Abstract

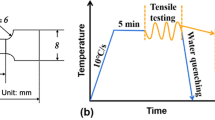

The microstructure and yield plateau of an annealed extruded Mg-6.8Y-2.5Cu alloy were investigated. During the annealing process, the 18R-LPSO phase transformed into a 14H-LPSO phase. With increasing annealing time, the grain size increased while the number of dislocations decreased in the extruded alloy. Uneven plastic deformation occurred in the annealed alloy during the yield stage, accompanied by Lüders band formation. The yield strain significantly decreased with extended annealing time. Dislocation multiplication and interactions between dislocations and solute atoms or second phases led to the formation of yielding phenomenon in both extruded and annealed alloys. The grain size and dislocation density affected the yield strain of the annealed alloy, and their corresponding influence mechanisms were evaluated for different annealing time.

Similar content being viewed by others

References

Z. Zhao, J. Chen, X. Wu et al., Design of a Mg-7Li-2.6Al-0.4Si Alloy with Simultaneously Improved Strength and Ductility, Mater. Today Commun., 2021, 27, p 102244. https://doi.org/10.1016/j.mtcomm.2021.102244

Y.H. Liu, Z.R. Zhang, J. Wang et al., A Novel Mg-Gd-Y-Zn-Cu-Ni Alloy with Excellent Combination of Strength and Dissolution via Peak-Aging Treatment, J. Magn. Alloys, 2023, 11(2), p 720–734. https://doi.org/10.1016/j.jma.2022.05.012

J. ** New Mg Alloy as Potential Bone Repair Material Via Constructing Weak Anode Nano-Lamellar Structure, J. Magn. Alloys, 2023, 11(1), p 154–175. https://doi.org/10.1016/j.jma.2022.08.011

Z. Zhao, Y. Zhuang, T. Wang et al., Influence of Al-Si Eutectic Alloy on the Mechanical Behaviors and Microstructure Feature of Ultralight Dual-Phase Mg-8Li-x(Al-126 Si) Alloys, Mater. Today Commun., 2022, 30, p 103201. https://doi.org/10.1016/j.mtcomm.2022.103201

Z. Zhao, X. Liu, S. Li et al., Study on Strengthening and Toughening of Mechanical Properties of Mg-Li Alloy by Adding Non-Rare-Earth Elements Al and Si, JOM, 2022, 74(7), p 2554–2565. https://doi.org/10.1007/s11837-022-05296-y

Z. Zhang, J. **e, J. Zhang et al., Simultaneously Improving Yield Strength and Formability Potential of Mg Alloy Via Introducing Nano Precipitates and Texture-Weakened Heterogeneous Grains, J. Market. Res., 2023, 24, p 5486–5500. https://doi.org/10.1016/j.jmrt.2023.04.171

Z. Wei, H. Dong, J. Zhang et al., Preparation of High Strength Mg–Li–Zn–Y Alloy by MgLi2Zn Precipitation, Mater. Sci. Eng., A, 2024, 890, 145842. https://doi.org/10.1016/j.msea.2023.145842

Z. Li, J. Zhang, T. **ao et al., Regulating Microstructure and Improving Precipitation Hardening Response of Fine-Grained Mg-RE-Ag Hot-Extruded Alloy by Extreme Short-Time Heat Treatment, Mater. Sci. Eng., A, 2024, 892, 146059. https://doi.org/10.1016/j.msea.2023.146059

T. Lee, C.H. Park, D.L. Lee et al., Enhancing Tensile Properties of Ultrafine-Grained Medium-Carbon Steel Utilizing Fine Carbides, Mater. Sci. Eng., A, 2011, 528(21), p 6558–6564. https://doi.org/10.1016/j.msea.2011.05.007

W. Wen and J.G. Morris, The Effect of Cold Rolling and Annealing on the Serrated Yielding Phenomenon of AA5182 Aluminum Alloy, Mater. Sci. Eng., A, 2004, 373(1–2), p 204–216. https://doi.org/10.1016/j.msea.2004.01.041

O. Nijs, B. Holmedal, J. Friis et al., Sub-Structure Strengthening and Work Hardening of an Ultra-Fine Grained Aluminium–Magnesium Alloy, Mater. Sci. Eng., A, 2008, 483, p 51–53. https://doi.org/10.1016/j.msea.2006.11.166

