Abstract

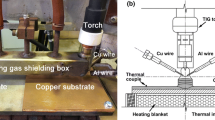

Wire arc additive manufacturing (WAAM) is an approach to develop unique and sophisticated design products in comparison to other traditional techniques. In the present study, the components of Cu-Si alloy have been developed using WAAM with a robotic gas metal arc welding technique. In this process, the current and voltage varied from 70 to 110 A and 17 to 19 V, respectively. The effect of process parameters on the microstructure, hardness, and wear behavior of components have been studied in details. The results show that the surface roughness of the components reduced with the increase in current and voltage. The microstructure of the uppermost surface of WAAM components shows columnar followed by dendritic with equiaxed morphology. The process parameter also affects the mechanical and wear resistance properties of WAAM components. The results show that the microhardness (from 100.03 to 160.03 HV) and wear resistance of the Cu-Si alloy component increase with the increases in current and voltage.

Similar content being viewed by others

References

J. Liu, Y. Xu, Y. Ge, Z. Hou, and S. Chen, Wire and Arc Additive Manufacturing of Metal Components: A Review of Recent Research Developments, Int. J. Adv. Manufact. Technol., 2020, 111(1–2), p 149–198.

S.K. Sharma and C. Sharma, Processing Techniques, Microstructural and Mechanical Properties of Wire Arc Additive Manufactured Stainless Steel: A Review, J. Inst. Eng. Ser. C, 2022, 31, p 1–15.

A. Queguineur, G. Rückert, F. Cortial, and J.Y. Hascoët, Evaluation of WAAM for Large-Sized Components in Naval Applications, Weld. World, 2017, 62(2), p 259–266.

D. Ding, Z.S. Pan, D. Cuiuri, and H. Li, A Tool-Path Generation Strategy for Wire and Arc Additive Manufacturing, Int. J. Adv. Manufact. Technol., 2014, 73(1), p 173–183.

B. Wu, Z. Pan, D. Ding, D. Cuiuri, H. Li, J. Xu, and J. Norrish, A Review of the Wire Arc Additive Manufacturing of Metals: Properties, Defects and Quality Improvement, J. Manufact. Process., 2018, 35, p 127–139.

S.K. Sharma, K. Biswas, and J. Dutta Majumdar, Studies on Electron Beam Surface Remelted Inconel 718 Superalloy, Met. Mater. Int., 2021, 27(12), p 5360–5373.

S.K. Sharma, K. Biswas, A.K. Nath, I. Manna, and J.D. Majumdar, Microstructural Characterization of Laser Surface-Melted Inconel 718, J. Opt., 2020, 49(4), p 494–509.

T. DebRoy, H.L. Wei, J.S. Zuback, T. Mukherjee, J.W. Elmer, J.O. Milewski, A.M. Beese, A. de Wilson-Heid, A. De, and W. Zhang, Additive Manufacturing of Metallic Components-Process, Structure and Properties, Prog. Mater. Sci., 2018, 92, p 112–224.

D. Kong, C. Dong, X. Ni, C. Man, K. **ao, and X. Li, Insight into the Mechanism of Alloying Elements (Sn, Be) Effect on Copper Corrosion during Long-Term Degradation in Harsh Marine Environment, Appl. Surf. Sci., 2018, 455, p 543–553.

J. Baby and M. Amirthalingam, Microstructural Development during Wire Arc Additive Manufacturing of Copper-Based Components, Weld. World, 2020, 64(2), p 395–405.

B. Dong, Z. Pan, C. Shen, Y. Ma, and H. Li, Fabrication of Copper-Rich Cu-Al Alloy Using the Wire-Arc Additive Manufacturing Process, Metall. Mater. Trans. B, 2017, 48(6), p 3143–3151.

C.V. Haden, G. Zeng, F.M. Carter, C. Ruhl, B.A. Krick, and D.G. Harlow, Wire and Arc Additive Manufactured Steel: Tensile and Wear Properties, Addit. Manuf., 2017, 16, p 115–123.

