Abstract

Operational requirements of photovoltaic (PV) modules result in their inherent exposure to harsh environmental conditions. The performance of solar cells decreases with increasing temperature, with both efficiency and power output getting affected. High ambient temperature coupled with irradiance absorption leads to an elevated photovoltaic cell operating temperature, adversely affecting the panels' lifespan. Superhydrophobic nanocoatings are the preferred solution to reduce the accumulation of dust (soiling) over the surface of the panels. This article aims to study the effects of nanocoatings on module operating temperature and temperature-dependent cell parameters, such as open-circuit voltage (\({V}_{\mathrm{oc}}\)), short-circuit current (\({I}_{\mathrm{sc}}\)) and power generation. The application of nanocoating over the surface of solar panels reduces the operating temperatures while improving power generation in a temperate location with high annual atmospheric temperatures.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Solar photovoltaic (PV) generation, with an increase of 23% in 2020, is the second-fastest-growing renewable technology (IEA 2021a). With an exponential rise in installed capacity and substantial research in improving conversion efficiencies, PV is now the third-largest renewable electricity technology (almost 3%) in global electricity generation after hydropower and onshore wind (IEA 2021b). Solar cells absorb a significant portion of the incident solar radiation and transform only a range of wavelengths of the spectrum of light into electricity, depending on the conversion efficiency of the cell technology (Wysocki and Rappaport 2004). The remainder of the incident radiation gets converted to heat, raising the solar cell temperatures. Detrimental phenomena, such as dust accumulation on PV panels (soiling) (Chanchangi et al. 2020), increased cell operating temperatures, etc., reduce the panel’s conversion efficiency and operational lifetime (Idoko et al. 2018). Meta-analysis studies have found that the long-term degradation rate of the commonly used mono-crystalline silicon panels is close to 0.4% per year under nominal operating conditions (Jordan and Kurtz 2012). It is estimated that a modest 1 °C reduction in operating temperature can extend module life by nearly 2 years (Dupré et al. 2017). Soiling directly reduces the power output of the solar power plant, with the annual power loss due to soiling at the surface reaching up to 50% in some areas (Mani and Pillai 2010). It also causes the formation of local hotspots in the solar cells, which also raises their temperature leading to reduced panel performance and accelerated cell degradation (Kim et al. 2016).

Various methods for regulating temperatures such as air cooling, water cooling, use of heat pipe, phase change materials and thermoelectric cooling have been explored by research works (Shukla et al. 2017) to reduce the adverse effects of temperature on PV cells. While effective in controlling the temperature rise of PV cells, all these techniques involve significant capital expenditure and physical modifications to the plant installation, such as pi**, fixtures, mountings, etc. All these systems will have a long payback period making them economically less feasible (Dwivedi et al. 2020) (Sharaf et al. 2022). Developments in the field of nanomaterials have resulted in the advent of specialized coatings for the panel surface. The commonly used coating types are anti-reflective coatings (ARC) to reduce optical loss of electrical power due to surface reflection and self-cleaning coatings to reduce soiling on the cover glass (Sarkın et al. 2020). The self-cleaning coatings either have water-repelling (hydrophobic) or water-dispersing (hydrophilic) properties (Zhi and Zhang 2018). Sarkın et al. (2020) have conducted a detailed review of anti-reflection and self-cleaning coatings on photovoltaic panels highlighting the pros of both; ARCs reduce reflection, while self-cleaning coatings reduce soiling. Sarkın et al. (2020) also show that fabricating superhydrophobic surfaces stands out among other methods. While both coatings lead to improved cell efficiency and an increase in overall power generation, there is a lack of conclusive studies on the effects of self-cleaning (or superhydrophobic) coatings on module operating temperatures and power generation. Ehsan et al. (2021) conducted detailed research on the impact of superhydrophobic coatings in the mitigation of soiling. They compared various coating formulations, provided a detailed methodology for selecting an appropriate solution and demonstrated nearly 11% improvement in power generation. While the authors have attributed this increase to reduced soiling on the coated surface (nearly 41% lower dust accumulation from the uncoated surface), they have not studied the underlying impacts of temperature effects on the surface by adding a new layer over the existing glass surface.

The present paper is organized as follows: Sect. 2 describes the methodology employed, including the descriptions of the location, solar panels and superhydrophobic nanocoatings. Section 3 presents the results on transmittance, operating temperature and cell parameters, along with an economic analysis of two large-scale, grid-interactive power plants. Finally, Sect. 4 gives conclusions on this work.

Methodology

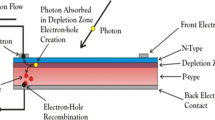

Bare silicon, which forms a vital component of any solar cell, has a high surface reflection of over 30% (PV Education 2022). While the solar radiation spectrum includes bands between 100 nm and 1 mm, encompassing ultraviolet (UV), visible, and infrared (IR) radiation, silicon solar cells typically operate from 400 to 1100 nm (PV Education 2022), which covers the entire range of the visible spectrum (about 380–750 nm). The solar photovoltaic cell does not convert all the light falling on its surface into electricity, even if it is at the right wavelength. Studies show that 8–10% of the incident light is reflected from the clean surface of a cover glass (Sutha et al. 2017). The silicon cell itself reflects 35–36% of the light reaching its surface (Yu et al. 2015). Some of the light energy becomes heat, and some reflect off the cell’s surface. Solar glass manufacturers have also noted that the significant increase in temperature of the glass shifts the infrared absorption edge to shorter wavelengths and the ultraviolet (UV) edge to longer wavelengths due to the broadening of the UV absorption bands (Advanced Optics, SCHOTT AG, Germany 2005), leading to transmission of some infrared and UV wavelengths onto the cell surface. This further increases the surface temperature of the cells. Since solar cells are essentially semiconductors, they are sensitive to temperature (Dhankar et al. 2022). An increase in temperature reduces the semiconductor's bandgap, affecting most material parameters. The open-circuit voltage (\({V}_{\mathrm{oc}}\)), short-circuit current (\({I}_{\mathrm{sc}}\)), maximum power point (\({P}_{\mathrm{max}}\)), fill factor (\(\mathrm{FF}\)), and cell efficiency (\(\eta\)) are all affected by solar cell temperature. \({V}_{\mathrm{oc}}\), \({P}_{\mathrm{max}}\), \(\mathrm{FF}\) and \(\eta\) decrease with cell temperature (negative temperature coefficient), while \({I}_{\mathrm{sc}}\) increases with temperature (positive temperature coefficient) (Chander et al. 2015). The effective irradiance depends on \({I}_{\mathrm{sc}}\) and can be calculated as (IEC 2009)

