Abstract

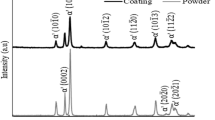

The inter-particle bonding (IPB) mechanism of cold-sprayed titanium alloy during heat treatment (HT) is not clear. The interfacial microstructure and bonding characteristics at the interface of cold-sprayed Ti6Al4V after HT were studied at the micro- and nano-scale. As a result, the nanocrystallization at IPB during cold spray (CS) cannot cause obvious metallurgical bonding between Ti6Al4V particles. The average Young’s modulus of CS Ti6Al4V is 57% higher than that of powder, but the average Young’s modulus of HT sample decreases by 16%. The internal stress and dislocation distribution of interfacial microstructure can lead to various microstructure features and non-uniform rates of microstructure growth at deformed transition layer and IPB during HT. The nanograins at the IPB grow into micron-equiaxed grains. On the contrary, the micron martensitic laths at deformed transition layer adjacent to IPB show the characteristics of equiaxed nanograins transformation under the action of grain boundary bulges induced by dislocation entanglement.

Similar content being viewed by others

Data Availability

Data will be made available on request.

References

W. Li, C. Cao, and S. Yin, Solid-State Cold Spraying of Ti and Its Alloys: A Literature Review, Prog. Mater. Sci., 2020, 110, p 100633.

S. Yin, M. Hassani, Q. **e, and R. Lupoi, Unravelling the Deposition Mechanism of Brittle Particles in Metal Matrix Composites Fabricated Via Cold Spray Additive Manufacturing, Scr. Mater., 2021, 194, p 113614.

Y. **e, R.-N. Raoelison, P. Herve, M.-P. Planche, S. Deng, R. Huang, and J. Wang, Zhongming Ren & Hanlin Liao Strengthened Peening Effect on Metallurgical Bonding Formation in Cold Spray Additive Manufacturing, J. Therm. Spray Technol., 2019, 28, p 881.

S. Yin, N. Fan, C. Huang, Y. **e, C. Zhang, R. Lupoi, and W. Li, Towards High-Strength Cold Spray Additive Manufactured Metals: Methods, Mechanisms, and Properties, J. Mater. Sci. Technol., 2024, 170, p 47-64.

D. Guo, M. Kazasidis, A. Hawkins, N. Fan, Z. Leclerc, D. MacDonald, A. Nastic, R. Nikbakht, R. Ortiz-Fernandez, S. Rahmati, M. Razavipour, P. Richer, S. Yin, R. Lupoi, and B. Jodoin, Cold Spray: Over 30 Years of Development Toward a Hot Future, J. Therm. Spray Technol., 2022, 31, p 2244.

P. Poza and M.Á. Garrido-Maneiro, Cold-Sprayed Coatings: Microstructure, Mechanical Properties, and Wear Behaviour, Prog. Mater. Sci., 2022, 123, p 100839.

A.W.Y.T.N.W. Khun, K.J.W. Bi, and E. Liu, Effects of Working Gas on Wear and Corrosion Resistances of Cold Sprayed Ti-6Al-4V Coatings, Surf. Coat. Technol., 2016, 302, p 1-12.

L.I. Perez-Andrade, V.S. Bhattiprolu, W.M. Schuette, and L.N. Brewer, Influence of Powder Properties and Processing Gas on the Microstructural Evolution of Armstrong CP-Titanium and Ti6Al4V Powders Processed by Cold Spray, Surf. Coat. Technol., 2022, 431, p 128011.

V.K.C.J.A.M. Birt, R.D. Sisson Jr., and D. Apelian, Microstructural Analysis of Cold-Sprayed Ti-6Al-4V at the Micro- and Nano-Scale, J. Therm. Spray Technol., 2015, 24, p 1277-1288.

X.-T. Luo, Y.-K. Wei, Y. Wang, and C.-J. Li, Microstructure and Mechanical Property of Ti and Ti6Al4V Prepared by an In-Situ Shot Peening Assisted Cold Spraying, Mater. Des., 2015, 85, p 527-533.

