Abstract

In this study, CaO-Fe and CaO-Ag nanocomposites were synthesized and various biological properties were characterized. E. coli cell viability, antimicrobial, antioxidant, antibiofilm, and DNA cleavage properties were examined. All nanocomposites, namely raw CaO-Ag (R-CaO-Ag), hydrolyzed CaO-Ag (H-CaO-Ag), raw CaO-Fe (R-CaO-Fe), and hydrolyzed CaO-Fe (H-CaO-Fe), were found to have good antioxidant, antimicrobial, and antibiofilm properties. They showed antioxidant activity of 83.33%, 70.60%, 74.73%, and 72.78%, respectively, at 200 mg/L nanocomposites. When DNA cleavage properties of R-CaO-Ag, H-CaO-Ag, R-CaO-Fe, and H-CaO-Fe were evaluated at different concentrations, single-strand break was observed for all samples. It was shown that R-CaO-Ag was more effective against S. aureus and C. tropicalis, and H-CaO-Ag was more effective against E. hirae. It was found that the antimicrobial activities of R-CaO-Ag and H-CaO-Ag were higher compared to R-CaO-Fe and H-CaO-Fe. The microbial cell viability of nanocomposites was examined at three different concentrations. Even at the lowest concentration (125 mg/L), high values of E. coli inhibition were found as 98.65%, 100%, 90.24%, and 88.63%, respectively. Also, it was observed that all nanocomposites exhibited excellent biofilm inhibition activities. The antibiofilm abilities of one Gr (+) and one Gr (−) microorganism at three different concentrations were investigated. Biofilm inhibition percentages of R-CaO-Ag, H-CaO-Ag, R-CaO-Fe, and H-CaO-Fe were found as 65.83%, 86.5%, 89.67%, and 93.62% for S. aureus at 500 mg/L, respectively, while it was 50.06%, 90.68%, 71.69%, and 92.36% for P. aeruginosa, respectively, at 500 mg/L.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Antimicrobial resistance is one of today’s leading health problems, and the World Health Organization (WHO) has drawn attention to this problem in recent years [1]. Excessive and incorrect use of antibiotics to destroy microorganisms or slow their growth has led to the formation of antibiotic-resistant bacteria [2]. As a result of this situation, existing antibiotics became less effective or ineffective, and antibiotic-based treatments became insufficient [3]. At the same time, it becomes easier for these microbes to adapt to a certain environment due to biofilm formation, causing them to become more pathogenic and more resistant to treatments [4]. Nowadays, we replace different antibiotics with chemical approaches and materials called nanomaterials [5]. Nanoparticles are more than just materials that can penetrate and interact with biological systems with a high surface-to-volume ratio and tunable physical and chemical properties [6]. While the application of nanomaterials in medicine is called “nanomedicine,” recent developments in this field attract attention. In addition to biomedicine, it is important for use in the fight against bacteria and their resistant species [7]. It is known that nanoparticles are also used as good drug carriers due to their biocompatibility, controllable pore volumes, controllable size, and high surface/volume ratios. In addition, it is known that their ability to encapsulate drugs increases their solubility compared to traditional drugs [8]. Another contribution of nanoparticles to drug delivery is that they provide controlled and targeted release of drugs. This is important because the controlled release of drugs can maintain drug concentration in the body, opening a therapeutic window for long-term treatments. In short, the mentioned nanoparticles are one of the most promising materials for combating antimicrobials [9, 10].

Nanotechnology is basically a field that covers the design, production, characterization, and application of nanometer-sized structures. Today, this rapidly develo** technology constitutes a multidisciplinary field that produces tools, materials, and structures at the molecular level—often at the atomic level. Nanomaterials, which refer to structures with at least one dimension smaller than 100 nm, have a high surface-to-volume ratio, and they are quite different in terms of their physicochemical properties compared to bulk materials. These size-dependent physicochemical properties vary depending on bulk materials, resulting in nanoproducts and causes the rapid increase in nanomaterial production [11]. Nanomaterials are generally classified according to their building blocks: carbon-based (organic), metal and metal oxide–based (inorganic), or composite (hybrid) materials [12]. Carbon-based nanomaterials are generally consisting of carbon, such as fullerenes and carbon nanotubes. These nanomaterials that can be found in the form of spheres, ellipsoids, or tubes. Metal and metal oxide–based nanomaterials include nanometer-sized materials such as silver, gold, zinc oxide, iron oxide, and quantum dots [13]. Composite nanomaterials consist of multiple components. It is commonly called nanocomposite. These nanomaterials can be formed with organic-organic, organic-inorganic, or inorganic-inorganic connections.

Composite nanomaterials have high stability in biological fluids, and they also have features such as biodegradability, renewability, and biocompatibility [14, 15]. The fact that these properties can be improved makes composite materials suitable for use in agriculture, energy, cosmetics, etc., and enables its use in various sectors including pharmaceuticals, food safety, and preservation [16, 17]. In addition, nanocomposites have been integrated into many industrial sectors such as automotive, electronics, aerospace, defense, energy, and biotechnology.

Synthetic materials commonly used in nanocomposite production are aliphatic polyesters, aliphatic-aromatic polyesters, polyvinyl alcohols, polyesteramides, polystyrenes, nanoclays, glass, and carbon fibers and carbon nanotubes. However, the use of these materials has also brought with it decrease in organic components due to decrease in oil and gas resources, degradation or incineration of materials causes global warming, uneconomic prices, recycling, and toxicity risks for consumers [18]. For these reasons, biowaste materials have come to the fore as an alternative component in nanotechnological products. Applications for biowaste materials, like eggshell waste, have seen a huge surge in interest [19, 20]. Because of their high catalytic activity, ease of handling, reusability, and benign nature, low-cost eggshell waste has been used extensively in recent years [21]. Eggshells are inexpensive, readily available biomaterials with inherent pore structure. In addition to offering a financially viable and environmentally responsible method of producing heterogeneous catalysts, the use of waste eggshell as a support streamlines the process and makes it completely sustainable. Eggshell waste has been utilized as a catalyst in the production of dimethyl carbonate, biodiesel, and lactose isomerization [22,23,24]. Strong metal-protein bonding can be easily used, which makes it especially appealing for the synthesis of metal nanoparticles. Nasrollahzadeh et al. (2016) investigated the environmentally friendly and cost-effective synthesis of Cu/eggshell, Fe3O4/eggshell, and Cu/Fe3O4/eggshell nanocomposites using an aqueous extract of Orchis mascula L. leaves without the need of a stabilizer or surfactant. High catalytic activity was demonstrated by the nanocomposites in the reduction of various dyes [21]. Fecheyr-Lippens et. al. (2017) studied the possibility of protecting two popular synthetic polymers (nylon and polystyrene) from UV rays using raw chicken eggshells. They demonstrated that raw chicken eggshells offered strong and reliable UV protection [25].