where \({G}_{\mathrm{eff}}\) is the effective irradiance reaching the solar cells, \({I}_{\mathrm{sc},\mathrm{ STC}}\) is the short-circuit current at Standard Test Conditions (STC), \(T\) is the back of module temperature, \({T}_{\mathrm{o}}\) is the back of module temperature at STC, typically 25 °C, and \(\alpha\) is the temperature coefficient of the short-circuit current. The parameter most affected by an increase in temperature is \({V}_{\mathrm{oc}}\) (Honsberg and Bowden 2019). The temperature dependence of \({V}_{\mathrm{oc}}\) is exemplified by

where \(q\) is the absolute value of electron charge, \(T\) is the absolute temperature (K), \(k\) is the Boltzmann's constant, \({I}_{0}\) is the saturation current, and \({I}_{\mathrm{L}}\) is the light-generated current. The strong negative temperature dependence of \({V}_{\mathrm{oc}}\) results in the negative temperature coefficient of PV conversion (Dupré et al. 2017). The dependence of cell efficiency (\(\eta\)) with temperature is determined by (Dubey et al. 2013)

where \({\eta }_{{T}_{\mathrm{ref}}}\) is the cell’s efficiency at the reference temperature \({T}_{\mathrm{ref}}\) (usually \({T}_{\mathrm{o}}\)), \(\beta\) is the temperature coefficient (around 0.004 K−1) and \({T}_{\mathrm{c}}\) is the current cell temperature.

The impact of increasing temperature on the I–V curve of a typical solar cell is a commonly studied phenomenon. With the increase in temperature, \({I}_{\mathrm{sc}}\) increases slightly, \({V}_{\mathrm{oc}}\) decreases strongly, and the power output reduces. The slight increase in \({I}_{\mathrm{sc}}\), estimated to be around 0.1%/°C (Andreev et al. 1997), originates from the narrowing of the bandgap along with the increase in the number of photons and density of states in the conduction and valence bands. The substantial decrease in \({V}_{\mathrm{oc}}\) is linked to the increase of the leakage current. As a result, \({P}_{\mathrm{max}}\) decreases with increasing temperature (**ao et al. 2014), usually in the range of 0.2–0.5% every 1 °C (Shukla et al. 2017). Hence, the instantaneous power output of a PV module depends on its operating temperature, which in turn depends on the geographical location, climatic conditions, and season.

Experiments to study the effects of superhydrophobic nanocoatings on PV module temperatures are carried out in real-time conditions at Bharat Heavy Electricals Limited (BHEL) campus in Tiruchirappalli, Tamil Nadu, India [10° 48′ 18″ N, 78° 41′ 8″ E]. The location has an elevation of 88 m from sea level (Ehsan et al. 2017). The climatological average annual temperature values of Tiruchirappalli are 27.73 °C (average), 22.86 °C (minimum), and 33.92 °C (maximum) (NASA 2021). With an average clearness index of 0.54, average daylight of 12.13 h and direct normal radiation of 4.77 kWh/m2/day, the location is ideal for large-scale solar power plants (Ehsan et al. 2014). L1280S mono-crystalline silicon modules of 80 Wp peak power manufactured by BHEL’s Solar Business Division (SBD) are used for conducting all the experiments in this work to ensure uniformity in module design and construction. The module’s open-circuit voltage (\({V}_{\mathrm{oc}}\)) and short-circuit current (\({I}_{\mathrm{sc}}\)) at STC are 20 V and 5.2 A, respectively. All the modules used for testing are mounted on a dedicated structure, designed, and fabricated to mimic the actual PV plant installations. The structure has the exact dimensions as the module mounting structure (MMS) of the 5 MWp solar power plant in the BHEL Tiruchirappalli campus. It has a south-facing inclination of 10.8° from the surface, corresponding to the location's latitude. The structure can hold up to four panels simultaneously. Only two panels (one coated and one uncoated) are installed next to each other during the power generation and temperature tests. However, the \({V}_{\mathrm{oc}}\) tests are conducted with four panels mounted simultaneously (one uncoated and three coated). The panels faced no other obstructions, apart from the thermocouples affixed on both top and bottom surfaces.

Various nanocoating formulations are available in the market, claiming to mitigate dust accumulation. However, very few samples are explicitly developed for application over the surface of solar modules. Most are just migrated from other coating applications, such as vehicle windscreens, to solar. As such, their inherent properties are very different from the application requirements in solar photovoltaics. Studies have observed that hydrophilic coating is ineffective in arid or dry regions (Hu et al. 2015). Since Tiruchirappalli is hot and dry for nearly 8 months in a year, hydrophilic nanocoatings are not employed in this work. All the available superhydrophobic nanocoatings are subjected to various characterization tests provided by Ehsan et al. (2021) to determine the optimal coating solution. Three such samples, denoted as “A”, “B” and “C”, are chosen for further studies. The coating formulations generally comprise metal oxides/mixed metal oxides, typically exhibiting a rutile structure with a tetragonal unit cell with nanoscale microstructure formation. Table 1a–c shows the typical material composition of the nanocoating samples “A”, “B” and “C”, respectively, reproduced verbatim from their material safety data sheets (MSDS) and product data sheets (PDS) submitted by the manufacturers. Surface characterization and morphology studies of the coatings are also carried out using Olympus BX51M Optical Microscope, Carl ZEISS Crossbeam 340 Field Emission Scanning Electron Microscope (FESEM), EDAX Octane Elite Super Energy Dispersive Spectroscopy (EDS), and Malvern PANalytical EMPYREAN X-ray Diffractometer (XRD). Figure 1a, b shows the Scanning Electron Microscope (SEM) micrographs of the surface coated with “B” under 500x and 1220x magnification, respectively. It is observed from the figure that the coating layer cannot be discerned clearly from the electrically conductive, nonporous carbon tape background used for SEM/EDS studies in magnifications below 500x. The layer is visible as uniformly distributed white spots in magnifications beyond 1000x. However, the spots cannot be differentiated clearly from the carbon background even after increasing the magnification further, showing that the coating particles get applied on a tiny scale.

Panels coated with the nanocoating samples and the uncoated modules are exposed to the environment for analysis and comparison. All the modules' top and bottom surface temperatures are measured using fast-response, welded-tip \(K\)-type thermocouples with polytetrafluoroethylene (PTFE) insulation to protect them from constant exposure to sunlight. These thermocouples have a short time constant or thermal response time. Response Time is defined as the time required to reach 63.2% of an instantaneous temperature change (Omega Engineering 2019). Keysight Technologies’ 34972A LXI Data Acquisition/Switch Unit data logger with 60 multi-input channels is used to measure various parameters, such as voltage and temperature simultaneously. The data logger is configured to record the values on all its channels every second. Chino KR2S00 digital temperature recorder with six channels is also used to record the temperatures. Influencing weather parameters such as solar irradiance, atmospheric temperatures and wind speed are also recorded using a Dynalab DAM 8101 thermopile pyranometer with a measuring range of 0–1500 W/m2, a Dynalab DWT 8102X Platinum RTD element with a measuring range of − 40 °C to + 60 °C and a Dynalab DWA 8600 3-cup Anemometer with a measuring range of 0–65 m/s, respectively.

