Abstract

The current research is focused to address the implementation of nanobubbles technology to antibacterial agents against Staphylococcus aureus infections. Nanobubbles technology is a novel, latest research employed in many medical fields including drug discovery. In this present work, supramolecular nanoliquid formulation of potential antiseptic agent chloroxylenol-based Dettol and its enhanced antibacterial activity, biocompatibility assessment was studied. Nanobubble technology was adopted to prepare nanoformulation (NB-D) using a household hand mixer under thermostatically controlled conditions. A high-stability nanoformulation with high potential antibacterial activity against human pathogenic strains of Pseudomonas aeruginosa and Staphylococcus aureus was produced by the nanobubbles created in the antiseptic solution. The overall vitality of both strains was significantly reduced in all dose tests on NB-D treatment as a result of the antibacterial activity as assessed by the well-diffusion assay, turbidometric microdilution assay, biofilm inhibition assay, and total count reduction assay. Biocompatibility of the NB-D formulation was studied by the determination of cytotoxicity against HaCaT—human keratinocytes and hemocytes. NB-D treatment did not induce any notable cytotoxic effect on HaCaT cells by showing none of the changes in cell morphology and architecture. No toxic effect on the hematocytes was observed in NB-D treatment. The enhanced antibacterial activity and best biocompatibility of NB-D result shows that the nanobubble technology could be used as an effective strategy for the formulation of antiseptics or disinfectants against high health risk infectious organisms. The novelty of the work is the formation of supramolecular nanoformulation on antiseptic agent which promised the results enhanced than the raw antiseptic agent.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Reasonable interest has been sparked by the necessity to treat illnesses caused by multidrug-resistant (MDR) microorganisms (Sharada et al. 2013). Disinfectants serve a key role in preventing infectious organisms and are a crucial component of the infection control strategy (Okore et al. 2014). Dettol is a basic chloroxylenol-based disinfectant that is frequently used in household and healthcare facilities for a variety of tasks, including the cleaning of environmental surfaces, items, and skin. Dettol-H and Alpilon were considered sufficient dilutions for the different organisms tested (Kapoor et al. 1998). Antimicrobial activity of Dettol adopting paper disc agar diffusion assay against pathogenic microorganisms reported (Mahmood et al. 2008) that strong micro biocidal activity is due to damage of the cell wall, cell membrane, and protein precipitation. The distinct antimicrobial properties of chloroxylenol, Dettol’s primary chemical component, and other chlorinated phenol are highly effective against a wide range of microorganisms known to kill bacterial vegetative cells, fungi, and most viruses. The nanobubble-based drug carrier system focuses on enhancing antimicrobial effectiveness properties against a wide range of pathogens known to cause severe health complications (Cavalli et al. 2016). The inactivation of the Ebola virus’s effect during outbreaks is possible by the effective use of the Dettol disinfection agent (Todd A. Cutts et al. 2019). A recent study on hygiene products such as Dettol and Lysol revealed that these products are efficient enough to break the chain of COVID-19 infection (M Khalid Ijaz et al. 2020). Established cell culture-based techniques can be used as a valuable tool for screening of toxicity of the various compounds (Li et al. 2022). For instance, P. aeruginosa and S. aureus could coexist, at least in the initial phases of infection, in acute wound infection models that include serum in the growth medium. Interspecific interactions therefore looked to be tightly controlled and reliant on the environment. Since P. aeruginosa excretes virulence agents, such as pyoverdine, pyocyanin, and elastases, intercellular communication impacts the synthesis of such component strains.

Previous study demonstrated the efficacy of the secondary metabolites (lariciresinol and berberine) of the North-Western Himalayan region's Zingiber officinale Roscoe against MDR Salmonella typhimurium by inhibiting the efflux pump (Parmanik et al. 2022). The results showed that lariciresinol decreased the MIC by two-to-fourfold, while berberine boosted antibacterial activity by two-to-fourfold. Lariciresinol was found to have the capacity to block the efflux pump and kill drug-resistant S. typhimurium. Saponins and bromo-polyphenols, which are plant-derived secondary metabolites, were discovered to be effective against MDR pathogens (E. coli and M. tuberculosis) isolated from Ganga river water, milk, and chicken flesh. Compared to the usual rifampicin antibiotics, there was a significantly greater inhibition of bacterial RNA polymerase. These phytoconstituents could be employed as therapeutic adjuncts in the future to help prevent and treat MDR bacterial infections; it was determined (Chakraborty et al. 2022).