Raw, boiled, and calcined waste chicken eggshell powder was used to obtain calcium oxide (CaO) catalyst. A 3-h process of boiling and calcining of raw chicken eggshell at 900 °C resulted in modifications [26]. A one-step thermally assisted method was used to create in situ silver nanoparticles (AgNPs) in poultry hen egg shell powder (ESP) using the collagen that is naturally present as a reducing agent. Excellent antibacterial activity was shown by nanocomposite egg shell powder (NCESP) against both Gram-positive and Gram-negative bacteria [27]. Jasvil et al. [28] looked into the crystallographic evolution of CaO from the waste materials of chicken eggshells using a straightforward calcination procedure for the photocatalytic breakdown of the methylene blue dye. Under natural sunlight in the ambient environment, the methylene blue dye was degraded in distilled water using the photocatalytic activity of the prepared CaO. In 180 min, a maximum photocatalytic degradation efficiency of about 98% was observed. Eggshells from chickens were calcined at 1100 °C for 2 h to produce recycled calcium oxide (CaO) nanoparticles [29]. Palladium nanoparticles are loaded onto the surface of calcium oxide (Pd@CaO) to create a novel nanocomposite that is successfully fabricated through solid-solid interaction. In the presence of Pd@CaO, mild conditions were ideal for crystal violet photocatalytic degradation.

The goal of Amarasinghe’s research (2019) [30] is to remove dyes from water bodies by employing calcined egg shell powder, which is made from waste egg shells as a novel material, for photocatalytic dye removal. The results show that, under the same conditions, calcined egg shell powder (CESP) has a dye degradation capability of 80%, which is significantly higher than that of raw egg shell powder (RESP), which is 20%. The biological synthesis of MnO2 nanoparticles and MnO2@eggshell nanocomposite was reported by [31]. Under basic pH conditions, 0.025 M MnCl2 solution with 1.0% (m/v) plant powder (Ocimum basilicum) content-based extract was found to have the best conditions for the biosynthesis of MnO2 NPs. After cleaning and finely powdering the egg shell waste from poultry, a one-step hydrothermal process was used to modify the material with in situ produced copper nanoparticles (CuNPs) and cuprous oxide nanoparticles (Cu2ONPs) [32]. Excellent antibacterial activity was shown by the MESP against both Gram-positive and Gram-negative bacteria. Therefore, the inexpensive MESP containing in situ produced CuNPs and Cu2ONPs can be utilized as an antibacterial filler when creating polymer composites as well as an antibacterial cleaning powder for household items.

In this study, CaO-Fe and CaO-Ag nanocomposites were synthesized using raw and hydrolyzed waste chicken eggshells, and various biological properties of these nanocomposites such as antimicrobial, biofilm inhibition activity, DNA fragmentation, and antioxidant activity were investigated. To the best of our knowledge, no reports of in situ biosynthesis of Fe and Ag NPs supported on the CaO produced from waste eggshell have been reported so far. The proposed nanocomposite synthesis is sustainable and innovative as it is based on a simple, economical, and environmentally friendly method.

2 Materials and methods

2.1 Preparation of raw and hydrolyzed eggshell

Waste chicken eggshells (WCEs) were prepared for the synthesis process as given in our previous work [33]. A schematic follow of raw and hydrolyzed eggshell preparation is shown in Fig. 1. Briefly, the collected WCEs were grounded, washed (3 times) with deionized water, and dried in an oven at 373 K for 2 h to eliminate any remaining water in the eggshell. Then, the dried WCE was sifted through a 900 μm-sieve. The resulting WCE at this stage was designated as Raw-WCE (R-WCE). The hydrolysis of R-WCE was carried out in a homemade stainless steel reactor, details of which have been given previously [33]. A total of 100 g of R-WCE and 130 mL of deionized water were mixed in the abovementioned reactor, and the reactor was sealed, pressurized by N2 gas, and heated to 513 K for 2 h. Finally, the obtained hydrolyzed WCE (H-WCE) was washed 3 times using deionized water, dried at 371 K for 12 h, and stored for further use.

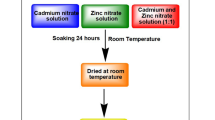

2.2 Synthesis of CaO-Fe and CaO-Ag nanocomposites

R-WCE and H-WCE samples were used to synthesize CaO-Fe and CaO-Ag nanocomposites in the subcritical water medium. A schematic follow of raw and hydrolyzed CaO-Fe and CaO-Ag nanocomposite preparation is given in Fig. 2. For CaO-Fe nanocomposites, 15 g of R-WCE was put in the reactor followed by 2 g of (NH4)2Fe(SO4)2·6H2O, 12.5 mL of 1 M KOH, and 100 mL of deionized water. Similarly, this process was repeated when using H-WCE samples as CaO sources instead of R-WCE. Finally, the reactor was sealed and pressurized by N2 to 30 bar of initial pressure. The temperature of the reactor was increased to 393 K and synthesis of the CaO-Fe nanocomposites was continued for 1 h at mentioned temperature. After the completion of the synthesis time, the resulting samples were washed with deionized water and dried at 371 K for 12 h in each case. According to the input WCE used, the CaO-Fe nanocomposite obtained when using R-WCE and H-WCE samples were named R-CaO-Fe and H-CaO-Fe nanocomposite, respectively. The same procedure given above was applied to synthesize CaO-Ag nanocomposites. The only difference was the use of AgNO3 instead of (NH4)2Fe(SO4)2·6H2O. Therefore, the obtained CaO-Ag nanocomposites were named R-CaO-Ag and H-CaO-Ag when using R-WCE and H-WCE samples as input, respectively.

2.3 Antioxidant activity (DPPH)

Evaluation of the antioxidant activity of R-CaO-Ag, H-CaO-Ag, R-CaO-Fe, and H-CaO-Fe against stable free radical DPPH was applied with minor modifications in the method developed by Ağırtaş et al. [34]. DMSO was used in the preparation of stock solutions of previously prepared complexes. Then, samples were prepared with serial dilutions from the stock solution at concentrations ranging from 12.5 to 200%. Each prepared complex solution was taken into different test tubes at 1-mL concentrations and shaken vigorously for about 2–3 s. Then, it was left to incubate in a dark environment at room temperature for about 30 min, and when the incubation period was completed, the absorbance of each solution was measured at 517 nm with the help of a UV-visible spectrophotometer. The measured test results were calculated using the percent formula of free radical scavenging activity expressed as percent DPPH inhibition (Eq. 1).

