Abstract

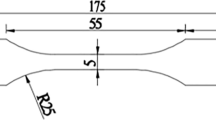

Fitness-for-service testing on an extruded magnesium (Mg) alloy containing 10 wt.% cerium (Ce) has been conducted to understand how increased level of Ce affects the elevated temperature properties of Mg. Optical and scanning electron microscopy revealed a 39.4% area percentage of the Mg12Ce phase. The Mg12Ce intermetallic was formulated along the grain boundaries in semi-circular, asymmetrical and polyhedral morphologies. The Mg alloy was subjected to a room temperature (RT) and 200 °C tensile test and a 200 °C staircase creep test. At RT, the Mg-10Ce alloy exhibited an ultimate tensile strength (UTS), total elongation and toughness of 271 MPa, 0.95% and 1.6 MJ/m3, respectively. At 200 °C, the alloy exhibited a UTS, 0.2% yield strength, total elongation and toughness of 111 MPa, 103 MPa, 43 % and 39.8 MJ/m3, respectively. The alloy exhibits an increase in RT strength and 200°C toughness compared to conventional Mg alloys (i.e., AE44, WE43 etc.). The staircase creep experiment revealed steady-state creep rates of 1.88 x 10− 8, 3.40 × 10− 7 and 2.00 x 10− 6 s− 1 for applied loads of 22, 40 and 55 MPa, respectively. The stress exponent (4.88) calculated between 20 and 40 MPa indicated that power-law dislocation climb and activated cross-slip of the pyramidal planes (\(10\overline{1}1\)) are the two dominant creep mechanisms, which are typical for high temperature and low-stress applications. The stress exponent (5.57) calculated between 40 and 55 MPa indicated that power-law breakdown dislocation climb and activated cross-slip of the basal planes (0002) were the two dominant creep mechanisms. A stress exponent value above 5 indicated that the alloy was moved into the transitional phase of creep between high-temperature/low-load creep and high-temperature/high-load creep. The alloy’s strong basal (0002) texture and high volume fraction Mg12Ce intermetallic contributed to its poor creep performance.

Similar content being viewed by others

References

EPA, The 2021 EPA Automotive Trends Report,” Epa, no. March, pp. 1–12, 2021

A.A. Luo, R.K. Mishra and A.K. Sachdev, High-Ductility Magnesium – Zinc – Cerium Extrusion Alloys, Scr. Mater., 2010, 64(2011), p 410–413. https://doi.org/10.1016/j.scriptamat.2010.10.045

A.A. Luo, Recent Magnesium Alloy Development for Elevated Temperature Applications, Int. Mater. Rev., 2004, 49(1), p 13–30. https://doi.org/10.1179/095066004225010497

S. You, Y. Huang, K.U. Kainer and N. Hort, Recent Research and Developments on Wrought Magnesium Alloys, J. Magnes. Alloy., 2017, 5(3), p 239–253. https://doi.org/10.1016/j.jma.2017.09.001

A.A. Luo, Magnesium Casting Technology for Structural Applications, J. Magnes. Alloy., 2013, 1(1), p 2–22. https://doi.org/10.1016/j.jma.2013.02.002

W.A. Curtin, R. Ahmad, B. Yin, and Z. Wu, Design of Ductile Rare-Earth-Free Magnesium Alloys, Magnes. Technol., pp. 19–24, 2020. https://doi.org/10.1007/978-3-030-36647-6_5

S. Tekumalla, S. Seetharaman, A. Almajid and M. Gupta, Mechanical Properties of Magnesium-Rare Earth Alloy Systems: A Review, Metals (Basel), 2014, 5(1), p 1–39. https://doi.org/10.3390/met5010001

M. Pekguleryuz and M. Celikin, Creep Resistance in Magnesium Alloys, Int. Mater. Rev., 2010, 55(4), p 197–217. https://doi.org/10.1179/095066010X12646898728327

D.G. Sediako and M.A. Gharghouri, Neutron Diffraction Measurements of Residual Stresses in Creep-Resistant Magnesium Alloys, Magnes. Technol., 2008, 0002, p 407–409.

M. El Mehtedi, S. Spigarelli, E. Evangelista and G. Rosen, Creep Behaviour of the ZM21 Wrought Magnesium Alloy, Mater. Sci. Eng. A, 2009, 510–511, p 403–406. https://doi.org/10.1016/j.msea.2008.04.102

D. Sediako and S. Shook, “Application of Neutron Diffraction in In-situ Studies of Stress Evolution in High Temperature Creep Testing of Creep-Resistant Magnesium Alloys,” in Magnes. Technol. TMS, Feb. 15–19, 2009, pp. 255–259.

