Abstract

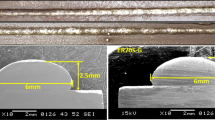

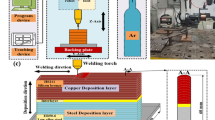

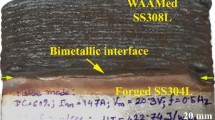

Bimetallic parts are used in many industrial fields, such as pressure vessels, shipbuilding, aerospace, and automotive industries. Conventional bimetallic part production involves a combination of two different metals that are joined using welding and brazing operations. Additive manufacturing technologies offer a cost-effective and innovative manufacturing alternative for complex 3D-shaped parts that can have multi-material designs for better structural performance. However, the structural performance of bimetallic components is primarily influenced by the combination of the employed materials, the interface’s morphology, and interface bonding strength. This work investigated the microstructure and mechanical behavior of a bimetallic thick-walled structure as “WAAM Wall” fabricated by depositing low-alloyed metal-cored wire on the top of 316L stainless steel by robotic wire arc additive manufacturing (WAAM) process. The results showed that both low-carbon steel and austenitic stainless steel SS316L wires are suitable for manufacturing defect-free bimetallic WAAM components, which may widen the design flexibility to manufacture bi-metallic and or functionally graded WAAM components. However, detailed microstructural characterization indicated that martensitic microstructure containing chrome carbides was developed at the bimetallic interface due to an increase in Ni and Cr contents, resulting in a sudden increase of 95% in hardness and a sharp decrease of 70% in fracture toughness at the interface region compared to the SS 316L side. This high-hardness region also resulted in an increase of about 113% and 86% for yield and tensile strengths and a sharp reduction of 69% for elongation values in horizontal interface specimens compared to vertical interface specimens.

Graphical Abstract

Similar content being viewed by others

References

R.U. Ahsan, X. Fan, G. Seo, C. Ji, M. Noakes, A. Nycz, P. Liaw, D.B. Kim, J. Mater. Sci. Technol 74, 176–188 (2021). https://doi.org/10.1016/j.jmst.2020.10.001

B. Wu, Z. Qiu, Z. Pan, K. Carpenter, T. Wang, D. Ding, S.V. Duin, H. Li, J. Mater. Sci. Technol 52, 226–234 (2020). https://doi.org/10.1016/j.jmst.2020.04.019

M.D.B. Kumar, M. Manikandan, Met. Mater. Int. 28, 54–111 (2022). https://doi.org/10.1007/s12540-021-01015-5

F. Martina, J. Ding, S. Williams, A. Caballero, G. Pardal, L. Quintino, Addit. Manuf. 25, 545–550 (2019). https://doi.org/10.1016/j.addma.2018.11.022

W. **, C. Zhang, S. **, Y. Tian, D. Wellmann, W. Liu, Appl. Sci. 10(5), 1563 (2020). https://doi.org/10.3390/app10051563

A. Queguineur, G. Ruckert, F. Cortial, J.Y. Hascoet, Weld. World 62(2), 259–266 (2017). https://doi.org/10.1007/s40194-017-0536-8

A. Kumar, K. Maji, J. Mater. Eng. Perform. 30(7), 5413–5425 (2021). https://doi.org/10.1007/s11665-021-05819-9

S. Dilibal, S. Nohut, C. Kurtoglu, J. Owusu-Danquah, S. Dilibal, S. Nohut, C. Kurtoglu, J. Owusu-Danquah. Data-Driven Generative Design Integrated with Hybrid Additive Subtractive Manufacturing (HASM) for Smart Cities. Springer, 205–228. (2021). https://doi.org/10.1007/978-3-030-72139-8_10

L. Wang, D. Chen, Z. Gao, F. Lyu, X. Zhan, Met. Mater. Int. (2023). https://doi.org/10.1007/s12540-023-01474-y

M.D.B. Kumar, M. Manikandan, Met. Mater. Int. 28, 3033–3056 (2022). https://doi.org/10.1007/s12540-022-01185-w

R. Pramod, S.M. Kumar, A.R. Kannan, N.S. Shanmugam, R. Tangestani, Met. Mater. Int. 28, 307–321 (2022). https://doi.org/10.1007/s12540-021-01026-2

G. **an, M. Cheepu, J. Yu, S.M. Cho, J. Yeom, Y.S. Choi, N. Kang, Met. Mater. Int. 29, 501–514 (2023). https://doi.org/10.1007/s12540-022-01272-y

Y. **ong, D. Wen, Z. Zheng, C. Sun, J. **e, J. Li, Met. Mater. Int. 29, 3009–3023 (2023). https://doi.org/10.1007/s12540-023-01428-4