Results and discussion

Photovoltaic modules are tested at a temperature of 25 °C (at STC), where the module’s nameplate datasheet values are determined. Practically, the average annual surface temperatures in the tropical and temperate zones are considerably higher than the STC temperature (Ehsan et al. 2014). Depending on their installed location, heat generated by rising temperatures can reduce the panel’s output efficiency by 10–25% (Honsberg and Bowden 2019). The peak or maximum power temperature coefficient (%/°C or mV/°C) in the panel’s datasheet indicates how much power the panel will lose when the temperature rises by 1 °C above STC. For a panel constantly exposed to temperatures above 30 °C, the generation efficiency decreases between 1% and 2% due to temperature (Andreev et al. 1997).

The L1280S mono-crystalline silicon modules used in this work have a maximum power temperature coefficient of − 0.45%/°C. Surface meteorological data (NASA 2021) shows that the location has a climatological monthly average of 33.92 °C in maximum temperature and 27.73 °C in average temperature. This implies that the module’s power generation will decrease by − 4% and − 1.23% at maximum and average temperatures, respectively. Since these temperature values are monthly averages for a given month averaged for that month over the 30 years, the actual dip in power generation due to increased temperature is high due to the rapid environmental phenomena.

Effect on transmittance

Transmittance, denoted as \(T\), is the ratio of the light passing through a specimen to the light incident on it (Brydson 1999). Studying its transmittance can determine the optical properties of any given sample. According to the Beer–Lambert law, the final transmittance of the sample depends on the sum of optical depths of its individual attenuating species (Höpe 2014), where the optical depth or optical thickness (τ) is the natural logarithm of the ratio of incident to transmitted radiant power through a material. For \(N\) attenuating species in the material sample, transmittance \(T\) is given by

Hence, every layer on the surface of the panel glass, including specialized coatings, accumulated dust etc., will attenuate the transmission of light through it. Therefore, the optical effects of the coating on the PV panel’s glass cover and, ultimately, its power generation can be studied by transmission characterization.

Optical tests cannot be conducted directly on the PV glass without damaging it as it is hermetically sealed with the module to protect the underlying solar cells from damage (Deb and Bhargava 2022). Standard, optical quality microscope slides made of soda-lime glass (75 mm length × 25 mm height × 1.0 mm thickness) are used to simulate the PV glass surface. Variations in dimensions as per the glass manufacturer are ± 1 mm in size and ± 0.1 mm in thickness. As every layer on the glass surface will attenuate light transmission, all the slides are thoroughly cleaned using a lint-free cloth and Isopropyl Alcohol (IPA). The dimensions, especially thickness, of all slides have been reconfirmed using a calibrated Vernier scale to ensure uniformity in the test samples.

As transmittance can be analyzed for a sample in either solid, liquid, or gaseous forms, the coating solutions' optical properties are also studied in their original liquid state. The transmittance tests on the coating solutions “A”, “B”, and “C” have been conducted using a Shimadzu-make UV-2600 UV–Vis spectrophotometer. It is a single monochromator system without the two-detector integrating sphere (Shimadzu Corporation 2022a) and has a measuring range of 200–700 nm, configured on the UVProbe software. The device has two pre-installed cuvettes for holding the reference and sample liquids. The standard operating procedure for measuring the transmittance of dissolved materials inside the carrier is to use either the carrier solution itself as the reference liquid or other standard reference materials (SRM) (Mavrodineanu 1972). As the exact composition of the nanocoating solutions, especially the carrier liquid, is unknown, distilled water has been used as a reference for all the samples. The transmittance values of the coating solutions are shown in Fig. 2.

It can be observed from the figure that sample “C” exhibits the best transmittance values in its original liquid form, whereas sample “A” has comparatively lower transmittance to light. This can be directly correlated with the appearance of these samples in their liquid form—sample “A” has a milky white appearance, sample “B” has a yellowish appearance and sample “C” has a clear, transparent appearance. However, the appearance of these solutions in their liquid form does not correlate to better transmission performance after application on the glass surface.

The transmittance of glass with and without the coatings has been studied using a Jasco-make V-670 UV–Vis–NIR spectrophotometer. Any light that is not absorbed by a glass or reflected at its surface will be transmitted through the glass (Kopp Glass Inc 2022). The V-670 double-beam spectrophotometer utilizes a unique, single monochromator (with automatically exchanging dual gratings) design, covering a wavelength range from 190 to 2000 nm (JASCO Deutschland GmbH 2022). Transmittance values are captured using the Spectra Manager II software at a periodicity of 0.5 nm. Referencing/calibration of the equipment has been carried out using a plain slide without any coating. The slides have been coated with the solutions “A”, “B” and “C”. It is to be noted here that the manufacturer-recommended application procedure using a low volume, medium pressure (LVMP) spray gun could not be employed due to the small dimensions of the glass slides. The transmission characterization tests have been carried out in two phases—one with a single layer of coating on the slide surface and the second with multilayer coating (three layers). Multilayer tests have been conducted to study the optical effects of coating the glass surface with multiple layers and also to crosscheck the coating procedure laid out by the manufacturers. For example, the manufacturer of “A” has declared that multiple layers will not affect the first coat. In contrast, the manufacturer of “C” asked to avoid multiple layers as the subsequent layers will not stick to the original. Each coating layer has been allowed to cure before the application of the next layer. Figure 3a, b shows the transmittance plots for the nanocoating solutions with a single coat layer and multiple layers of coating juxtaposed with an uncoated slide. While the transmittance values were captured for the entire spectrum on the spectrophotometer, the figure shows values from 190 to 1000 nm, covering the ultraviolet, visible and near-infrared regions of the electromagnetic spectrum.