D. Sediako, L. Bichler, M. Van Hanegem and S. Shook, Compressive Creep Properties of Wrought High Temperature Magnesium Alloys in Axial and Transverse Orientation - A Neutron Diffraction Study, Magnes. Technol., 2013 https://doi.org/10.1007/978-3-319-48150-0_2

M. Fletcher, L. Bichler, D. Sediako and R. Klassen, Compressive Creep Behaviour of Extruded Mg Alloys at 150 °C, Magnes. Technol., 2011 https://doi.org/10.1002/9781118062029.ch17

D. Sediako, S. Shook, S. Vogel and A. Sediako, Application of Neutron Diffraction in Characterization of Texture Evolution during High-Temperature Creep in Magnesium Alloys, Magnes. Technol., 2011 https://doi.org/10.1002/9781118062029.ch45

X.J. Zhang and G.H. Geng, Research of Resistance to High Temperature and Creep Resistant Magnesium Alloy, Adv. Mater. Res., 2013, 750–752, p 715–720. https://doi.org/10.4028/www.scientific.net/AMR.750-752.715

D. Weiss, A.A. Kaya, E. Aghion and D. Eliezer, Microstructure and Creep Properties of a Cast Mg-1.7%wt Rare Earth-0.3%wt Mn Alloy, J. Mater. Sci., 2002, 37(24), p 5371–5379. https://doi.org/10.1023/A:1021001813867

K. Milička, J. Čadek and P. Ryš, High Temperature Creep Mechanisms in Magnesium, Acta Metall., 1970, 18(10), p 1071–1082. https://doi.org/10.1016/0001-6160(70)90005-2

M. Celikin, D. Sediako, and M. Pekguleryuz, “Texture change in pure Mg and Mg-1.5wt%Mn casting alloy during compressive creep-deformation,” in Magnes. Technol. TMS, Feb. 14–18, 2010, pp. 249–251.

Y.L. Xu, L. Wang, M. Huang, F. Gensch, K.U. Kainer and N. Hort, The Effect of Solid Solute and Precipitate Phase on Young’s Modulus of Binary Mg–RE Alloys, Adv. Eng. Mater., 2018, 20(10), p 1–9. https://doi.org/10.1002/adem.201800271

D. Weiss, Improved High-Temperature Aluminum Alloys Containing Cerium, J. Mater. Eng. Perform., 2019, 28(4), p 1903–1908. https://doi.org/10.1007/s11665-019-3884-2

Y. Chino, M. Kado and M. Mabuchi, Enhancement of Tensile Ductility and Stretch Formability of Magnesium by Addition of 0.2 wt.%(0.035 at%)Ce, Mater. Sci. Eng. A, 2008, 494(1–2), p 343–349. https://doi.org/10.1016/j.msea.2008.04.059

T.L. Chia, M.A. Easton, S.M. Zhu, M.A. Gibson, N. Birbilis and J.F. Nie, The Effect of Alloy Composition on the Microstructure and Tensile Properties of Binary Mg-Rare Earth Alloys, Intermetallics, 2009, 17(7), p 481–490. https://doi.org/10.1016/j.intermet.2008.12.009

S.H. Park, B.S. You, R.K. Mishra and A.K. Sachdev, Effects of Extrusion Parameters on the Microstructure and Mechanical Properties of Mg-Zn-(Mn)-Ce/Gd Alloys, Mater. Sci. Eng. A, 2014, 598, p 396–406. https://doi.org/10.1016/j.msea.2014.01.051

R.K. Mishra, A.K. Gupta, P. Rao Rama, A.K. Sachdev, A.M. Kumar and A.A. Luo, Influence of cerium on texture and ductility of magnesium extrusions, Essential Readings in Magnesium Technology. S.N. Mathaudhu, A.A. Luo, N.R. Neelameggham, E.A. Nyberg, W.H. Sillekens Ed., Springer, Cham, 2016

A.A. Luo, W. Wenyun, R.K. Mishra, L. **, A.K. Sachdev and W. Ding, Microstructure and Mechanical Properties of Extruded Magnesium-Aluminum-Cerium Alloy Tubes, Metall. Mater. Trans. A Phys. Metall. Mater. Sci., 2010, 41(10), p 2662–2674. https://doi.org/10.1007/s11661-010-0278-3

D. Zhao et al., A comparative study on the microstructures and mechanical properties of the Mg-xCa/Mn/Ce alloys and pure Mg, Mater. Sci. Eng. A, 2021 https://doi.org/10.1016/j.msea.2020.140508

N. Hort, Y. Huong and K.U. Kainer, Intermetallics in Magnesium Alloys, Adv. Eng. Mater., 2006, 8(4), p 235–240. https://doi.org/10.1002/adem.200500202

A. Ru Wu and C. Qing **a, Study of the Microstructure and Mechanical Properties of Mg-rare Earth Alloys, Mater. Des., 2007, 28(6), p 1963–1967.