B. Parvaresh, R. Salehan, and R. Miresmaeili, Investigating Isotropy of Mechanical and Wear Properties in As-Deposited and Inter-Layer Cold Worked Specimens Manufactured by Wire Arc Additive Manufacturing, Met. Mater. Int., 2021, 27(1), p 92–105.

G.A.O. Yuan, J. Jie, P. Zhang, J. Zhang, T. Wang, and T. Li, Wear Behavior of High Strength and High Conductivity Cu Alloys under Dry Sliding, Trans. Nonferrous Met. Soc., 2015, 25(7), p 2293–2300.

X.L. Kong, Y.B. Liu, and L.J. Qiao, Dry Sliding Tribological Behaviors of Nanocrystalline Cu–Zn Surface Layer after Annealing in Air, Wear, 2004, 256(7–8), p 747–753.

C. Lorenzo-Martin, O.O. Ajayi, K. Hartman, S. Bhattacharya, and A. Yacout, Effect of Al2O3 Coating on Fretting Wear Performance of Zr Alloy, Wear, 2019, 426, p 219–227.

L. **n, Q. Huang, Y. Han, Y. Lu, W. Zhang, and T. Shoji, The Damage Mechanism of Alloy 690TT against Alloy 600 Caused by Fretting Wear in Room Temperature Pure Water, Mater., 2020, 161, p 110176.

M.D. Barath Kumar and M. Manikandan, Assessment of Process, Parameters, Residual Stress Mitigation, Post Treatments and Finite Element Analysis Simulations of Wire Arc Additive Manufacturing Technique, Metals Mater. Int., 2022, 28(1), p 54–111.

C.R. Cunningham, J.M. Flynn, A. Shokrani, V. Dhokia, and S.T. Newman, Invited Review Article: Strategies and Processes for High Quality Wire Arc Additive Manufacturing, Addit. Manuf., 2018, 22, p 672–686.

Y. Wang, S. Konovalov, X. Chen, Y. Ivanov, S. Jayalakshmi, and R.A. Singh, Research on Cu-6.6%Al-3.2%Si Alloy by Dual Wire Arc Additive Manufacturing, J. Mater. Eng. Perform., 2021, 30(3), p 1694–1702.

W.E. Frazier, Metal Additive Manufacturing: A Review, J. Mater. Eng. Perform., 2014, 23(6), p 1917–1928.

V.A. Popovich, E.V. Borisov, A.A. Popovich, V.S. Sufiiarov, D.V. Masaylo, and L. Alzina, Functionally Graded Inconel 718 Processed by Additive Manufacturing: Crystallographic Texture, Anisotropy of Microstructure and Mechanical Properties, Mater. Des., 2017, 114, p 441–449.

B.E. Carroll, T.A. Palmer, and A.M. Beese, Anisotropic Tensile Behavior of Ti–6Al–4V Components Fabricated with Directed Energy Deposition Additive Manufacturing, Acta Mater., 2015, 87, p 309–320.

S.K. Sharma, K. Biswas, A.K. Nath, I. Manna, and J. Dutta Majumdar, Wear Behavior of Laser Surface Melted Inconel 718, Lasers Eng., 2021, 50(1–3), p 1–13.

T. Klein, M. Schnall, B. Gomes, P. Warczok, D. Fleischhacker, and P.J. Morais, Wire-Arc Additive Manufacturing of a Novel High-Performance Al-Zn-Mg-Cu Alloy: Processing, Characterization and Feasibility Demonstration, Addit. Manuf., 2021, 37, p 101663.

S. Basak, S.K. Sharma, M. Mondal, K.K. Sahu, S. Gollapudi, J. Dutta Majumdar, and S.-T. Hong, Electron Beam Surface Treatment of 316L Austenitic Stainless Steel: Improvements in Hardness, Wear, and Corrosion Resistance, Met. Mater. Int., 2021, 27(5), p 953–961.

Funding

This research received no specific grant from any funding agency.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Kazmi, K.H., Sharma, S.K., Das, A.K. et al. Development of Wire Arc Additive Manufactured Cu-Si Alloy: Study of Microstructure and Wear Behavior. J. of Materi Eng and Perform 33, 110–119 (2024). https://doi.org/10.1007/s11665-023-07972-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-023-07972-9