It can be observed from Fig. 3a that all the coated surfaces show improved transmittance when compared to the uncoated slide. All the test samples (including the uncoated) show transmittance of over 90% around the visible spectrum (around 380–750 nm). Sample “C” exhibits higher transmittance values followed by “B” and “A”, respectively. The values drop drastically to nearly 20% around the near ultraviolet region (around 250–320 nm), corresponding to the spectrum regions of UV-A and UV-B subdivisions as per ISO 21348:2007 (International Organization for Standardization (ISO) 2002). The sudden decreases in the transmission indicate absorption bands (Optics for Devices, SCHOTT North America Inc. 2005). Apart from the drop around this region, all coated glass surfaces exhibit transmittance across the entire radiation spectrum. However, it is observed that the uncoated, clear glass slide does not transmit wavelengths from 190 to around 350 nm and transmits all wavelengths above 350 nm. This behaviour in clear glass has also been recorded in the solar transmittance studies conducted by Shimadzu Corporation (2022b), a leading measurement instrument manufacturer, especially for molecular spectroscopy. Since solar transmittance, an index of the transmission characteristics of sunlight, includes visible to near-infrared light, its value will be slightly lower than that of the visible light transmittance (Shimadzu Corporation 2022b).

Applying multiple layers of coatings on the glass surface decreases the transmittance values marginally, as shown in Fig. 3b. While the single-coated surfaces of all coatings show transmittance values above 90% in the visible spectrum, it drops to 80–90% after multiple layers of coating. After the application of three layers of coating, it is observed that sample “A” shows higher transmittance values than “B” and “C”, respectively. This finding conforms with the application guidelines for the coatings provided by the respective manufacturers and reiterates the importance of correct application. Transmission characterization studies show that applying nanocoatings improves the glass's transmittance values.

Effect on \({{\varvec{V}}}_{\mathbf{o}\mathbf{c}}\) and \({{\varvec{I}}}_{\mathbf{s}\mathbf{c}}\)

Huang et al. (2011) have conducted experimental investigations to observe the effect of operating temperatures (between 40 and 80 °C) on \({V}_{\mathrm{oc}}\) at different values of solar radiation (200–1000 W/m2). The investigations show that irrespective of the value of solar radiation, \({V}_{\mathrm{oc}}\) decreases uniformly with rise in cell operating temperature. In contrast, studies have found that \({V}_{\mathrm{oc}}\) of the panels is not affected by dust accumulation (Ndiaye et al. 2013). To cross verify its relationship with dust accumulation, \({V}_{\mathrm{oc}}\) of the four panels—an uncoated panel, and the panels coated with “A”, “B”, and “C” is monitored using Keysight Technologies’ 34972A data logger for 10 days (September 3–12, 2021). The values are captured every 10 s in the data logger. Since the entire data set for the duration comprises nearly 5000 values per channel, plotting all the values results in various fine-scale structures and rapid phenomena due to frequent environmental changes. The data set, hence, needs to be smoothed to create an approximating function that attempts to capture important patterns in the data. In smoothing, the data points are modified so that individual points are reduced, and points that are lower than the adjacent points are increased, leading to a smoother signal. Adjacent-Averaging (AA) smoothing algorithm is applied to the data sets in OriginLab Corporation’s Origin scientific graphing and data analysis program. AA essentially takes the average of a user-specified number of data points around each point in the data and replaces that point with the new average value (OriginLab Corporation 2022). Each smoothed point is the average of the data points within a moving window, which is user-defined based on the original plot’s total number of data points.

It is observed that the \({V}_{\mathrm{oc}}\) of all four panels remained consistent despite a gradual increase in dust accumulation as the number of days of exposure increased, as also noted by Ndiaye et al. (2013) and Paudyal et al. (2017). Figure 4 shows the comparison between \({V}_{\mathrm{oc}}\) of the uncoated panel and the panels coated with samples “A”, “B”, and “C” for 10 days. The data sets for all plots are smoothed using a 50-point AA algorithm. The average recorded \({V}_{\mathrm{oc}}\) of the uncoated panel for the duration is 16.23 V. The maximum recorded voltage is 19.41 V. The average and maximum \({V}_{oc}\) values for “A” are 15.44 V and 19.09 V, respectively. Similarly, the average and maximum recorded \({V}_{\mathrm{oc}}\) for “B” are 16.97 V and 19.46 V, respectively. 16.62 V and 19.46 V are the respective values for “C”. All the maximum recorded open-circuit voltages are observed on the same day for all panels. Panel coated with “C” has reached closest to the L1280S’ nameplate \({V}_{\mathrm{oc}}\) value of 20 V at STC. The average voltage difference between “A” and uncoated panel is observed to be − 0.80 V for the entire period. The difference between “B” and uncoated is 0.15 V and that between “C” and uncoated is 0.39 V. The average recorded atmospheric temperature during this period is 30.78 °C with a peak of 36.13 °C.

Solar irradiance (W/m2) of the location also affects the open-circuit voltage of the panel. Figure 5 shows the recorded \({V}_{\mathrm{oc}}\) of all four panels (coated and uncoated) with irradiance during the day (September 12, 2021). All the data displayed in this work, citing time of day, is plotted from 6 am to 7 pm on all days. It is observed from the figure that the \({V}_{\mathrm{oc}}\) rises and drops rapidly during the early morning and late evening, respectively, with minor variations during the majority of the day in response to changes in irradiance. It is noted that the \({V}_{\mathrm{oc}}\) is mainly independent of irradiance for all the panels. It can be observed from both figures, Figs. 4 and 5, that coatings “B” and “C” have higher open-circuit voltages than the uncoated panel under the same environmental conditions. However, “A” has recorded slightly lower \({V}_{oc}\) values than the other panels.

Equation (1) shows that the short-circuit current (\({I}_{\mathrm{sc}}\)) is a function of solar irradiance. \({I}_{\mathrm{sc}}\) values of all panels are recorded along with the irradiance. Figure 6a–c shows the recorded short-circuit current for all the panels along with irradiance during the day. It is clearly seen from the figure that the coated panels, “\(A\)” and “\(B\)”, have recorded higher \({I}_{\mathrm{sc}}\) values than their corresponding uncoated panel during most of the day. However, “C” has recorded slightly lower \({I}_{\mathrm{sc}}\) values that its corresponding uncoated panel. It can also be confirmed from the figure that \({I}_{\mathrm{sc}}\) is directly proportional to solar irradiance, unlike \({V}_{\mathrm{oc}}\). The \({I}_{\mathrm{sc}}\) values follow the same pattern as irradiance during the day. The average recorded \({I}_{\mathrm{sc}}\) for the day from “A” is 1.59 A against its corresponding uncoated panel’s average of 1.55 A. Similarly, the average \({I}_{\mathrm{sc}}\) from “B” is 1.71 A against 1.67 A from its uncoated panel. The values for “C” and its uncoated pair are 2.03 A and 2.07 A, respectively, which corroborates panel “C” recording slightly lower \({I}_{\mathrm{sc}}\) values.

