Abstract

There is an increasing demand for materials capable of withstanding ever-higher temperatures. However, because the difficulties associated with carrying out experimental investigations at very high temperatures are significant, the published information relating to the phase stability of potential refractory materials is, in many instances, still lacking. The work described in this paper attempts to rectify this deficit through the on-going development of a thermodynamic database for high-temperature materials based on carbides, nitrides, borides, and silicides. Because of technological requirements of high-temperature stability and strength, combined with lightness, these are the materials that come into question most frequently for high-temperature applications. In develo** the present database, and to ensure reliability of its use, emphasis has been placed on the need to maintain the compatibility of data and modeling when assessing experimental data and estimating missing values. The methods used to achieve compatibility of published information are described and calculations of phase equilibria relevant to the industrial application of various refractory materials are presented. The similarity to, and the importance of the scientific background and published work of Ted Massalski for the work of the present author is stressed.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Preparation of this paper and research into Ted Massalski’s scientific background made clear that the time he spent at Birmingham University, UK, where he obtained his Ph.D. and D.Sc. were of particular importance. There he interacted closely with eminent and ground-breaking scientists such as Cottrell, Raynor, Cahn (Robert), Eshelby and Charles Barrett. The years at Birmingham laid the foundation for his future work, centered closely around the theory and critical evaluation of phase diagrams.

The present author has been privileged to share a closely similar early background, having also obtained his B.Sc. and Ph.D. from the Department of Physical Metallurgy at Birmingham University and having interacted with the same eminent scientists (except for Cottrell) as Ted.

It is very appropriate, therefore, that the present paper should be directed to describing the development of a thermodynamic database allowing computer calculation of phase equilibria in a particular group of alloy systems, namely high-temperature refractory carbide, nitride, boride, and silicide systems. These materials are finding ever-increasing use in many areas of technology, yet the amount of published phase diagram information available for them is still limited. Some examples of use of these non-oxide refractories are in furnace construction, high-temperature coatings, cutting tools, abrasives, aircraft brake linings, rockets, jets, turbines, nuclear power plants and as precipitates imparting strength and hardening to certain light alloys and steels.

The significant experimental difficulties associated with the determination of phase equilibria and thermodynamic properties of materials at high temperatures (temperature measurement, specimen-container interactions, oxidation problems, etc.) result in a generally lower accuracy of the assessed thermodynamic parameters for refractory systems. Many of the published experimental ternary phase diagrams originate from work carried out some 30 or more years ago, and in some cases now show incompatibility with accepted binary phase equilibria. However, the data in the present database (denoted SpMCBN), which has been developed for use with the FactSage software (www.factsage.com), are believed to allow generally reliable calculation of thermodynamic properties and phase equilibria for the temperatures and temperature ranges covered by the phase diagrams accompanying the documentation of the database.

The procedures used to obtain missing data and carry out thermodynamic assessment work for binary and ternary alloys, often based on information in the ASM Binary and Ternary Alloy Phase Diagram compilations[1,2,3] for which Massalski was an editor, are described below. Necessary simplifications involved in maintaining compatibility of the database when combining assessments from different authors are discussed and example calculations for binary, ternary and higher-order systems presented.

By combining available data with various estimation methods, it has been possible to produce thermodynamic parameters for many previously un-assessed systems. This significantly expands the capability to investigate the phase constitution of existing and potential new refractory materials based on carbides, nitrides, borides, and silicides.

In the current version of the database, calculations of thermodynamic properties and phase diagrams can be carried out for ca. 272 binary, and 585 ternary systems, for the individual temperatures or temperature ranges covered by the available experimental information. Phase equilibria in higher-order systems can be calculated, with some loss of reliability, by combination of the assessed thermodynamic parameters for the relevant binary and ternary sub-systems.

2 Data Assessment and Estimation

The elements included in the Database are:

-

B, C, N, Si with

-

Al, (Ca), Co, Cr, Fe, Hf, (Mg), Mn, Mo, Nb, Ni, Re, Sc, Ta, Tc, Ti, V, W, Y, Zr

-

(Ca and Mg are included in only a very few selected systems).

As reference basis for the high temperature stability of different refractory materials, the melting temperatures of many carbides, nitrides, borides, silicides, and oxides are shown in Fig. 1.

