Abstract

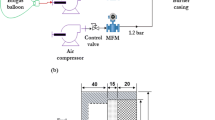

Combustion in porous burners (PBs) highly rely on the material of the media. Current study conducts an experimental exploration on various kinds of porous material and their feasibility on being used in a PB. The in-house developed PB is double layered, consisting of preheat zone (PZ) and combustion zone (CZ). The materials used in PZ and CZ for study are alumina, silicon carbide, zirconia, and mild steel. Moreover, the effect of varying shapes (square and circular), porosity (7 to 90%), and thickness also have been investigated. The effect of using different materials along with the above mentioned parameters has been analyzed based on the lean stable combustion range, temperature distribution, and exhaust gas emissions (CO and NOx) of the PB. Locally available biogas was used as the fuel for combustion. The methane and carbon dioxide composition of the biogas varied between 43–56% and 34–38%, respectively. The porous materials were tested in the firing rate of 5 to 10 kW. The investigation showed that the combination of silicon carbide as CZ and alumina as PZ delivered the most favorable results. This pair was able to provide lean combustion limits (equivalence ratio, 0.75–0.97) and significantly low exhaust emissions. The minimum values of exhaust CO and NOx were as low as 101 ppm and 3.4 ppm, respectively.

Similar content being viewed by others

Data availability

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

Abbreviations

- Al2O3 :

-

Alumina

- CH4 :

-

Methane

- CO:

-

Carbon monoxide

- CO2 :

-

Carbon dioxide

- CZ:

-

Combustion zone

- d :

-

Diameter of the porous ceramic

- LCFG:

-

Low calorific fuel gas

- LCFGWO:

-

Low calorific fuel gas without oxygen

- LCV:

-

Low calorific value (J/kg)

- LHV:

-

Lower heating value (J/kg)

- MFM:

-

Mass flow meter

- NG:

-

Natural gas

- NOx :

-

Nitrous oxides

- P i :

-

Input power (kW)

- PB:

-

Porous burner

- ppm:

-

Parts per million

- RZ:

-

Reaction zone

- SiC:

-

Silicon carbide

- T :

-

Temperature (°C)

- t :

-

Thickness

- ϕ :

-

Equivalence ratio

- ε :

-

Porosity (%)

References

El-Dalatony MM, Sharma P, Hussein EE, Elnaggar AY, Salama ES (2022) Pig- and vegetable-cooked waste oils as feedstock for biodiesel, biogas, and biopolymer production. Biomass Convers Biorefin. https://doi.org/10.1007/s13399-021-02281-4

Karaeva JV, Timofeeva SS, Bashkirov BVN (2023) Thermochemical processing of digestate from biogas plant for recycling dairy manure and biomass. Biomass Convers Biorefin 13:685–695. https://doi.org/10.1007/s13399-020-01138-6

Al-Da’asen A, Al-Harahsheh A, Al-Hwaiti M (2022) Biogas production via anaerobic codigestion of chemically treated wheat straw with sewage sludge or cow manure. Biomass Convers Biorefin. https://doi.org/10.1007/s13399-022-02760-2

Kambiz V (2015) Handbook of porous media. CRC Press

Pantangi VK, Karuna KASSR, Mishra SC, Sahoo N (2007) Performance analysis of domestic LPG cooking stoves with porous media. RERIC Int Energy J 8:139–144 http://rericjournal.ait.ac.th/index.php/reric/article/view/203/150

Kurchania AK, Panwar NL, Pagar SD (2011) Development of domestic biogas stove. Biomass Convers Biorefin 1:99–103. https://doi.org/10.1007/s13399-011-0011-5

Kesting A, Pickenacker O, Trimis D, Durst F (1999) Development of a radiation burner for methane and pure oxygen using the porous burner technology. In: Proc. Int. Conf. Technologies and Combust. Clean Environ. (Clean Air V), Lisbon, Portugal

Trimis D, Durst F (1996) Combustion in a porous medium - advances and applications. Combust Sci Technol 121:153–168. https://doi.org/10.1080/00102209608935592

Weinberg FJ (1971) Combustion temperatures: the future? Nature 233:239–241. https://doi.org/10.1038/233239a0

Fateev GA (1972) Heat transfer in a reacting porous body during filtration of a gas. Foreign Technology Division, Wright-Pattrerson AFB, Ohio Accession number: AD0745460

Mujeebu MA, Abdullah MZ, Bakar MA, Mohamad AA, Muhad RMN, Abdullah MK (2009) Combustion in porous media and its applications-a comprehensive survey. J Environ Manage 90:2287–2312. https://doi.org/10.1016/j.jenvman.2009.09.017

Devi S, Sahoo N, Muthukumar P (2020) Experimental studies on biogas combustion in a novel double layer inert porous radiant burner. Renew Energy 149:1040–1052. https://doi.org/10.1016/j.renene.2019.10.092

Kaushik LK, Mahalingam AK, Muthukumar P (2020) Performance analysis of a biogas operated porous radiant burner for domestic cooking application. Environ Sci Pollut Res 28:12168–12177. https://doi.org/10.1007/s11356-020-10862-5

