Abstract

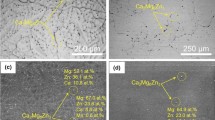

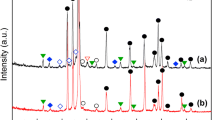

A low-alloyed Mg-1.2Zn-0.1Ca (wt%) alloy was extruded at different temperatures (150 °C, 200 °C, 250 °C, 300 °C), and the effect of extrusion temperature on the microstructure and tensile properties was investigated systematically. While the as-cast alloy presented many cracks on the surface when extruded at 150 °C, it demonstrated good extrudability at temperatures above 200 °C. With increasing extrusion temperature from 200 to 300 °C, the average dynamic recrystallization (DRX) grain size increased from ~ 2.6 to ~ 6.4 μm, and < 10–10 > texture gradually transformed to < 11–21 > rare-earth texture component. Solute segregation was observed along grain boundaries and dislocations. The sample extruded at 200 °C exhibited a superior combination of both strength and ductility, with a yield strength of 179 MPa, an ultimate tensile strength of 228 MPa and an elongation of 35%. The improved tensile properties were mainly attributed to the fine grain size together with a high density of dislocations. The basal slip Schmid factor increased with increasing extrusion temperature due to the attainment of full DRX microstructure and the presence of non-basal texture component, which resulted in a lower yield strength at higher extrusion temperatures. The findings pave the way for the development of low-cost and low-alloyed high-performance magnesium alloys via the strategy of tailoring extrusion temperatures.

Similar content being viewed by others

Data availability

The raw/processed data required to reproduce these findings cannot be shared at this time as the data also forms part of an ongoing study.

References

Mao GW, ** XX, Sun J, Han XZ, Zeng M, Qiu YS, Bian WG (2021) Microalloying design of biodegradable Mg–2Zn–0.05Ca promises improved bone-implant applications. Acs Biomater Sci Eng 7:2755–2766. https://doi.org/10.1021/acsbiomaterials.1c00218

Ding PF, Liu YC, He XH, Liu DB, Ghen MF (2019) In vitro and in vivo biocompatibility of Mg–Zn–Ca alloy operative clip. Bioact Mater 4:236–244. https://doi.org/10.1016/j.bioactmat.2019.07.002

Chino Y, Huang X, Suzuki K, Mabuchi M (2010) Enhancement of stretch formability at room temperature by addition of Ca in Mg–Zn Alloy. Mater Trans 51:818–821. https://doi.org/10.2320/matertrans.M2009385

Wang G, Huang G, Chena X, Deng Q, Tang A, Jiang B, Pan F (2017) Effects of Zn addition on the mechanical properties and texture of extruded Mg–Zn–Ca–Ce magnesium alloy sheets. Mater Sci Eng A 705:46–54. https://doi.org/10.1016/j.msea.2017.08.036

Nie JF, Shin KS, Zeng ZR (2020) Microstructure, deformation, and property of wrought magnesium alloys. Metall Mater Trans A 51:6045–6109. https://doi.org/10.1007/s11661-020-05974-z

Nakata T, Xu C, Kamado S (2020) Improving tensile properties of a room-temperature formable and heat-treatable Mg–6Zn-0.2 Ca (wt%) alloy sheet via micro-alloying of Al and Mn. Mater Sci Eng A 772:138690. https://doi.org/10.1016/j.msea.2019.138690

Gungor A, Incesu A (2021) Effects of alloying elements and thermomechanical process on the mechanical and corrosion properties of biodegradable Mg alloys. J Magnes Alloy 9:241–253. https://doi.org/10.1016/j.jma.2020.09.009

Pulido-González N, Hidalgo-Manrique P, García-Rodríguez S, Torres Rams BJ (2022) Effect of heat treatment on the mechanical and biocorrosion behaviour of two Mg–Zn–Ca alloys. J Magnes Alloy 10:540–554. https://doi.org/10.1016/j.jma.2021.06.022

Zeng Z, Stanford N, Davies CHJ, Nie J-F, Birbilis N (2018) Magnesium extrusion alloys: a review of developments and prospects. Int Mater Rev 64:27–62. https://doi.org/10.1080/09506608.2017.1421439

Zeng ZR, Zhu YM, Liu RL, Xu SW, Davies CHJ, Nie JF, Birbilis N (2018) Achieving exceptionally high strength in Mg-3Al-1Zn-0.3Mn extrusions via suppressing intergranular deformation. Acta Mater 160:97–108. https://doi.org/10.1016/j.actamat.2018.08.045