X. Lu, Y.F. Zhou, X.L. **ng, L.Y. Shao, Q.X. Yang, S.Y. Gao, Int. J. Adv. Manuf. Technol. 93, 2145–2154 (2017). https://doi.org/10.1007/s00170-017-0636-z

A. Bandyopadhyay, Y. Zhang, B. Onuike, Virtual Phys. Prototyp. 17(2), 256–294 (2022). https://doi.org/10.1080/17452759.2022.2040738

J. Zhang, C. Li, L. Ba, X. Di, Met. Mater. Int. 29, 767–776 (2023). https://doi.org/10.1007/s12540-022-01247-z

H. Tianying, Y. Shengfu, R. Yu, B. Zheng, Int. J. Adv. Manuf. Technol. 119, 6601–6612 (2022). https://doi.org/10.1007/s00170-021-08477-2

T.A. Rodrigues, N. Bairrao, F.W.C. Farias, A. Shamsolhodaei, J. Shen, N. Zhou, E. Maawad, N. Schell, T.G. Santos, J.P. Oliveira, Mater. Des 213, 110270 (2022). https://doi.org/10.1016/j.matdes.2021.110270

S. Singh, A.N. **oop, I.A. Palani, C.P. Paul, K.P. Tomar, K.G. Prashanth, Mater. Lett. 303, 130499 (2021). https://doi.org/10.1016/j.matlet.2021.130499

A. Motwani, A. Kumar, Y. Puri, N.K. Lautre, Weld. World 67, 967–980 (2023). https://doi.org/10.1007/s40194-022-01403-4

T. Abe, H. Sasahara, Precis. Eng. 45, 387–395 (2016). https://doi.org/10.1016/j.precisioneng.2016.03.016

A.R. Kannan, S.M. Kumar, N.P. Kumar, N.S. Shanmugam, A.S. Vishnu, Y. Palguna, Mater. Lett. 274, 127968 (2020). https://doi.org/10.1016/j.matlet.2020.127968

R. Sasikumar, A.R. Kannan, S.M. Kumar, R. Pramod, N.P. Kumar, N.S. Shanmugam, Y. Palguna, S. Sivankalai, CIRP J. Manuf. Sci. Technol. 38, 230–242 (2022). https://doi.org/10.1016/j.cirpj.2022.05.005

R.U. Ahsan, A.N.M. Tanvir, T. Ross, A. Elsawy, M. Oh, D.B. Kim, Rapid Prototyp. J. 26(3), 519–530 (2020). https://doi.org/10.1108/RPJ-09-2018-0235

L.P. Raut, R.V. Taiwade, J. Mater. Eng. Perform. 31, 8531–8541 (2022). https://doi.org/10.1007/s11665-022-06856-8

V. Uralde, A. Suarez, E. Aldalur, F. Veiga, T. Ballesteros, Materials 15(17), 5828 (2021). https://doi.org/10.3390/ma15175828

Y. Chen, X. Zuo, W. Zhang, Z. Hao, Y. Li, Z. Luo, S. Ao, Mater. Sci. Eng. A 856, 143984 (2022). https://doi.org/10.1016/j.msea.2022.143984

R.U. Md, A.N.M. Ahsan, G. Tanvir, B. Seo, W. Bates, C. Hawkins, P.K. Lee, M. Liaw, A. Noakes, D.B. Nycz, Kim, Addit. Manuf. 32, 101036 (2020). https://doi.org/10.1016/j.addma.2020.101036

G. Çam, M. Koçak, Progress in joining of advanced materials. Int. Mater. Rev. 43(1), 1–44 (1998). https://doi.org/10.1179/imr.1998.43.1.1

J. Besson, Y. Madi, A. Motarjemi, M. Koçak, G. Martin, P. Hornet, Mater. Sci. Eng. A 397, 84–91 (2005). https://doi.org/10.1016/j.msea.2005.01.056

U. Gürol, B. Turgut, N. Güleçyüz, S. Dilibal, M. Koçak, Int. J. 3D Print. Technol. Digit. Ind. 5(3), 721–729 (2021). https://doi.org/10.46519/ij3dptdi.1033374

A.K. Motarjemi, M. Koçak, V. Ventzke, Mechanical and fracture characterization of a bi-material steel plate. Int. J. Press. Vessels Pip. 79, 181–191 (2002). https://doi.org/10.1016/S0308-0161(02)00012-1

K. Qi, R. Li, Z. Hu, X. Bi, T. Li, H. Yue, B. Zhang, J. Mater. Eng. Perform. 31, 4631–4641 (2022). https://doi.org/10.1007/s11665-022-06587-w