L. Yang, B. Li, J. Yao, and Z. Li, Effects of Diamond Size on the Deposition Characteristic and Tribological Behavior of Diamond/Ni60 Composite Coating Prepared by Supersonic Laser Deposition, Diam. Relat. Mater., 2015, 58, p 139-148.

R. Cheng, X. Luo, G. Huang, and C.J. Li, Corrosion and Wear Resistant WC17Co-TC4 Composite Coatings with Fully Dense Microstructure Enabled by In-Situ Forging of the Large-Sized WC17Co Particles in Cold Spray, J. Mater. Process. Technol., 2021, 296, p 117231.

W.J. Feng Guo, G. Tang, Z. **e, H. Dai, E. Wang, Y. Chen, and L. Liu, Enhancing Anti-wear and Anti-corrosion Performance of Cold Spraying Aluminum Coating by High Current Pulsed Electron Beam Irradiation, Vacuum, 2020, 182, p 109772.

Z. Zhao, J. Tang, H. Liu, H. Liu, Y. Ren, M. Tong, L. Yin, H. Du, J. Wang, and T. **ong, Effect of Rolling Temperature on Microstructure and Mechanical Properties of Ti/Steel Clad Plates Fabricated by Cold Spraying and Hot-Rolling, Mater. Sci. Eng. A, 2020, 795, p 139982.

C.J. Huang, X.C. Yan, W.Y. Li, W.B. Wang, C. Verdy, M.P. Planche, H.L. Liao, and G. Montavon, Post-Spray Modification of Cold-Sprayed Ni-Ti Coatings by High-Temperature Vacuum Annealing and Friction Stir Processing, Appl. Surf. Sci., 2018, 451, p 56-66.

P.H. Wen Wang, Y. Wang, T. Zhang, P. Peng, K. Qiao, Z. Wang, Z. Liu, and K. Wang, High-Performance Bulk Pure Al Prepared Through Cold Spray-Friction Stir Processing Composite Additive Manufacturing, J Mater Res Technol, 2020, 9, p 9073-9079.

Y. Xu, J. Ge, B. Ji, and W. Li, Mechanical Alloying of Cold-Sprayed Ni-Nb-Si Composite Coating by Friction Stir Processing: Improvement in Microstructure and Resistance Against Molten Silicates Corrosion, Surf. Coat. Technol., 2022, 451, p 129051.

V.S. Bhattiprolu, K.W. Johnson, O.C. Ozdemir, and G.A. Crawford, Influence of Feedstock Powder and Cold Spray Processing Parameters on Microstructure and Mechanical Properties of Ti-6Al-4V Cold Spray Depositions, Surf. Coat. Technol., 2018, 335, p 1-12.

L. Yang, P. Wang, X. Luo, H. Li, H. Yang, S. Wang, and Q. Li, Nanocrystallization of Interfacial Microstructure of Deformed Particles in Cold Sprayed Ti6Al4V Deposits, Mater. Des., 2021, 210, p 110117.

J.Y. Lek, A. Bhowmik, A.W.-Y. Tan, W. Sun, X. Song, W. Zhai, P.J. Buenconsejo, F. Li, E. Liu, Y.M. Lam, and C.B. Boothroyd, Understanding the Microstructural Evolution of Cold Sprayed Ti-6Al-4V Coatings on Ti-6Al-4V Substrates, Appl. Surf. Sci., 2018, 459, p 492-504.

A. Bhowmik, A. Wei-Yee Tan, W. Sun, Z. Wei, I. Marinescu, and E. Liu, On the Heat-Treatment Induced Evolution of Residual Stress and Remarkable Enhancement of Adhesion Strength of Cold Sprayed Ti-6Al-4V Coatings, Results Mater., 2020, 7, p 100119.

M.S. Renzhong Huang, W. Ma, and H. Fukanuma, The Effects of Heat Treatment on the Mechanical Properties of Cold-Sprayed Coatings, Surf. Coat. Technol., 2015, 261, p 278-288.

C.Z.W.-Y. Li, H. Liao, and C. Coddet, Effect of Heat Treatment on Microstructure and Mechanical Properties of Cold Sprayed Ti Coatings with Relatively Large Powder Particles, J. Coat. Technol. Res., 2009, 6, p 401-406.