It should be noted, that for several carbides and nitrides, because they display a range of stoichiometry, the melting temperature shown in the figure corresponds to a maximum melting composition a little removed from that corresponding to the stoichiometric formula. Such displacements are of an average order of 0.03 mol fraction toward higher metal concentrations.

Throughout the database assessment work, the liquid phase in all alloy systems has been described by the Bragg-Williams random mixing model with a Redlich-Kister-Muggianu (R-K) polynomial expression of the excess Gibbs energy.

Figure 2 illustrates the binary systems for which assessed data are available in the SpMCBN Database, together with the likely quality of the assessment in each case. The assignment of a particular level of quality to each system is somewhat subjective, but is based on the amount, the type, and the accuracy of the experimental information available, as well as on the consistency between reported thermodynamic and phase boundary values.

The original, basic approach taken in the development of the SpMCBN Database has been to combine the phase boundary information contained in the ASM Handbooks of Binary and Ternary Alloy Phase Diagrams[1,2] and in the more recent ASM Alloy Phase Diagram Database, 2016[3] with available assessed thermodynamic data obtained from the original literature and from SGTE compilations.[4,5] In the case of binary or ternary systems for which the ASM compilations present several, differing published phase diagrams, the version given greatest weight in the present assessment work is included in the references accompanying the database (www.factsage.com).

There is a great scarcity of published experimental thermodynamic data for the phases of refractory alloys. For this reason, the simplification of additivity of element entropy and heat capacity data (Neumann-Kopp’s Rule) has been used frequently as the basis for obtaining a complete set of thermodynamic values for binary and ternary compounds. Adjustments to the additive values has followed in many cases, to achieve satisfactory agreement between experimental and calculated phase equilibria.

Enthalpies of formation are particularly important in determining the stability of a phase but are more difficult to estimate when no experimental value is available. For this reason, a few methods have been used to provide good starting values for further assessment work. Two of these methods, due to Pettifor[6] and to Chen and Podloucky[7] are described below.

To map the appearance of different crystal structures of elements and their compounds in a more logical manner, Pettifor re-arranged the Periodic Table into a single string, as shown in Fig. 3, whereby each element is allocated what Pettifor terms a Mendeleev Number.

The Pettifor single string arrangement of the Periodic Table—redrawn from Ref 6

The illustrated element sequence through the transition periods has proved very effective in providing missing values of enthalpies of formation of the high melting temperature carbides, nitrides, borides and silicides relevant to the present database. This is exemplified in the following figures, where a regular, essentially linear behavior of enthalpy of formation with the Pettifor Mendeleev Number, is observed for compounds with the same crystal structure.

Chen and Podloucky[7] have revised Miedema’s model[8] in combination with ab initio results to produce a method for calculation of enthalpies of formation of any binary element combination. Their predicted results for carbides and nitrides are included with the assessed values in Fig. 4.

A very recent new source of thermodynamic values, including enthalpies of formation, is represented by the AIMP Database under development by GTT Technologies[9]. This database is based on ‘first principles’ methodology but with extension of the thermodynamic stability to relevant temperatures. Because of the potential importance of the AIMP Database content for development of the present database, the reliability of the methodology has been tested by comparing its predicted values for selected carbides, nitrides, borides, and silicides with available assessed data. Some results relevant to the present work are presented in Table 1 and in the Pettifor arrangement of the Periodic Table in Fig. 5.

The continuing growth in the number of assessed systems in the SpMCBN Database has necessitated the introduction of new elements into existing phases, as well as the self-compatible description of a particular phase occurring in different binary and ternary systems, but for which the thermodynamic modeling used by different authors is not compatible and often represents differing ranges of stoichiometry. It is not a realistic proposition to carry out reassessments of the very large number of systems for which there is incompatibility in the published modeling. For this reason, development of the present database has been achieved, in some cases, by simplification of certain phases, such as the MU and LAVES phases, which often display limited ranges of stoichiometry, to line compounds. This allows calculations for higher-order systems which are still of satisfactory reliability with respect both to thermodynamic properties and phase equilibria.

The simplified modeling used for certain frequently occurring phases observed in refractory alloy systems is exemplified here for the MU phase.

