Abstract

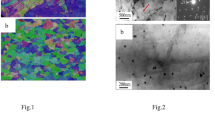

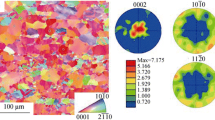

Magnesium (Mg) sheets that are thinner than 1 mm show significant advantages in the fabrication of shells of electronic equipment, as they are lightweight while also providing excellent electromagnetic shielding. Rolling is the most commonly used method for preparing such thin sheets, but it easily leads to edge cracks and poor mechanical properties related to the evolution of grain structure and texture. To this end, a two-stage rolling process under decreasing temperature conditions is proposed to obtain thin Mg alloy sheets with satisfied surface quality and excellent mechanical properties. The results demonstrated that after two-stage rolling, the thin sheets show satisfied surface quality, basically without edge cracks. The grain structure of the Mg sheets with thicknesses of 1.0, 0.6, 0.3, and 0.1 mm is homogeneous and significantly refined, with the smallest average grain size being approximately 5.3 μm. The 1.0-mm thin sheet exhibits a bimodal texture that transforms into a conventional (0001) basal texture as the rolling process proceeds. This is due to the low deformation temperature during warm rolling, which makes it difficult to activate non-basal slip, and thus, basal slip dominates deformation. Furthermore, based on the effect of inhomogeneous texture components and different Schmid factors in varying directions, all thin sheets show anisotropy in mechanical properties. The 0.6-mm thin sheet indicates a good combination of superior strength and medium ductility, which can be attributed to the combined effect of grain refinement and dislocation strengthening.

Similar content being viewed by others

References

J.F. Song, J. Chen, X.M. **ong, X.D. Peng, D.L. Chen, and F.S. Pan, Research Advances of Magnesium and Magnesium Alloys Worldwide in 2021, J. Magnes. Alloys, 2022, 10(4), p 863–898.

J.L. Zhang, L.W. Lu, B. Che, M. Ma, Z.Q. Wu, T. Zhou, H. Zhang, and F.G. Qi, Effects of Rolling-Cryogenic Process on Microstructure and Mechanical Properties of AZ31 Magnesium Alloy Sheets, J. Mater. Eng. Perform., 2023, 32, p 6448–6464.

Y.D. Fan, K.K. Deng, C.J. Wang, K.B. Nie, and Q.X. Shi, Work Hardening and Softening Behavior of Mg–Zn–Ca Alloy Influenced by Deformable Ti Particles, Mater. Sci. Eng. A, 2022, 2022(833), p 142336.

S.V.S. Prasad, S.B. Prasad, K. Verma, R.K. Mishra, V. Kumar, and S. Singh, The Role and Significance of Magnesium in Modern Day Research-A Review, J. Magnes. Alloys, 2022, 10(1), p 1–61.

M.Z. Bian, T.T. Sasaki, T. Nakata, Y. Yoshida, N. Kawabe, S. Kamado, and K. Hono, Bake-Hardenable Mg–Al–Zn–Mn–Ca Sheet Alloy Processed by Twin-Roll Casting, Acta Mater., 2018, 158, p 278–288.

C.H. Li, H. Hou, R.F. Dong, X.Y. Zhang, X.L. Xu, and Y.H. Zhao, Recrystallization Behavior and Mechanical Properties of AZ31B Alloy During the Hot-Rolling Process, J. Mater. Res. Technol., 2023, 24, p 1005–1014.

H.Y. Ning, Y.D. Yu, K. Lin, L.H. Wen, and C.X. Liu, Superplastic Properties of AZ31 and AZ31-1.0Y-1.3Sr Alloy Produced by Twin-Roll Casting and Sequential Hot Rolling, J. Mater. Eng. Perform., 2016, 25, p 635–641.

Y. Li, P.J. Hou, Z.G. Wu, Z.L. Feng, Y. Ren, and H. Choo, Dynamic Recrystallization of a Wrought Magnesium Alloy: Grain Size and Texture Maps and Their Application for Mechanical Behavior Predictions, Mater. Des., 2021, 202, p 109562.

H.C. Pan, R.S. Cheng, S. Du, H.B. **e, L. Wu, Z.Y. Deng, C.L. Yang, L.F. Ma, and G.W. Qin, Achieving High Strength in Micro-Alloyed Mg–Al–Ca–Zn–Mn–Ce Alloy Sheet Processed by Single-Pass Large-Strain Rolling, J. Mater. Eng. Perform., 2020, 29, p 7115–7124.

M.Z. Bian, X.S. Huang, and Y. Chino, Substantial Improvement in Cold Formability of Concentrated Mg–Al–Zn–Ca Alloy Sheets by High Temperature Final Rolling, Acta Mater., 2021, 220, p 117328.

