Abstract

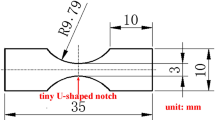

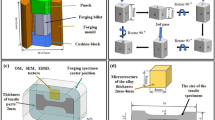

The influence of microstructures (bimodal and basketweave) on the tensile properties and deformation mechanism of Ti-5Al-1V-1Sn-1Zr-0.8Mo alloy was investigated via an in situ tensile test monitored by electron backscatter diffraction (EBSD)-assisted slip trace analysis. The bimodal structure exhibited good plasticity, but its tensile strength was lower than that of the basketweave structure. These variations could be attributed to the larger α colony structure in the basketweave structure. In situ tensile testing showed that the α colony in the basketweave structure can promote the formation of shear bands, leading to decreased plasticity. The activation of numerous slip systems in αp of the bimodal structure ensured good plasticity. Meanwhile, deformation twins were occasionally observed in the bimodal structure. However, dislocation slip and deformation twins were observed inside the large-sized grain boundary α (αGB) phase in the basketweave structure. The results of this study can extend the potential application of Ti alloys.

Similar content being viewed by others

References

J. Been and K. Faller, Using Ti-5111 for Marine Fastener Applications, JOM, 1999, 51, p 21–24.

S. Nimer, J. Wolk, and M. Zupan, Local Property Characterization of Friction Stir Welded Ti-5111: Transverse Orientation Measurements, Acta Mater., 2013, 61, p 3050–3059.

I.V. Okulov, A.S. Volegov, H. Attar, M. Bönisch, S. Ehtemam-Haghighi, M. Calin, and J. Eckert, Composition Optimization of Low Modulus and High-Strength TiNb-Based Alloys for Biomedical Applications, J. Mech. Behav. Biomed. Mater., 2017, 65, p 866–871.

I.V. Okulov, S. Pauly, U. Kühn, P. Gargarella, T. Marr, J. Freudenberger, L. Schultz, J. Scharnweber, C.-G. Oertel, W. Skrotzki, and J. Eckert, Effect of Microstructure on the Mechanical Properties of As-Cast Ti-Nb-Al-Cu-Ni alloys for biomedical application, Mater. Sci. Eng. C, 2013, 33, p 4795–4801.

D. Banerjee and J.C. Williams, Perspectives on Titanium Science and Technology, Acta Mater., 2013, 61, p 844–879.

D.S. Xu, H. Wang, J.H. Zhang, C.G. Bai, and R. Yang, Titanium Alloys: From Properties Prediction to Performance Optimization, Handbook of Materials Modeling: Applications: Current and Emerging Materials. W. Andreoni, S. Yip Ed., Springer, Cham, 2019, p 1–39

Y.L. Hao, Z.B. Zhang, S.J. Li, and R. Yang, Microstructure and Mechanical Behavior of a Ti-24Nb-4Zr-8Sn Alloy Processed by Warm Swaging and Warm Rolling, Acta Mater., 2012, 60, p 2169–2177.

J. Zhu, H. Wu, D. Wang, Y. Gao, H. Wang, Y. Hao, R. Yang, T.Y. Zhang, and Y. Wang, Crystallographic Analysis and Phase Field Simulation of Transformation Plasticity in a Multifunctional β-Ti Alloy, Int. J. Plast., 2017, 89, p 110–129.

I.V. Okulov, M. Bönisch, U. Kühn, W. Skrotzki, and J. Eckert, Significant Tensile Ductility and Toughness in an Ultra Fine-Structured Ti68.8 Nb13.6 Co6 Cu5.1 Al6.5 Bi-modal Alloy, Mater. Sci. Eng. A, 2014, 615, p 457–463.

K.E. Knipling and R.W. Fonda, Microstructural Evolution in Ti-5111 Friction Stir Welds, Metall. Mater. Trans. A, 2011, 42, p 2312–2322.

K. Gangwar and M. Ramulu, Friction Stir Welding of Titanium Alloys: A Review, Mater. Des., 2018, 41, p 230–255.

R.P. Kolli, A.A. Herzing, and S. Ankem, Characterization of Yttrium-Rich Precipitates in a Titanium Alloy Weld, Mater. Charact., 2016, 122, p 30–35.