Effect of nanocoatings on surface temperature

To study the effect of superhydrophobic nanocoatings on panel surface temperatures, the coating samples “A”, “B”, and “C” are applied over the module surface and then exposed to the environment. A set of uncoated and coated panels are installed on the module mounting structure sequentially. Three different panels (but the same L1280S) are used as the uncoated panel against each coated panel. All panels are cleaned thoroughly using acetone solution before coating and again with water before installation on the structure. They are not further cleaned afterward to observe the effect of dust accumulation on solar panel surface temperatures after prolonged environmental exposures. The solar modules' top and bottom surface temperatures are monitored and recorded for 10 days for each set of panels (from June 27 to July 6, 2021 for “A”, from July 17 to 26, 2021 for “B”, and from August 19 to 28, 2021 for “C”). The tests are conducted in the order the coatings are applied to the panel surfaces by their respective manufacturers. The thermocouples are fixed on all panels' top and bottom surfaces (one each). Keysight Technologies’ 34972A LXI Data Acquisition/Switch Unit is configured to capture the temperature data along with voltage and current every 10 s. With a recording duration of over 13 h (6 am to 7 pm) from sunrise to sunset, nearly 5000 values per day are captured for each channel. The plots of top and bottom surface temperatures of all three coated panels against their respective uncoated panel after continuous exposure, smoothed using a 100-point AA algorithm, are shown in Fig. 7a–c. The uncoated panel's top and bottom surface temperatures are higher than that of all three coated panels. It can also be seen that the recorded temperature patterns vary every day depending on the meteorological conditions.

The average top surface temperature for “A” is 48.15 °C, against its corresponding uncoated panel average of 51.63 °C. The average top surface temperature for “B” is 43.49 °C against its corresponding uncoated panel average of 46.67 °C. Similarly, the average top surface temperature for “C” is 44.64 °C, against its corresponding uncoated panel average of 46.90 °C. The lowest recorded top surface temperatures for “A” and uncoated are 27.29 °C and 30.45 °C, respectively. The highest recorded top surface temperatures are 66.93 °C and 73.66 °C, respectively, for the same pair. The lowest recorded top surface temperatures are 28.17 °C and 31.64 °C for “B” and uncoated, respectively. For the same pair, the highest recorded top surface temperatures 65.12 °C and 67.16 °C, respectively. Similarly, the lowest recorded top surface temperatures are 26.17 °C and 31.71 °C for “C” and uncoated, respectively. The highest recorded top surface temperatures 67.55 °C and 70.22 °C, respectively, for the same pair.

The average bottom surface temperature for “A” is 49.56 °C\(,\) against its corresponding uncoated panel average of 49.95 °C. The average bottom surface temperature for “B” is 46.01 °C, against its corresponding uncoated panel average of 46.34 °C. Similarly, the average top surface temperature for “C” is 45.09 °C\(,\) against its corresponding uncoated panel average of 46.89 °C. The lowest recorded bottom surface temperatures for “\(A\)” and uncoated are 26.79 °C and 31.27 °C, respectively. The highest recorded bottom surface temperatures 66.80 °C and 69.31 °C, respectively, for the same pair. The lowest recorded bottom surface temperatures are 32.56 °C and 32.68 °C for “B” and uncoated, respectively. For the same pair, the highest recorded top surface temperatures 64.91 °C and 68.53 °C, respectively. Similarly, the lowest recorded bottom surface temperatures are 30.83 °C and 32.27 °C for “C” and uncoated, respectively. The highest recorded bottom surface temperatures 67.64 °C and 69.80 °C, respectively, for the same pair.

It is observed that the top and bottom surface temperatures (average, minimum and maximum) of the coated panels are lower than that of their corresponding uncoated panels, irrespective of the coating solution used and climatic conditions. This pattern is the same on all observed days. The AA algorithm makes it easier to plot the pattern from a large quantum of data. However, it is hard to discern the accurate representation of individual data blocks once they are smoothed. Figure 8a–c shows the plots of top and bottom surface temperatures of coated panels against their corresponding uncoated panels recorded on a day. Atmospheric temperatures recorded on the same dates for each set are also plotted. It can be seen from the figure that the top surface temperature of the uncoated panel is higher than its bottom surface temperature for most of the day. However, the top surface starts cooling off faster than the bottom later in the evening, which results in the bottom temperature being higher than the top on some occasions. These wide variations in top surface temperatures are also not uniform between the panels. They can be attributed to the top surface’s direct environmental exposure, which results in a quicker response to atmospheric changes. The trend is similar for the top and bottom temperatures for the coated panels, irrespective of the coating. However, it can be clearly observed that the uncoated panel's top and bottom temperatures are higher than the coated panels' top and bottom temperatures in absolute values for most of the day, especially during peak generation. This shows that the coating results in a better temperature performance of the solar panels in real-life conditions.

As shown in Fig. 8, the panel surface temperatures have a nonlinear relationship with atmospheric temperature. While the atmospheric temperature gradually rises as the day progresses, the panel surface temperatures initially increase but start to decrease late afternoon. In the evening, all temperatures start decreasing proportionally. Since the surface temperatures directly result from conductive heat transfer, their response to environmental changes is more pronounced than that of the atmospheric temperature resulting from radiative heat transfer. Though the climatic conditions between the three different periods differ, the temperature patterns exhibited by all the panels are similar. It can be clearly seen from these figures that the surface temperatures also follow the same pattern as solar power generation in temperate climate zones, i.e., they are the lowest during the morning and late evening and reach their peak values around mid-day, which also coincides with theoretical maximum power generation.

Thermal imagery, or a thermogram, creates an image of an object using infrared radiation emitted from the object. Thermography can capture variations in temperature as the amount of radiation emitted by an object increases with temperature. Figure 9a, b shows the thermogram of the panel surfaces under two different conditions on the same day during peak generation hours captured using a Fluke Ti25 Thermal Imager. The panel on the left is coated, and that on the right is uncoated. Figure 9a shows the thermogram of the panels under a clear sky, and Fig. 9b shows the same under the cloud cover. It can be observed from the figures that, within a matter of 3 min, the surface temperatures drop drastically once the clouds move over the panel. This shows that the top surface undergoes instantaneous and wide variations in surface temperatures due to its direct environmental exposure. While it is difficult to discern between the panels in Fig. 9a, it can be observed from Fig. 9b that the coated panel cools off faster than the uncoated panel resulting in slightly lower surface temperatures in those conditions.