2.4 DNA clevage ability

The cleavage of pBR 322 plasmid DNA with R-CaO-Ag, H-CaO-Ag, R-CaO-Fe, and H-CaO-Fe was investigated by gel electrophoresis method. The pBR 322 plasmid DNA, which was obtained from Thermo Fisher Scientific™, was used during the cleavage study. The pBR 322 plasmid DNA used in the study was treated with different concentrations of R-CaO-Ag, H-CaO-Ag, R-CaO-Fe, and H-CaO-Fe and incubated at 37.5 °C for 60 min. Then, it was loaded onto a 1% agarose gel mixed with loading buffer and electrophoresed at 120 V for 80 min in 1XTAE buffer (40 mM Tris/acetate and 1 mM EDTA, pH 8.0). The gel used for the study is a 1.5% agarose gel, which was stained in ethidium bromide (EtBr) (1 mg/mL) during preparation. When the electrophoresis time expired, the bands formed were illuminated with a UV illuminator and photographed [35, 36].

2.5 Antimicrobial activity of R-CaO-Ag, H-CaO-Ag, R-CaO-Fe, and H-CaO-Fe

For the determination of antimicrobial properties of R-CaO-Ag, H-CaO-Ag, R-CaO-Fe, and H-CaO-Fe, various bacteria (L. pneumophila subsp. pneumophila, S. aureus, P. aeruginosa, E. coli, E. hirae, E. faecalis) and two fungal species (C. parapisilosis and C. tropicalis) were used. R-CaO-Ag, H-CaO-Ag, R-CaO-Fe, and H-CaO-Fe composites were analyzed by serial dilution method for determination of minimum inhibitory concentrations (MICs). Microorganisms to be used for the test were grown for 1 day at 37.5 °C before microdilution in Nutrient Broth (NB). Microorganisms whose incubation period expired were inoculated into a medium containing R-CaO-Ag, H-CaO-Ag, R-CaO-Fe, and H-CaO-Fe at different concentrations into well plates. They were left to incubate for 24 h and MICs were determined.

2.6 Biofilm inhibition activity

While evaluating the biofilm prevention capacity of R-CaO-Ag, H-CaO-Ag, R-CaO-Fe, and H-CaO-Fe, the same method was used with minor changes in the method specified by Farajzadeh et al. (2022) [37]. Although many types of microorganisms are known to form biofilms, S. aureus and P. aeruginosa were preferred as model microorganisms in this study. Different concentrations of R-CaO-Ag, H-CaO-Ag, R-CaO-Fe, and H-CaO-Fe were first added into 24-well plates containing NB and then bacterial strains were inoculated. They were incubated in a 24-well plate at 37.5 °C for 72 h. Afterwards, the wells of the plate were emptied. The wells were gently washed with distilled water. This process was repeated 2 times. The plates were then left to dry for 1 h at 80 °C. Samples incubated with crystal violet for 1 h were poured again and the wells were washed 2 times with distilled water. Finally, ethanol was attached to the wells and it was incubated for 15 min to recover the absorbed CV. The obtained results were calculated according to the antibiofilm activity Eq. (2).

2.7 Bacterial viability

In our study, the ability of R-CaO-Ag, H-CaO-Ag, R-CaO-Fe, and H-CaO-Fe to inhibit bacterial cell viability was also evaluated. The strain E. coli was preferred to evaluate the ability of R-CaO-Ag, H-CaO-Ag, R-CaO-Fe, and H-CaO-Fe to inhibit bacterial cell viability [38]. Pelletizing the E. coli used in the study was done before the study. Then, different concentrations of R-CaO-Ag, H-CaO-Ag, R-CaO-Fe, and H-CaO-Fe were incubated for 90 min at 37.5 °C with E. coli. The mixtures were then diluted at different ratios, inoculated on nutrient agar media and allowed to re-incubate at 37.5°C for 1 day. The results were obtained at the end of the incubation, the colonies were counted and finally, the cell viability inhibition was calculated using Eq. (3).

3 Result and discussion

3.1 Synthesis of nanocomposites in subcritical water medium

Nanocomposites were synthesized at 393 K, which corresponds to the temperature range of the subcritical water medium. The subcritical water method is not only an environmentally friendly method, but is also widely preferred because it requires less energy compared to the supercritical water environment [39, 40]. In fact, in this method, the desired physicochemical properties for the synthesis can be achieved under the conditions of temperature (373–647 K) and pressure (sufficient to keep water in liquid form under the applied temperature conditions). It has been reported that nano metal oxides with high crystal functionality are produced in subcritical water medium [40]. Therefore, to benefit from the unique synthesis properties of the subcritical water medium, nanocomposite synthesis was carried out at 393 K, which corresponds to the subcritical temperature range.

3.2 Surface characteristics analysis

Surface characteristics based on the SEM and EDX analysis of raw and hydrolysed eggshells was previously performed [33, 41]. Briefly, when the SEM images of raw egg shell samples were examined, it was reported that small particles were located on irregularly distributed large particles, and in hydrolyzed samples, irregular shapes came together to form a flatter surface, but the porosity on the surface increased. The intense presence of nano-sized particles was observed in the SEM images of both samples. In EDX images, it was reported that the weight percentage of C and O decreased in hydrolyzed eggshells [13].

3.3 Antioxidant activity (DPPH)

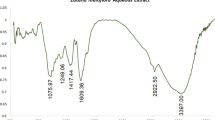

The DPPH radical capture test is a preferred antioxidant method because it is a feasible test and also a low-cost, useful, and influential test. The basis of this method is the reduction of DPPH with a synthesized molecule and causing a strong color reduction change. The resulting color change was then evaluated at 517 nm with the aid of a spectrophotometer. The results of the compounds examined in our study at different concentrations are presented in Fig. 3. It was observed that R-CaO-Ag, H-CaO-Ag, R-CaO-Fe, and H-CaO-Fe exhibited excellent antioxidant ability. The antioxidant ability was found to be 50.43% at 12.5 mg/L, 65.25% at 50 mg/L, and 84.33% at 200 mg/L for R-CaO-Ag and 36.45% at 12.5 mg/L, 51.03% at 50 mg/L, and 70.60% at 200 mg/L for H-CaO-Ag. In addition to these, the radical inhibition activities of R-CaO-Fe and H-CaO-Fe were 24.79% and 34.14% at 12.5 mg/L, 49.21% and 51.15% at 50 mg/L, and 74.73% and 72.78 at 200 mg/L, respectively. The highest antioxidant ability among the compounds was achieved with R-CaO-Ag as 84.33% at 200 mg/L. Al-Asfar et al. (2018) [42] investigated the antioxidant properties of Ag@Fe nanoparticles obtained by green synthesis and found that the antioxidant activity increased with increasing extract concentration. Erdem et al. (2022) investigated the antioxidant activities of Primula vulgaris by synthesizing silver nanoparticles using different aqueous parts of P. vulgaris extracts [43]. It was noticed that the highest antioxidant activity of AgNPs was 90.6%. The DPPH method was used to investigate the antioxidant activities of AgNPs synthesized from Seseli resinosum Freyn & Sint and it demonstrated 22% antioxidant ability [44]. R-CaO-Ag, H-CaO-Ag, R-CaO-Fe, and H-CaO-Fe also seem to be the best candidates due to their significant antioxidant activities. In conclusion, the evaluation of antioxidant activity for may be very important and necessary before their use in animal models, in vivo research, or human applications.