There are numerous ways to block the systems that control MDR transporters (Akan et al. 2005). Cytotoxic medications cause the MDR protein gene to express in tumor cells, but a number of pharmacological inhibitors that interfere with signaling pathways prevent this gene expression (Feldmann et al. 2006). By directly interacting with and activating the nuclear steroid and xenobiotic receptor (SXR), taxol was shown to activate the expression of the MDR1 and cytochrome p450 3A4 (CYP3A4) genes, increasing drug resistance and accelerating drug clearance. Hence, to deal with the up-regulation of MDR1 and CYP3A4, antagonists of the nuclear steroid and xenobiotic receptor may be used in addition to anticancer medications.

Avoiding the total elimination of bone marrow stem cells is a critical dose-limiting toxicity factor for anticancer medications (Sarkadi et al. 2004). By transferring vectors containing the MDR1 cDNA into bone marrow cells, Gottesman et al. were able to create multidrug-resistant cells. With this process, they were able to administer a chemotherapy treatment at levels that would have previously been intolerable, defeating MDR (Asadi et al. 2020).

Current research suggests that a mutant ABCG2 protein is a prime option for gene therapy selectable markers and human stem cell protection (Chen et al. 2011). This protein’s cDNA is only approximately 2 kb in size, and the overexpressed cells spontaneously produce the active dimer. The R482G variation of ABCG2 offers a distinct benefit in gene therapy applications, because it has different substrate specificity from the wild-type protein. The use of an apoptosis-inducing monoclonal antibody targeted against the CD20 receptor is a unique method for evading MDR processes. Chemotherapy is more effective when drug-sensitive cells are forced to undergo apoptosis.

Though, glutathione (GSH) is likely to play a role in the development of the resistance, the precise mechanism by which MRP1 is implicated in multidrug resistance is yet unclear. A pro-glutathione medication is called N-acetylcysteine (NAC). BSO, or dl-Buthionine (S,R)-sulfoximine, prevents the production of GSH. We recently looked at how NAC and BSO affected the MRP1-mediated resistance to vincristine and doxorubicin in human embryonic kidney (HEK293) and its MRP1 transfected 293MRP cells. A plasmid encoding the entire MRP1 gene was transfected into human embryonic kidney (HEK293) cells.

Materials and methods

Reagents, chemicals, and culture media

Dettol (Reckitt Benckiser Private Ltd, Mysore, Karnataka, India) as a commercially formulated product was obtained from the Medical store, Sholinganallur, Chennai. Active ingredients of this formulation are as follows: Chloroxylenol 4.8% (v/v), Tertineol − 9.0%, Alcohol (denaturized)—13.1% Reagents, and chemicals used for further studies were obtained as analytical grade used without any purification. The culture media used for the antibacterial study were purchased from Hi-Media (Mumbai), India. Media and reagents for the cell culture studies were obtained from Sigma-Aldrich. Dimethyl Sulphoxide (DMSO) was obtained (Merck). All solutions were made with Millipore water.

Preparation of nanobubble formulated Dettol (NB-D)

The Nanobubble formulation generation was carried out by minor modification of our recent study using a household hand mixer as per the procedure stated in our earlier publication (G. Senthilkumar et al.), as shown in Fig. 1.

The size of NBs was in the order of 80–100 nm, as revealed by AFM. The dynamic light scattering (DLS) was used to examine the particle-size distribution. The primary characterization of NB-D was carried out by atomic force microscopy (AFM). Sample preparation is an essential part of AFM analysis, which involves placing 100 µL of the sample in a clean glass slide and allowed to dry at room temperature to get a thin film of the sample. The AFM analysis was performed using AFM Ntegra Prima-NTMDT, Ireland, and the zeta potential and particle size were performed using the Zetasizer (Malvern, UK) at 25 °C. Averages of three replicates are taken for results and discussion.