S. Nimer, R.K. Everett, and M. Zupan, Microtensile Characterization of Titanium 5111 Alloy Mechanical Properties and Comparison of Failure Mechanisms at Two Microstructural Length Scales, Mater. Des., 2019, 183, p 108081.

K.E. Knipling and R.W. Fonda, Texture Development in the Stir Zone of Near-α Titanium Friction Stir Welds, Scr. Mater., 2009, 60, p 1097–1100.

S. Nimer, J. Wolk, and M. Zupan, Location and Orientation Specific Material Property Evaluation of Friction Stir Welded Ti-5111: A Microsample Approach, Adv. Eng. Mater., 2014, 16, p 453–458.

P.S. Pao, R.W. Fonda, H.N. Jones, C.R. Feng, and D.W. Moon, Fatigue Crack Growth in Friction Stir Welded Ti-5111, Tms Annual Meeting, 2009

R.W. Fonda and K.E. Knipling, Texture Development in Near-α Ti Friction Stir Welds, Acta Mater., 2010, 58, p 6452–6463.

G. Lutjering, Influence of Processing on Microstructure and Mechanical Properties of (α+β) Titanium Alloys, Mater. Sci. Eng. A, 1998, 243, p 32–45.

I.V. Okulov, U. Kühn, J. Romberg, I.V. Soldatov, J. Freudenberger, L. Schultz, A. Eschke, C.-G. Oertel, W. Skrotzki, and J. Eckert, Mechanical Behavior and Tensile/Compressive Strength Asymmetry of Ultrafine Structured Ti-Nb-Ni-Co-Al Alloys with Bi-modal Grain Size Distribution, Mater. Des., 2014, 62, p 14–20.

I.V. Okulov, M. Bönisch, A.S. Volegov, H. Shakur Shahabi, H. Wendrock, T. Gemming, and J. Eckert, Micro-to-Nano-Scale Deformation Mechanism of a Ti-Based Dendritic-Ultrafine Eutectic Alloy Exhibiting Large Tensile Ductility, Mater. Sci. Eng. A, 2017, 682, p 673–678.

S. Nimer, R.K. Everett, and M. Zupan, Microtensile Characterization of Titanium 5111 Alloy Mechanical Properties and Comparison of Failure Mechanisms at Two Microstructural Length Scales, Mater. Des., 2019, 183, p 108081.

Q. Wang, J. Ren, B. Zhang, C. **n, Y. Wu, and M. Ye, Influence of Microstructure on the Fatigue Crack Growth Behavior of a Near-Alpha TWIP Ti Alloy, Mater. Charact., 2021, 178, p 111208.

Q. Wang, J. Ren, B. Zhang, C. **n, Y.K. Wu, and L. Zhang, Simultaneously Improved Strength and Elongation at Cryogenic Temperature in Ti-5Al-1V-1Sn-1Zr-0.8Mo Alloy with a Bimodal Structure, Mater. Sci. Eng. A, 2021, 824, p 141792.

T. Furuhara and H.I. Aaronson, Crystallography and Interfacial Structure of Proeutectoid α Grain Boundary Allotriomorphs in a Hypoeutectoid Ti-6.62 at.% Alloy, Acta Metall. Mater., 1991, 39, p 2887–2899.

J. Ren, Q. Wang, B. Zhang, D. Yang, X. Lu, X. Zhang, X. Zhang, and J. Hu, Influence of Microstructure on Fatigue Crack Growth Behavior of Ti-6Al-3Nb-2Zr-1Mo alloy: Bimodal vs. Lamellar Structures, Intermetallics, 2021, 130, p 107058.

L. Wang, Z. Zheng, H. Phukan, P. Kenesei, J.S. Park, J. Lind, R.M. Suter, and T.R. Bieler, Direct Measurement of Critical Resolved Shear Stress of Prismatic and Basal Slip in Polycrystalline Ti using High Energy X-ray Diffraction Microscopy, Acta Mater., 2017, 132, p 598–610.