3.4 DNA cleavage study with agarose gel electrophoresis

When various metal complexes are examined, it is generally seen that they interact with DNA. It is also known that metal complexes often have a strong influence on DNA. They were found to have an important affinity for DNA and can induce DNA cleavage [45]. When investigating the bioactivity of most anticancer drugs, the result was generally seen to be related to their ability to interact with DNA. It is thought that such compounds can disrupt DNA structure in cancer cells and lead to the inhibition of apoptosis as well as cell growth [46]. In this study, the DNA cleavage activity of R-CaO-Ag, H-CaO-Ag, R-CaO-Fe, and H-CaO-Fe was examined. The results are shown in Fig. 4. Single-strand break DNA fragmentation was observed for R-CaO-Ag, H-CaO-Ag, R-CaO-Fe, and H-CaO-Fe at all concentrations of 50 mg/, 100 mg/L, and 200 mg/L. In a study, the DNA fragmentation activity of FeONPs synthesized from water and methanol extract was investigated. As a result, it was found that FeONPs synthesized from water extract completely degraded the DNA molecule, while FeONPs synthesized from methanol extract caused single-chain breaks [47]. In a different study, when the DNA fragmentation activity of CuFeO2-NPs was tested, it was determined that CuFeO2 did not show DNA fragmentation activity at 10 mg/L, 50 mg/L, and 100 mg/L [48]. Because of their unique physico-chemical characteristics, AgNPs have superior antibacterial activity due to their DNA damage and protein dysfunction [49,50,51]. When AgNPs enter a cell, they turn into Ag+ ions and at the end of the reaction, they easily bind intracellular biomolecules and cause cell damage. They can also bind to DNA and inhibit DNA replication and cell division by binding to membrane and cellular proteins that also aid cell division functions [52]. The results attributed to DNA fragmentation for R-CaO-Ag, H-CaO-Ag, R-CaO-Fe, and H-CaO-Fe can be important data for inhibiting the growth of pathogenic microorganisms and cancer cells by fragmenting their genomes.

DNA cleavage activity of R-CaO-Ag, H-CaO-Ag, R-CaO-Fe, and H-CaO-Fe. Lane 1: pBR 322 DNA; lane 2: pBR 322 DNA+50 mg of R-CaO-Ag; lane 3: pBR 322 DNA+100 mg of R-CaO-Ag; lane 4: pBR 322 DNA+200 mg of R-CaO-Ag; lane 5: pBR 322 DNA+50 mg/L of H-CaO-Ag; lane 6: pBR 322 DNA+100 mg/L of H-CaO-Ag; lane 7: pBR 322 DNA+200 mg of H-CaO-Ag; lane 8: pBR 322 DNA+50 mg/L of R-CaO-Fe; lane 9: pBR 322 DNA+100 mg/L of R-CaO-Fe; lane 10: pBR 322 DNA+200 mg of R-CaO-Fe; lane 11: pBR 322 DNA+50 mg/L of H-CaO-Fe; lane 12: pBR 322 DNA+100 mg/L of H-CaO-Fe; lane 13: pBR 322 DNA+200 mg of H-CaO-Fe

3.5 In vitro antimicrobial activity

The increasing application of nanoparticles in drug industry has led to an expanding number of investigations synthesizing potential antimicrobial mechanisms of nanoparticles. In order for NPs to perform their antimicroial functions, they must be in contact with bacterial cells. These forms of contact include van der Waals forces, receptor–ligand and hydrophobic, and also electrostatic attraction interactions. NPs then cross the microbial membrane and accumulate along the metabolic pathway, affecting the function and morphology of the cell membrane. Thereafter, NPs interact with the microbial cell’s basic macromolecules and components, such as lysosomes, DNA, ribosomes, proteins, enzymes, cell membrane electrolyte balance disorders, and enzyme inhibition and can cause protein deactivation, DNA mutation, disruption of protein synthesis and enzyme inhibitions, and also change in gene expression. The following antimicrobial mechanisms are the most constantly suggested in current research: metal ion release non-oxidative mechanisms and oxidative stress [53]. In vitro anti-microbial abilities of R-CaO-Ag, H-CaO-Ag, R-CaO-Fe, and H-CaO-Fe were also tested against several common pathogen microorganisms and results were evaluated with MIC values. The MICs of R-CaO-Ag, H-CaO-Ag, R-CaO-Fe, and H-CaO-Fe ranged from 128 to 1024 mg/L, which indicated different susceptibility of test bacteria to R-CaO-Ag, H-CaO-Ag, R-CaO-Fe, and H-CaO-Fe (Table 1). The MIC values of R-CaO-Ag were determined as 128 mg/L for S. aureus and C. tropicalis, and 256 mg/L for L. pneumophila subsp. pneumophila, P. aeruginosa, E. faecalis, C. parapisilosis and E. hirae, and 512 mg/L for E. coli; meanwhile, the MICs of H-CaO-Ag were as 128 mg/L for E. hirae; 256 mg/L for S. aureus, E. faecalis, C. tropicalis, P. aeruginosa, C. parapisilosis and L. pneumophila subsp. Pneumophila; and 512 mg/L for E. coli. The MIC values of R-CaO-Fe were found to be 256 mg/L for E. hirae, S. aureus, and E. faecalis; 512 mg/L for C. parapisilosis, C. tropicalis, E. coli, and L. pneumophila subsp. pneumophila; and 1024 mg/L for P. aeruginosa and also the MICs of H-CaO-Fe were as 256 mg/L for E. hirae and C. tropicalis, 512 mg/L for C. parapisilosis; E. coli, S. aureus, E. faecalis, and P. aeruginosa; and 1024 mg/L for L. pneumophila subsp. pneumophila. Sondi and Salopek-Sondi (2004) reported that they investigated the growth of E. coli on agar plates and in a liquid medium supplemented with AgNPs as an antimicrobial agent [54]. It was found that they completely inhibited bacterial growth when NPs were present on agar plates. In another study, the antimicrobial effect of Ag-Fe bimetallic NPs against E. coli and S. aureus was examined. They stated that the concentration of bimetallic Ag-Fe-NPs increased the antimicrobial ability against the tested microorganisms [42]. Yoonus et al. (2020) informed that they studied the antibacterial activity of α-Fe2O3 nanoparticles against S. mutans, S. aureus, P. aeruginosa, and E. coli [55]. One or more of the antimicrobial mechanisms mentioned above may have caused the NPs we tested to show antimicrobial activity. They reported that α-Fe2O3 nanoparticles showed antimicrobial activity. Based on the antimicrobial screening results, we can conclude that R-CaO-Ag, H-CaO-Ag, R-CaO-Fe, and H-CaO-Fe can be considered a more potent antimicrobial against Gr-positive microorganisms.