Antibacterial activity

The determination of antibacterial activity was carried out by the modified method of agar diffusion assay (qualitative) and microdilution broth turbidometric assay against human pathogenic strains Pseudomonas aeruginosa (ATCC 10,145) and Staphylococcus aureus (ATCC 12,034). The effect of NB-D on the survival rate and death rate was also studied. Further, the biofilm inhibition adopting spectrophotometric crystal violet assay was performed to confirm the antibacterial activity.

Bacterial strains

American Type culture collection strains Pseudomonas aeruginosa (ATCC 10,145) and Staphylococcus aureus (ATCC 12,034) were selected in the study. The respective strain on trypticase soy agar slant was maintained with pure culture. Subculturing was done every 10 day interval using trypticase soy broth.

Inoculum preparation

Trypticase soy broth was employed for inoculum preparation. Tryptic soy broth was inoculated with a loopful slant culture of bacterial strain and incubated at 37 ℃ for 12 h under vibrating condition.

Evaluation of stability

Stability of Nanoformulation was checked by exposing the sample at ambient temperature (30 °C) for 30 days. At different time periods, the sample was withdrawn aseptically, and the stability studies were carried out. Stability study for antibacterial activity of NB-D samples collected at different time intervals using well-diffusion assay, microdilution broth turbidometric assay, and determination of survival rates against the tested bacterial strains was conducted.

Results

Characterization of nanobubble formulation

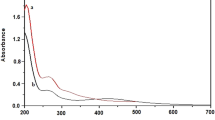

Figure 1 shows three-dimensional images of the mechanical stirrer used for Nanobubble generation. AFM and particle-size analysis did the primary characterization of Nanobubble formulation. A glass sheet was taken in which 100 µL of Nanoformulation was kept till it was dried and subjected to AFM. Figure 3 depicts the surface morphology of generated nanobubbles, with surface roughness of 1.546 nm. Figures 2 and 3 show a 2D, 3D morphology in horizontal and vertical axis (1 micrometer = 100 nanometers). The respective graphs of each bubble are shown in the right side of Fig. 4.

Evaluation of enhanced antibacterial activity

The zone of inhibition of Dettol against P. aeruginosa and S. aureus was found to be 12 0.0 and 14.4 mm, and an increase in zone of inhibition against both the tested strains was increased in Nanobubble treatment, which recorded 21.0 and 24.0 mm as revealed from Fig. 5. Table 2 shows that the Nanobubble exhibited inhibition of both the tested strains at a lower concentration.

Stability

The stability of NB-D was checked by exposing the formulation at ambient temperature (30 °C) for 10, 20, and 30 days. After the respective period of incubation, the average particle size and roughness were measured using atomic force microscopy (AFM).

Discussions

Ultra-small gas bubbles in liquid with diameters of micron and submicron-order, the so-called micro-Nanobubbles, play a significant role in various fields of science and technology, and their application in diverse fields is massive due to specific characteristic physical and chemical properties like buoyancy behavior (slow), unique surface charges (negative), free radical formation, and increased water molecule mobility. In this study, Nanobubble generated chloroxyphenol based antiseptic agent Dettol was prepared by the method of our recent study using mechanical stirring (Senthilkumar et al. 2018).There are various mechanisms by which the primary confirmation study with a good diffusion assay indicates an effective inhibition of both the tested bacterial strains. It can be seen that both the tested strains were susceptible to the respective samples (Table 1).

However, a significant difference was recorded in Nanobubble samples (P = 0.005), which reveals enhanced activity against both the tested strains (Table 1). Figure 5 shows the antibacterial activity of samples, which indicates an increase in the inhibition zone in Nanobubble concentration.

A similar effect was observed in the MBC study, indicating the high antibacterial potential of Nanobubble samples. The biofilm inhibitory effect against tested bacterial strains was characterized with spectrophotometric assay. Figure 6 indicates an influence on the formation of biofilm NB-D formulation.