The MU-Phase description in the SpMCBN Database is based on a 3-sublattice model with site occupation 7:2:4. The element occupation of the lattices is

-

7: Co, Cr, Fe, Mn, Mo, Nb, Ni, Ta, V

-

2: Mn, Mo, Nb, Ta, Ti, V, W, Zr

-

4: Co, Cr, Fe, Mn, Mo, Nb, Ni, Ta, Ti, V, W, Zr

Because the MU-Phase has the general stoichiometry of M7X6 (where M and X are the two elements involved) the model does not allow representation of those systems in which Co, Fe, and Ni correspond to X6 in the formula (e.g. Ta7Ni6, Nb7Ni6, Nb7Co6, etc.), because Co, Fe and Ni are not present on the sublattice with occupation 2. For this reason, the M7C6 phase has been created with stoichiometry M7X6 or X7M6, as a simplification allowing the MU-Phase to be treated as a line compound as and where necessary.

This simplified stoichiometric format, used for phases displaying small ranges of composition allows mixing descriptions in higher-order systems not only for the MU-Phase, but also for other non-stoichiometric phases which appear frequently in refractory metal alloys. Examples of the effect of some simplifications on calculated binary phase equilibria are illustrated in the following diagrams (Fig. 6).

A further, more recent development of the SpMCBN Database is represented by the introduction of volumetric and thermal conductivity parameters for 184 pure solid phases (Table 2, compiled by Gheribi 10). Volumetric properties (density at 298.15 K, volumetric thermal expansivity, compressibility and derivative of the Bulk Modulus) and thermal conductivity parameters (based on the Debye Temperature, Gruneisen Parameter, and atoms per crystallographic cell) are now available for the following carbides, nitrides, and borides, Table 2.

3 Applications of the SpMCBN Database

3.1 Calculation of Ternary Phase Equilibria

The stored thermodynamic parameters allow calculation of any section in a defined ternary or higher-order system for temperature ranges covered by the assessed data. Such calculations provide important information on the alloy constitution, which otherwise could only be obtained by very lengthy and expensive experimental investigation.

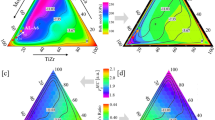

Examples of this capability for a system (B-Re-Ta) containing various binary and ternary solution and compound phases (Fig. 7) and for a system (B-Mo-W) presenting a relatively complex liquidus surface (Fig. 8) are shown below.

Scientists at Brown University have used ab initio molecular dynamics calculations to find a material that has the highest melting point of any known substance. They find this temperature to be 4126 °C (4399 K). The theoretical alloy is a combination of hafnium, carbon and nitrogen and has the chemical formula HfC0.51N0.38[11].

Figure 9 allows comparison of the theoretically calculated melting temperature with the value obtained (4170 K) from liquidus surface calculations using the SpMCBN Database.

3.2 Calculation of Quaternary Phase Equilibria

An example calculation for a quaternary system is illustrated below for the section between HfC and TiB2 in the Hf-Ti B-C system (Fig. 10).

Calculated HfC-TiB2 section in the Hf-Ti-B-C system (The red dot denotes the composition and temperature used for the calculation in Table 2) (Color figure online)

After carrying out the calculation, it is possible in FactSage to click on any point in the diagram, such as that shown, to obtain a tabulated output giving the amount of each phase present and its composition at the selected point.