Z. Hu, X. Qin, Y. Li, J. Yuan, Q. Wu, J. Intell. Manuf. 31, 1133–1147 (2020). https://doi.org/10.1007/s10845-019-01501-z

U. Gürol, M. Tümer, S. Dilibal, Trans. Indian Inst. Met. 76, 1371–1379 (2023). https://doi.org/10.1007/s12666-022-02797-x

U. Gürol, S. Dilibal, B. Turgut, M. Koçak, Mater. Test. 64(6), 755–767 (2022). https://doi.org/10.1515/mt-2021-2155

B. Turgut, U. Gürol, R. Önler, Int. J. Adv. Manuf. Technol. 126, 5277–5288 (2023). https://doi.org/10.1007/s00170-023-11481-3

J. Vora, R. Pandey, P. Dodiya, V. Patel, S. Khanna, V. Vaghasia, R. Chaudhari, Materials 16, 5147 (2023). https://doi.org/10.3390/ma16145147

B. Silwal, N. Pudasaini, S. Roy, A.B. Murphy, A. Nycz, M.W. Noakes, Appl. Sci. 12, 3679 (2022). https://doi.org/10.3390/app12073679

J. **ong, Y. Li, Z. Yin, H. Chen, Chin. J. Mech. Eng. 31, 74 (2018). https://doi.org/10.1186/s10033-018-0276-8

K. Dağyıkan, U. Gürol, M. Koçak, Weld. World 67, 1009–1019 (2023). https://doi.org/10.1007/s40194-022-01424-z

T.A. Rodrigues, J.D. Escobar, J. Shen, V.R. Duarte, G.G. Ribamar, J.A. Avila, E. Maawad, N. Schell, T.G. Santos, J.P. Oliveira, Addit. Manuf. 48, 102428 (2021). https://doi.org/10.1016/j.addma.2021.102428

U. Gürol, Int. J. Met. 17, 1021–1033 (2023). https://doi.org/10.1007/s40962-022-00834-5

V.T. Le, D.S. Mai, T.K. Doan, H. Paris, Eng. Sci. Technol. Int. J. 24(4), 1015–1026 (2021). https://doi.org/10.1016/j.jestch.2021.01.009

Y. Li, Y. Luo, J. Li, D. Song, B. Xu, X. Chen, J. Nucl. Mater. 550, 152933 (2021). https://doi.org/10.1016/j.jnucmat.2021.152933

R. Yılmaz, M. Tumer, Int. J. Adv. Manuf. Technol. 67, 1433–1447 (2013). https://doi.org/10.1007/s00170-012-4579-0

H. Ban, R. Bai, K.F. Chung, Y. Bai, Fire Saf. J. 112, 102964 (2020). https://doi.org/10.1016/j.firesaf.2020.102964

U. Gürol, Y. Altınay, A. Günen, Ã.S. Bölükbaşı, M. Koçak, G. Çam, Surf. Coat. Technol. 468, 129742 (2023). https://doi.org/10.1016/j.surfcoat.2023.129742

Y. Koli, S. Aravindan, P.V. Rao, Mater. Charact. 194, 112363 (2022). https://doi.org/10.1016/j.matchar.2022.112363

J.D. Farren, J.N. Dupont, F.F. Noecker, Weld. J. 86(3), 55-s–61-s (2007)

M. Rafieazad, M. Ghaffari, A.V. Nemani, A. Nasiri, Int. J. Adv. Manuf. Technol. 105, 2121 (2019). https://doi.org/10.1007/s00170-019-04393-8

K.H. Schwalbe, M. Koçak, Performance of strength mis-matched welded or bonded joints (GKSS Research Center, Geesthacht, 1997)

Acknowledgements

The authors sincerely thank members of the Gedik Test Center, Istanbul-Turkey for their technical support during the testing and characterization of the WAAM components.

Funding

This study has been supported by the Scientific and Technological Research Council of Turkey (TUBITAK) under the University-Industry Cooperation Support Program scope with project number 5220023.

Author information

Authors and Affiliations

Contributions

UG conceptualization, material preparation, data collection, writing (original draft, review, and editing). BT conceptualization, material preparation, data collection, writing (original draft). HK material preparation and data collection. SD conceptualization, writing (original draft, review, and editing). MK conceptualization, writing (review and editing).

Corresponding author

Ethics declarations

Conflict of interest

The authors have no relevant financial or non-financial interests to disclose.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Gürol, U., Turgut, B., Kumek, H. et al. Fabrication and Characterization of Wire Arc Additively Manufactured Ferritic-Austenitic Bimetallic Structure. Met. Mater. Int. 30, 1342–1355 (2024). https://doi.org/10.1007/s12540-023-01568-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-023-01568-7