Abstract

Proton exchange membrane fuel cells (PEMFCs) have been identified as a highly promising means of achieving sustainable energy conversion. A crucial factor in enhancing the performance of PEMFCs for further potential energy applications is the advancement in the field of catalyst engineering that has led to remarkable performance enhancement in facilitating the oxygen reduction reaction (ORR). Subsequently, it is important to acknowledge that the techniques used in preparation of membrane electrode assemblies (MEAs), the vital constituents of PEMFCs, also possess direct and critical influence on exhibiting the full catalytic activity of meticulously crafted catalysts. Here, a succinct summary of the most recent advancements in Pt catalysts for ORR was offered and their underly catalytic mechanism were discussed. Then, both laboratory-scale and industrial-scale MEA fabrication techniques of Pt catalysts were summarized. Furthermore, a detailed analysis of the connections between materials, process, and performance in MEA fabrication was presented in order to facilitate the development of optimal catalyst layers.

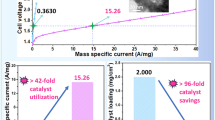

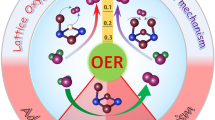

Graphical abstract

摘要

质子交换膜燃料电池(PEMFC)被认为是实现可持续能源转换的极具前景的装置之一。催化剂活性直接影响着氧还原反应(ORR)速率,开发高活性催化剂是提高质子交换膜燃料电池性能,实现潜在能源应用的重要途径。此外,膜电极(MEA)作为PEMFC的重要组成部分,其制备技术对于催化剂活性的充分发挥具有关键影响。在此,本文总结了用于ORR的铂基催化剂的最新研究进展及其催化机理,介绍了实验室规模和工业规模的MEA制备技术,分析了MEA制备过程中材料、工艺和性能之间的联系,旨在促进高性能燃料电池的发展。

Reproduced with permission from Ref. [50]. Copyright 2012, Wiley–VCH. c Change of SA and MA at 0.93 V as a function of particle sizes; d dispersion and surface percentage of atoms on edges, where (111) and (100) facets as a function of particle sizes; e oxygen binding energy as a function of particle size. Reproduced with permission from Ref. [51]. Copyright 2011, American Chemical Society

Reproduced with permission from Ref. [34]. Copyright 2018, Royal Society of Chemistry

Reproduced with permission from Ref. [122]. Copyright 2019, Elsevier. Different methods and related CL SEM images of d spray coating, e tape casting and f slot-die coating. Reproduced with permission from Ref. [125]. Copyright 2019, Elsevier. g, h CV curves and i Nyquist plots of MEAs with different PEMs fabricated by roll-to-roll slot-die coating method. Reproduced with permission from Ref. [126]. Copyright 2022, Elsevier

Similar content being viewed by others

References

Chang C, Li BY, Ji BW, Men HC, Wang Q. Research progress of cathode materials for solid oxide fuel cells. Chin J Rare Met. 2023;47(8):1143. https://doi.org/10.13373/j.cnki.cjrm.XY23020016.

Wang SC, Deng WW, Geng ZY, Li PY, Hu NQ, Zhu LM, Sun W, Li CM. Significantly raising tetracyanoquinodimethane electrode performance in zinc-ion battery at low temperatures by eliminating impurities. Battery Energy. 2023;2(2):20220050. https://doi.org/10.1002/bte2.20220050.

Li C, Zhao DH, Long HL, Li M. Recent advances in carbonized non-noble metal–organic frameworks for electrochemical catalyst of oxygen reduction reaction. Rare Met. 2021;40(10):2657. https://doi.org/10.1007/s12598-020-01694-w.

Liu JB, Gong HS, Ye GL, Fei HL. Graphene oxide-derived single-atom catalysts for electrochemical energy conversion. Rare Met. 2022;41(5):1703. https://doi.org/10.1007/s12598-021-01904-z.

Cao S, Sun T, Li JR, Li QZ, Hou CC, Sun Q. The cathode catalysts of hydrogen fuel cell: from laboratory toward practical application. Nano Res. 2022;16(4):4365. https://doi.org/10.1007/s12274-022-5082-z.

Huang L, Zaman S, Tian X, Wang Z, Fang W, **a BY. Advanced platinum-based oxygen reduction electrocatalysts for fuel cells. Acc Chem Res. 2021;54(2):311. https://doi.org/10.1021/acs.accounts.0c00488.

Yang ZX, Li XG, Yao QL, Lu ZH, Zhang N, **a J, Yang K, Wang YQ, Zhang K, Liu HZ, Zhang LT, Lin HJ, Zhou QJ, Wang F, Yu ZM, Ma JM. 2022 roadmap on hydrogen energy from production to utilizations. Rare Met. 2022;41(10):3251. https://doi.org/10.1007/s12598-022-02029-7.

Nguyen H, Klose C, Metzler L, Vierrath S, Breitwieser M. Fully hydrocarbon membrane electrode assemblies for proton exchange membrane fuel cells and electrolyzers: an engineering perspective. Adv Energy Mater. 2022;12(12):2103559. https://doi.org/10.1002/aenm.202103559.

Li Z, Li B, Hu Y, Wang S, Yu C. Highly-dispersed and high-metal-density electrocatalysts on carbon supports for the oxygen reduction reaction: from nanoparticles to atomic-level architectures. Mater Adv. 2022;3(2):779. https://doi.org/10.1039/d1ma00858g.

Zaman S, Douka AI, Noureen L, Tian X, Ajmal Z, Wang H. Oxygen reduction performance measurements: discrepancies against benchmarks. Battery Energy. 2023;2(3):20220060. https://doi.org/10.1002/bte2.20220060.

Shinozaki K, Morimoto Y, Pivovar BS, Kocha SS. Re-examination of the Pt particle size effect on the oxygen reduction reaction for ultrathin uniform Pt/C catalyst layers without influence from Nafion. Electrochim Acta. 2016;213:783. https://doi.org/10.1016/j.electacta.2016.08.001.

