10.1016/j.envint.2020.106274

Rathinamoorthy R, Raja Balasaraswathi S (2021) Investigations on the impact of handwash and laundry softener on microfiber shedding from polyester textiles. J Tex Inst. 113(7):1428–1437. https://doi.org/10.1080/00405000.2021.1929709

Report to the Legislature on the Findings of the Synthetic Microfiber Working Group (2019) https://portal.ct.gov/-/media/DEEP/p2/microfiber_pollution/DraftstrategyJanuary2019pdf.pdf. Accessed 08 Jan 2022

Research and Markets (2020) Global Healthcare Personal Protective Equipment (PPE) Market 2020–2030: COVID-19 Impact, Growth and Change, https://www.prnewswire.com/news-releases/global-healthcare-personal-protective-equipment-ppe-market-2020-2030-covid-19-impact-growth-and-change-for-the-7-83-billion-market-301172679.html

Reusable Face Mask Market (2020) The market Size, Share & Trends Analysis Report by Material (Cotton, Nylon), by Application (Personal, Commercial), by Distribution Channel (Offline, Online), by Region, and Segment Forecasts, 2020–2027. https://www.researchandmarkets.com/reports/5186212/reusable-face-mask-market-size-share-and-trends

Riberio F, Okoffo ED, Brien OJW, Fraissinet-Tachet S, O’Brien S, Gallen M, Samanipour S, Kaserzon S, Muller JF, Galloway T, Thomas KV (2020) Quantitative Analysis of Selected Plastics in High-Commercial-Value Australian Seafood by Pyrolysis Gas Chromatography Mass Spectrometry. Environ Sci Technol 54:9408–9417. https://doi.org/10.1021/acs.est.0c02337

Roberts KP, Bowyer C, Kolstoe S, Fletcher S (2020) Coronavirus face masks: an environmental disaster that might last generations, https://theconversation.com/coronavirus-face-masks-an-environmental-disaster-that-might-last-generations-144328

Roberts KP, Phang SC, Williams J, Hutchinson DJ, Kolstoe S, De Bie J, Williams ID, Stringfellow AM (2021) Lockdown Litter: A critical analysis of global COVID-19 PPE litter and measures for mitigation. Research Square; 2021. https://doi.org/10.21203/rs.3.rs-134183/v1

Rowan NJ, Laffey JG (2020) Challenges and solutions for addressing critical shortage of supply chain for personal and protective equipment (PPE) arising from Coronavirus disease (COVID19) pandemic – case study from the Republic of Ireland. Sci Total Environ 725:138532. https://doi.org/10.1016/j.scitotenv.2020.138532

Rubio-Romero JC, Pardo-Ferreira MC, Torrecilla-García JA, Calero-Castro S (2020) Disposable masks: Disinfection and sterilization for reuse, and non-certified manufacturing, in the face of shortages during the COVID-19 pandemic. Saf Sci 129:104830. https://doi.org/10.1016/j.ssci.2020.104830

Sailu F, Veronelli M, Raguso C, Barana D, Galli P, Lasagni M (2021) The release process of microfibers: from surgical face masks into the marine environment. Environ Adv 4:100042. https://doi.org/10.1016/j.envadv.2021.100042

Sanchez-Vidal A, Thompson RC, Canals M, de Haan WP (2018) The imprint of microfibres in southern European deep seas. PLoS ONE 13(11):e0207033. https://doi.org/10.1371/journal.pone.0207033

Selonen S, Dolar A, Kokalj AJ, Skalar T, Dolcet LP, Hurley R, van Gestel CAM (2019) Exploring the impacts of plastics in soil – The effects of polyester textile fibers on soil invertebrates. Sci Total Environ 400:134451. https://doi.org/10.1016/j.scitotenv.2019.134451

Sharma N, Hasan Z, Velayudhan A, Emil MA, Mangal DK, Gupta SD (2020) Personal Protective Equipment: Challenges and Strategies to Combat COVID-19 in India: A Narrative Review. J Health Manag 22:157–168. https://doi.org/10.1177/0972063420935540

Shen M, Zeng Z, Song BYH, Hu T, Zhang Y, Zeng G, **ao R (2021) Neglected microplastics pollution in global COVID-19: Disposable surgical masks. Sci Total Environ 790:148130. https://doi.org/10.1016/j.scitotenv.2021.148130

Shruti VC, Pérez-Guevara F, Elizalde-Martínez I, Kutralam-Muniasamy G (2020) Reusable masks for COVID-19: A mission piece of the microplastic problem during the global health crisis. Mar Pollut Bull 161:111777. https://doi.org/10.1016/j.marpolbul.2020.111777

Silva ALP, Prata JC, Walker TR, Duarte AC, Ouyang W, Barcelò D, Rocha-Santos T (2021) Increased plastic pollution due to COVID-19 pandemic: Challenges and recommendations. Chem Eng J 405:126683. https://doi.org/10.1016/j.cej.2020.126683