MIC of Dettol against P. aeruginosa and S. aureus were 0.25 and 0.30 ml, and the Nanobubble samples show 0.12 and 0.15 ml, respectively (Table 2).

Adherent bacterial communities on solid surfaces covered with a protective matrix of extracellular polymeric substance (EPS) termed as biofilm now recognized as the major virulence factors of most of the pathogenic microorganisms by aiding in attachment or adherence of the bacterial cells to the host tissue, prevent the entry of antibiotics or other chemotherapeutic molecules and serve to promote bacteria persistence by resisting antibiotic treatment and host immune responses (Baker and Banfield 2003, Baillie and Douglas 2000). In this study, the biofilm inhibitory effect of NB- D was determined by determining the optical density or absorbance of ethanol solubilized mixture of adherent biofilm in a microtitre plate. The results were represented as an inhibitory percentage. However, free Dettol brought about biofilm inhibition. The inhibitory effect was observed as a dose-dependent manner, which reveals that Dettol's maximum dosage recorded high inhibition with the tested samples, unlike the high inhibitory effect of NB-D with all the dosages. The vulnerability of the cell aggregates caused damages in both free and Nanoformulation. Both of the examined bacterial strains' biofilm showed total biofilm destruction due to fragmentation or disintegration into free-floating cells after receiving NB-D treatment, which was followed by complete dehydration (Figs. 7, 8).

Figure 9 illustrates data derived from variations in the total viable count of respective bacterial strains treated with NB-D. These data show that entire viability was lost in both free and NB-D treatments, and the rate of decrease was found to be higher at longer time intervals.

DRT was substantially higher than free Dettol for both of the tested strains, as shown in Fig. 10. Free Dettol (FD) reported 5.01 min for P. aeruginosa, compared to 1.21 min for NB-D. S. aureus showed a similar result.

The enhanced anti-biofilm effect of the Nanoformulation may be the result of the biochemical components of the biofilm matrix degrading, which in turn affects the biofilm's structural integrity. Additionally, the Nanobubble created in the antiseptic solution facilitated the rapid diffusion of chloroxylenol, an active biocidal compound of Dettol, through the channels present in the matrix, followed by the sustained release, which results in effective antimicrobial activity. To further investigate the antibacterial activity of NB-D, total viability (%), decimal reduction time, lag L, and lag E were determined (extrapolation number). study of the death curves and lag Nt/No of the tested bacterial strains. According to Fig. 11, the NB-D therapy showed a substantial difference in lag L and Lag E. Compared to free Dettol, NB-D therapy resulted in a lower lag L and a greater lag E. (FD). It is evident from the results that NB-D had a longer initial growth time (Lag phase) and a smaller lag E (active phase), which may be related to the controlled or sustained release of chloroxylenol, an active ingredient in Dettol that promotes interaction with viable cells of the tested pathogenic strains.

Additionally, the free lag Nt/No and the NB-D reveal a negative slope (Fig. 12). These results show that NB-D had stronger antibacterial activity against both of the tested bacterial strains, which was supported by the successful viability reduction.

Results indicate that particle size and measured roughness were not changed in all the tested time periods (Fig. 13). The particle size and roughness pattern remain the same in the respective time period (Fig. 14).

No significant difference (P = 0.5%) in both tested parameters of the NB-D during the incubation period indicates the high state of stability. The Nanobubble stability was influenced by various parameters like time of mechanical stirring, the addition of various adjuvants. A study by Ohmori et al. reveals the addition of ethanol and NaCl to Nanobubble water caused specific changes in the particle size. Further, stability was determined by the evaluation of enhanced antibacterial activity. Further, stability was examined by measuring antibacterial activity changes, adopting well-diffusion assay, turbidometric microdilution assay, and determination of survival rates. The significant difference in the zone of inhibition, minimum inhibitory concentration (MIC), viability, decimal reduction time, lag L and Lag E, and log No/Nt parameters was not noticed in the samples exposed to different time periods. In well-diffusion assay, the zone of inhibition recorded at respective storage time of NB-D treatment did not exhibit any changes (Table 3).