T = 3337 K |

P = 1 atm |

V = 0 dm3 |

Stream constituents | Amount/mol |

B2Ti | 1.9830E−01 |

HfC | 8.0170E−01 |

Equil amt. | Mol fracn. | Activity | |

|---|---|---|---|

Phase: liquid | mol | ||

B | 3.1113E−01 | 3.3492E−01 | 7.6541E−02 |

C | 2.5715E−01 | 2.7682E−01 | 3.3847E−02 |

Hf | 1.9450E−01 | 2.0937E−01 | 1.5246E−02 |

Ti | 1.6619E−01 | 1.7890E−01 | 6.5424E−03 |

Total: | 9.2897E−01 | 1.0000E + 00 | 1.0000E + 00 |

Phase: FCC | mol | Mol fracn. | Activity |

|---|---|---|---|

Hf:Va | 8.8276E−03 | 1.3808E−02 | 9.1883E−03 |

Hf:C | 5.1719E−01 | 8.0898E−01 | 6.8347E−01 |

Hf:B | 8.1181E−02 | 1.2698E−01 | 3.0244E−03 |

Ti:Va | 4.6684E−04 | 7.3021E−04 | 3.3165E−03 |

Ti:C | 2.7351E−02 | 4.2782E−02 | 9.1376E−02 |

Ti:B | 4.2931E−03 | 6.7152E−03 | 1.0424E−10 |

TOTAL: | 6.3931E−01 | 1.0000E + 00 | 1.0000E + 00 |

Site fraction of sublattice constituents:

Hf | 0.94977 | Stoichiometry = 1 |

Ti | 5.0227E−02 |

Va | 1.4538E−02 | Stoichiometry = 1 |

C | 0.85177 | |

B | 0.13370 |

The SpMCBN Database can be used in conjunction with other FactSage-compatible databases, such as the Fact Pure Substances Database, the SGTE Pure Substances Database, the Fact Oxide Database, or the Fact Steel Database, to carry out relevant predictive calculations. Some examples follow.

3.3 Calculation of Optimum Variables for Production of Refractories

Different potential processes for production of refractory carbides, nitrides and borides are regularly being reported in the literature. The SpMCBN Database allows rapid theoretical investigation of optimum process conditions prior to carrying out experiments. An example is the borothermic reduction of ZrO2 to produce ZrB2.

Figure 11 illustrates the narrow calculated composition range and temperatures at which ZrB2 can be formed as the only solid phase.

3.4 Liquid and Gaseous Corrosion of Refractories

Of particular importance is the capability to investigate potential reactions of a refractory material in a liquid or gaseous environment. The content of molten alloys at very high temperatures, where a chemically aggressive gaseous environment may also be a factor, sets severe limits on the choice of reactor hot-zone materials that can be used.

Refractory nitrides, carbides, and borides are of particular interest for such applications and TaC, for example, has already found use for temperatures more than 2200 °C.

Figure 12 presents the calculated results for the effect of temperature on the composition of a molten superalloy contained in a TaC crucible. Note the pickup of C and Ta in the alloy with increasing temperature, which corresponds to loss of crucible material into the melt.

3.5 Environmentally-Friendly Production of Binary and Ternary Carbides

Calculations have been carried out to determine the optimum conditions for production of several binary and ternary refractory metal carbides, together with hydrogen-rich gases.[12]

The potential environmentally-friendly production process involves the use of methane as the reducing agent for several oxides. Chemically, methane contains 4 hydrogen atoms for each carbon atom. Therefore, carbide production using methane (or natural gas) is an environmentally more friendly process than direct reduction of the oxides with carbon.

A thermodynamic analysis of the reduction of MoO3 with CH4 using the SpMCBN Database clarifies the progression of the reduction process with temperature (Fig. 13) and predicts that Mo2C will be the only stable solid phase at temperatures above about 1000 K.

X-ray diffraction studies carried out in conjunction with the experimental MoO3–CH4 reduction confirmed that Mo2C is the only solid product of the reaction at 1273 K.[12]

Calculations have also been carried out for the reduction of zirconium silicate (Zircon) with methane.

The phase stability diagram for ZrSiO4 - CH4 (Fig. 14) shows that a phase region exists above 1800 K in which the solid ZrC and SiC carbides are formed together with a hydrogen-rich syngas.

Because the two carbides, SiC and ZrC, show very little mutual solubility, methane reduction of ZrSiO4 represents an interesting method for simultaneous production of both carbides.

4 Production of (Ti,Al)N Coatings

In PVD coating processes, the low-temperature substrate inhibits diffusion of the depositing atoms, and the film is therefore constrained to be a single-phase structure. The structure should therefore reflect the energetically most stable single-phase form available to it at the temperature of the substrate.

Deposition of mixtures in the AlN-TiN system can result in coatings with either the hcp or fcc structure, depending on the composition involved. Industrial applications of (Ti, Al) N coatings, such as for cutting tools, make use of the mechanically stronger and more stable fcc structure and knowledge of the composition limits of stability of the potential hcp (AlN) and fcc (TiN) coating structures are therefore of prime importance. This information can be found directly from Gibbs energy versus composition (G/x) diagrams for the pseudo-binary AlN-TiN system.