Li GQ, Zhang JH, Wu RZ, Liu SJ, Song B, Jiao YF, Yang Q, Hou LG (2019) Improving age hardening response and mechanical properties of a new Mg–RE alloy via simple pre-cold rolling. J Alloys Compd 777:1375–1385. https://doi.org/10.1016/j.jallcom.2018.11.082

Zareian Z, Emamy M, Malekan M, Mirzadeh H, Kim WJ, Bahmani A (2020) Tailoring the mechanical properties of Mg–Zn magnesium alloy by calcium addition and hot extrusion process. Mater Sci Eng A 774:138929. https://doi.org/10.1016/j.msea.2020.138929

Lu SH, Wu D, Yan M, Chen RS (2021) Effect of twin and grain size strengthening on tensile properties of a multi-directionally impact forged Mg–Gd–Y alloy. J Mater Res Technol 15:4502–4515. https://doi.org/10.1016/j.jmrt.2021.10.060

Luo Y, Cheng W, Li H, Yu H, Wang H, Niu X, Wang L, You Z, Hou H (2022) Achieving high strength-ductility synergy in a novel Mg–Bi–Sn–Mn alloy with bimodal microstructure by hot extrusion. Mater Sci Eng A 834:42623. https://doi.org/10.1016/j.msea.2022.142623

Zhang Z, Zhang J, ** a low-alloyed fine-grained Mg alloy with high strength-ductility based on dislocation evolution and grain boundary segregation. Scr Mater 209:114414. https://doi.org/10.1016/j.scriptamat.2021.114414

Zhao LY, Guan B, **n YC, Huang XX, Liu CL, Wu PD, Liu Q (2021) A quantitative study on mechanical behavior of Mg alloys with bimodal texture components. Acta Mater 214:117013. https://doi.org/10.1016/j.actamat.2021.117013

Stanford N, Barnett MR (2008) The origin of “rare earth” texture development in extruded Mg-based alloys and its effect on tensile ductility. Mater Sci Eng A 496:399–408. https://doi.org/10.1016/j.msea.2008.05.045

Lee DH, Moon BG, Kim YM, Park SH (2021) Unusual relationship between extrusion temperature and tensile strength of extruded Mg–Al–Zn–Ca–Y–MM alloy. J Alloys Compd 862:158051. https://doi.org/10.1016/j.jallcom.2020.158051

Zeng ZR, Bian MZ, Xu SW, Davies CHJ, Birbilis N, Nie JF (2016) Effects of dilute additions of Zn and Ca on ductility of magnesium alloy sheet. Mater Sci Eng A 674:459–471. https://doi.org/10.1016/j.msea.2016.07.049

Wang H, Zhang DT, Cao GH, Qiu C (2022) Improving room-temperature ductility of a Mg–Zn–Ca alloy through friction stir processing. J Mater Res Technol 17:1176–1186. https://doi.org/10.1016/j.jmrt.2022.01.082

Luo XC, Zhang DT, Cao GH, Qiu C, Chen DL (2019) Multi-pass submerged friction stir processing of AZ61 magnesium alloy: strengthening mechanisms and fracture behavior. J Mater Sci 54:8640–8654. https://doi.org/10.1007/s10853-018-03259-w

Ma E, Zhu T (2017) Towards strength–ductility synergy through the design of heterogeneous nanostructures in metals. Mater Today 20:323–331. https://doi.org/10.1016/j.mattod.2017.02.003

Cao D (2023) Strengthening the interphase of thermoplastic sandwich composites by interleaving carbon nanotube yarns. Mater Today Commun 36:106655. https://doi.org/10.1016/j.mtcomm.2023.106655

Cao D, Malakooti S, Kulkarni VN, Ren Y, Lu H (2020) Nanoindentation measurement of core–skin interphase viscoelastic properties in a sandwich glass composite. Mech Time-Depend Mater 25:353–363. https://doi.org/10.1007/s11043-020-09448-y

Zhang JB, Tong LB, Xu C, Jiang ZH, Cheng LR, Kamado S, Zhang HJ (2017) Influence of Ca–Ce/La synergistic alloying on the microstructure and mechanical properties of extruded Mg–Zn alloy. Mater Sci Eng A 708:11–20. https://doi.org/10.1016/j.msea.2017.09.113