Q. Liu, Y. Liu, Q. Luo, J.F. Song, B.Q. **ao, B. Jiang, L.Y. Wu, H. Zhao, Q.Y. Shen, and F.S. Pan, Ameliorating the Edge Cracking Behavior of Mg–Mn–Al Alloy Sheets Prepared by Multi-pass Online Heating Rolling, J. Manuf. Process., 2023, 85, p 977–986.

Z. Wang, M. Mamatzunun, Y.H. Wu, Y.J. Wu, C.J. Bian, and R. Zhu, Influence of Rolling Temperature on the Mechanical Properties and Microstructure of Variable-Plane-Rolled Mg–3Al–1Zn Alloy, J. Mater. Eng. Perform., 2019, 28, p 1772–1779.

Q.H. Chen, R.N. Chen, J. Su, Q.S. He, B. Tan, C. Xu, X. Huang, Q.W. Dai, and J. Lu, The Mechanisms of Grain Growth of Mg Alloys: A Review, J. Magnes. Alloys, 2022, 10(9), p 2384–2397.

K.B. Nie, X.J. Wang, K.K. Deng, F.J. Xu, K. Wu, and M.Y. Zheng, Microstructures and Mechanical Properties of AZ91 Magnesium Alloy Processed by Multidirectional Forging under Decreasing Temperature Conditions, J. Alloys Compd., 2014, 617, p 979–987.

C. Cui, J. He, W.K. Wang, W.Z. Chen, and W.C. Zhang, Microstructure, Texture and Mechanical Properties of Extruded AZ31 Mg Alloy During Small Strain Multi-directional Forging with Gradient Cooling, J. Alloys Compd., 2022, 909, p 164795.

L.B. Tong, J.H. Chu, W.T. Sun, C. Xu, D.N. Zou, K.S. Wang, S. Kamado, and M.Y. Zheng, Achieving an Ultra-High Strength and Moderate Ductility in Mg–Gd–Y–Zn–Zr Alloy Via a Decreased-Temperature Multi-Directional Forging, Mater Charact, 2021, 171, p 110804.

D.F. Zhang, Q.W. Dai, L. Fang, and X.X. Xu, Prediction of Edge Cracks and Plastic-Damage Analysis of Mg Alloy Sheet in Rolling, Trans. Nonferrous Metals Soc. China, 2011, 21(5), p 1112–1117.

C.C. Zhi, L.F. Ma, Q.X. Huang, Z.Q. Huang, and J.B. Lin, Improvement of Magnesium Alloy Edge Cracks by Multi-cross Rolling, J. Mater. Process. Technol., 2018, 255, p 333–339.

B.B. Dong, Z.M. Zhang, J.M. Yu, X. Che, M. Meng, and J.L. Zhang, Microstructure, Texture Evolution and Mechanical Properties of Multi-directional Forged Mg–13Gd–4Y–2Zn–0.5Zr Alloy under Decreasing Temperature, J. Alloys Compd., 2020, 823, p 153776.

F. Guo, D.F. Zhang, X.S. Yang, L.Y. Jiang, S.S. Chai, and F.S. Pan, Influence of Rolling Speed on Microstructure and Mechanical Properties of AZ31 Mg Alloy Rolled by Large Strain Hot Rolling, Mater. Sci. Eng. A, 2014, 607, p 383–389.

J.W. Cha and S.H. Park, Variations in Dynamic Recrystallization Behavior and Mechanical Properties of AZ31 Alloy with Extrusion Temperature, J. Magnes. Alloys, 2023, 11(7), p 2351–2365.

Z. Zhang, J.H. Zhang, J.S. ** a Low-Alloyed Fine-Grained Mg Alloy with High Strength-Ductility Based on Dislocation Evolution and Grain Boundary Segregation, Scr. Mater., 2022, 209, p 114–414.

R. Ma, Y.Q. Zhao, and Y.N. Wang, Grain Refinement and Mechanical Properties Improvement of AZ31 Mg Alloy Sheet Obtained by Two - Stage Rolling, Mater. Sci. Eng. A, 2017, 691, p 81–87.

F. Guo, D.F. Zhang, X.S. Yang, L.Y. Jiang, and F.S. Pan, Influence of Rolling Speed on Microstructure and Mechanical Properties of AZ31 Mg Alloy Rolled by Large Strain Hot Rolling, Mater. Sci. Eng. A, 2014, 607, p 383–389.

H. Zhang, W.L. Cheng, J.F. Fan, B.S. Xu, and H.B. Dong, Improved Mechanical Properties of AZ31 Magnesium Alloy Sheets by Repeated Cold Rolling and Annealing Using a Small Pass Reduction, Mater. Sci. Eng. A, 2015, 637, p 243–250.

T. Zhou, Z. Yang, D. Hu, T. Feng, M.B. Yang, and X.B. Zhai, Effect of the Final Rolling Speeds on the Stretch Formability of AZ31 Alloy Sheet Rolled at a High Temperature, J. Alloys Compd., 2015, 650, p 436–443.