3.6 Cell viability

The effects of R-CaO-Ag, H-CaO-Ag, R-CaO-Fe, and H-CaO-Fe on the viability of bacterial cells were investigated by using E. coli as the bacterial strain. The results are shown in Fig. 5. Looking at the cell viability inhibition abilities of R-CaO-Ag, H-CaO-Ag, R-CaO-Fe, and H-CaO-Fe, they demonstrated a strong E. coli inhibition effect at all concentrations. Relevant microbial cell viability abilities of R-CaO-Ag against E. coli growth were 98.35% at 125 mg/L, 99.99% at 250 mg/L, and 99.99% at 500 mg/L. In the study performed with the same method, the effectiveness against E. coli growth was 100% at 125 mg/L, 250 mg/L, and 500 mg/L for H-CaO-Ag. E. coli cell viability was inhibited as 90.24% at 125 mg/L, 99.99% at 250 mg/L, and 99.99% at 500 mg/L by R-CaO-Fe. The corresponding microbial cell viability inhibition of H-CaO-Fe was also 88.63% at 125 mg/L, 99.99% at 250 mg/L, and 99.99% at 500 mg/L. Işık et al. (2023) investigated the cell viability inhibition of FeONPs obtained from water and methanol extract of Centaurea solstitialis leaves [47]. Microbial cell viability inhibitions of E. coli were found to be 93.24%, 96.31%, and 99.98%, respectively, at 125, 250, and 500 mg/L FeONP concentrations obtained from the water extract, respectively. FeONPs obtained from the methanol extract also caused 91.87%, 95.09%, and 99.92% E. coli cell viability inhibition rates at 125, 250, and 500 mg/L, respectively. According to the cell viability results, it is seen that the newly synthesized R-CaO-Ag, H-CaO-Ag, R-CaO-Fe, and H-CaO-Fe are quite effective on E. coli bacteria. After further research, we can say that these composites can be used as antimicrobial agents in medical fields.

3.7 Biofilm inhibition

Biofilm is one of the structures formed by various microorganisms and is responsible for some bacterial infections. Microorganism communities that cause biofilm formation can sometimes form a biofilm layer that cannot be easily treated with antibiotics. Thanks to these resistant structures, microorganisms can develop resistance to some antibiotics, making the treatment of bacterial infections difficult. Today, alternative methods are urgently needed to treat microorganisms that cause biofilm formation. Therefore, in our study, the antibiofilm abilities of R-CaO-Ag, H-CaO-Ag, R-CaO-Fe, and H-CaO-Fe were investigated using the crystal violet binding test. Crystal violet has the ability to bind to the biofilm layer synthesized by microorganisms. The more biofilm layers there are, the more crystal violet binds to the microbial biofilm layer. The bound crystal violet to the biofilm layer is recovered with ethanol. As a result of retrieval, the darker color indicates that the biofilm layer is high, and the lighter color indicates that the biofilm layer is low. This is the key findings of biofilm inhibition of newly synthesized NPs. As shown in Figs. 6 and 7, it was observed that the antibiofilm abilities of R-CaO-Ag, H-CaO-Ag, R-CaO-Fe, and H-CaO-Fe were concentration dependent. The biofilm inhibition activities for R-CaO-Ag, H-CaO-Ag, R-CaO-Fe, and H-CaO-Fe against S. aureus were found to be 41.97%, 51.38%, 71.98%, and 73.42% at 125 mg/L, respectively. The respective antibiofilm abilities of R-CaO-Ag, H-CaO-Ag, R-CaO-Fe, and H-CaO-Fe for the same microorganism were 65.83%, 86.50%, 89.67%, and 93.62% at 500 mg/L, respectively. The best efficacy for S. aureus at all concentrations was found as H-CaO-Fe>R-CaO-Fe>H-CaO-Ag>R-CaO-Ag, respectively. On the other hand, the highest antibiofilm activities of R-CaO-Ag, H-CaO-Ag, R-CaO-Fe, and H-CaO-Fe were determined as 50.06%, 90.68%, 71.69%, and 92.36% for P. aeruginosa at 500 mg/L, respectively. When the two microorganisms were compared in terms of composites, a more effective biofilm activity was observed with S. aureus. Bharathi et al. (2020) showed the antibiofilm ability of Cd-AgNPs with Cordia dichotomous extract against S. aureus and E. coli at concentration ranges of 25–100 mg/L [56]. As a result, they stated that it showed dose-dependent biofilm inhibition activity and it demonstrated more than 90% biofilm activity against S. aureus and E. coli. Singh et al. (2018) examined the antibiofilm ability of AgNPs and AuNPs derived from Rhodiola rosea rhizome extract against P. aeruginosa and E. coli. [57]. It was stated that AgNPs and AuNPs showed good antibiofilm activity against two microorganisms. R-CaO-Ag, H-CaO-Ag, R-CaO-Fe, and H-CaO-Fe can be used as a strong alternative in medical and environmental applications, reducing the severity of infection, increasing the efficiency of wastewater treatment, with their antibiofilm activity. It is also thought that they may have significant potential for use in wound dressings and other biomedical fields and also R-CaO-Ag, H-CaO-Ag, R-CaO-Fe, and H-CaO-Fe can control the antibiofilm-forming abilities of the clinical isolates tested.

4 Conclusion

In our study, various biological ability properties of R-CaO-Ag, H-CaO-Ag, R-CaO-Fe, and H-CaO-Fe were investigated. Various biological activities of green synthesized nanoparticles have been also tested by different researchers in literature, and they are compatible with the data obtained in this study (Table 2). R-CaO-Ag, H-CaO-Ag, R-CaO-Fe, and H-CaO-Fe appeared to exhibit significant antioxidant and antimicrobial activities. They also showed DNA cleavage ability. In addition, when the biofilm inhibition property of R-CaO-Ag, H-CaO-Ag, R-CaO-Fe, and H-CaO-Fe was investigated using S. aureus and P. aeruginosa, it was found that they displayed significant antibiofilm activity. When the nanocomposites were examined for bacterial viability, all samples were shown to exhibit very good antibacterial properties even at the lowest concentrations. The study is not only valuable but also significant in terms of new literature in terms of shedding light on current medicine and drug research.