Swansea University (2021) Nanoplastics and other harmful pollutants found within disposable face masks, https://www.swansea.ac.uk/press-office/news-events/news/2021/05/nanoplastics-and-other-harmful-pollutants-found-within-disposable-face-masks.php. Accessed 25 June 2021

Tiwari M, Rathod TD, Ajmal PY, Bhangare RC, Sahu SK (2019) Distribution and characterization of microplastics in beach sand from three different Indian coastal environments. Mar Pollut Bull 140:262–273. https://doi.org/10.1016/j.marpolbul.2019.01.055

UNE (2020) UNE 0065:2020. Reusable hygienic masks for adults and children. Materials,design, manufacturing, marking and use requirements. https://www.une.org/encuentra-tu-norma/busca-tu-norma/norma/?c=N0063661.

van Doremalen N, Bushmaker T, Morris DH, Holbrook MG, Gamble A, Williamson BN, Munster VJ (2020) Aerosol and surface stability of SARS-CoV-2 as compared with SARS-CoV-1. N Engl J Med 382:e1564–e1567. https://doi.org/10.1056/NEJMc2004973

Veerasingam S, Khayat JA, Vethamony P (2020) COVID19 personal protection equipment (PPE): A potential source of microplastic pollution in the State of Qatar, Environmental Science Center, Qatar University, Doha, Qatar. https://doi.org/10.29117/quarfe.2020.0284

Wang X, Li C, Liu K, Zhu L, Song Z, Li D (2019) Atmospheric microplastic over the South China Sea and East Indian Ocean: abundance, distribution and source. J Hazard Mater 389:121846. https://doi.org/10.1016/j.jhazmat.2019.121846

Wang Z, An C, Chen X, Lee K, Zhang B, Fend Q (2021) Disposable masks release microplastics to the aqueous environment with exacerbation by natural weathering. J Hazard Mater 417:126036. https://doi.org/10.1016/j.jhazmat.2021.126036

WHO, (2020a). Advice on the Use of Masks in the Context of COVID-19. https://www.who.int/publications/i/item/advice-on-the-use-of-masks-in-the-community-during-home-care-and-in-healthcare-settings-in-the-context-of-the-novel-coronavirus-(2019-ncov)-outbreak.

WHO (2020b) Shortage of personal protective equipment endangering health workers worldwide, https://www.who.int/news/item/03-03-2020b-shortage-of-personal-protective-equipment-endangering-health-workers-worldwide

WHO (World Health Organization) (2020c) Rational Use of Personal Protective Equipment for Coronavirus Disease 2019 (COVID-19). Retrieved. https://apps.who.int/iris/handle/10665/331695

Witzig CS, Földi C, Wörle K, Habermehl P, Pittroff M, Müller YK, Lauschke T, Fiener P, Dierkes G, Freier KP, Zumbülte N (2020) When Good Intentions go Bad-False Positive Microplastic Detection caused by Disposable Gloves. Environ Sci Technol 54:12164–12172. https://doi.org/10.1021/acs.est.0c03742

WWF (World Wildlife Fund) (2020) In the disposal of masks and gloves, responsibility is required. www.wwf.it/scuole/?53500%2FNello-smaltimento-di-mascherine-e-guanti-serve-responsabilita (in Italian)

Yang L, Qiao F, Lei K, Li H, Kang Y, Cui S, An L (2019) Microfiber release from different fabrics during washing. Environ Pollut 249:136–143. https://doi.org/10.1016/j.envpol.2019.03.011

Zambrano MC, Pawlak JJ, Daystar J, Ankeny M, Cheng JJ, Venditti RA (2019) Microfibers generated from the laundering of cotton, rayon and polyester based fabrics and their aquatic biodegradation. Mar Pollut Bull 142:394–407. https://doi.org/10.1016/j.marpolbul.2019.02.062

Zhao S, Zhu L, Li D (2016) Microscopic anthropogenic litter in terrestrial birds from Shanghai, China: Not only plastics but also natural fibers. Sci Total Environ 550:1110–1115. https://doi.org/10.1016/j.scitotenv.2016.01.112

Zhao S, Zhu L, Wang T, Li D (2014) Suspended microplastics in the surface water of Yangtze Estuary System, China: First observations on occurrence, distribution. Mar Pollut Bull 86:562–568. https://doi.org/10.1016/j.marpolbul.2014.06.032

Acknowledgements

Not applicable.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

We wish to confirm that there are no known conflicts of interest associated with this publication and there has been no significant financial support for this work that could have influenced its outcome.

Additional information

Editorial responsibility: Samareh Mirkia.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Rathinamoorthy, R., Raja Balasaraswathi, S. Impact of coronavirus pandemic litters on microfiber pollution—effect of personal protective equipment and disposable face masks. Int. J. Environ. Sci. Technol. 20, 9205–9224 (2023). https://doi.org/10.1007/s13762-022-04462-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13762-022-04462-8