B. Klusemann, G. Fischer, T. Böhlke et al., Thermomechanical Characterization of Portevin–Le Châtelier bands in AlMg3 (AA5754) and Modeling Based on a Modified Estrin–McCormick Approach, Int. J. Plast, 2015, 67, p 192–216. https://doi.org/10.1016/j.ijplas.2014.10.011

J. Koike, T. Kobayashi, T. Mukai et al., The Activity of Non-basal Slip Systems and Dynamic Recovery at Room Temperature in Fine-Grained AZ31B Magnesium Alloys, Acta Mater., 2003, 51(7), p 2055–2065. https://doi.org/10.1016/s1359-6454(03)00005-3

T. Zhao, Y. Hu, C. Zhang et al., Influence of Extrusion Conditions on Microstructure and Mechanical Properties of Mg-2Gd-0.3Zr Magnesium Alloy, J. Magn. Alloys, 2022, 10(2), p 387–399. https://doi.org/10.1016/j.jma.2020.06.019

M. Bian, X. Huang, and Y. Chino, A Combined Experimental and Numerical Study on Room Temperature Formable Magnesiu-Silver-Calcium Alloys, J. Alloy. Compd., 2020, 834, 155017. https://doi.org/10.1016/j.jallcom.2020.155017

S. Gao, A. Shibata, M. Chen et al., Correlation Between Continuous/Discontinuous Yielding and Hall-Petch Slope in High Purity Iron, Mater. Trans., 2014, 55(1), p 69–72. https://doi.org/10.1016/j.jallcom.2020.155017

Y.N. Wang and J.C. Huang, The Role of Twinning and Untwinning in Yielding Behavior in Hot-Extruded Mg-Al-Zn Alloy, Acta Mater., 2007, 55(3), p 897–905. https://doi.org/10.1016/j.actamat.2006.09.010

J. Wang, M.R.G. Ferdowsi, S.R. Kada et al., Influence of Precipitation on Yield Elongation in Mg-Zn Alloys, Scripta Mater., 2019, 160, p 5–8. https://doi.org/10.1016/j.scriptamat.2018.09.023

O. Muránsky, M.R. Barnett, V. Luzin, and S. Vogel, On the Correlation Between Deformation Twinning and Lüders-Like Deformation in an Extruded Mg Alloy: In Situ Neutron Diffraction and EPSC.4 modelling, Mater. Sci. Eng. A, 2010, 527(6), p 1383–1394. https://doi.org/10.1016/j.msea.2009.10.018

D. Zhang, H. Wen, M.A. Kumar et al., Yield Symmetry and Reduced Strength Differential in Mg-2.5Y Alloy, Acta Mater., 2016, 120, p 75–85. https://doi.org/10.1016/j.actamat.2016.08.037

X. Luo, Z. Feng, T. Yu et al., Transitions in Mechanical Behavior and in Deformation Mechanisms Enhance the Strength and Ductility of Mg-3Gd, Acta Mater., 2020, 183, p 398–407. https://doi.org/10.1016/j.actamat.2019.11.034

J. Wang, G. Zhu, L. Wang et al., Dislocation-Induced Plastic Instability in a Rare Earth Containing Magnesium Alloy, Materialia, 2021, 15, 101038. https://doi.org/10.1016/j.mtla.2021.101038

G. Bi, N. Zhang, J. Jiang et al., Microstructure and Yield Phenomenon of an Extruded Mg-Y-Cu Alloy with LPSO Phase, J. Rare Earths, 2023, 41(3), p 454–461. https://doi.org/10.1016/j.jre.2022.01.011

X. Yang, S. Wu, S. Lü et al., Effects of Ni Levels on Microstructure and Mechanical Properties of Mg-Ni-Y Alloy Reinforced with LPSO Structure, J. Alloy. Compd., 2017, 726, p 276–283. https://doi.org/10.1016/j.jallcom.2017.08.003

G. Bi, D. Fang, L. Zhao et al., Double-Peak Ageing Behavior of Mg-2Dy-0.5Zn Alloy, J. Alloys Compd., 2011, 509(32), p 8268–8275. https://doi.org/10.1016/j.jallcom.2011.05.117

C. Li, X. Li, X. Ke et al., Enhancing corrosion resistance of Mg-Li-Zn-Y-Mn Alloy Containing Long Period Stacking Ordered (LPSO) Structure through Homogenization Treatment, Corros. Sci., 2024, 228, 111829. https://doi.org/10.1016/j.corsci.2024.111829