Watanabe M, Yano H, Uchida H, Tryk DA. Achievement of distinctively high durability at nanosized Pt catalysts supported on carbon black for fuel cell cathodes. J Electroanal Chem. 2018;819:359. https://doi.org/10.1016/j.jelechem.2017.11.017.

Li YR, Li MX, Li SN, Liu YJ, Chen J, Wang Y. A review of energy and environment electrocatalysis based on high-index faceted nanocrystals. Rare Met. 2021;40(12):3406. https://doi.org/10.1007/s12598-021-01747-8.

Mahata A, Nair AS, Pathak B. Recent advancements in Pt-nanostructure-based electrocatalysts for the oxygen reduction reaction. Catal Sci Technol. 2019;9(18):4835. https://doi.org/10.1039/c9cy00895k.

Morozan A, Jousselme B, Palacin S. Low-platinum and platinum-free catalysts for the oxygen reduction reaction at fuel cell cathodes. Energ Environ Sci. 2011;4(4):1238. https://doi.org/10.1039/c0ee00601g.

Li MF, Zhao ZP, Cheng T, Fortunelli A, Chen CY, Yu R, Zhang QH, Gu L, Merinov BV, Lin ZY, Zhu EB, Yu T, Jia QY, Guo JH, Zhang L, Goddard WA, Huang Y, Duan XF. Ultrafine jagged platinum nanowires enable ultrahigh mass activity for the oxygen reduction reaction. Science. 2016;354(6318):1414. https://doi.org/10.1126/science.aaf9050.

Litster S, McLean G. PEM fuel cell electrodes. J Power Sources. 2004;130(1–2):61. https://doi.org/10.1016/j.jpowsour.2003.12.055.

Ostroverkh A, Johánek V, Dubau M, Kúš P, Khalakhan I, Šmíd B, Fiala R, Václavů M, Ostroverkh Y, Matolín V. Optimization of ionomer-free ultra-low loading Pt catalyst for anode/cathode of PEMFC via magnetron sputtering. Int J Hydrogen Energ. 2019;44(35):19344. https://doi.org/10.1016/j.ijhydene.2018.12.206.

Uchida M, Park YC, Kakinuma K, Yano H, Tryk DA, Kamino T, Uchida H, Watanabe M. Effect of the state of distribution of supported Pt nanoparticles on effective Pt utilization in polymer electrolyte fuel cells. Phys Chem Chem Phys. 2013;15(27):11236. https://doi.org/10.1039/C3CP51801A.

Yurko Y, Elbaz L. The effect of membrane electrode assembly methods on the performance in fuel cells. Electrochim Acta. 2021;389:138676. https://doi.org/10.1016/j.electacta.2021.138676.

Gao W, Yin Q, Zhang X, Zhang C, Lei Y, Wang C. Low-platinum dissymmetric membrane electrode assemblies for fuel cells suitable for a variety of external humidification conditions. J Power Sources. 2022;547:232013. https://doi.org/10.1016/j.jpowsour.2022.232013.

Qi M, Zeng Y, Hou M, Gou Y, Song W, Chen H, Wu G, Jia Z, Gao Y, Zhang H, Shao Z. Free-standing and ionomer-free 3D platinum nanotrough fiber network electrode for proton exchange membrane fuel cells. Appl Catal B Environ. 2021;298:120504. https://doi.org/10.1016/j.apcatb.2021.120504.

Yoshino S, Shinohara A, Kodama K, Morimoto Y. Fabrication of catalyst layer with ionomer nanofiber scaffolding for polymer electrolyte fuel cells. J Power Sources. 2020;476:228584. https://doi.org/10.1016/j.jpowsour.2020.228584.

Sassin MB, Garsany Y, Atkinson RW, Hjelm RME, Swider-Lyons KE. Understanding the interplay between cathode catalyst layer porosity and thickness on transport limitations en route to high-performance PEMFCs. Int J Hydrogen Energ. 2019;44(31):16944. https://doi.org/10.1016/j.ijhydene.2019.04.194.

Turtayeva Z, Xu F, Dillet J, Mozet K, Peignier R, Celzard A, Maranzana G. Manufacturing catalyst-coated membranes by ultrasonic spray deposition for PEMFC: identification of key parameters and their impact on PEMFC performance. Int J Hydrogen Energ. 2022;47(36):16165. https://doi.org/10.1016/j.ijhydene.2022.03.043.

Wang Z, Yang Y, Wang X, Lu Z, Guo C, Shi Y, Tan H, Shen L, Cao S, Yan C. A three-dimensional ordered honeycomb nanostructure anchored with Pt–N active sites via self-assembly of a block copolymer: an efficient electrocatalyst towards the oxygen reduction reaction in fuel cells. J Mater Chem A. 2022;10(22):12141. https://doi.org/10.1039/d2ta00752e.

Wee JH, Lee KY, Kim SH. Fabrication methods for low-Pt-loading electrocatalysts in proton exchange membrane fuel cell systems. J Power Sources. 2007;165(2):667. https://doi.org/10.1016/j.jpowsour.2006.12.051.

**e M, Chu TK, Wang TT, Wan KC, Yang DJ, Li B, Ming PW, Zhang CM. Preparation, performance and challenges of catalyst layer for proton exchange membrane fuel cell. Membranes (Basel). 2021;11(11):879. https://doi.org/10.3390/membranes11110879.

Huang TH, Shen HL, Jao TC, Weng FB, Su A. Ultra-low Pt loading for proton exchange membrane fuel cells by catalyst coating technique with ultrasonic spray coating machine. Int J Hydrogen Energ. 2012;37(18):13872. https://doi.org/10.1016/j.ijhydene.2012.04.108.

Lee E, Kim DH, Pak C. Effects of cathode catalyst layer fabrication parameters on the performance of high-temperature polymer electrolyte membrane fuel cells. Appl Surf Sci. 2020;510:145461. https://doi.org/10.1016/j.apsusc.2020.145461.

Zhao J, Shahgaldi S, Ozden A, Alaefour IE, Li X, Hamdullahpur F. Effect of catalyst deposition on electrode structure, mass transport and performance of polymer electrolyte membrane fuel cells. Appl Energ. 2019;255:113802. https://doi.org/10.1016/j.apenergy.2019.113802.