A similar result was also observed in MIC and MBC studies, showing no remarkable effect (Table 4). Further confirmation of stability was also inferred from the total count data, revealing no count reduction in the NB-D kept at the respective periods. No significant variation on the viability (%), decimal reduction time, lag L and extrapolation number, and log No/Nt in the NB-D were exposed to different time periods (Figs. 15, 16, 17, 18, 19, 20, 21, 22, 23, 24).

Conclusion

In recent years, Nanobubble-guided delivery of chemotherapeutics has been the focus of increasing attention to enhance antimicrobial activity. In the present study, the Nanobubble formulation of commonly used chloroxylenol-based antiseptic agent Dettol has been evaluated for the enhanced antibacterial activity strains and its non-target effect. The mechanical stirring process was employed for NB-D preparation, and this process brought about high stable Nanobubble with a size range of 260–290 nm. Prepared NB-D exhibited enhanced antibacterial activity by adopting well-diffusion assay, microtitre plate spectrophotometric crystal violet assay, turbidometric broth dilution assay, and total viability (%) decimal reduction time, lag L & lag E (extrapolation number), log Nt/No studies, respectively, than free Dettol. Such NB-D motifs have a high safety profile, according to in vivo safety assessments. These tiny compounds have the potential to be researched further and developed into fresh antibacterial treatments for MDR infections. The solvent exchange method, hydrodynamic cavitation method, electrolysis, gas–liquid circulation method, and temperature change method can be adopted for NB-D preparation to test the efficacy, as future study.

Data availability statement

All the data related to this research are included in the manuscript.

References

Agarwal A, Ng WJ, Liu Y (2011) Principle and applications of microbubble and Nanobubble technology for water treatment. Chemosphere 84:1175–1180

Akan, I., Akan, S., Akca, H., B. Savas, T. Ozben., (2005) Multidrug resistance-associated protein 1 (MRP1) mediated vincristine resistance: effects of N-acetylcysteine and Buthionine sulfoximine. Cancer Cell Int 5 22–32.

Alford MA, Mann S, Akhoundsadegh N et al (2022) Competition between Pseudomonas aeruginosa and Staphylococcus aureus is dependent on intercellular signaling and regulated by the NtrBC two-component system. Sci Rep 12:9027. https://doi.org/10.1038/s41598-022-12650

Asadi A, Abdi M, Kouhsari E, Panahi P, Sholeh M, Sadeghifard N et al (2020) Minocycline, focus on mechanisms of resistance, antibacterial activity, and clinical effectiveness: Back to the future. Journal of Global Antimicrobial Resistance 22:161–174

Cavalli R, Soster M, Argenziano M (2016) Nanobubbles: a promising efficient tool for therapeutic delivery. TherDeliv 7(2):117–138

Chakraborty AK, Saha S, Poria K, Samanta T, Gautam S, (2022) Mukhopadhyay J. A saponin-polybromophenol antibiotic (CU1) from Cassia fistula bark against multi-drug resistant bacteria targeting RNA polymerase. Curr Res Pharmacol Drug Discov https://doi.org/10.1016/j.crphar.2022.100090.

Chioma C. Okore, Ogechukwu N. Mbanefo Bright C. Onyekwere, Simon C. OnyewenjoAgaptus U. Ozurumba1, Chinyere A.M. (2014) Abba-FatherAntimicrobial efficacy of selected disinfectants American Journal of Biology and Life Sciences 2 (2): 53-57

Chen M, Yang Z, Wu H, Pan X, **e X, Wu C (2011) Antimicrobial activity and the mechanism of silver nanoparticle thermosensitive gel. Int J Nanomedicine 6:2873–2877

Cooley MB, Abenojar EC, Wegierak D, Sen Gupta A, Kolios MC, Exner AA. (2022) Characterization of the interaction of nanobubble ultrasound contrast agents with human blood components. Bioact Mater 19: 642-652. doi: https://doi.org/10.1016/j.bioactmat.2022.05.001. PMID: 35600972; PMCID: PMC9109121.