K. Liu, J. Zhang, D. Tang et al., Precipitates Formed in a Mg-7Y-4Gd-0.5Zn-0.4Zr Alloy During Isothermal Ageing at 250°C, Mater. Chem. Phys., 2009, 117(1), p 107–112. https://doi.org/10.1016/j.matchemphys.2009.05.015

L. Yu, X. Chen, S. Wang et al., Atomic-Scale Observation of β′ and LPSO Phase in Mg–Y–Ni Alloy by HAADF-STEM, J. Mater. Res., 2019, 34(20), p 3545–3553. https://doi.org/10.1557/jmr.2019.147

Y.M. Zhu, A.J. Morton, and J.F. Nie, Growth and Transformation Mechanisms of 18R and 14H in Mg-Y-Zn Alloys, Acta Mater., 2012, 60(19), p 6562–6572. https://doi.org/10.1016/j.actamat.2012.08.022

Y. Yin, B. Li, Z. Yuan et al., Enhanced Hydrogen Storage Performance of Mg-Cu-Ni System Catalyzed by CeO2 Additive, J. Rare Earths, 2020, 38(9), p 983–993. https://doi.org/10.1016/j.jre.2019.07.010

X. Cui, W. Fu, D. Fang et al., Mechanical Properties and Deformation Mechanisms of a Novel Fine-Grained Mg-Gd-Y-Ag-Zr-Ce Alloy with High Strength-Ductility Synergy, J. Mater. Sci. Technol., 2021, 66, p 64–73. https://doi.org/10.1016/j.jmst.2020.05.028

R.G. Li, P.F. Song, G.L. Wu et al., Tensile Yielding Plateau in Fine-Grained Mg-15Gd Binary Alloy, Mater. Lett., 2022, 324, 132757. https://doi.org/10.1016/j.matlet.2022.132757

W. Wang, W.U. Di, R. Chen et al., Influence of Temperature and Strain Rate on Serration Type Transition in NZ31 Mg Alloy, Trans. Nonferrous Metals Society of China, 2015, 25(11), p 3611–3617. https://doi.org/10.1016/s1003-6326(15)64002-x

D.H. Johnson, M.R. Edwards, and P. Chard-Tuckey, Microstructural Effects on the Magnitude of Lüders Strains in a Low Alloy Steel, Mater. Sci. Eng., A, 2015, 625, p 36–45. https://doi.org/10.1016/j.msea.2014.11.084

R.G. Li, D.Y. Zhao, J.H. Zhang et al., Room Temperature Yielding Phenomenon in Extruded or/and Aged Mg-14Gd-2Ag-0.5Zr alloy with Fine-Grained Microstructure, Mater. Sci. Eng. A, 2020, 787, p 139551. https://doi.org/10.1016/j.msea.2020.139551

W.H. Yang, A Generalized von Mises Criterion for Yield and Fracture, J. Appl. Mech., 1980, 47(2), p 297–300. https://doi.org/10.1115/1.3153658

J. Koike, R. Ohyama, T. Kobayashi et al., Grain-Boundary Sliding in AZ31 Magnesium Alloys at Room Temperature to 523 K, Mater. Trans., 2003, 44(4), p 445–451. https://doi.org/10.2320/matertrans.44.445

J.P. Bailon, A. Loyer, and J.M. Dorlot, The Relationships Between Stress, Strain, Grain Size and Dislocation Density in Armco Iron at Room Temperature, Mater. Sci. Eng., 1971, 8(5), p 288–298. https://doi.org/10.1016/0025-5416(71)90095-4

Acknowledgments

This work was financially supported by National Natural Science Foundations of China (Nos. 52261027, 52001152 and 51961021), Project supported by the Natural Science Foundation of Gansu Province, China (No. 22JR5RA251), Undergraduate Innovation and Entrepreneurship Training Program (Nos. DC20231188, DC20231482 and DC20231558), and Sinoma Institute of Materials Research (Guang Zhou) Co., Ltd (SIMR) for hel** TEM/SEM work.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Bi, G., Yan, H., Jiang, J. et al. Microstructure and Yield Plateau of an Annealed Extruded Mg-Y-Cu Alloy. J. of Materi Eng and Perform (2024). https://doi.org/10.1007/s11665-024-09639-5

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11665-024-09639-5