Abstract

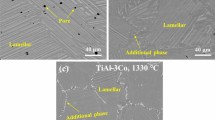

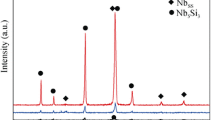

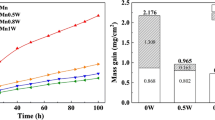

Self-passivating tungsten heavy alloys are important due to their high melting point, strong mechanical properties, and good oxidation resistance. Powder metallurgy is a key process in the preparation of these alloys, where it allows for precise control over composition and the inclusion of alloying elements. In the present study, we aim to evaluate the effect of alloying elements on the oxidation resistance of W-1Si-0.3Y2O3, W-10Ni-3Co-0.3Y2O3 and W-10Ni-3Co-1Si-0.3Y2O3 alloys fabricated by mechanical alloying followed by conventional pressureless sintering. The isothermal oxidation behaviour of synthesized alloys was conducted at 800, 1000 and 1200 °C up to 10 h to study oxide growth kinetics, phase and microstructure evolution. The addition of 1 wt.% Si into tungsten produces fine SiO2 particles on tungsten oxide grain boundaries during oxidation, which effectively prevents WO3 grain growth and crack propagation. However, low Si content results in a lack of continuous oxide layer, leading to WO3 volatilization. In contrast, alloys W-10Ni-1Si-0.3Y2O3 and W-10Ni-3Co-1Si-0.3Y2O3 exhibit enhanced oxidation resistance due to the formation of a dense NiWO4/CoWO4 layer beneath the porous WO3 + SiO2 layer. The resistance of tungsten to oxidation was significantly increased through the addition of Si, Y2O3, Ni and Co.

Similar content being viewed by others

References

A. Patra, R. Saxena, S.K. Karak, T. Laha, and S.K. Sahoo, Fabrication and Characterization of Nano-Y2O3 Dispersed W-Ni-Mo and W-Ni-Ti-Nb Alloys by Mechanical Alloying and Spark Plasma Sintering, J. Alloys Compd., 2017, 707, p 245–250. https://doi.org/10.1016/j.jallcom.2016.11.424

R. Saxena, A. Patra, S.K. Karak, and L. Ciupinski, Fabrication and Characterization of Nano-Y2O3 Dispersed W-Ni-Nb Alloys, Int. J. Refract. Met. Hard Mater., 2018, 71, p 70–81. https://doi.org/10.1016/j.ijrmhm.2017.11.004

C.L. Chen and S.H. Ma, Study on Characteristics and Sintering Behavior of W-Ni-Co Tungsten Heavy Alloy by A Secondary Ball Milling Method, J. Alloys Compd., 2018, 731, p 78–83. https://doi.org/10.1016/j.jallcom.2017.09.125

C.-L. Chen, Y. Zeng, and J.-G. Lee, Microstructure Evolution of Tungsten-Based ODS Alloys Reinforced with the γ(Ni,~Fe) Phase by a Secondary Ball Milling Method, Acta Physica Polonica A, 2014, 126(4), p 907–911. https://doi.org/10.12693/APhysPolA.126.907

E. Lassner and W.-D. Schubert, Tungsten Properties, Chemistry, Technology of the Element, Alloys, and Chemical Compounds, Kluwer Academic Plenum Publishers, Austria, 2005.

S. Segantin, S. Meschini, R. Testoni and M. Zucchetti, Preliminary Investigation of Neutron Shielding Compounds for ARC-Class Tokamaks, Fusion Eng. Des., 2022, 185, p 113335. https://doi.org/10.1016/j.fusengdes.2022.113335

C. Cheng, Y. Fu, C. Du, Z. Du, Z. Jiang, F. Zhou, K. Zhong, and X. Wang, Experimental and Numerical Study of Tantalum-Tungsten Alloy Rod Penetrator Impacting Thick Armor Plate, Int. J. Refract. Met. Hard Mater., 2022, 107, p 105873. https://doi.org/10.1016/j.ijrmhm.2022.105873