Cutts, Todd.A., Ijaz, M.K., Nims, R.W. et al. (2019) Effectiveness of Dettol Antiseptic Liquid for Inactivation of Ebola Virus in Suspension. Sci Rep. https://doi.org/10.1038/s41598-019-42386-5

Feldmann H (2006) Mechanisms and strategies to overcome multiple drug resistance in cancer. FEBS Lett 580:2903–2909

Gao-Feng Zha, Habbanakuppe D. Preetham, Shobith Rangappa, Kothanahally S. Sharath Kumar, Yarabahally R. Girish, Kadalipura P. Rakesh, Milad Ashrafizadeh, Ali Zarrabi, Kanchugarakoppal S. Rangappa (2021) Benzimidazole analagues as efficient arsenals in war against methicillin-resistance staphylococcus aureus (MRSA) and its SAR studies. Bioorganic Chemistry 115 (2021) 105175

Gobinath S, Senthilkumar G, Beemkumar N (2019) Air Nanobubble-enhanced combustion study using mustard biodiesel in a common rail direct injection engine. Energy Sources, Part a: Recovery, Utilization, Environ Effects 41(15):1809–1816

Hampton MA, Nguyen AV (2010) Nanobubbles and the nanobubblebridging capillary force. AdvColl Interface Sci 154(2):30–55

Hayakumo S, Arakawa S, Takahashi M, Kondo K, Mano Y, Izumi Y (2014) Effects of ozone nano-bubble water on periodontopathic bacteria and oral cells - in vitro studies. Sci Technol Adv Mater 15:055003

Kapoor H, Muralidhar S, Jais M, Thakur R, Aggarwal P (1998) Evaluation of efficacy of Dettol-H in hospital use. J Commun Dis 30(2):167–170

M Khalid Ijaz et al. (2020) Microbicidal Actives with Virucidal Efficacy against SARS-CoV-2: AJIC, American Journal of Infection Control, https://doi.org/10.1016/j.ajic.2020.05.015.

Kim, Soo-Hwan Hyeong-Seon Lee, Deok-SeonRyu, Soo-Jae Choi, Dong-Seok Lee. (2011) Antibacterial activity of Silver-nanoparticles against Staphylococcus aureus and Escherichia coli.Korean J Micro biol Biotechnol; 39 (1) 77–85.

Li T,Jia Z Chunlei Z, **ao Z, Jiaqi N, Hualin F, Jie S, Daxiang Cui, (2018) Surface-engineered Nanobubbles with pH-/light-responsive drug release and charge-switchable behaviors for active NIR/MR/US imaging-guided tumor therapy. NPG Asia Materials 10: 1046-1060

Liu G, Wu Z, Craig VSJ (2010) Cleaning of protein-coated surfaces using Nanobubbles: an investigation using a quartz crystal microbalance. J Phys Chem Part C 112(1):16748–16753

Liu S, Kawagoe Y, Makino Y, Oshita S (2013) Effects ofnanobubbles on the physicochemical properties of water: The basis for peculiar properties of water containing Nanobubbles Chem. Eng Sci 93:250–256

Liu, Y. Otsuka, Y. Kawagoe, Y. Makino, S. Oshita, (2012) Effects of the water containing Nanobubbles on metabolic activities of barley seeds, Proceedings of the sixth international symposium on machinery and mechatronics for agriculture and Biosystems engineering (ISMAB). 18–20

Mahmood ME, Doughari JH (2008) Effect of Dettolon viability of some microorganisms associated with nosocomial infections. Afr J Biotech 7(10):1554–1562

Ofonime M. Ogba, Patience E. Asukwo, Iquo B. Otu-Bassey, (2018) Assessment of bacterial carriage on the hands of primary school children in Calabar municipality, Nigeria, Biomedical Dermatology https://doi.org/10.1186/s41702-017-0017-0.