Conde JJ, Folgado MA, Ferreira-Aparicio P, Chaparro AM, Chowdhury A, Kusoglu A, Cullen D, Weber AZ. Mass-transport properties of electrosprayed Pt/C catalyst layers for polymer-electrolyte fuel cells. J Power Sources. 2019;427:250. https://doi.org/10.1016/j.jpowsour.2019.04.079.

Park J, Kang Z, Bender G, Ulsh M, Mauger SA. Roll-to-roll production of catalyst coated membranes for low-temperature electrolyzers. J Power Sources. 2020;479:228819. https://doi.org/10.1016/j.jpowsour.2020.228819.

Wang YJ, Long W, Wang L, Yuan R, Ignaszak A, Fang B, Wilkinson DP. Unlocking the door to highly active ORR catalysts for PEMFC applications: polyhedron-engineered Pt-based nanocrystals. Energ Environ Sci. 2018;11(2):258. https://doi.org/10.1039/c7ee02444d.

Tian XL, Zhao X, Su YQ, Wang LJ, Wang HM, Dang D, Chi B, Liu HF, Hensen EJM, Lou XW, **a BY. Engineering bunched Pt-Ni alloy nanocages for efficient oxygen reduction in practical fuel cells. Science. 2019;366(6467):850. https://doi.org/10.1126/science.aaw7493.

Gülzow E, Schulze M, Wagner N, Kaz T, Reissner R, Steinhilber G, Schneider A. Dry layer preparation and characterisation of polymer electrolyte fuel cell components. J Power Sources. 2000;86(1–2):352. https://doi.org/10.1016/s0378-7753(99)00451-6.

Creel EB, Tjiptowidjojo K, Alex Lee J, Livingston KM, Randall Schunk P, Bell NS, Serov A, Wood Iii DL. Slot-die-coating operability windows for polymer electrolyte membrane fuel cell cathode catalyst layers. J Colloid Interface Sci. 2022;610:474. https://doi.org/10.1016/j.jcis.2021.11.047.

Fouzaï I, Gentil S, Bassetto VC, Silva WO, Maher R, Girault HH. Catalytic layer-membrane electrode assembly methods for optimum triple phase boundaries and fuel cell performances. J Mater Chem A. 2021;9(18):11096. https://doi.org/10.1039/d0ta07470e.

Wang Z, Nagao Y. Effects of Nafion impregnation using inkjet printing for membrane electrode assemblies in polymer electrolyte membrane fuel cells. Electrochim Acta. 2014;129:343. https://doi.org/10.1016/j.electacta.2014.02.133.

Nie Y, Li L, Wei Z. Recent advancements in Pt and Pt-free catalysts for oxygen reduction reaction. Chem Soc Rev. 2015;44(8):2168. https://doi.org/10.1039/c4cs00484a.

Wang T, Chutia A, Brett DJL, Shearing PR, He G, Chai G, Parkin IP. Palladium alloys used as electrocatalysts for the oxygen reduction reaction. Energ Environ Sci. 2021;14(5):2639. https://doi.org/10.1039/d0ee03915b.

Stephens IEL, Bondarenko AS, Grønbjerg U, Rossmeisl J, Chorkendorff I. Understanding the electrocatalysis of oxygen reduction on platinum and its alloys. Energ Environ Sci. 2012;5(5):6744. https://doi.org/10.1039/c2ee03590a.

Wang X, Li Z, Qu Y, Yuan T, Wang W, Wu Y, Li Y. Review of metal catalysts for oxygen reduction reaction: from nanoscale engineering to atomic design. Chem. 2019;5(6):1486. https://doi.org/10.1016/j.chempr.2019.03.002.

Wang XX, Swihart MT, Wu G. Achievements, challenges and perspectives on cathode catalysts in proton exchange membrane fuel cells for transportation. Nat Catal. 2019;2(7):578. https://doi.org/10.1038/s41929-019-0304-9.

Hammer B, Norskov JK. Electronic factors determining the reactivity of metal surfaces. Surf Sci. 1996;343(3):211. https://doi.org/10.1016/0039-6028(96)80007-0.

Greeley J, Norskov JK, Mavrikakis M. Electronic structure and catalysis on metal surfaces. Annu Rev Phys Chem. 2002;53:319. https://doi.org/10.1146/annurev.physchem.53.100301.131630.

Norskov JK, Abild-Pedersen F, Studt F, Bligaard T. Density functional theory in surface chemistry and catalysis. PANS. 2011;108(3):937. https://doi.org/10.1073/pnas.1006652108.

Ma Z, Cano ZP, Yu AP, Chen ZW, Jiang GP, Fu XG, Yang L, Wu TN, Bai ZY, Lu J. Enhancing oxygen reduction activity of Pt-based electrocatalysts: from theoretical mechanisms to practical methods. Angew Chem Int Ed Engl. 2020;59(42):18334. https://doi.org/10.1002/anie.202003654.

Inaba M, Zana A, Quinson J, Bizzotto F, Dosche C, Dworzak A, Oezaslan M, Simonsen SB, Kuhn LT, Arenz M. The oxygen reduction reaction on Pt: why particle size and interparticle distance matter. ACS Catal. 2021;11(12):7144. https://doi.org/10.1021/acscatal.1c00652.

Perez-Alonso FJ, McCarthy DN, Nierhoff A, Nierhoff A, Hernandez-Fernandez P, Strebel C, Stephens IE, Nielsen JH, Chorkendorff I. The effect of size on the oxygen electroreduction activity of mass-selected platinum nanoparticles. Angew Chem Int Ed Engl. 2012;51(19):4641. https://doi.org/10.1002/anie.201200586.

Shao M, Peles A, Shoemaker K. Electrocatalysis on platinum nanoparticles: particle size effect on oxygen reduction reaction activity. Nano Lett. 2011;11(9):3714. https://doi.org/10.1021/nl2017459.

Nesselberger M, Ashton S, Meier JC, Katsounaros I, Mayrhofer KJ, Arenz M. The particle size effect on the oxygen reduction reaction activity of Pt catalysts: influence of electrolyte and relation to single crystal models. J Am Chem Soc. 2011;133(43):17428. https://doi.org/10.1021/ja207016u.