H. Li, D.E. Mason, T.R. Bieler, C.J. Boehlert, and M.A. Crimp, Methodology for Estimating the Critical Resolved Shear Stress Ratios of α-Phase Ti using EBSD-Based Trace Analysis, Acta Mater., 2013, 61, p 7555–7567.

K. Kishida, J.G. Kim, T. Nagae, and H. Inui, Experimental Evaluation of Critical Resolved Shear Stress for the First-Order Pyramidal c + a Slip in Commercially Pure Ti by Micropillar Compression Method, Acta Mater., 2020, 196, p 168–174.

H. Li, D. Mason, Y. Yang, T. Bieler, M. Crimp, and C. Boehlert, Comparison of the Deformation Behavior of Commercially Pure Titanium and Ti-5Al-2.5Sn(wt.%) at 296 and 728 K, Philos. Mag., 2013, 93, p 2875–2895.

H. Li, C. Boehlert, T. Bieler, and M. Crimp, Analysis of Slip Activity and Heterogeneous Deformation in Tension and Tension-Creep of Ti-5Al-2.5Sn (wt.%) using In-Situ SEM Experiments, Philos. Mag., 2012, 92, p 2923–2946.

J.Q. Ren, Q. Wang, X.F. Lu, W.F. Liu, P.L. Zhang, and X.B. Zhang, Effect of Oxygen Content on Active Deformation Systems in Pure Titanium Polycrystals, Mater. Sci. Eng. A, 2018, 731, p 530–538.

H. Li, D. Mason, T. Bieler, C. Boehlert, and M. Crimp, Methodology for Estimating the Critical Resolved Shear Stress Ratios of α-Phase Ti using EBSD-Based Trace Analysis, Acta Mater., 2013, 61, p 7555–7567.

C. Lavogiez, S. Hemery, and P. Villechaise, Concurrent Operation of <c+a> Slip and Twinning under Cyclic Loading of Ti-6Al-4V, Scr. Mater., 2018, 157, p 30–33.

S. Xu, P. Zhou, G. Liu, D. **ao, M. Gong, and J. Wang, Shock-Induced Two Types of 10 1 2 Sequential Twinning in Titanium, Acta Mater., 2019, 165, p 547–560.

M.H. Yoo, Slip, Twinning, and Fracture in Hexagonal Close-Packed Metals, Metall. Mater. Trans. A, 1981, 12, p 409–418.

P.G. Partridge, The Crystallography and Deformation Modes of Hexagonal Close-Packed Metals, Metall. Rev., 1967, 12, p 169–194.

Y.T. Zhu, X.Z. Liao, and X.L. Wu, Deformation Twinning in Anocrystalline Materials, Prog. Mater. Sci., 2012, 57, p 1–62.

B. Li and E. Ma, Atomic Shuffling Dominated Mechanism for Deformation Twinning in Magnesium, Phys. Rev. Lett., 2009, 103, p 035503.

J. Wang, J.P. Hirth, and C.N. Tome, Twinning Nucleation Mechanisms in Hexagonal-Close-Packed Crystals, Acta Mater., 2009, 57, p 5521–5530.

J.W. Christian and S. Mahajant, Deformation Twinning, Prog. Mater Sci., 1995, 39, p 1–157.

Acknowledgments

This project is financially supported by the National Natural Science Foundation of China (52061025), the Natural Science Foundation of Shaanxi Province (2020JC-50), Basic research plan of key scientific research projects of Henan universities (22A430027), Scientific and technological breakthroughs in Henan Province (222102240068) and Key Research Program of Education Department of Gansu Province (GSSYLXM-03).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Ren, J., Chen, R., Wang, Q. et al. Influence of Microstructure on Tensile Properties and Deformation Mechanism of Ti-5Al-1V-1Sn-1Zr-0.8Mo Alloy: Bimodal Versus Basketweave Structures. J. of Materi Eng and Perform 32, 10354–10362 (2023). https://doi.org/10.1007/s11665-023-07846-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-023-07846-0