Abstract

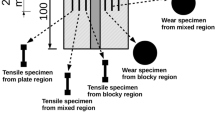

The present study focuses on the mechanical and erosive wear properties of functionally-graded polymer materials (FGPMs) and functionally-graded hybrid composites. Polyester resin is used as a polymeric matrix, while titanium dioxide (TiO2) and aluminum (Al) as particles and glass fiber (GG) as fiber reinforcements are used in the composites. The samples are fabricated through the lay-up lamination technique. Initially, four-layered FGPMs were fabricated using TiO2 and Al particles individually in weight percentages varying from 2 to 8% (by wt). Then, four-layered hybrid functionally-graded composites were prepared using 2–4% (by wt) Al and TiO2 along with two layers of glass fibers. A comparison among functionally-graded materials and functionally-graded hybrid materials in terms of mechanical strength (tensile, flexural and interlaminar) and erosion behavior is evaluated on a universal testing machine and air jet erosion testing apparatus, respectively. The improved tensile strength is shown by aluminum-based functionally-graded and hybrid functionally-graded composites owing to their greater ductility. Nevertheless, titanium dioxide-based functional- graded and hybrid functional-graded composites exhibited greater flexural strength due to their high hardness. From the erosion results, Al and TiO2 functional-graded composites revealed semi-ductile and semi-brittle behavior, respectively. Moreover, hybrid functional composites display altered material behavior at their extreme layers. Two layers of glass fiber (GG) with Al (2.4% by wt) filler functional composite achieved 1.91% maximum tensile strength compared to Al (2, 4, 6, 8% by wt) filler composite.

Graphical abstract

Similar content being viewed by others

Data availability

Data is available with the authors, it can be shared if required.

References

Pereira AL, Banea MD, Neto JSS, Cavalcanti DKK (2020) Mechanical and thermal characterization of natural intralaminar hybrid composites based on sisal. Polymers (Base l) 12:866

Amiri Delouei A, Emamian A, Karimnejad S, Sajjadi H, **g D (2021) Two-dimensional temperature distribution in FGM sectors with the power-law variation in radial and circumferential directions. J Therm Anal Calorim 144:611–621

Boggarapu V, Adapa S, Kanakam R, Ojha S, Gujjala R (2022) Research on mechanical and erosion behavior of stepped polymeric functionally graded materials reinforced with aluminum. Polym Compos 43:1048–1059

Oza MJ, Schell KG, Bucharsky EC, Laha T, Roy S (2021) Develo** a hybrid Al–SiC-graphite functionally graded composite material for optimum composition and mechanical properties. Mater Sci Eng A 805:140625

Ravikumar P, Suresh AR, Rajeshkumar G (2022) An investigation into the tribological properties of bidirectional jute/carbon fiber reinforced polyester hybrid composites. J Nat Fiber 19:943–953

Loknath D, Kumar VR (2022) A review on processing and characterization of bulk functionally graded polymer materials. Mater Today Proc 56:1192–1200

Singh S, Dwivedi UK, Shukla SC (2021) Recent advances in polymer based functionally graded composites. Mater Today Proc 47:3001–3005

Farahnakian M, Elhami Joosheghan S, Moradi M (2021) Dual filler functionally graded polymermaterials–manufacturing process and characteristics. Mater Manuf Proc 36:301–307

Ostolaza M, Arrizubieta JI, Lamikiz A, Plaza S, Ortega N (2023) Latest developments to manufacture metal matrix composites and functionally graded materials through AM: a state-of-the-art review. Materials 16:1746

Ostolaza M, Arrizubieta JI, Lamikiz A, Cortina M (2021) Functionally graded AISI 316L and AISI H13 manufactured by L-DED for die and mould applications. Appl Sci 11:771

Alhazmi WH, Jazaa Y, Mousa S, Abd-Elhady AA, Sallam HE (2021) Tribological and mechanical properties of epoxy reinforced by hybrid nanoparticles. Latin Am J Solid Struct 18:3. https://doi.org/10.1590/1679-78256384

Singh S, Dwivedi UK, Chandra Shukla S (2021) Recent advances in polymer based functionally graded composites. Mater Today Proc 47:3001–3005

Prasad L, Singh G, Pokhriyal M (2018) A comparative study on physical and mechanical behavior of functionally graded composite materials reinforced with natural fillers. Mater Today Proc 5:16990–16994

Alsaadi M, Erkliğ A (2018) Effect of perlite particle contents on delamination toughness of S-glass fiber reinforced epoxy matrix composites. Compos Part B Eng 141:182–190

Singh AK, Siddhartha, (2019) An investigation on the mechanical and thermal performance of a novel functionally graded materials–based thermoplastic composites. J Thermoplast Compos Mater 32:1691–1713

Boggarapu V, Ruthik L, Gara DK, Ojha S, Jain S, Gujjala R, Bandaru AK, Inala R (2022) Study on mechanical and tribological characteristics of layered functionally graded polymer composite materials. Proc Instit Mech Eng J Proc Mech Eng 236:1857–1868

Chowdary MS, Raghavendra G, Kumar MSRN, Ojha S, Boggarapu V (2020) Influence of nano-silica on enhancing the mechanical properties of sisal/Kevlar fiber reinforced polyester hybrid composites. SILICON 14:539–546

Punugupati G, Bose PSC, Raghavendra G, Punugupati G, Bose PS, Raghavendra G, Rao CS, Ojha S (2020) Erosion behavior of gelcast fused silica ceramic composites. SILICON 12:903–911

Sanjay MR, Yogesha B (2018) Studies on hybridization effect of jute/kenaf/E-glass woven fabric epoxy composites for potential applications: effect of laminate stacking sequences. J Ind Text 47:1830–1848

Manikanta PS, Chowdary MS, Niranjan MSR (2018) Effect of nano silica on the tensile property of woven banana and S-glass fiber reinforced hybrid polyester composites. J Emerg Technol Innov Res 5:147

Shahapure N, Shinde D, Kelkar A (2023) Atomistic modeling and molecular dynamic simulation of polymer nanocomposites for thermal and mechanical property characterization: a review. AIMS Mater Sci 10:249–287

Basim Abdul-Hussein A, Saadi Abdel Kareem E, Subhi Atallah M (2018) Effect of carbon nano tubes on erosion wear of carbon fiber, glass fiber & Kevlar fiber reinforced unsaturated polyester composites. J Eng Sustain Dev 22:74–89

Nayak SK, Satapathy A, Mantry S (2021) Role of test parameters and material composition on the erosion behavior of waste marble dust-filled glass-polyester composites. J Brazil Soc Mech Sci Eng 43:1–14

Acknowledgements

The authors would like to thank the chairperson and Principal of KITS and Director of NIT-Warangal, faculty members and laboratory staff of Mechanical Engineering Departments for their support in the completion of this work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Ojha, S., Raghavendra, G., Prudhvidhar, K. et al. A study on the mechanical and erosion wear of functionally-layered polymer composites and hybrid functionally-layered polymer composites. Iran Polym J 33, 647–657 (2024). https://doi.org/10.1007/s13726-024-01282-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13726-024-01282-0