The antimicrobial activity of CaO-Fe and CaO-Ag nanocomposites against Gram-negative, Gram-positive, and yeast fungi was investigated using the microdilution technique and the results were evaluated with various graphs. R-CaO-Ag was shown to be more effective against S. aureus and C. tropicalis, while H-CaO-Ag was shown to be more effective against E. hirae. The antimicrobial activities of R-CaO-Ag and H-CaO-Ag were found to be higher than R-CaO-Fe and H-CaO-Fe. Microbial cell viability of nanocomposites was examined at three different concentrations and inhibition values were found to be high even at the lowest concentration. It was also observed that all nanocomposites exhibited excellent biofilm inhibition activities. The antibiofilm abilities of one Gr (+) and one Gr (−) microorganism at three different concentrations were investigated. When their antioxidant activities were investigated, they showed 83.33%, 70.60%, 74.73%, and 72.78% antioxidant activity at 200 mg/L, respectively. When the DNA cleavage properties of R-CaO-Ag, H-CaO-Ag, R-CaO-Fe, and H-CaO-Fe were evaluated at different concentrations, single-strand breakage was observed in all samples. The R-CaO-Ag, H-CaO-Ag, R-CaO-Fe, and H-CaO-Fe nanocomposites produced from waste chicken eggshells can be used to create antibacterial hybrid nanocomposites at a low cost.

Data availability

All data generated or analyzed during this study are included in this published article.

References

WHO (2014) Antimicrobial resistance: global report on surveillance. World Health Organization, Geneva

Paul D, Mangla S, Neogi S (2020) Antibacterial study of CuO-NiO-ZnO trimetallic oxide nanoparticle. Mater Lett 271:127740. https://doi.org/10.1016/j.matlet.2020.127740

Gao W, Thamphiwatana S, Angsantikul P, Zhang L (2014) Nanoparticle approaches against bacterial infections: nanoparticle against bacterial infections. WIREs Nanomed Nanobiotechnol 6:532–547. https://doi.org/10.1002/wnan.1282

Das M, Sandhu P, Gupta P, Rudrapaul P, De U, Tribedi P (2016) Attenuation of Pseudomonas aeruginosa biofilm formation by Vitexin: a combinatorial study with azithromycin and gentamicin. Sci Rep 6:23347. https://doi.org/10.1038/srep23347

Mousavifar L, Roy R (2019) Alternative therapeutic strategies to fight bacterial infections. Front Drug Chem Clin Res 2(1):1–4. https://doi.org/10.15761/FDCCR.1000115

Ramos A, Cruz M, Tovani C, Ciancaglini P (2017) Biomedical applications of nanotechnology. Biophys Rev 9:79–89. https://doi.org/10.1007/s12551-016-0246-2

Rai M, Deshmukh S, Ingle A, Gade A (2012) Silver nanoparticles: the powerful nanoweapon against multidrug-resistant bacteria: Activity of silver nanoparticles against MDR bacteria. J Appl Microbiol 112:841–852. https://doi.org/10.1111/j.1365-2672.2012.05253.x

Wang Y, Zhao Q, Han N, Bai L, Li J, Liu J (2015) Mesoporous silica nanoparticles in drug delivery and biomedical applications. Nanomed: Nanotechnol Biol Med 11:313–327. https://doi.org/10.1016/j.nano.2014.09.014

Rr W (2017) Types of nanocarriers–formulation method and applications. Bioequiv Availab 9:3. https://doi.org/10.4172/jbb.10000e77

Kamaly N, Yameen B, Wu J, Farokhzad O (2016) Degradable controlled-release polymers and polymeric nanoparticles: mechanisms of controlling drug. Chem Rev 116:2602–2663. https://doi.org/10.1021/acs.chemrev.5b00346

Agrawal U, Sharma R, Gupta M, Vyas SP (2014) Is nanotechnology a boon for oral drug delivery? Drug Discov Today 19(10):1530–1546

Nair R, Varghese SH, Nair BG, Maekawa T, Yoshida Y, Kumar DS (2010) Nanoparticulate material delivery to plants. Plant Sci 179(3):154–163

Ahmad KS, Jaffri SB (2018) Phytosynthetic Ag doped ZnO nanoparticles: Semiconducting green remediators: photocatalytic and antimicrobial potential of green nanoparticles. Open Chem 16(1):556–570. https://doi.org/10.1515/chem-2018-0060

Draz MS, Fang BA, Zhang P, Hu Z, Gu S, Weng KC, Gray JW, Chen FF (2014) Nanoparticle-mediated systemic delivery of siRNA for treatment of cancers and viral infections. Theranostics 4(9):872

Mu L, Seow PH (2006) Application of TPGS in polymeric nanoparticulate drug delivery system. Colloids Surf B: Biointerfaces 47(1):90–97

Ijaz M, Zafar M, Afsheen S, Iqbal T (2020) A review on Ag-nanostructures for enhancement in shelf time of fruits. J Inorg Organomet Polym Mater 30:1475–1482. https://doi.org/10.1007/s10904-020-01504-x

Zafar M, Iqbal T (2022) Green synthesis of silver and zinc oxide nanoparticles for novel application to enhance shelf life of fruits. Biomass Convers Biorefn. https://doi.org/10.1007/s13399-022-02730-8

Leja K, Lewandowicz G (2010) Polymer biodegradation and biodegradable polymers-a review. Polish J Environ Stud 19(2):255–266

Wei Z, Xu C, Li B (2009) Application of waste eggshell as low-cost solid catalyst for biodiesel production. Bioresour Technol 100(11):2883–2885

Yoo S, Hsieh JS, Zou P, Kokoszka J (2209) Utilization of calcium carbonate particles from eggshell waste as coating pigments for ink-jet printing paper. Bioresour Technol 100(24):6416–6421

Nasrollahzadeh M, Sajadi SM, Hatamifard A (2016) Waste chicken eggshell as a natural valuable resource and environmentally benign support for biosynthesis of catalytically active Cu/eggshell, Fe3O4/eggshell and Cu/Fe3O4/eggshell nanocomposites. Appl Catal B: Environ 191:209–227

Sharma YC, Singh B, Korstad J (2010) Application of an efficient nonconventional heterogeneous catalyst for biodiesel synthesis from Pongamia pinnata oil. Energy Fuels 24(5):3223–3231

Montilla A, del Castillo MD, Sanz ML, Olano A (2005) Egg shell as catalyst of lactose isomerisation to lactulose. Food Chem 90:883–890

Gao Y, Xu C (2012) Synthesis of dimethyl carbonate over waste eggshell catalyst. Catal Today 190:107–111

Fecheyr-Lippens D, Nallapaneni A, Shawkey MD (2017) Exploring the use of unprocessed waste chicken eggshells for UV-protective applications. Sustainability 9:232. https://doi.org/10.3390/su9020232