Tong TW, Li W (1995) Enhancement of thermal emission from porous radiant burners. J Quant Spectrosc Radiat Transf 53:235–248. https://doi.org/10.1016/0022-4073(95)90010-1

Yu B, Kum SM, Lee CE, Lee S (2013) Combustion characteristics and thermal efficiency for premixed porous-media types of burners. Energy 53:343–350. https://doi.org/10.1016/j.energy.2013.02.035

Tiwari A, Alenezi MR, Jun SC (2006) Advanced composite materials. John Wiley & Sons

Krittacom B, Kamiuto K (2009) Radiation emission characteristics of an open-cellular porous burner. J Therm Sci Technol 4:13–24. https://doi.org/10.1299/jtst.4.13

Hale MJ, Bohn MS (1993) Measurement of the radiative transport properties of reticulated alumina foams. In: ASME/ASES Joint Solar Energy Conf. NREL, New York DOE Contract Number: AC02-83CH10093

Wang G, Tang P, Li Y, Xu J, Durst F (2019) Flame front stability of low calorific fuel gas combustion with preheated air in a porous burner. Energy 170:1729–1288

Herrera B, Cacua K, Villalba LO (2015) Combustion stability and thermal efficiency in a porous media burner for LPG cooking in the food industry using Al2O3 particles coming from grinding wastes. Appl Therm Eng 91:1127–1133. https://doi.org/10.1016/j.applthermaleng.2015.08.079

Keramiotis C, Katoufa M, Vourliotakis G, Hatziapostolou A, Founti MA (2015) Experimental investigation of a radiant porous burner performance with simulated natural gas, biogas and synthesis gas fuel blends. Fuel 158:835–842. https://doi.org/10.1016/j.fuel.2015.06.041

Barra AJ, Diepvens G, Ellzey JL, Henneke MR (2003) Numerical study of the effects of material properties on flame stabilization in a porous burner. Combust Flame 134:369–379. https://doi.org/10.1016/S0010-2180(03)00125-1

Devi S, Sahoo N, Muthukumar P (2022) Effect of combustion zone material on the thermal performance of a biogas-fuelled porous media burner: experimental studies. Biomass Convers Biorefin 12:1555–1563. https://doi.org/10.1007/s13399-020-01073-6

Gao H, Qu Z, Feng X, Tao W (2014) Combustion of methane/air mixtures in a two-layer porous burner: a comparison of alumina foams, beads, and honeycombs. Exp Therm Fluid Sci 52:215–220. https://doi.org/10.1016/j.expthermflusci.2013.09.013

Bubnovich VI, Zhdanok SA, Dobrego KV (2006) Analytical study of the combustion waves propagation under filtration of methane-air mixture in a packed bed. Int J Heat Mass Transf 49:2578–2586. https://doi.org/10.1016/j.ijheatmasstransfer.2006.01.019

Gao H, Qu Z, Tao W, He Y, Zhou J (2011) Experimental study of biogas combustion in a two-layer packed bed burner. Energy Fuel 25:2887–2895. https://doi.org/10.1021/ef200500j

Gao HB, Qu ZG, Tao WQ, He YL (2013) Experimental investigation of methane/(Ar, N2, CO2)–air mixture combustion in a two-layer packed bed burner. Exp Therm Fluid Sci 44:599–606. https://doi.org/10.1016/j.expthermflusci.2012.08.023

Keramiotis C, Founti MA (2013) An experimental investigation of stability and operation of a biogas fueled porous burner. Fuel 103:278–284. https://doi.org/10.1016/j.fuel.2012.09.058

Huang R, Cheng L, Qiu K, Zheng C, Luo Z (2016) Low-calorific gas combustion in a two layer porous burner. Energy Fuel 30:1364–1374. https://doi.org/10.1021/acs.energyfuels.5b02399

Wang G, Shi Z, Xu G, Luo D, Xu J (2022) Experimental study on the combustion of low-calorific NG/N2 in a porous burner. Energy Sci Eng 10(4):1202–1213. https://doi.org/10.1002/ese3.1095

Zhou H, Wang G, Tu H, Luo D, Xu J (2023) Combustion temperature in a three-dimensional porous stove with a high-fidelity structure. Appl Therm Eng 233:121108. https://doi.org/10.1016/j.applthermaleng.2023.121108

Avdic F (2004) Application of the porous medium gas combustion technique to household heating systems with additional energy sources (Doctoral dissertation, Erlangen, Nürnberg, Univ., Diss.)

Kline SR, McClintock FA (1953) Describing uncertainties in single sample experiments. Mech Eng 75:3–8

Funding

This work was supported by Ministry of Human Resource and Development (MHRD), Govt. of India [Project Number: IMPRINT – 6727].

Author information

Authors and Affiliations

Contributions

Dr. SD: methodology, investigation, data curation, analysis, and writing—original draft. Prof NS: supervision and writing—review and editing. Prof. PM: conceptualization, supervision, and writing—review and editing.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Devi, S., Sahoo, N. & Muthukumar, P. Impact of porous materials on the performance of a biogas porous burner. Biomass Conv. Bioref. (2024). https://doi.org/10.1007/s13399-023-05240-3

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13399-023-05240-3