Using the SpMCBN Database, the relevant Gibbs energy curves for the hcp and fcc phases have been calculated for various temperatures (Fig. 15). The point of intersection of these curves at each temperature defines the composition at which there is a transition from one structure to the other. This composition is found to be nearly temperature independent with a calculated value around 0.3 mole fraction TiN.

Experimental investigations of the extent of the metastable cubic range in the section AlN-TiN have been carried out by Cremer et al. 13 using electron probe micro-analysis, X-ray photoelectron spectroscopy and thin film X-ray diffraction. The results showed a transition from hexagonal to cubic coating structure at a composition of approximately 0.33 mol fraction TiN at 473 K, with a narrow hcp + fcc 2-phase region develo** in the coatings at a deposition temperature of 873 K .

The very satisfactory agreement between the experimental and calculated results demonstrates the considerable predictive potential of thermodynamic calculations in develo** new coating materials.

5 Conclusions

The SpMCBN database significantly expands the capability to investigate the phase constitution of existing and potential new refractory materials based on carbides, nitrides, borides, and silicides.

By combining available data with various estimation methods, it has been possible to produce thermodynamic parameters for many previously un-assessed systems.

Combination of the SpMCBN database with other available FactSage-compatible databases allows calculation of optimum conditions for carrying out existing processes or designing potential new processes for the production and application of refractory materials with the required composition and purity.

References

T.B. Massalski, H. Okamoto, Eds., Binary Alloy Phase Diagrams 2nd edn. ASM, Materials Park, 2010

P. Villars, A. Prince, H. Okamoto, Eds., Handbook of Ternary Alloy Phase Diagrams ASM, Materials Park, 1995

ASM Alloy Phase Diagram Database, 2016, accessible on-line.

SGTE Data for Pure Elements, A.T. Dinsdale, Calphad 15 (1991) 317-425.

SGTE Solution Database, see www.sgte.net.

D. Pettifor, New Scientist, (1986) p.48.

X.-Q. Chen, and R. Podloucky, Miedema’s model revisited: The parameter ϕ* for Ti, Zr, and Hf, Calphad, 2006, 30, p 266–269.

A.R. Miedema, A simple model for alloys. I. Rules for the alloying behavior of transition metals, Philips Technical Review, 1973, 33, p 149–160.

The AIMP Database, see http://www.gtt-technologies.de.

C.W. Bale, E. Bélisle, P. Chartrand, S.A. Decterov, G. Eriksson, A.E. Gheribi, K. Hack, I.H. Jung, Y.B. Kang, J. Melançon, A.D. Pelton, S. Petersen, C. Robelin, J. Sangster, P. Spencer, and M.-A. Van Ende, FactSage thermochemical software and databases, 2010–2016, Calphad, 2016, 54, p 35–53.

Q.J. Hong, and A. van de Walle, Prediction of the material with highest known melting point from ab initio molecular dynamics calculations, Phys. Rev. B, 2015, 92, p 020104(R).

S. K. Saxena, P. J. Spencer and V. Drozd, Monatshefte für Chemie in memoriam Heinz Gamsjäger, 149, No.1, 2018.

R. Cremer, M. Witthaut, D. Neuschütz, in `Value Addition Metallurgy', Eds. W.D.Cho and H.Y.Sohn, The Minerals, Metals & Materials Society (1998) p. 249.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

This invited article is part of a special tribute issue of the Journal of Phase Equilibria and Diffusion dedicated to the memory of Thaddeus B. “Ted” Massalski. The issue was organized by David E. Laughlin, Carnegie Mellon University; John H. Perepezko, University of Wisconsin–Madison; Wei **ong, University of Pittsburgh; and JPED Editor-in-Chief Ursula Kattner, National Institute of Standards and Technology (NIST).

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Spencer, P.J. The Development of a Thermodynamic Database for Calculation and Prediction of Phase Equilibria in High-Temperature Refractory Alloys: A Tribute to Ted Massalski. J. Phase Equilib. Diffus. (2023). https://doi.org/10.1007/s11669-023-01063-x

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11669-023-01063-x