In general, the rate at which heat energy (of flux) is conducted between two bodies is a function of the temperature difference between them and the properties of the interface through which the heat is transferred (Sharaf et al. 2022). Hence, the heat transmitted from the top to the bottom surface is directly proportional to their temperature difference (Yanniotis 2008). Accurately modelling the heat transfer at the module's front and the back surface is challenging (Dupré et al. 2017). The transmission of heat energy from the top to the bottom surface of the panel will raise the temperatures of the solar cells that lie in the pathway. The average temperature difference between top and bottom surfaces (\(\Delta T\)) is observed to be − 1.41 °C in the panel coated with “A” against 1.68 °C in its uncoated pair. The difference is − 2.52 °C in panel coated with “B” against 0.33 °C in the respective uncoated panel. Similarly, the values for “C” and its pair are − 0.45 °C and 0.01 °C, respectively. Considering the varying conditions for each set of tests, the averages of \(\Delta T\) between all coated and uncoated surfaces can be regarded as their representative results. Since all the recorded temperatures in the location are above the STC, these temperature differences (\(\Delta T\)) can be taken as the temperature increase in the power temperature coefficient of the panels, which stands as − 0.45%/°C from the manufacturer’s datasheet. Accordingly, the uncoated panel will show a 0.303% drop in power generation, whereas the coated panels will show a 0.657% increase in generation.

It can be clearly seen that the difference between the top and bottom average surface temperatures are all negative for the coated panels and positive for the uncoated panels. This indicates that the average bottom surface temperatures of the coated panels are higher than their top surface temperatures. As the conduction of heat flux is a function of temperature difference, it is conclusive that the coated surfaces are conductive in nature. The coated surface has conducted most of the heat across the panel depth instead of absorbing it. Since the top surface is colder than the bottom surface, further conduction of heat will not happen, resulting in lower solar cell operating temperatures. The thermal images also corroborate this in Fig. 9, where the coated surface is observed to cool off faster than the uncoated panel. In contrast, the average top surface temperatures of the uncoated panels are higher than their bottom surface temperatures. This means that its surface absorbs more heat from the environment, resulting in higher solar cell operating temperatures. It can be concluded that the nanocoatings, irrespective of their composition, result in better cell operating temperatures for the solar panels.

Effect on voltage, current, and power generation

Solar irradiance, along with the temperature of the location, also affects the power generation (Ehsan et al. 2021). Irradiance and atmospheric temperatures are also monitored on all days, along with the load voltage, load current and power generation of the uncoated and coated panels, “A”, “B”, and “C”. The plots of power generated from the coated and uncoated panels with atmospheric temperature and irradiance against time, captured on a particular day, are shown in Fig. 10a–c. Power generated from the coated and uncoated panel, and the atmospheric temperature is plotted along the primary Y-axis. Irradiance is plotted along the secondary Y-axis.

Since no 2 days are similar due to varying environmental conditions, the power generation trend differs significantly between the tests. The power generation is affected substantially by the clearness index (CI). CI is defined as the ratio of global solar irradiance measured at ground level and its counterpart estimated at the top of the atmosphere (Ehsan et al. 2014). It can be seen from Fig. 10 that the Y1 and Y2 scales in all three plots are different. The day during comparison of “A” vs uncoated (July 5, 2021) has a smooth trend indicating a clearer day but with lower power generation values. The day during the comparison of “B” vs uncoated (July 25, 2021) has recorded higher power generation values but with many variations in the values, indicating widely varying clearness index. The power generation trend falls midway between both these days for the day during the comparison of “C” vs uncoated (August 26, 2021). It is also evident from Fig. 10 that power generation follows the same pattern as that of solar irradiance during the day. Figure 10 also shows the direct proportionality of power generation with irradiance, wherein the days with higher irradiance have recorded higher instantaneous power generation. However, power has a nonlinear relationship with atmospheric temperature. It increases with atmospheric temperature to a certain extent and then decreases despite rising temperatures during the latter part of the day.

Figure 11a–c shows the plots of power generated from all three coated panels with their respective uncoated panels for a prolonged duration of time. Solar irradiance for the same period is also shown in the figure. All values are averaged using a 50-point AA algorithm. It can be clearly seen that solar irradiance has a direct effect on power generation. The figure shows that the coated panels have a higher instantaneous power generation over their uncoated panels, irrespective of the variations in irradiance and other climatic conditions. However, their trend mimics the variations in irradiance during the day. It is also observed from the figure that the difference in instantaneous power generated between the coated panels and their corresponding uncoated panels' increases as the duration of exposure to the environment. The average difference between the averages of the instantaneous power generated by “A” during the day and that of the uncoated panel is observed to be 0.32 W during the first half of observation and 0.44 W during the second half. Similarly, the average difference between “B” and the uncoated panel is 0.00 W during the first half and 0.52 W during the second half. The corresponding values for “C” and uncoated panel are 0.76 W and 1.36 W, respectively.

Figure 12a–c shows the recorded panel load voltage and current values plotted with the power generation on the same days for all three coated panels against their respective uncoated panel. Power generation and voltage values are plotted along the primary Y-axis, and the current is plotted along the secondary Y-axis. The power, voltage, current, temperature and irradiance scales in all the plots are varied according to the recorded absolute values for each day. The legend for all parameters is kept uniform throughout this work for better representation. It is clear that both the load voltage and current values recorded from the coated panel are higher than those from the uncoated panel during much of the day.

Effectively, the power generation from the coated panel is also observed to be higher than that of the uncoated panel. During the monitoring period, “A” shows a 2.91% improvement in instantaneous power generation over the uncoated panel. Similarly, “B” and “C” have shown nearly 2.43% and 12.99% improvement in the instantaneous power generation, respectively, over their uncoated panel pairs. Considering the varying conditions for each set of tests, the averages of \(\Delta P\) between all coated and uncoated surfaces can be regarded as their representative results. Hence, the nanocoatings show approximately 6.11% improvement in power generation under all environmental conditions, irrespective of their composition. It can also be surmised from Figs. 5, 10, and 12 that the load voltage, the load current (and effectively, power generation), and the short-circuit current (\({I}_{\mathrm{sc}}\)) all follow the same trend as solar irradiance during the day, unlike the open-circuit voltage (\({V}_{\mathrm{oc}}\)), which shows minimal variations to changes in irradiance.