Tan XY, Shahgaldi S, Li XG. The effect of non-spherical platinum nanoparticle sizes on the performance and durability of proton exchange membrane fuel cells. Adv Appl Energy. 2021;4:100071. https://doi.org/10.1016/j.adapen.2021.100071.

Deng R, **a Z, Sun R, Wang S, Sun G. Nanostructured ultrathin catalyst layer with ordered platinum nanotube arrays for polymer electrolyte membrane fuel cells. J Energy Chem. 2020;43:33. https://doi.org/10.1016/j.jechem.2019.07.015.

Wang W, Wang Z, Yang M, Zhong CJ, Liu CJ. Highly active and stable Pt (111) catalysts synthesized by peptide assisted room temperature electron reduction for oxygen reduction reaction. Nano Energy. 2016;25:26. https://doi.org/10.1016/j.nanoen.2016.04.022.

Mastronardi V, Magliocca E, Gullon JS, Brescia R, Pompa PP, Miller TS, Moglianetti M. Ultrasmall, coating-free, pyramidal platinum nanoparticles for high stability fuel cell oxygen reduction. ACS Appl Mater Inter. 2022;14(32):36570. https://doi.org/10.1021/acsami.2c07738.

Yu T, Kim DY, Zhang H, **a Y. Platinum concave nanocubes with high-index facets and their enhanced activity for oxygen reduction reaction. Angew Chem Int Ed Engl. 2011;50(12):2773. https://doi.org/10.1002/anie.201007859.

Abdelhafiz A, Zhao B, **ao Z, Zeng J, Deng X, Lang L, Ding Y, Song H, Liu M. Facile room-temperature synthesis of a highly active and robust single-crystal Pt multipod catalyst for oxygen reduction reaction. ACS Appl Mater Inter. 2020;12(44):49510. https://doi.org/10.1021/acsami.0c06652.

Deng YJ, Wiberg GKH, Zana A, Sun SG, Arenz M. Tetrahexahedral Pt nanoparticles: Comparing the oxygen reduction reaction under transient vs steady-state conditions. ACS Catal. 2016;7(1):1. https://doi.org/10.1021/acscatal.6b02201.

Byeon JH, Park DH, Lee WJ, Kim MH, Lee HJ, Park KW. Kirkendall effect-driven formation of hollow PtNi alloy nanostructures with enhanced oxygen reduction reaction performance. J Power Sources. 2023;556:232483. https://doi.org/10.1016/j.jpowsour.2022.232483.

Zeng WJ, Wang C, Yin P, Tong L, Yan QQ, Chen MX, Xu SL, Liang HW. Alloying matters for ordering: synthesis of highly ordered PtCo intermetallic catalysts for fuel cells. Inorg Chem. 2023;62(13):5262. https://doi.org/10.1021/acs.inorgchem.3c00331.

Liu X, Zhao Z, Liang J, Li S, Lu G, Priest C, Wang T, Han J, Wu G, Wang X, Huang Y, Li Q. Inducing covalent atomic interaction in intermetallic Pt alloy nanocatalysts for high-performance fuel cells. Angew Chem Int Ed. 2023;62(23):e202302134. https://doi.org/10.1002/anie.202302134.

Di S, Guo C, Dai Y, Wang F, Wang Z, Zhu H. Nitrogen-doped porous carbon-supported PtCo nanoparticle electrocatalyst for oxygen reduction reaction prepared by a dual-template method. ACS Appl Energ Mater. 2023;6(3):1639. https://doi.org/10.1021/acsaem.2c03543.

Gong S, Sun M, Lee Y, Becknell N, Zhang J, Wang Z, Zhang L, Niu Z. Bulk-like Pt(100)-oriented ultrathin surface: combining the merits of single crystals and nanoparticles to boost oxygen reduction reaction. Angew Chem Int Ed Engl. 2023;62(4):e202214516. https://doi.org/10.1002/anie.202214516.

Wu J, Qi L, You H, Gross A, Li J, Yang H. Icosahedral platinum alloy nanocrystals with enhanced electrocatalytic activities. J Am Chem Soc. 2012;134(29):11880. https://doi.org/10.1021/ja303950v.

Xu W, Zhu Z, Wang Y, Cui P, Tong L, Zhao K, Yuan J, Zhou ZY, Liang HW, Tian N, Sun SG. Nitrogen do** to accelerate the phase transition to ordered intermetallic Pt3Co catalyst for the oxygen reduction reaction in fuel cells. J Mater Chem A. 2023;11(8):4078. https://doi.org/10.1039/d2ta07784a.

Zaman S, Huang L, Douka AI, Yang H, You B, **a BY. Oxygen reduction electrocatalysts toward practical fuel cells: progress and perspectives. Angew Chem Int Ed Engl. 2021;60(33):17832. https://doi.org/10.1002/anie.202016977.

Mayrhofer KJJ, Blizanac BB, Arenz M, Stamenkovic VR, Ross PN, Markovic NM. The impact of geometric and surface electronic properties of Pt-catalysts on the particle size effect in electrocatalysis. J Phys Chem B. 2005;109:14433. https://doi.org/10.1021/jp051735z.

Jäger R, Härk E, Kasatkin PE, Pikma P, Joost U, Paiste P, Aruväli J, Kallio T, Jiang H, Lust E. Carbide derived carbon supported Pt nanoparticles with optimum size and amount for efficient oxygen reduction reaction kinetics. J Electrochem Soc. 2017;164(4):F448. https://doi.org/10.1149/2.0281706jes.

Nørskov JK, Rossmeisl J, Logadottir A, Lindqvist L, Kitchin JR, Bligaard T, Jónsson H. Origin of the overpotential for oxygen reduction at a fuel-cell cathode. J Phys Chem B. 2004;108(46):17886. https://doi.org/10.1021/jp047349j.

Sandbeck DJS, Inaba M, Quinson J, Bucher J, Zana A, Arenz M, Cherevko S. Particle size effect on platinum dissolution: practical considerations for fuel cells. ACS Appl Mater Interfaces. 2020;12(23):25718. https://doi.org/10.1021/acsami.0c02801.