ASTM, Standard Guide for Preparation of Metallographic Specimens, ASTM Copyright, ASTM International, West Conshohocken, PA. pp. 1–12, 2017, doi: https://doi.org/10.1520/E0003-11R17.1

Paul W. Lisowski and Kurt F. Schoenberg, The Los Alamos Neutron Science Center, Nucl. Instruments Methods Phys. Res. Sect. A Accel. Spectrometers, Detect. Assoc. Equip., 2006, 562(2), p 910–914. https://doi.org/10.1016/j.nima.2006.02.178

H.R. Wenk, L. Lutterotti and S. Vogel, Texture Analysis with the New HIPPO TOF Diffractometer, Nucl. Instruments Methods Phys. Res. A, 2003, 515(3), p 575–588. https://doi.org/10.1016/j.nima.2003.05.001

S. Takajo and S.C. Vogel, Determination of Pole Figure Coverage for Texture Measurements with Neutron Time-of-Flight Diffractometers, J. Appl. Crystallogr., 2018, 51(2005), p 895–900. https://doi.org/10.1107/S1600576718007732

L. Lutterotti, “MAUD tutorial - Hippo Texture Analysis Wizard.” University of Trento, Trento, Italy, Oct. 2007. Available from http://maud.radiographema.eu/ [Online]. Accessed Dec 2, 2021.

ASTM, E8 / E8M-21, Standard Test Methods for Tension Testing of Metallic Materials, ASTM Copyright, ASTM International, West Conshohocken, PA. pp. 1–30, 2021, doi: https://doi.org/10.1520/E0008

L. **, K. Liu and X.G. Chen, Evolution of Dispersoids and Their Effects on Elevated-Temperature Strength and Creep Resistance in Al-Si-Cu 319 Cast Alloys with Mn and Mo Additions, Mater. Sci. Eng. A, 2020, 770, p 1–11. https://doi.org/10.1016/j.msea.2019.138554

M.T. Di Giovanni, E. Cerri, D. Casari, M. Merlin, L. Arnberg and G.L. Garagnani, The Influence of Ni and V Trace Elements on High-Temperature Tensile Properties and Aging of A356 Aluminum Foundry Alloy, Metall. Mater. Trans. A, 2016, 47(5), p 2049–2057. https://doi.org/10.1007/s11661-016-3366-1

J. Stroh, D. Sediako and D. Weiss, The Effects of Iron-Bearing Intermetallics on the Fitness-for-Service Performance of a Rare-Earth-Modified A356 Alloy for Next Generation Automotive Powertrains, Metals (Basel), 2021, 11(788), p 1–20. https://doi.org/10.3390/met11050788

H. Hu, A. Yu, N. Li and J.E. Allison, Potential Magnesium Alloys for High Temperature Die Cast Automotive Applications: A Review, Mater. Manuf. Process., 2003, 18(5), p 687–717. https://doi.org/10.1081/AMP-120024970

D. G. Sediako, W. Kasprzak, F. Czerwinski, A. M. Nabawy, and A. R. Farkoosh, High Temperature Creep Evolution in Al-Si Alloys Developed for Automotive Powertrain Applications: A neutron In-situ Study on HKL-Plane Creep Response, Light Metals, 2016, pp. 131–136. https://doi.org/10.1007/978-3-319-48251-4_23

M. Fletcher, L. Bichler and D. Sediako, The role of Intermetallics on Creep Behaviour of Extruded Magnesium Alloys, Magnes. Technol., 2012 https://doi.org/10.1007/978-3-319-48203-3_80

M. Celikin, A.A. Kaya, R. Gauvin and M. Pekguleryuz, Effects of Manganese on the Microstructure and Dynamic Precipitation in Creep-Resistant cast Mg-Ce-Mn Alloys, Scr. Mater., 2012, 66(10), p 737–740. https://doi.org/10.1016/j.scriptamat.2012.01.043

D. Panda, R.K. Sabat, S. Suwas, V.D. Hiwarkar and S.K. Sahoo, Texture Weakening in Pure Magnesium during Grain Growth, Philos. Mag., 2019, 99(11), p 1362–1385. https://doi.org/10.1080/14786435.2019.1581382

O. Engler and V. Randle, Introduction to texture analysis: Macrotexture, Microtexture and Orientation Map**. Amsterdam: Gordon and Breach Science Publishers, 2000

Y.N. Wang and J.C. Huang, Texture Analysis in Hexagonal Materials, Mater. Chem. Phys., 2003, 81(1), p 11–26. https://doi.org/10.1016/S0254-0584(03)00168-8

Z. Jiang, B. Jiang, Y. Zeng, J. Dai and F. Pan, Role of Al Modification on the Microstructure and Mechanical Properties of as-cast Mg-6Ce Alloys, Mater. Sci. Eng. A, 2015, 645, p 57–64. https://doi.org/10.1016/j.msea.2015.08.002

D. Griffiths, Explaining Texture Weakening and Improved Formability in Magnesium Rare Earth Alloys, Mater. Sci. Technol. (United Kingdom), 2015, 31(1), p 10–24. https://doi.org/10.1179/1743284714Y.0000000632

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

This invited article is part of a special topical focus in the Journal of Materials Engineering and Performance on Magnesium. The issue was organized by Prof. C. (Ravi) Ravindran, Dr. Raja Roy, Mr. Payam Emadi, and Mr. Bernoulli Andilab, Ryerson University.

Rights and permissions

About this article

Cite this article

Kozakevich, J., Stroh, J., Sediako, D. et al. Elevated Temperature Creep and Tensile Performance of Extruded Mg-10Ce Alloy. J. of Materi Eng and Perform 32, 2758–2765 (2023). https://doi.org/10.1007/s11665-022-06935-w

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-022-06935-w