Abstract

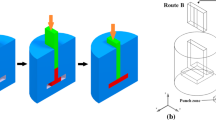

AZ80-1.5 Vol.% SiC nanocomposite was produced by the stir-casting method. The cast specimens were annealed and subjected to multi-directional forging (MDF) for up to 8 passes at 250 °C. Shear punch test (SPT), Vickers microhardness test, and uniaxial tension test were employed to evaluate the mechanical properties of nanocomposite before and after MDF process. Microstructural studies showed that the average grain structure was refined and the grain size distribution became more uniform after all MDF passes. The most pronounced grain refinement was obtained after eighth passes of MDF, where the average grain size of the unprocessed material was reduced from 31.4 to 4.9 µm. Based on the results of shear punch test (SPT), both shear yield stress (SYS) and ultimate shear strength (USS) of the nanocomposite were significantly improved after eight passes of the MDF process. The values of SYS and USS in the unprocessed specimen were 123.7 and 158.9 MPa, respectively, which increased to 164.6 and 194.1 MPa after eight MDF passes. Processing by MDF resulted in the enhancement of microhardness, strength, and ductility of the nanocomposite. After 8 MDF passes, improvements of 22.4, 48.1, 45.2, and 8.5% were obtained for the microhardness, TYS, USS, and elongation, respectively. The mechanisms of these improvements were discussed based on the microstructural features of the material.

Similar content being viewed by others

References

F. Barati, M. Esfandiari, and S. Babaei, The Effect of 2% SiO2 Nanopowder on Mechanical Behavior of Mg AZ31, J. Stress. Anal., 2020, 5(1), p 69–76.

H.Z. Ye and X.Y. Liu, Review of Recent Studies in Magnesium Matrix Composites, J. Mater. Sci., 2004, 39(20), p 6153–6171.

S.M. Masoudpanah and R. Mahmudi, The Microstructure, Tensile, and Shear Deformation Behavior of an AZ31 Magnesium Alloy after Extrusion and Equal Channel Angular Pressing, Mater. Des., 2010, 31(7), p 3512–3517.

S. Aravindan, P.V. Rao, and K. Ponappa, Evaluation of Physical and Mechanical Properties of AZ91D/SiC Composites by Two Step Stir Casting Process, J. Magnes. Alloy., 2015, 3(1), p 52–62.

M.Z. Rong, M.Q. Zhang, Y.X. Zheng, H.M. Zeng, R. Walter, and K. Friedrich, Structure-Property Relationships of Irradiation Grafted Nano-Inorganic Particle Filled Polypropylene Composites, Polymer. Guildf, 2001, 42(1), p 167–183.

G.H. Majzoobi, K. Rahmani, and M. Kashfi, The Effect of Pre-Compaction on Properties of Mg/SiC Nanocomposites Compacted at High Strain Rates, J. Stress. Anal., 2020, 4(2), p 19–28.

H. Mozafari and F. Akbaripanah, Changes in Grain Size, Texture, and Mechanical Properties of AZ31/(TiO2)p Nanocomposites Processed by Isothermal Multidirectional Forging, J. Stress. Anal., 2020, 4(2), p 45–53.

M.J. Shen, X.J. Wang, C.D. Li, M.F. Zhang, X.S. Hu, M.Y. Zheng, and K. Wu, Effect of Submicron Size SiC Particles on Microstructure and Mechanical Properties of AZ31B Magnesium Matrix Composites, Mater. Des., 2014, 54, p 436–442.

K.B. Nie, K.K. Deng, X.J. Wang, T. Wang, and K. Wu, Influence of SiC Nanoparticles Addition on the Microstructural Evolution and Mechanical Properties of AZ91 Alloy during Isothermal Multidirectional Forging, Mater. Charact., 2017, 124, p 14–24.

F. Akbaripanah, M. Sabbaghian, N. Fakhar, P. Minárik, J. Veselý, P.T. Hung, G. Kapoor, O. Renk, K. Máthis, J. Gubicza, and J. Eckert, Influence of High Pressure Torsion on Microstructure Evolution and Mechanical Properties of AZ80/SiC Magnesium Matrix Composites, Mater. Sci. Eng. A, 2021, 826, p 141916.

K.B. Nie, K. Wu, X. Wang, K. Deng, Y.W. Wu, and M. Zheng, Multidirectional Forging of Magnesium Matrix Composites: Effect on Microstructures and Tensile Properties, Mater. Sci. Eng., 2010, 527, p 7364–7368.

N. Azizi and R. Mahmudi, Microstructure, Texture, and Mechanical Properties of the Extruded and Multi-Directionally Forged Mg–XGd Alloys, Mater. Sci. Eng. A, 2021, 817, p 141385.

Q.F. Wang, X.P. **ao, J. Hu, W.W. Xu, X.Q. Zhao, and S.J. Zhao, An Ultrafine-Grained AZ31 Magnesium Alloy Sheet With Enhanced Superplasticity Prepared by Accumulative Roll Bonding, J. Iron. Steel. Res. Int., 2007, 14(5), p 167–172.