Yu K, Groom DJ, Wang X, Yang Z, Gummalla M, Ball SC, Myers DJ, Ferreira PJ. Degradation mechanisms of platinum nanoparticle catalysts in proton exchange membrane fuel cells: the role of particle size. Chem Mater. 2014;26(19):5540. https://doi.org/10.1021/cm501867c.

Liu S, Cao SH, Tian N, **ao C, Zhou ZY, Chen Z, Li YQ, Sun SG. Fluorescence enhancement mediated by high-index-faceted Pt nanocrystals: roles of crystal structures. Chem Commun (Camb). 2018;54(16):2016. https://doi.org/10.1039/c7cc08810h.

**ao J, Liu S, Tian N, Zhou ZY, Liu HX, Xu BB, Sun SG. Synthesis of convex hexoctahedral Pt micro/nanocrystals with high-index facets and electrochemistry-mediated shape evolution. J Am Chem Soc. 2013;135(50):18754. https://doi.org/10.1021/ja410583b.

Sui S, Wang X, Zhou X, Su Y, Riffat S, Liu CJ. A comprehensive review of Pt electrocatalysts for the oxygen reduction reaction: nanostructure, activity, mechanism and carbon support in PEM fuel cells. J Mater Chem A. 2017;5(5):1808. https://doi.org/10.1039/c6ta08580f.

Guo S, Zhang S, Sun S. Tuning nanoparticle catalysis for the oxygen reduction reaction. Angew Chem Int Ed Engl. 2013;52(33):8526. https://doi.org/10.1002/anie.201207186.

**a Y, **ong Y, Lim B, Skrabalak SE. Shape-controlled synthesis of metal nanocrystals: simple chemistry meets complex physics. Angew Chem Int Ed Engl. 2009;48(1):60. https://doi.org/10.1002/anie.200802248.

Narayanan R, El-Sayed MA. Catalysis with transition metal nanoparticles in colloidal solution: nanoparticle shape dependence and stability. J Phys Chem B. 2005;109:12663. https://doi.org/10.1021/jp051066p.

Mukerjee S, Srinivasan S. Enhanced electrocatalysis of oxygen reduction on platinum alloys in proton exchange membrane fuel cells. J Electroanal Chem. 1993;357:201. https://doi.org/10.1016/0022-0728(93)80380-Z.

Stamenkovic VR, Mun BS, Arenz M, Mayrhofer KJJ, Lucas CA, Wang G, Ross PN, Markovic NM. Trends in electrocatalysis on extended and nanoscale Pt-bimetallic alloy surfaces. Nat Mater. 2007;6(3):241. https://doi.org/10.1038/nmat1840.

Singh AP, Sharma S, Pramanik H. Studies on the effect of solvent for the synthesis of low-cost and efficient Pt-Co/C-AB cathode electrocatalyst to enhance the performance of a hydrogen-based PEMFC. Can J Chem Eng. 2023;101(8):4460. https://doi.org/10.1002/cjce.24793.

Zhao ZG, Guo P, Shen LX, Liu YY, Zhang ZY, Tu FD, Ma M, Liu XW, Zhang YL, Zhao L, Shao GJ, Wang ZB. Triple-phase interfacial engineering Pt-CeO2-nitrogen-doped carbon electrocatalysts for proton exchange membrane fuel cells. Appl Surf Sci. 2023;609:155302. https://doi.org/10.1016/j.apsusc.2022.155302.

Ganguly D, Ramanujam K, Sundara R. Low-temperature synthesized Pt3Fe alloy nanoparticles on etched carbon nanotubes catalyst support using oxygen-deficient Fe2O3 as a catalytic center for PEMFC applications. ACS Sustain Chem Eng. 2023;11(8):3334. https://doi.org/10.1021/acssuschemeng.2c06453.

Shahgaldi S, Zhao J, Alaefour I, Li X. Investigation of catalytic vs reactant transport effect of catalyst layers on proton exchange membrane fuel cell performance. Fuel. 2017;208:321. https://doi.org/10.1016/j.fuel.2017.07.035.

Liu S, Li S, Wang R, Rao Y, Zhong Q, Hong K, Pan M. Preparation of high performance and ultra-low platinum loading membrane electrode assembly for PEMFC commercial application. J Electrochem Soc. 2019;166(16):F1308. https://doi.org/10.1149/2.0151916jes.

Gomes Bezerra CA, Deiner LJ, Tremiliosi-Filho G. Unexpected performance of inkjet-printed membrane electrode assemblies for proton exchange membrane fuel cells. Adv Eng Mater. 2019;21(11):1900703. https://doi.org/10.1002/adem.201900703.

Shukla S, Domican K, Karan K, Bhattacharjee S, Secanell M. Analysis of low platinum loading thin polymer electrolyte fuel cell electrodes prepared by inkjet printing. Electrochim Acta. 2015;156:289. https://doi.org/10.1016/j.electacta.2015.01.028.

Liu R, Zhou W, Ling W, Li S, Li F. Performance optimization of ultra-low platinum loading membrane electrode assembly prepared by electrostatic spraying. Int J Hydrogen Energ. 2021;46(17):10457. https://doi.org/10.1016/j.ijhydene.2020.12.127.

Modak A, Velayudham P, Bendikov T, Mohan R, Schechter A. A trifunctional N-doped activated carbon–ceria shell, derived from covalent porphyrin polymers for promoting Pt activity in fuel cell cathode performance. Catal Sci Technol. 2023;13(4):1180. https://doi.org/10.1039/d2cy02034c.

Liu T, Sun F, Huang M, Guan L. Ternary PtZnCu intermetallic nanoparticles as an efficient oxygen reduction electrocatalyst for fuel cells with ultralow Pt loading. ACS Appl Energ Mater. 2022;5(10):12219. https://doi.org/10.1021/acsaem.2c01692.