X. Chen, B.E. Schuster, L.J. Kecskes, and Q. Wei, Ballistic Performance of Tungsten-Based Heterogeneous Multilayer Structures, J. Dyn. Behav. Mater., 2022, 8, p 89–103. https://doi.org/10.1007/s40870-021-00319-2

L. Zhang, X. Chen, Y. Huang, W. Liu, and Y. Ma, Microstructural Characteristics and Evolution Mechanisms of 90W–Ni–Fe Alloy under High-Strain-Rate Deformation, Mater. Sci. Eng. A., 2021, 811, p 141070. https://doi.org/10.1016/j.msea.2021.141070

C.L. Chen and S.H. Ma, Effects of Ni/Co Ratio and Mechanical Alloying on Characteristics and Sintering Behavior of W-Ni-Co Tungsten Heavy Alloys, J. Alloys Compd., 2017, 711, p 488–494. https://doi.org/10.1016/j.jallcom.2017.04.037

Z.A. Hamid, S.F. Moustafa, W.M. Daoush, F.A. Mouez, and M. Hassan, Fabrication and Characterization of Tungsten Heavy Alloys Using Chemical Reduction and Mechanical Alloying Methods, Open, J. Appl. Sci., 2013, 03, p 15–27. https://doi.org/10.4236/ojapps.2013.31003

G. Prabhu, R. Arockia Kumar, and T.K. Nandy, Effect of Yttrium Oxide Dispersion on The Microstructure and Properties of Tungsten Heavy Alloys, Def. Sci. J., 2018, 68, p 406–411. https://doi.org/10.14429/dsj.68.12255

Y. Liu, X. Li, J. Zhou, K. Fu, W. Wei, M. Du, and X. Zhao, Effects of Y2O3 Addition on Microstructures and Mechanical Properties of WC-Co Functionally Graded Cemented Carbides, Int. J. Refract. Met. Hard Mater., 2015, 50, p 53–58. https://doi.org/10.1016/j.ijrmhm.2014.11.004

S. Telu, R. Mitra, and S.K. Pabi, Effect of Y2O3 Addition on Oxidation Behavior of W-Cr Alloys, Metall Mater. Trans. A Phys. Metall. Mater. Sci., 2015, 46, p 5909–5919. https://doi.org/10.1007/s11661-015-3166-z

A. Patra, R. Saxena, and S.K. Karak, Combined Effect of Ni and Nano-Y2O3 Addition on Microstructure, Mechanical and High Temperature Behavior of Mechanically Alloyed W-Mo, Int. J. Refract. Met. Hard Mater., 2016, 60, p 131–146. https://doi.org/10.1016/j.ijrmhm.2016.07.017

A. Patra, R.R. Sahoo, S.K. Karak, and S.K. Sahoo, Effect of nano Y2O3 Dispersion on Thermal, Microstructure, Mechanical and High Temperature Oxidation Behavior of Mechanically Alloyed W-Ni-Mo-Ti, Int. J. Refract. Met. Hard Mater., 2018, 70, p 134–154. https://doi.org/10.1016/j.ijrmhm.2017.09.015

A. Hedayat, H. Davilu, and J. Jafari, Loss of Coolant Accident Analyses on Tehran Research Reactor by RELAP5/MOD3.2 code, Prog. Nucl. Energy., 2007, 49, p 511–528. https://doi.org/10.1016/j.pnucene.2007.07.009

T. Wegener, F. Klein, A. Litnovsky, M. Rasinski, J. Brinkmann, F. Koch, and C. Linsmeier, Development and Analyses of Self-Passivating Tungsten Alloys for DEMO Accidental Conditions, Fusion Eng. Des., 2017, 124, p 183–186. https://doi.org/10.1016/j.fusengdes.2017.03.072

F. Koch, S. Köppl, and H. Bolt, Self Passivating W-Based Alloys as Plasma-Facing Material, J. Nucl. Mater., 2009, 386–388, p 572–574. https://doi.org/10.1016/j.jnucmat.2008.12.179