Awogbemi O, Inambao F, Onuh EI (2020) Modification and characterization of chicken eggshell for possible catalytic applications. Heliyon 6(10):e05283. https://doi.org/10.1016/j.heliyon.2020.e05283

Yorseng K, Siengchin S, Ashok B, Rajulu AV (2020) Nanocomposite egg shell powder with in situ generated silver nanoparticles using inherent collagen as reducing agent. J Bioresour Bioprod 5(2):101–107

Jaiswal KK, Dutta S, Pohrmen CB, Verma R, Kumar A, Ramaswamy AP (2021) Bio-waste chicken eggshell-derived calcium oxide for photocatalytic application in methylene blue dye degradation under natural sunlight irradiation. Inorg Nano-Metal Chem 51(7):995–1004. https://doi.org/10.1080/24701556.2020.1813769

Nassar AM, Alotaibi NF (2021) Eggshell recycling for fabrication of Pd@CaO, characterization and high-performance solar photocatalytic activity. Environ Sci Pollut Res Int 28(3):3515–3523. https://doi.org/10.1007/s11356-020-10751

Amarasinghe A, Wanniarachchi D (2019) Eco-friendly photocatalyst derived from egg shell waste for dye degradation. J Chem 8184732:13. https://doi.org/10.1155/2019/8184732

Moeen M, Nouren S, Zaib M, Bibi I, Kausar A, Sultan M (2022) Green synthesis, characterization and sorption efficiency of MnO2 nanoparticles and MnO2@waste eggshell nanocomposite. J Taibah Univ Sci 16(1):1075–1095. https://doi.org/10.1080/16583655.2022.2139483

Phuthotham M, Siengchin S, Ashok B, Rajulu V (2019) Modification of egg shell powder with in situ generated copper and cuprous oxide nanoparticles by hydrothermal method. Mater Res Express 7:015010

Yabalak E, Isik Z, Dizge N (2022) Catalytical efficiency, mechanism and characterization of hydrolyzed waste eggshell in the subcritical water oxidation of pistachio processing wastewater. J Environ Manag 317:115326. https://doi.org/10.1016/j.jenvman.2022.115326.df

Ağırtas M, Cabir B, Gonca S, Ozdemir S (2021) Antioxidant, antimicrobial, DNA cleavage, fluorescence properties and synthesis of 4- (3,4,5-trimethoxybenzyloxy) phenoxy substituted zinc phthalocyanine. Polycycl Aromat Compd:922469. https://doi.org/10.1080/10406638.2021.1922469

Shailaja SJ, Sangamesh AP, Mahantesh K, Prashant BR (2018) Green synthesis of nano sized transition metal complexes containing heterocyclic Schiff base: structural and morphology characterization and bioactivity study. J Mol Struct 1164(2018):378–385. https://doi.org/10.1016/j.molstruc.2018.03.084

Özge Y, Alper TÇ, Murat Y, Tuba İ, Pinar O-V, Emel T, Ferdağ Ç (2017) The syntheses, characterization, antimicrobial, DNA cleavage and cytotoxic activities of novel terephthalato complexes. J Mol Struct 1127:668–674. https://doi.org/10.1016/j.molstruc.2016.08.018

Farajzadeh N, Ozdemir S, Tollu G, Bayır Z, Koçak M (2022) Biological properties of hexadeca-substituted metal phthalocyanines bearing different functional groups. J Inorg Biochem 234:111888. https://doi.org/10.1016/j.**orgbio.2022.111888

M’barek I, Isik Z, Ozay Y, Ozdemir S, Tollu G, Moussaoui Y, Dizge N (2022) Nanocellulose synthesis from Tamarix aphylla and preparation of hybrid nanocellulose composites membranes with investigation of antioxidant and antibacterial effects. Sep Purif Technol 292:120815. https://doi.org/10.1016/j.seppur.2022.120815

Sue K, Kawasaki SI, Suzuki M, Hakuta Y, Hayashi H, Arai K, Takebayashi Y, Yoda S, Furuya T (2011) Continuous hydrothermal synthesis of Fe2O3, NiO, and CuO nanoparticles by superrapid heating using a T-type micro mixer at 673 K and 30 MPa. Chem Eng J 166(3):947–953

Mutlu RN, Yabalak E, Acar AN et al (2022) Green synthesis of Fe (II, III) oxides nanoparticles in the subcritical water medium and evaluation of their catalytic performance in the oxidation of metoprolol. J Nanostruct Chem 12:79–92. https://doi.org/10.1007/s40097-021-00403-y

Yabalak E, MNM A-N, Saleh M, Isik Z, Dizge N, Balakrishnan D (2022) Catalytic efficiency of raw and hydrolyzed eggshell in the oxidation of crystal violet and dye bathing wastewater by thermally activated peroxide oxidation method. Environ Res 212:113210. https://doi.org/10.1016/j.envres.2022.113210

Al-Asfar A, Zaheer Z, Aazam E (2018) Eco-friendly green synthesis of Ag@Fe bimetallic nanoparticles: antioxidant, antimicrobial and photocatalytic degradation of bromothymol blue. J Photochem Photobiol B Biol 185:143–152. https://doi.org/10.1016/j.jphotobiol.2018.05.028

Erdem B, Çifçi H, Şahin Y (2022) Antimicrobial and antioxidant potential of silver nanoparticles synthesized from Primula vulgaris. MSU J of Sci 10:1013–1022. https://doi.org/10.18586/msufbd.1126542

Bakir O, Güller P, Kurbanoglu E (2022) Synthesis, characterization, antibacterial, antioxidant activity, and lipoxygenase enzyme inhibition profile of silver nanoparticles (AgNPs)by green synthesis from Seseli resinosum Freyn & Sint. Int J Plant Bas Pharm 2(2):182–189. https://doi.org/10.55484/ijpbp.1076620

Grazul M, Besic-Gyenge E, Maake C, Ciolkowski M, Czyz M, Sigel R (2014) Synthesis, physico-chemical properties and biological analysis of newly obtained copper(II) complexes with pyrazole derivatives. J Inorg Biochem 135:68–76. https://doi.org/10.1016/j.**orgbio.2014.02.014

Sigel R, Pyle A (2007) Alternative roles for metal ions in enzyme catalysis and the implications for ribozyme chemistry. Chem Rev 107:97–113. https://doi.org/10.1021/cr0502605

Isik Z, Bouchareb R, Arslan H, Ozdemir S, Gonca S, Dizge N, Prasad S (2023) Green synthesis of iron oxide nanoparticles derived from water and methanol extract of Centaurea solstitialis leaves and tested for antimicrobial activity and dye decolorization capability. Environ Res 115072. https://doi.org/10.1016/j.envres.2022.115072