Economic analysis

BHEL, Tiruchirappalli has five grid-interactive solar installations, totalling 12.62 MWp, in various generation capacities (20 kWp—1 no.; 50 kWp—2 nos.; 5 MWp—1 no.; 7.5 MWp—1 no.). The two large-scale, grid-interactive power plants (5 MWp and 7.5 MWp) are used for captive power generation. The 5 MWp plant generated 5,450,796 kWh in 2019 fiscal and 4,481,469 kWh in 2020. The 7.5 MWp plant generated 8,837,700 kWh in 2019 and 5,516,496 kWh in 2020. Both plants generated a cumulative 24,286,461 kWh in 2019 and 2020 combined, which accounts for nearly 31.1% of the factory’s consumption of 78,115,461 kWh in 2 years. Despite a 42% reduction in energy consumption in 2020 over 2019 due to the lockdown imposed by the Government of India in response to the COVID-19 pandemic and the change in the business portfolio, the share of renewable energy in the campus’ annual consumption increased to 34.8% in 2020 (of 28,723,365 kWh) from 28.9% in 2019 (of 49,392,096 kWh). The campus incurred significant energy bill expenditures of INR (Indian Rupees) 292,054,237 in 2019 and INR 177,108,629 in 2020, totalling a massive expenditure of INR 469,162,866 (in actuals). The normalized operating cost of electricity per kWh is the average of the monthly normalized unit cost obtained by dividing the energy bill by the actual metered consumption from power utility and diesel generator (DG), which comes out to be INR 8.89 in 2019 and INR 11.17 in 2020. The factory’s energy bill would have been even higher if not for the two large-scale solar plants. Consuming the 24,286,461 units generated by both plants in 2019 and 2020 from the utility grid would have added nearly INR 220,534,359 (INR 120,453,973 in 2019 and INR 100,080,386 in 2020) to the energy overheads for the organization, which is approximately 47% of the bill in its entirety for those 2 years. These rates are calculated from the monthly solar generation values priced at the monthly normalized operating cost of electricity per unit.

With this generation values constant under the same conditions, the anticipated reduction in power generation due to the power temperature coefficient is − 43,294 kWh in 2019 and − 30,294 kWh in 2020. If all the 19,968 panels of 250 Wp power in the 5 MWp plant and the 25,420 panels of 300 Wp power in the 7.5 MWp plant had been coated with superhydrophobic nanocoating since 2019, the estimated increase in power generation due to the power temperature coefficient is 93,875 kWh in 2019 and 65,687 kWh in 2020. Reduction in the panel operating temperatures due to the application of the superhydrophobic nanocoating leads to the generation of an additional 233,150 kWh by both plants in 2 years (137,170 kWh in 2019 and 95,980 kWh in 2020), resulting in a savings of INR 2,338,495 in 2 years (at annually averaged per kWh normalized operating rates of INR 10.03 in 2 years). This increase in power generation would have reduced the energy bill of the campus by 0.498% in 2 years. Nearly 2 °C reduction in temperature due to the nanocoating will also extend the life of 45,388 modules by approximately 4 years (Dupré et al. 2017). While these anticipated savings may seem insignificant, the coating application also provides an added advantage by improving power generation due to the mitigation of soiling losses (Ehsan et al. 2021). With a 6.11% anticipated power generation improvement, both plants generate an additional 1,483,903 kWh (873,027 kWh in 2019 and 610,876 kWh in 2020) under the same operating conditions. This results in a savings of INR 14,883,545 in 2 years (at INR 10.03 per kWh). Combined with the anticipated savings from improved operating temperatures, the additional power generated would have reduced the energy expenditure by 3.671% (INR 17,222,040) in the 2-year period. Table 2 summarises the economic impact of nanocoatings on solar plants due to the improvements in temperature performance and power generation. At the prevailing market rate of the coating at INR 560 per panel (including material and labour costs, based on the budgetary quotation from coating manufacturers), the net cash outflow for applying the coatings on 45,388 panels in both panels will be INR 25,417,280, which will get paid back in mere 3.4 years.

This shows that the application of superhydrophobic nanocoatings over the surface of solar panels actually reduces the panel operating temperature despite having dust accumulation over a prolonged period of exposure to the environment. Reduction in surface temperatures effectively increases the power generation efficiency of solar panels due to reduced power temperature coefficient values and also improves the module life.

Conclusions

The temperature of the installed location plays a crucial role in determining the operating efficiency of a solar photovoltaic module. Constant exposure to sunlight increases the solar cells' surface temperature, reducing the module's power output. This research shows that the application of superhydrophobic nanocoatings reduces the panel operating temperatures, despite prolonged exposure to the sun. In turn, this reduces the solar cell temperatures beneath the covering glass, eventually reducing cell degradation and improving generation life. The coated surfaces exhibit lower temperatures than the uncoated surfaces and respond faster to environmental changes. This makes the coating more effective in tropical and temperate zones, where the average atmospheric temperature is high throughout the year. The coated surfaces also exhibit better transmittance performance than an uncoated surface across the electromagnetic spectrum, ensuring that the solar cells receive increased light intensity. The coatings also show an improvement in power generation irrespective of the climatic conditions. The anticipated cost savings per year solely due to improvement in panel operating temperatures, when applied to a 12.5 MWp captive solar plant, is calculated to be around INR 1.2 million. When combined with the improvement in power generation, the savings is around INR 8.6 million per annum. Hence, this research work will aid the large-scale adoption of superhydrophobic nanocoatings in solar power plants worldwide. The coatings can be considered for introduction into the panel manufacturing process itself to reap its benefits right from the plant installation.

Data availability statement

The data that support the findings of this study are available from the corresponding author upon reasonable request.

References

Advanced Optics, SCHOTT AG, Germany (2005) TIE-35: transmittance of optical glass

Andreev VM, Grilikhes VA, Rumyantev VD (1997) Photovoltaic conversion of concentrated sunlight. Wiley, Hoboken, p 308

Brydson J (1999) Plastics materials, 7th edn. Butterworth-Heinemann, Oxford, pp 110–123

Chanchangi YN, Ghosh A, Sundaram S, Mallick TK (2020) An analytical indoor experimental study on the effect of soiling on PV, focusing on dust properties and PV surface material. Sol Energy 203:46–68

Chander S, Purohit A, Sharma A, Arvind, Nehra SP, Dhaka M (2015) A study on photovoltaic parameters of mono-crystalline silicon solar cell with cell temperature. Energy Rep 1:104–109

Deb D, Bhargava K (2022) Degradation, mitigation, and forecasting approaches in thin film photovoltaics. Academic Press, New York, pp 19–37

Dhankar U, Dahiya S, Chawla R, Kumar P, Gupta N (2022) Numerical simulation of temperature dependency on performance of solar PVC. SILICON. https://doi.org/10.1007/s12633-022-01804-6

Dubey S, Sarvaiya JN, Seshadri B (2013) Temperature dependent photovoltaic (PV) efficiency and its effect on pv production in the world a review. In: PV Asia Pacific conference 2012

Dupré O, Vaillon R, Green MA (2017) Thermal behavior of photovoltaic devices. Springer, Cham, p 142

Dwivedi P, Sudhakar K, Soni A, Solomin E, Kirpichnikova I (2020) Advanced cooling techniques of P.V. modules: a state of art. Case Stud Therm Eng 21:100674