P. López-Ruiz, F. Koch, N. Ordás, S. Lindig, and C. García-Rosales, Manufacturing of Self-Passivating W-Cr-Si Alloys by Mechanical Alloying and HIP, Fusion Eng. Des., 2011, 86, p 1719–1723. https://doi.org/10.1016/j.fusengdes.2011.03.107

V. Suman, R.S. Maurya, M. Debata, and D. Chaira, Effect of Si Addition on Phase Evolution and Microstructure in Y2O3 Dispersed Tungsten (W) and W-Based Alloys Synthesized via Mechanical Alloying and Consecutive Conventional Sintering, Mater. Today Commun., 2022, 31, p 103341. https://doi.org/10.1016/j.mtcomm.2022.103341

E.A. Gulbransen and K.F. Andrew, Kinetics of the Oxidation of Pure Tungsten from 500° to 1300°C, J. Electrochem. Soc., 1960, 107, p 619. https://doi.org/10.1149/1.2427787

F. Koch and H. Bolt, Self Passivating W-Based Alloys as Plasma Facing Material for Nuclear Fusion, Phys. Scr. T. T, 2007, 128, p 100–105. https://doi.org/10.1088/0031-8949/2007/T128/020

S. Samal, High-Temperature Oxidation of Metals, High Temp. Corros., 2016 https://doi.org/10.5772/63000

F.S.P. Neil Birks and G.H. Meier, High Temperature Oxidation of metals, 2nd ed. Cambridge University Press, Cambridge, 2000.

V.D.B. Rengstorff, Oxidation of Tungsten, Columbus 1, Ohio, 1961.

G. Yi, W. Liu, C. Ye, L. Xue, and Y. Yan, A self-Passivating W-Si-Y Alloy: Microstructure and Oxidation Resistance Behavior at High Temperatures, Corros. Sci., 2021, 192, p 109820. https://doi.org/10.1016/j.corsci.2021.109820

P. Hartman and H.K. Chan, Revised Effective Ionic Radii and Systenatic Studies of Interatomic Distances in Halides and Chalcogenides, Acta Crystallogr. Sect. A., 1976, 32, p 1052–1058. https://doi.org/10.1023/A:1018927109487

V.R. Talekar, A. Patra, and S.K. Sahoo, Oxidation Behavior of Oxide Dispersion-Strengthened W-Ni Alloys, Oxid. Met., 2020, 93, p 17–28. https://doi.org/10.1007/s11085-019-09942-w

W. Liu, C. Ye, L. Xue, W. Zhang, and Y. Yan, A self-Passivating Tungsten Bulk Composite: Effects of Silicon on its Oxidation Resistance, Int. J. Refract. Met. Hard Mater., 2021, 100, p 105631. https://doi.org/10.1016/j.ijrmhm.2021.105631

Acknowledgments

Authors are grateful to Dr. Mayadhar Debata, Principal Scientist, Council of Scientific and Industrial Research (CSIR)-Institute of Minerals and Materials Technology (IMMT) Bhubaneswar for allowing fabrication of samples by conventional sintering in H2 atmosphere for oxidation study.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

This article is an invited submission to the Journal of Materials Engineering and Performance selected from presentations at the 4th International Conference on Processing & Characterization of Materials (ICPCM 2022) held December 9-11, 2022, at the National Institute of Technology, Rourkela, Odisha, India. It has been expanded from the original presentation. The issue was organized by Prof. Joao Pedro Oliveira, Universidade NOVA de Lisboa, Portugal; Prof. B. Venkata Manoj Kumar, Indian Institute of Technology Roorkee, India; Dr. D. Arvindha Babu, DMRL, DRDO, Hyderabad, India; Prof. Kumud Kant Mehta and Prof. Anshuman Patra, National Institute of Technology Rourkela, Odisha, India; and Prof. Manab Mallik, National Institute of Technology Durgapur, India.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Suman, V., Chaira, D. Improvement of Oxidation Resistance in Tungsten Heavy Alloys through Si, Y2O3, Ni, and Co Addition. J. of Materi Eng and Perform 33, 5279–5290 (2024). https://doi.org/10.1007/s11665-023-08366-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-023-08366-7