Garsany Y, Atkinson RW, Gould BD, Martin R, Dubau L, Chatenet M, Swider-Lyons KE. Dual-layer catalyst layers for increased proton exchange membrane fuel cell performance. J Power Sources. 2021;514:230574. https://doi.org/10.1016/j.jpowsour.2021.230574.

Zhao Z, Liu Z, Zhang A, Yan X, Xue W, Peng B, **n HL, Pan X, Duan X, Huang Y. Graphene-nanopocket-encaged PtCo nanocatalysts for highly durable fuel cell operation under demanding ultralow-Pt-loading conditions. Nat Nanotechnol. 2022;17(9):968. https://doi.org/10.1038/s41565-022-01170-9.

Liu R, Zhou W, Wan L, Zhang P, Li S, Gao Y, Xu D, Zheng C, Shang M. Electrostatic spraying of membrane electrode for proton exchange membrane fuel cell. Curr Appl Phys. 2020;20(1):11. https://doi.org/10.1016/j.cap.2019.09.016.

Ott S, Orfanidi A, Schmies H, Anke B, Nong HN, Hubner J, Gernert U, Gliech M, Lerch M, Strasser P. Ionomer distribution control in porous carbon-supported catalyst layers for high-power and low Pt-loaded proton exchange membrane fuel cells. Nat Mater. 2020;19(1):77. https://doi.org/10.1038/s41563-019-0487-0.

Liang X, Pan G, Xu L, Wang J. A modified decal method for preparing the membrane electrode assembly of proton exchange membrane fuel cells. Fuel. 2015;139:393. https://doi.org/10.1016/j.fuel.2014.09.022.

Yang C, Han N, Wang Y, Yuan XZ, Xu J, Huang H, Fan J, Li H, Wang H. A novel approach to fabricate membrane electrode assembly by directly coating the Nafion ionomer on catalyst layers for proton-exchange membrane fuel cells. ACS Sustain Chem Eng. 2020;8(26):9803. https://doi.org/10.1021/acssuschemeng.0c02386.

Shahgaldi S, Alaefour I, Unsworth G, Li X. Development of a low temperature decal transfer method for the fabrication of proton exchange membrane fuel cells. Int J Hydrogen Energ. 2017;42(16):11813. https://doi.org/10.1016/j.ijhydene.2017.02.127.

Mao Q, Sun G, Wang S, Sun H, Wang G, Gao Y, Ye A, Tian Y, **n Q. Comparative studies of configurations and preparation methods for direct methanol fuel cell electrodes. Electrochim Acta. 2007;52(24):6763. https://doi.org/10.1016/j.electacta.2007.04.120.

Shahgaldi S, Alaefour I, Li X. Impact of manufacturing processes on proton exchange membrane fuel cell performance. Appl Energ. 2018;225:1022. https://doi.org/10.1016/j.apenergy.2018.05.086.

Toudret P, Blachot JF, Heitzmann M, Jacques PA. Impact of the cathode layer printing process on the performance of MEA integrating PGM free catalyst. Catalysts. 2021;11(6):669. https://doi.org/10.3390/catal11060669.

Rajalakshmi N, Dhathathreyan K. Nanostructured platinum catalyst layer prepared by pulsed electrodeposition for use in PEM fuel cells. Int J Hydrogen Energ. 2008;33(20):5672. https://doi.org/10.1016/j.ijhydene.2008.05.100.

Zhao X, Yang X, Wang M, Hwang S, Karakalos S, Chen M, Qiao Z, Wang L, Liu B, Ma Q, Cullen DA, Su D, Yang H, Zang HY, Feng Z, Wu G. Single-iron site catalysts with self-assembled dual-size architecture and hierarchical porosity for proton-exchange membrane fuel cells. Appl Catal B Environ. 2020;279:119400. https://doi.org/10.1016/j.apcatb.2020.119400.

Zhou Y, Chen G, Wang Q, Wang D, Tao XF, Zhang TR, Feng XL, Müllen K. Fe-N-C electrocatalysts with densely accessible Fe-N4 sites for efficient oxygen reduction reaction. Adv Funct Mater. 2021;31(34):2102420. https://doi.org/10.1002/adfm.202102420.

Wilson MS, Gottesfeld S. High performance catalyzed membranes of ultra-low Pt loadings for polymer electrolyte fuel cells. J Electrochem Soc. 1992;139:L28. https://doi.org/10.1149/1.2069277.

Jiao L, Zhang R, Wan G, Yang W, Wan X, Zhou H, Shui J, Yu SH, Jiang HL. Nanocasting SiO2 into metal-organic frameworks imparts dual protection to high-loading Fe single-atom electrocatalysts. Nat Commun. 2020;11(1):2831. https://doi.org/10.1038/s41467-020-16715-6.

Wan X, Liu X, Li Y, Yu R, Zheng L, Yan W, Wang H, Xu M, Shui J. Fe–N–C electrocatalyst with dense active sites and efficient mass transport for high-performance proton exchange membrane fuel cells. Nat Catal. 2019;2(3):259. https://doi.org/10.1038/s41929-019-0237-3.

Fu X, Gao R, Jiang G, Li M, Li S, Luo D, Hu Y, Yuan Q, Huang W, Zhu N, Yang L, Mao Z, **ong J, Yu A, Chen Z, Bai Z. Evolution of atomic-scale dispersion of FeNx in hierarchically porous 3D air electrode to boost the interfacial electrocatalysis of oxygen reduction in PEMFC. Nano Energy. 2021;83:105734. https://doi.org/10.1016/j.nanoen.2020.105734.

Tanuma T, Kinoshita S. Impact of cathode fabrication on MEA performance in PEFCs. ECS Trans. 2013;53(30):95. https://doi.org/10.1149/05330.0095ecst.

Park IS, Li W, Manthiram A. Fabrication of catalyst-coated membrane-electrode assemblies by doctor blade method and their performance in fuel cells. J Power Sources. 2010;195(20):7078. https://doi.org/10.1016/j.jpowsour.2010.05.004.

Cho HJ, Jang H, Lim S, Cho E, Lim TH, Oh IH, Kim HJ, Jang JH. Development of a novel decal transfer process for fabrication of high-performance and reliable membrane electrode assemblies for PEMFCs. Int J Hydrogen Energ. 2011;36(19):12465. https://doi.org/10.1016/j.ijhydene.2011.06.113.