J.R. Dong, D.F. Zhang, Y.F. Dong, S.S. Chai, and F.S. Pan, Microstructure Evolution and Mechanical Response of Extruded AZ31B Magnesium Alloy Sheet at Large Strains Followed by Annealing Treatment, Mater. Sci. Eng. A, 2014, 618, p 262–270.

F.S. Pan, Q.H. Wang, B. Jiang, J.J. He, Y.F. Chai, and J. Xu, An Effective Approach Called the Composite Extrusion to Improve the Mechanical Properties of AZ31 Magnesium Alloy Sheets, Mater. Sci. Eng. A, 2016, 655, p 339–345.

C.J. Wang, J.W. Kang, K.K. Deng, K.B. Nie, W. Liang, and W.G. Li, Microstructure and Mechanical Properties of Mg-4Zn-xGd (x=0, 05, 1, 2) Alloys, J. Magnes. Alloys, 2022, 8(2), p 441–451.

J. Suh, J. Victoria-Hernández, D. Letzig, R. Golle, and W. Volk, Enhanced Mechanical Behavior and Reduced Mechanical Anisotropy of AZ31 Mg Alloy Sheet Processed by ECAP, Mater. Sci. Eng. A, 2016, 650, p 523–529.

J. Suh, J. Victoria-Hernandez, D. Letzig, R. Golle, S. Yi, J. Bohlen, and W. Volk, Improvement in Cold Formability of AZ31 Magnesium Alloy Sheets Processed by Equal Channel Angular Pressing, J. Mater. Process. Technol., 2015, 217, p 286–293.

M. Rakshith and P. Seenuvasaperumal, Review on the Effect of Different Processing Techniques on the Microstructure and Mechanical Behaviour of AZ31 Magnesium Alloy, J. Magnes. Alloys, 2021, 9(5), p 1692–1714.

H. Huang and J. Zhang, Microstructure and Mechanical Properties of AZ31 Magnesium Alloy Processed by Multi-directional Forging at Different Temperatures, Mater. Sci. Eng. A, 2016, 674, p 52–58.

L.L. Guo, R. Fu, J.Y. Pei, J.Q. Wang, H.Y. Zhao, B.Y. Song, and Z.C. Chen, Microstructure, Texture, and Mechanical Properties of Continuously Extruded and Rolled AZ31 Magnesium Alloy Sheets, J. Mater. Eng. Perform., 2019, 28, p 6692–6703.

Q.H. Wang, H.W. Zhai, S. Chen, and L. Wang, Simultaneous Enhancement of Strength and Ductility in Friction Stir Welded AZ31 Alloy Via Multi-pass Hot-Rolling and Subsequent Annealing, J. Mater. Res. Technol., 2023, 23(6), p 5181–5192.

W.L. Xu, X.H. Chen, and F.S. Pan, Effect of Y Content on the Microstructure and Mechanical Anisotropy of Mg-6Zn-xY-0.5Ce-0.4Zr Alloy Subjected to Asymmetric Rolling, Mater. Sci. Eng. A, 2023, 882, p 145465.

X. Zeng, C.L. Liu, C.Y. Zhao, J. Dong, F. Roters, and D.K. Guan, Three-Dimensional Study of Grain Scale Tensile Twinning Activity in Magnesium: A Combination of Microstructure Characterization and Mechanical Modeling, Acta Mater., 2023, 255, p 119043.

D.K. Guan, W. Mark Rainforth, J.H. Gao, L. Ma, and B. Wynne, Individual Effect of Recrystallisation Nucleation Sites on Texture Weakening in a Magnesium Alloy: Part 2- Shear Bands, Acta Mater., 2018, 145, p 399–412.

Q.X. Shi, C.J. Wang, K.K. Deng, K.B. Nie, Y.C. Wu, W.M. Gan, and W. Liang, Microstructure and Mechanical Behavior of Mg-5Zn Matrix Influenced by Particle Deformation Zone, J. Mater. Sci. Technol., 2021, 60, p 8–20.

H. Somekawa, N. Motohashi, S. Kuroda, and T. Mandai, Mechanical and Functional Properties of Ultra-Thin Mg Foils, Mater. Sci. Eng. A, 2023, 872, p 144934.

Acknowledgments

The authors are grateful for the financial supports from the National Natural Science Foundation of China, China (No. 51901144), the Anhui Provincial Natural Science Foundation, China (No. 2108085QE185), and the University Natural Science Research Project of Anhui Province (No. 2022AH050316).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wang, L., Sun, L., Zhang, M. et al. Microstructure, Texture Evolution, and Mechanical Properties of Thin AZ31B Mg Alloy Sheets Prepared by Two-Stage Rolling. J. of Materi Eng and Perform (2024). https://doi.org/10.1007/s11665-024-09371-0

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11665-024-09371-0