E.I.P. Vo, J.-G. Legoux, and S. Yue, Mechanical and Microstructural Characterization of Cold-Sprayed Ti-6Al-4V After Heat Treatment, J. Therm. Spray Technol., 2013, 22, p 954-964.

P. Sirvent, M.Á. Garrido, J. Sharp, W.M. Rainforth, and P. Poza, Improving the Oscillating Wear Response of Cold Sprayed Ti-6Al-4V Coatings Through a Heat Treatment, Surf. Coat. Technol., 2020, 399, p 126128.

C. Chen, Y. **e, R. Huang, S. Deng, Z. Ren, and H. Liao, On the Role of Oxide Film’s Cleaning Effect into the Metallurgical Bonding During Cold Spray, Mater. Lett., 2018, 210, p 199-202.

R.T. Yuji Ichikawa, M. Tanno, and K. Ogawa, Elucidation of Cold-Spray Deposition Mechanism by Auger Electron Spectroscopic Evaluation of Bonding Interface Oxide Film, Acta Mater., 2019, 164, p 39-49.

M.D.V. Tian Liu, J.R. Bunn, T. Ungar, and L.N. Brewer, Quantifying Dislocation Density in Al-Cu Coatings Produced by Cold Spray Deposition, Acta Mater., 2020, 193, p 115-124.

H.W. Zhiying Liua, M.J.R. Hache, X. Chu, E. Irissou, and Y. Zou, Prediction of Heterogeneous Microstructural Evolution in Cold Sprayed Copper Coatings Using Local Zener-Hollomon Parameter and Strain, Acta Mater., 2020, 193, p 191-201.

Y. **e, N. Fan, J. Yang, W. Li, R. Lupoi, X. Guo, R. Huang, and S. Yin, Improvement of Tensile Strength of Cold Sprayed Fe Deposits via in-Process Powder Preheating, Mater. Lett., 2022, 316, p 132090.

J. Tam, B. Yu, W. Li, D. Poirier, J.-G. Legoux, J.D. Giallonardo, J. Howe, and U. Erb, The Effect of Annealing on Trapped Copper Oxides in Particle-Particle Interfaces of Cold-Sprayed Cu Coatings, Scr. Mater., 2022, 208, p 114333.

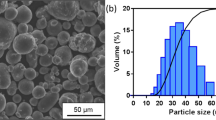

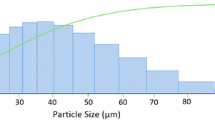

Y. Cui, Y. Zhao, H. Numata, H. Bian, K. Wako, K. Yamanaka, K. Aoyagi, C. Zhang, and A. Chiba, Effects of Plasma Rotating Electrode Process Parameters on the Particle Size Distribution and Microstructure of Ti-6Al-4 V Alloy Powder, Powder Technol., 2020, 376, p 363-372.

Y. Peng, P. Gao, W. Zhang, L. Cui, S. Liu, W. Chen, J. Li, R. Zhou, G. Liu, Q. Fang, and B. Liu, Severe Plastic Deformation Induced Nano Dispersion and Strengthening Effect in Oxide Dispersion Strengthened Copper Fabricated by Cold Spray Additive Manufacturing, Mater Charact, 2023, 205, p 113281.

Y. **e, S. Yin, C. Chen, M.-P. Planche, H. Liao, and R. Lupoi, New Insights into the Coating/Substrate Interfacial Bonding Mechanism in Cold Spray, Scr. Mater., 2016, 125, p 1-4.

Acknowledgments

The authors would like to appreciate the financial supports from National Natural Science Foundation of China (51701165) and Natural Science Basic Research Program of Shaanxi Province (2023-JC-YB-318, 2023-JC-QN-0641).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Yang, L., Wang, S., Luo, X. et al. Microstructural Nano-Scale Evolution at Inter-Particles Bonding Interface of Cold-Sprayed Ti6Al4V Deposits During Heat Treatment. J Therm Spray Tech 32, 2713–2728 (2023). https://doi.org/10.1007/s11666-023-01671-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-023-01671-6