Wu SD, Chou CP, Peng RG, Lee CH, Wang YZ. A novel scrape-applied method for the manufacture of the membrane–electrode assembly of the fuel–cell system. Acta Mech Sinica-Prc. 2009;25(6):831. https://doi.org/10.1007/s10409-009-0261-7.

Taylor AD, Kim EY, Humes VP, Kizuka J, Thompson LT. Inkjet printing of carbon supported platinum 3-D catalyst layers for use in fuel cells. J Power Sources. 2007;171(1):101. https://doi.org/10.1016/j.jpowsour.2007.01.024.

Wang W, Chen S, Li J, Wang W. Fabrication of catalyst coated membrane with screen printing method in a proton exchange membrane fuel cell. Int J Hydrogen Energ. 2015;40(13):4649. https://doi.org/10.1016/j.ijhydene.2015.02.027.

Shukla S, Stanier D, Saha MS, Stumper J, Secanell M. Analysis of inkjet printed PEFC electrodes with varying platinum loading. J Electrochem Soc. 2016;163(7):F677. https://doi.org/10.1149/2.1111607jes.

Klingele M, Breitwieser M, Zengerle R, Thiele S. Direct deposition of proton exchange membranes enabling high performance hydrogen fuel cells. J Mater Chem A. 2015;3(21):11239. https://doi.org/10.1039/c5ta01341k.

Willert A, Tabary FZ, Zubkova T, Santangelo PE, Romagnoli M, Baumann RR. Multilayer additive manufacturing of catalyst-coated membranes for polymer electrolyte membrane fuel cells by inkjet printing. Int J Hydrogen Energ. 2022;47(48):20973. https://doi.org/10.1016/j.ijhydene.2022.04.197.

Huang YH, Hsu YH, Pan YT. Fabrication of catalyst layers with preferred mass and charge transport properties through texture engineering. ACS Appl Energ Mater. 2022;5(3):2890. https://doi.org/10.1021/acsaem.1c03568.

Shan N, Jung H, Ahn JY, Kim JH, Kim SH. Electrospray-assisted fabrication of porous platinum-carbon composite thin layers for enhancing the electrochemical performance of proton-exchange membrane fuel cells. Curr Appl Phys. 2018;18(6):728. https://doi.org/10.1016/j.cap.2018.01.020.

Birry L, Bock C, Xue X, McMillan R, MacDougall B. DMFC electrode preparation, performance and proton conductivity measurements. J Appl Electrochem. 2008;39(3):347. https://doi.org/10.1007/s10800-008-9678-0.

Boaventura M, Mendes A. Activation procedures characterization of MEA based on phosphoric acid doped PBI membranes. Int J Hydrogen Energ. 2010;35(20):11649. https://doi.org/10.1016/j.ijhydene.2010.03.137.

Bolwin K, Giilzow E, Bevers D, Schnumberger W. Preparation of porous electrodes and laminated electrodemembrane structures for polymer electrolyte fuel cells (PEFC). Solid State Ion. 1995;77:324. https://doi.org/10.1016/0167-2738(95)00256-6.

Talukdar K, Helmly S, Schulze M, Sanchez DG, Handl M, Hiesgen R, Kraut J, Friedrich KA. Envelo** of catalyst powder by ionomer for dry spray coating in polymer electrolyte membrane fuel cells. J Power Sources. 2019;424:82. https://doi.org/10.1016/j.jpowsour.2019.03.093.

Mauger SA, Neyerlin KC, Yang-Neyerlin AC, More KL, Ulsh M. Gravure coating for roll-to-roll manufacturing of proton-exchange-membrane fuel cell catalyst layers. J Electrochem Soc. 2018;165(11):F1012. https://doi.org/10.1149/2.0091813jes.

Mauger SA, Wang M, Cetinbas FC, Dzara MJ, Park J, Myers DJ, Ahluwalia RK, Pylypenko S, Hu L, Litster S, Neyerlin KC, Ulsh M. Development of high-performance roll-to-roll-coated gas-diffusion-electrode-based fuel cells. J Power Sources. 2021;506:230039. https://doi.org/10.1016/j.jpowsour.2021.230039.

Bodner M, García HR, Steenberg T, Terkelsen C, Alfaro SM, Avcioglu GS, Vassiliev A, Primdahl S, Hjuler HA. Enabling industrial production of electrodes by use of slot-die coating for HT-PEM fuel cells. Int J Hydrogen Energ. 2019;44(25):12793. https://doi.org/10.1016/j.ijhydene.2018.11.091.

Sharma J, Lyu X, Reshetenko T, Polizos G, Livingston K, Li J, Wood DL, Serov A. Catalyst layer formulations for slot-die coating of PEM fuel cell electrodes. Int J Hydrogen Energ. 2022;47(84):35838. https://doi.org/10.1016/j.ijhydene.2022.08.157.

Du S, Guan S, Mehrazi S, Zhou F, Pan M, Zhang R, Chuang PYA, Sui PC. Effect of dispersion method and catalyst on the crack morphology and performance of catalyst layer of PEMFC. J Electrochem Soc. 2021;168(11):114506. https://doi.org/10.1149/1945-7111/ac3598.

Lazaridis T, Stühmeier BM, Gasteiger HA, El-Sayed HA. Capabilities and limitations of rotating disk electrodes versus membrane electrode assemblies in the investigation of electrocatalysts. Nat Catal. 2022;5(5):363. https://doi.org/10.1038/s41929-022-00776-5.

Park YC, Tokiwa H, Kakinuma K, Watanabe M, Uchida M. Effects of carbon supports on Pt distribution, ionomer coverage and cathode performance for polymer electrolyte fuel cells. J Power Sources. 2016;315:179. https://doi.org/10.1016/j.jpowsour.2016.02.091.

Yarlagadda V, Carpenter MK, Moylan TE, Kukreja RS, Koestner R, Gu W, Thompson L, Kongkanand A. Boosting fuel cell performance with accessible carbon mesopores. ACS Energy Lett. 2018;3(3):618. https://doi.org/10.1021/acsenergylett.8b00186.