Ehsan RM, Simon SP, Venkateswaran PR (2014) Artificial neural network predictor for grid-connected solar photovoltaic installations at atmospheric temperature. In: International conference on advances in green energy (ICAGE), Thiruvananthapuram, India

Ehsan RM, Simon SP, Venkateswaran PR (2017) Day-ahead forecasting of solar photovoltaic output power using multilayer perceptron. Neural Comput Appl 28:3981–3992

Ehsan RM, Simon SP, Sundareswaran K, Kumar KA, Sriharsha T (2021) Effect of soiling on photovoltaic modules and its mitigation using hydrophobic nanocoatings. J Photovolt 11(3):742–749

Honsberg C, Bowden S (2019) Effect on temperature. PV Education. https://www.pveducation.org/pvcdrom/solar-cell-operation/effect-of-temperature

Höpe A (2014) Experimental methods in the physical sciences. Academic Press, New York, pp 179–219

Hu J, Bodard N, Sari O, Riffat S (2015) CFD simulation and validation of self-cleaning on solar panel surfaces with superhydrophilic coating. Future Cities Environ 1(8):1–15

Huang B, Yang P, Lin Y, Lin B, Chen H, Lai R, Cheng J (2011) Solar cell junction temperature measurement of PV module. Sol Energy 85:388–392

Idoko L, Anaya-Lara O, McDonald A (2018) Enhancing PV modules efficiency and power output using multi-concept cooling technique. Energy Rep 4:357–369

IEA (2021a) Solar PV—tracking report. IEA. https://www.iea.org/reports/solar-pv

IEA (2021b) Renewable power—tracking report. https://www.iea.org/reports/renewable-power

IEC 60904-10:2009 (2019) Photovoltaic devices—part 10: methods of linearity measurement. IEC

International Organization for Standardization (ISO) (2022) ISO 21348:2007—Space environment (natural and artificial)—process for determining solar irradiances. https://www.iso.org/standard/39911.html

JASCO Deutschland GmbH (2022) V-670 UV-VIS-NIR spectrophotometer. https://www.jasco.de/en/content/V-670/~nm.13~nc.407/V-670-UV-VIS-NIR-Spectrophotometer.html

Jordan DC, Kurtz SR (2012) Photovoltaic degradation rates—an analytical review. National Renewable Energy Laboratory, Golden

Kim KA, Seo G-S, Cho B-H, Krein PT (2016) Photovoltaic hot spot detection for solar panel substrings using AC parameter characterization. Trans Power Electron 31(2):1121–1130

Kopp Glass Inc (2022) Optical Properties of glass: how light and glass interact. https://www.koppglass.com/blog/optical-properties-glass-how-light-and-glass-interact

Mani M, Pillai R (2010) Impact of dust on solar photovoltaic (PV) performance: research status, challenges and recommendations. Renew Sustain Energy Rev 14(9):3124–3131

Mavrodineanu R (1972) An accurate spectrophotometer for measuring the transmittance of solid and liquid materials. J Res Natl Bureau Standards Phys Chem 76A(5):405–425

NASA (2021) POWER (prediction of worldwide energy resources). NASA. https://power.larc.nasa.gov/

Ndiaye A, Kébé CMF, Ndiaye PA, Charki A, Kobi A, Sambou V (2013) Impact of dust on the photovoltaic (PV) modules characteristics after an exposition year in Sahelian environment: the case of Senegal. Int J Phys Sci 8(21):1166–1173

Omega Engineering (2019) Thermocouple response time. 17 April 2019. https://www.omega.com/en-us/resources/thermocouples-response-time

Optics for Devices, SCHOTT North America Inc. (2005) TIE-35: transmittance of optical glass. https://wp.optics.arizona.edu/optomech/wp-content/uploads/sites/53/2016/10/tie-35_transmittance_us.pdf

OriginLab Corporation (2022) Smoothing. OriginLab Corporation. https://www.originlab.com/doc/Origin-Help/Smoothing

Paudyal BR, Shakya SR, Paudyal DP, Mulmi DD (2017) Soiling-induced transmittance losses in solar PV modules installed in Kathmandu Valley. Ren Wind Water Solar. https://doi.org/10.1186/s40807-017-0042-z

PV Education (2022) Optical properties of silicon. PV Education. https://www.pveducation.org/pvcdrom/materials/optical-properties-of-silicon

Sarkın AS, Ekren N, Sağlam Ş (2020) A review of anti-reflection and self-cleaning coatings on photovoltaic panels. Sol Energy 199:63–73

Sharaf M, Yousef MS, Huzayyin AS (2022) Review of cooling techniques used to enhance the efficiency of photovoltaic power systems. Environ Sci Pollut Res 29:26131–26159

Shimadzu Corporation (2022a) UV-2600i, UV-2700i—specs. https://www.shimadzu.com/an/products/molecular-spectroscopy/uv-vis/uv-vis-nir-spectroscopy/uv-2600i-uv-2700i/spec.html

Shimadzu Corporation (2022b) Measurement of solar transmittance through plate glass, https://www.shimadzu.com/an/industries/electronics-electronic/solar-transmittance/index.html

Shukla A, Kant K, Sharma A, Biwole PH (2017) Cooling methodologies of photovoltaic module for enhancing electrical efficiency: a review. Sol Energy Mater Sol Cells 160:275–286

Sutha S, Suresh S, Raj B, Ravi KR (2017) Transparent alumina based superhydrophobic self–cleaning coatings for solar cell cover glass applications. Sol Energy Mater Sol Cells 165:128–137

Wysocki JJ, Rappaport P (2004) Effect of temperature on photovoltaic solar energy conversion. J Appl Phys 31(3):571–578

**ao C, Yu X, Yang D, Que D (2014) Impact of solar irradiance intensity and temperature on the performance of compensated crystalline silicon solar cells. Sol Energy Mater Sol Cells 128:427–434

Yanniotis S (2008) Heat transfer by conduction. solving problems in food engineering. Springer, New York, pp 55–65

Yu S, Guo Z, Liu W (2015) Biomimetic transparent and superhydrophobic coatings: from nature and beyond nature. Chem Commun 51:1775–1794

Zhi J, Zhang L-Z (2018) Durable superhydrophobic surface with highly antireflective and self-cleaning properties for the glass covers of solar cells. Appl Surf Sci 454:239–248

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Ethical approval

This article does not contain any studies with human participants or animals performed by any of the authors.

Informed consent

No informed consent is required for this article.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Ehsan, R.M., Simon, S.P., Kinattingal, S. et al. Effects of nanocoatings on the temperature-dependent cell parameters and power generation of photovoltaic panels. Appl Nanosci 12, 3945–3962 (2022). https://doi.org/10.1007/s13204-022-02633-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13204-022-02633-0