Antonoglou O, Lafazanis K, Mourdikoudis S, Vourlias G, Lialiaris T, Pantazaki A (2019) Biological relevance of CuFeO2 nanoparticles: antibacterial and anti-inflammatory activity, genotoxicity, DNA and protein interactions. Mater Sci Eng C 99:264–274. https://doi.org/10.1016/j.msec.2019.01.112

Zawadzka K, Felczak A, Nowak M, Kowalczyk A, Piwonski I, Lisowska K (2021) Antimicrobial activity and toxicological risk assessment of silver nanoparticles synthesized using an eco-friendly method with Gloeophyllum striatum. J Hazard Mater 418:126316. https://doi.org/10.1016/j.jhazmat.2021.126316

Huq M, Ashrafudoulla M, Rahman M, Balusamy S, Akter S (2022) Green synthesis and potential antibacterial applications of bioactive silver nanoparticles: a review. Polymers 14(4):742. https://doi.org/10.3390/polym14040742

Pachaiappan R, Rajendran S, Show P, Manavalan K (2021) Metal/metal oxide nanocomposites for bactericidal effect: a review. Chemosphere 128607. https://doi.org/10.1016/j.chemosphere.2020.128607

Rao S, Zhang R, Chen R, Gao Y, Gao L, Yang Z (2022) Nanoarchitectonics for enhanced antibacterial activity with Lactobacillus buchneri S-layer proteins-coated silver nanoparticles. J Hazard Mater 426:128029. https://doi.org/10.1016/j.jhazmat.2021.128029

Wang L, Hu C, Shao L (2017) The antimicrobial activity of nanoparticles: present situation and prospects for the future. Int J Nanomed 14(12):1227–1249

Sondi I, Salopek-Sondi B (2004) Silver nanoparticles as antimicrobial agent: a case study on E. coli as a model for Gram-negative bacteria. J Colloid Interface Sci 177–182. https://doi.org/10.1016/j.jcis.2004.02.012

Yoonus J, Resmi R, Beena B (2020) Evaluation of antibacterial and anticancer activity of green synthesized iron oxide (α-Fe2O3) nanoparticles. Mater Today Proc 46:2969–2974. https://doi.org/10.1016/j.matpr.2020.12.426

Bharathi D, Vasantharaj S, Bhuvaneshwari V (2020) Green synthesis of silver nanoparticles using Cordia dichotoma fruit extract and its enhanced antibacterial, anti-biofilm and photo catalytic activity. J Phys Energy 2:15–30. https://doi.org/10.1088/2053-1591/aac2ef

Singh P, Pandit S, Beshay M, Mokkapati V, Garnaes J, Olsson M (2018) Anti-biofilm effects of gold and silver nanoparticles synthesized by the Rhodiola rosea rhizome extracts. Arti Cell Nanomed Biotechnol 46:886–899. https://doi.org/10.1080/21691401.2018.1518909

Karunakaran G, Jagathambal M, Gusev A, Kolesnikov E, Mandal AR, Kuznetsov D (2016) Allamanda cathartica flower’s aqueous extract-mediated green synthesis of silver nanoparticles with excellent antioxidant and antibacterial potential for biomedical application. MRS Commun 6:41–46

Karunakaran G, Jagathambal M, Kolesnikov E, Dmitry A, Ishteev A, Gusev A, Kuznetsov D (2017) Floral biosynthesis of Mn3O4 and Fe2O3 nanoparticles using Chaenomeles sp. flower extracts for efficient medicinal applications. JOM 69:1325–1333

Ganachari SV, Bhat R, Deshpande R, Venkataraman A (2012) Extracellular biosynthesis of silver nanoparticles using fungi Penicillium diversum and their antimicrobial activity studies. Bionanoscience 2:316–321

Karunakaran G, Jagathambal M, Gusev A, Torres JAL, Kolesnikov E, Kuznetsov D (2017) Rapid biosynthesis of AgNPs using soil bacterium Azotobacter vinelandii with promising antioxidant and antibacterial activities for biomedical applications. JOM 69:1206–1212

Govindappa M, Farheen H, Chandrappa CP, Rai RV, Raghavendra VB (2016) Mycosynthesis of silver nanoparticles using extract of endophytic fungi, Penicillium species of Glycosmis mauritiana, and its antioxidant, antimicrobial, antiinflammatory and tyrokinase inhibitory activity. Adv Nat Sci Nanosci Nanotechnol 7:035014

Fatemi M (2018) Biosynthesis of iron oxide nanoparticles by cytoplasmic extracts of bacteria lactobacillus casei. Asian J Green Chem 2:181–188

Gulbagca F, Ozdemir S, Gülcan M, Şen F (2019) Synthesis and characterization of Rosa canina-mediated biogenic Silver nanoparticles for anti-oxidant, antibacterial, antifungal, and DNA cleavage activities. Heliyon 5(12):e02980. https://doi.org/10.1016/j.heliyon.2019.e02980

Aygün A, Özdemir S, Gulcan M, Cellat K, Sen F (2020) Synthesis and characterization of Reishi mushroom-mediated green synthesis of silver nanoparticles for the biochemical applications. J Pharm Biomed Anal 178:112970

Arslan H, Gonca S, Isik Z, Özdemir S, Yalvac M, Dizge N, Deepanraj B, Ashraf GA (2022) Iron oxide nanoparticles synthesis from vermicomposting leachate and its antioxidant activities. Front Mater 9:912066

Funding

Open access funding provided by the Scientific and Technological Research Council of Türkiye (TÜBİTAK).

Author information

Authors and Affiliations

Contributions

Gülşah Tollu: writing the original draft, experimentation, discussed the results, and commented on the manuscript. Erdal Yabalak: writing and correcting the original draft, review and editing, methodology, discussed the results and commented on the manuscript, critical feedback, organization, and helped shape the research, design of the article and corrections. Zelal Işık: formal analysis. Sadin Özdemir: writing and correcting the original draft, review and editing, discussed the results and commented on the manuscript, critical feedback, organization, and helped shape the research. Nadir Dizge: writing and correcting the original draft, review and editing, methodology, discussed the results and commented on the manuscript, formal analysis. All authors have read and agreed to the published version of the manuscript.

Corresponding author

Ethics declarations

Ethical approval

Not applicable

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Tollu, G., Yabalak, E., Özdemir, S. et al. Synthesis of CaO-Fe and CaO-Ag nanocomposites using raw and hydrolyzed waste chicken eggshell and investigation of their antimicrobial, biofilm inhibition activity, DNA cleavage ability, and antioxidant activity properties. Biomass Conv. Bioref. (2024). https://doi.org/10.1007/s13399-024-05271-4

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13399-024-05271-4