Ramaswamy N, Gu W, Ziegelbauer JM, Kumaraguru S. Carbon support microstructure impact on high current density transport resistances in PEMFC cathode. J Electrochem Soc. 2020;167(6):064515. https://doi.org/10.1149/1945-7111/ab819c.

Lopez-Haro M, Guetaz L, Printemps T, Morin A, Escribano S, Jouneau PH, Bayle-Guillemaud P, Chandezon F, Gebel G. Three-dimensional analysis of Nafion layers in fuel cell electrodes. Nat Commun. 2014;5:5229. https://doi.org/10.1038/ncomms6229.

Zhao Z, Hossain MD, Xu C, Lu Z, Liu YS, Hsieh SH, Lee I, Gao W, Yang J, Merinov BV, Xue W, Liu Z, Zhou J, Luo Z, Pan X, Zaera F, Guo J, Duan X, Goddard WA, Huang Y. Tailoring a three-phase microenvironment for high-performance oxygen reduction reaction in proton exchange membrane fuel cells. Matter. 2020;3(5):1774. https://doi.org/10.1016/j.matt.2020.09.025.

Andersen SM, Borghei M, Dhiman R, Ruiz V, Kauppinen E, Skou E. Adsorption behavior of perfluorinated sulfonic acid ionomer on highly graphitized carbon nanofibers and their thermal stabilities. J Phys Chem C. 2014;118(20):10814. https://doi.org/10.1021/jp501088d.

Andersen SM. Nano carbon supported platinum catalyst interaction behavior with perfluorosulfonic acid ionomer and their interface structures. Appl Catal B Environ. 2016;181:146. https://doi.org/10.1016/j.apcatb.2015.07.049.

Ren H, Teng Y, Meng X, Fang D, Huang H, Geng J, Shao Z. Ionomer network of catalyst layers for proton exchange membrane fuel cell. J Power Sources. 2021;506:230186. https://doi.org/10.1016/j.jpowsour.2021.230186.

Strong A, Thornberry C, Beattie S, Chen R, Coles SR. Depositing catalyst layers in polymer electrolyte membrane fuel cells: a review. J Fuel Cell Sci Tech. 2015;12(6):064001. https://doi.org/10.1115/1.4031961.

Park JH, Shin MS, Park JS. Effect of dispersing solvents for ionomers on the performance and durability of catalyst layers in proton exchange membrane fuel cells. Electrochim Acta. 2021;391:138971. https://doi.org/10.1016/j.electacta.2021.138971.

Sapkota P, Boyer C, Dutta R, Cazorla C, Aguey-Zinsou KF. Planar polymer electrolyte membrane fuel cells: powering portable devices from hydrogen. Sustain Energ Fuels. 2020;4(2):439. https://doi.org/10.1039/c9se00861f.

Uchida M, Aoyama Y, Eda N, Ohta A. New preparation method for polymer-electrolyte fuel cells. J Electrochem Soc. 1995;142(2):463. https://doi.org/10.1149/1.2044068.

Pan S, Qin J, Ning F, Bai C, Wen Q, Shen M, Li Y, Song Y, Chen J, Huang Y, Zou Y, Feng W, Zhou X. Well-dispersed Nafion array prepared by the freeze-drying method to effectively improve the performance of proton exchange membrane fuel cells. ACS Sustain Chem Eng. 2021;9(49):16770. https://doi.org/10.1021/acssuschemeng.1c06304.

Guo Y, Pan F, Chen W, Ding Z, Yang D, Li B, Ming P, Zhang C. The controllable design of catalyst inks to enhance PEMFC performance: a review. Electrochem Energy R. 2020;4(1):67. https://doi.org/10.1007/s41918-020-00083-2.

Lim BH, Majlan EH, Tajuddin A, Husaini T, Wan Daud WR, Mohd Radzuan NA, Haque MA. Comparison of catalyst-coated membranes and catalyst-coated substrate for PEMFC membrane electrode assembly: a review. Chin J Chem Eng. 2021;33:1. https://doi.org/10.1016/j.cjche.2020.07.044.

Van der Linden F, Pahon E, Morando S, Bouquain D. Optimizing proton exchange membrane fuel cell manufacturing process to reduce break-in time. In 2020 IEEE Vehicle Power and Propulsion Conference (VPPC); 2020. 1. https://doi.org/10.1109/vppc49601.2020.9330846

Deng X, Huang C, Pei X, Hu B, Zhou W. Recent progresses and remaining issues on the ultrathin catalyst layer design strategy for high-performance proton exchange membrane fuel cell with further reduced Pt loadings: a review. Int J Hydrogen Energ. 2022;47(3):1529. https://doi.org/10.1016/j.ijhydene.2021.10.141.

Chen M, Zhao C, Sun F, Fan J, Li H, Wang H. Research progress of catalyst layer and interlayer interface structures in membrane electrode assembly (MEA) for proton exchange membrane fuel cell (PEMFC) system. eTransportation. 2020;5:100075. https://doi.org/10.1016/j.etran.2020.100075.

Acknowledgements

This study was financially supported by the National Natural Science Foundation of China (Nos. 51802059, 21905070 and 22075062), Shenzhen Science and Technology Program (Nos. JCYJ20210324120400002 and SGDX20210823103803017), the Key Research and Development Program of Shandong Province (No. 2022CXGC010305), Heilongjiang Postdoctoral Fund (No. LBH-Z18066), Heilongjiang Touyan Team (No. HITTY-20190033), the Fundamental Research Funds for the Central Universities (No. FRFCU5710051922), the High-Level Professional Team in Shenzhen (No. KQTD20210811090045006) and Guangdong Basic and Applied Basic Research Foundation (No. 2022B1515120001).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interests

The authors declare that they have no conflict of interest.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Ma, M., Shen, LX., Liu, J. et al. Recent advances in Pt catalysts and membrane electrode assemblies fabrication for proton exchange membrane fuel cells. Rare Met. (2024). https://doi.org/10.1007/s12598-024-02698-6

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12598-024-02698-6