Ohnari H (2001) Fisheries experiments of cultivated shells using micro-bubbles techniques. J Heat Transfer Soc Jpn 40:2–7

Parmanik A, Das S, Kar B, Bose A, Dwivedi GR, Pandey MM, (2022) Current Treatment Strategies Against Multidrug-Resistant Bacteria: A Review. Curr Microbiol. 2022 79 (12):388. doi: https://doi.org/10.1007/s00284-022-03061-7. PMID: 36329256; PMCID: PMC9633024

Prudhvi Krishna Amburi, G. Senthilkumar, Ibsa (2022) Neme Mogose. Heat Transfer Augmentation: Experimental Study with Nanobubbles Technology Advances in Materials Science and Engineeering https://doi.org/10.1155/2022/5885280.

Rameshkumar C, Senthilkumar G, Subalakshmi R (2019a) Risa Gogoi, Generation and characterization of Nanobubbles by ionization method for wastewater treatment. Desalin Water Treat. https://doi.org/10.5004/dwt.2019.24389,164,98-101

Rameshkumar C, LakshmiSankar S, Senthilkumar G (2019b) Characterization of seed germination using nanobubbled water. Int J Ambient Energy. https://doi.org/10.1080/01430750.2019.1672581

Rameshkumar C, Senthilkumar G, Subalakshmi R (2021) Purification of tap water to drinking water: Nanobubbles technology. Desalin Water Treat. https://doi.org/10.5004/dwt.2021.27515,233,11-18

Sarkadi B, Ozvegy-Laczka C, Nemet K, Varadi A (2004) ABCG2 – a transporter for all seasons. FEBS Lett 567:116–120

G.Senthilkumar, S.Lakshmi Sankar. (2023) Implementation of Micro-Nanobubbles Technology for the Treatment of Domestic wastewater: Experimental Study. Water, Air and Soil Pollution https://doi.org/10.1007/s11270-023-06071-8. 234:46.

G. Senthilkumar, C. Rameshkumar, M.N.V.S. Nikhil, J. Navin Ram Kumar, (2018) An investigation of Nanobubbles in aqueous solutions for various applications. Applied Nanoscience 8 (6) 1557–1567.

Senthilkumar, G., Musharraf, S. T., Deepak, V. B. (2023) Review on nanobubbles behavior with hydrophobic and hydrophilic surfaces. environmental quality management https://doi.org/10.1002/tqem.21966.

M. Sharada, Jayaram Ashok, HiremathSavitha, H. Mahesh, E.R. Nagaraj (2013) comparative effectiveness of disinfectants with phenol onMultidrug resistant bacteria and fungi isolated from theClinical sample – an in vitro preliminary study Journal of Evolution of Medical and Dental Sciences 2 (18) 3055–3061.

R. Steitz, T. Gutberlet, T. Hauss, BeateKlosgen, R. Krastev, S. Schemmel, A.C. Simonsen, G.H. (2003) Findenegg, Nanobubbles and their precursor layer at the interface of water against a hydrophobic substrate, Langmuir. 19 (6) 2409–2418.

Rameshwari Verma, Santosh Kumar Verma, Kadalipura P. Rakesh, Yarabahally R. Girish, Milad Ashrafizadeh, Kothanahally S. Sharath Kumar, Kanchugarakoppal S. Rangappa, (2021b) Pyrazole-based analogs as potential antibacterial agents against methicillin-resistance staphylococcus aureus (MRSA) and its SAR elucidation, European Journal of MedicinalChemistry https://doi.org/10.1016/j.ejmech.2020.113134.

Uchida T, Ohshita S, Ohmori M, Tsuno T, Soejima S, Shinozaki S, Take Y, Mitsuda K (2011) Transmission electron microscopic observations of Nanobubbles and their capture ofimpurities in wastewater. Nanoscale Res Lett 6:295

Acknowledgements

We acknowledge the Centre for Nanoscience & Nanotechnology, Sathyabama Institute of Science & Technology for AFM analysis.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Research Involving Human Participants and/or Animals

The authors declare that no Human participants and/or Animals involved in this research.

Ethical approval

For this type of study, informed consent is not required.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Senthilkumar, G., Aravind Kumar, J. Nanobubbles: a promising efficient tool for therapeutic delivery of antibacterial agents for the Staphylococcus aureus infections. Appl Nanosci 13, 6177–6190 (2023). https://doi.org/10.1007/s13204-023-02854-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13204-023-02854-x