M.A. Salevati, A. Imam, R. Seifi, and F. Akbaripanah, The Effect of Repeated Upsetting Process on Microstructure, Shear Strength, and Fracture Toughness of SiC/AZ80 Nanocomposite, J. Mater. Eng. Perform., 2021 https://doi.org/10.1007/s11665-021-06215-z

A. Jamali and R. Mahmudi, Evolution of Microstructure, Texture, and Mechanical Properties in a Multi-Directionally Forged ZK60 Mg Alloy, Mater. Sci. Eng. A, 2019, 752, p 55–62.

M.A. Salevati, F. Akbaripanah, and R. Mahmudi, Microstructure, Texture, and Mechanical Properties of AM60 Magnesium Alloy Processed by Extrusion and Multidirectional Forging, J. Mater. Eng. Perform., 2019, 28(5), p 3021–3030.

X.G. Qiao, T. Ying, M.Y. Zheng, E.D. Wei, K. Wu, X.S. Hu, W.M. Gan, H.G. Brokmeier, and I.S. Golovin, Microstructure Evolution and Mechanical Properties of Nano-SiCp/AZ91 Composite Processed by Extrusion and Equal Channel Angular Pressing (ECAP), Mater. Charact., 2016, 121, p 222–230.

Y. Radi and R. Mahmudi, Effect of Al2O3 Nano-Particles on the Microstructural Stability of AZ31 Mg Alloy after Equal Channel Angular Pressing, Mater. Sci. Eng. A., 2010, 527(10–11), p 2764–2771.

S. Goyal, V. Karthik, K.V. Kasiviswanathan, M. Valsan, K.B.S. Rao, and B. Raj, Finite Element Analysis of Shear Punch Testing and Experimental Validation, Mater. Des., 2010, 31(5), p 2546–2552.

K.B. Nie, X.J. Wang, X.S. Hu, Y.W. Wu, K.K. Deng, K. Wu, and M.Y. Zheng, Effect of Multidirectional Forging on Microstructures and Tensile Properties of a Particulate Reinforced Magnesium Matrix Composite, Mater. Sci. Eng. A, 2011, 528(24), p 7133–7139.

X. **a, Q. Chen, Z. Zhao, M. Ma, X. Li, and K. Zhang, Microstructure, Texture and Mechanical Properties of Coarse-Grained Mg–Gd–Y–Nd–Zr Alloy Processed by Multidirectional Forging, J. Alloys. Compd., 2015, 623, p 62–68.

M.P. Reddy, V. Manakari, G. Parande, F. Ubaid, R.A. Shakoor, A.M. Mohamed, and M. Gupta, Enhancing Compressive, Tensile, Thermal and Dam** Response of Pure Al Using BN Nanoparticles, J. Alloys. Compd., 2018, 762, p 398–408.

S.F. Hassan, M. Paramsothy, F. Patel, and M. Gupta, High Temperature Tensile Response of Nano-Al2O3 Reinforced AZ31 Nanocomposites, Mater. Sci. Eng. A, 2012, 558, p 278–284.

J.B. Correia, H.A. Davies, and C.M. Sellars, Strengthening in Rapidly Solidified Age Hardened Cu-Cr and Cu-Cr-Zr Alloys, Acta. Mater., 1997, 45(1), p 177–190.

M.A. Salevati, A. Imam, R. Seifi, and F. Akbaripanah, Investigating the Microstructure, Hardness and Tensile Behavior of Magnesium AZ80 Alloy and AZ80/SiC Nanocomposite Manufactured Through Dual Equal Channel Lateral Extrusion (DECLE), Met. Mater. Int., 2020, 9, p 3538–3549.

W. Guo, Q. Wang, B. Ye, X. Li, X. Liu, and H. Zhou, Microstructural Refinement and Homogenization of Mg–SiC Nanocomposites by Cyclic Extrusion Compression, Mater. Sci. Eng. A, 2012, 556, p 267–270.

D.M. Lee, B.K. Suh, B.G. Kim, J.S. Lee, and C.H. Lee, Fabrication, microstructures, and tensile properties of magnesium alloy AZ91/SiCp composites produced by powder metallurgy, Mater. Sci. Technol, 1997, 7, p 590–595.

B.N. Sahoo and S.K. Panigrahi, Synthesis, characterization and mechanical properties of in-situ (TiC-TiB2) reinforced magnesium matrix composite, Mater. Des, 2016, 109, p 300–313.

A. Abbas and S.-J. Huang, Investigating the Hall-Petch Constants for As-Cast and Aged AZ61/CNTs Metal Matrix Composites and Their Role on Superposition Law Exponent, J. Compos. Sci, 2021, 5(3), p 103–112.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

This invited article is part of a special topical focus in the Journal of Materials Engineering and Performance on Magnesium. The issue was organized by Prof. C. (Ravi) Ravindran, Dr. Raja Roy, Mr. Payam Emadi, and Mr. Bernoulli Andilab, Ryerson University.

Rights and permissions

About this article

Cite this article

Akbaripanah, F., Zarin, M., Salevati, M.A. et al. Effects of Multi-Directional Forging on the Microstructure and Mechanical Properties of an AZ80/SiC Nanocomposite. J. of Materi Eng and Perform 32, 2676–2687 (2023). https://doi.org/10.1007/s11665-022-07307-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-022-07307-0