Du YZ, Zheng MY, Qiao XG, Wang DB, Peng WQ, Wu K, Jiang BL (2016) Improving microstructure and mechanical properties in Mg-6 mass% Zn alloys by combined addition of Ca and Ce. Mater Sci Eng A 656:67–74. https://doi.org/10.1016/j.msea.2016.01.034

Wang J, Zhu GM, Wang LY, Vasilev E, Park JS, Sha G, Zeng XQ, Knezevic M (2021) Origins of high ductility exhibited by an extruded magnesium alloy Mg-1.8Zn-0.2Ca: experiments and crystal plasticity modeling. J Mater Sci Technol 84:27–42. https://doi.org/10.1016/j.jmst.2020.12.047

Cano-Castillo G, Victoria-Hernandez J, Bohlen J, Letzig D, Kainer KU (2020) Effect of Ca and Nd on the microstructural development during dynamic and static recrystallization of indirectly extruded Mg–Zn based alloys. Mater Sci Eng A 793:139527. https://doi.org/10.1016/j.msea.2020.139527

Zhang E, Yang L (2008) Microstructure, mechanical properties and bio-corrosion properties of Mg–Zn–Mn–Ca alloy for biomedical application. Mater Sci Eng A 497:111–118. https://doi.org/10.1016/j.msea.2008.06.019

Huang XS, Chino Y, Yuasa M, Ueda H, Inoue M, Kido F, Matsumoto T (2017) Microstructure and mechanical properties of AZX912 magnesium alloy extruded at different temperatures. Mater Sci Eng, A 679:162–171. https://doi.org/10.1016/j.msea.2016.10.032

Sabbaghian M, Mahmudi R, Shin KS (2020) Microstructure, texture, mechanical properties and biodegradability of extruded Mg–4Zn–xMn alloys. Mater Sci Eng A 792:139828. https://doi.org/10.1016/j.msea.2020.139828

Stanford N (2010) Micro-alloying Mg with Y, Ce, Gd and La for texture modification—a comparative study. Mater Sci Eng A 527:2669–2677. https://doi.org/10.1016/j.msea.2009.12.036

Jiang MG, Yan H, Chen RS (2015) Twinning, recrystallization and texture development during multidirectional impact forging in an AZ61 Mg alloy. J Alloy Compd 650:399–409. https://doi.org/10.1016/j.jallcom.2015.07.281

Jiang MG, Xu C, Yan H, Fan GH, Nakata T, Lao CS, Chen RS, Kamado S, Han EH, Lu BH (2018) Unveiling the formation of basal texture variations based on twinning and dynamic recrystallization in AZ31 magnesium alloy during extrusion. Acta Mater 157:53–71. https://doi.org/10.1016/j.actamat.2018.07.014

Bohlen J, Yi SB, Letzig D, Kainer KU (2010) Effect of rare earth elements on the microstructure and texture development in magnesium-manganese alloys during extrusion. Mater Sci Eng A 527:7092–7098. https://doi.org/10.1016/j.msea.2010.07.081

Yi SB, Brokmeier HG, Letzig D (2010) Microstructural evolution during the annealing of an extruded AZ31 magnesium alloy. J Alloy Compd 506:364–371. https://doi.org/10.1016/j.jallcom.2010.07.008

He J, Chen WZ, Zhang ZJ, Chen XM, Ma JF, Wang WK, Zhang WC (2022) Extrusion techniques on microstructure optimization and quantitative analysis of texture influence on ductility improvement for heat-resistant Mg–Nd–Zn–Zr magnesium alloy. J Mech Sci 57:4334–4353. https://doi.org/10.1007/s10853-022-06881-x

Galiyev A, Kaibyshev R, Gottstein G (2001) Correlation of plastic deformation and dynamic recrystallization in magnesium alloy ZK60. Acta Mater 49:1199–1207. https://doi.org/10.1016/S1359-6454(01)00020-9

Victoria-Hernández J, Yi S, Letzig D (2022) Role of non-basal slip systems on the microstructure and texture development of ZXK-Mg alloy deformed in plane strain compression at elevated temperature. Scr Mater 208:114322. https://doi.org/10.1016/j.scriptamat.2021.114322

Imandoust A, Barrett CD, Oppedal AL, Whittington WR, Paudel Y, El Kadiri H (2017) Nucleation and preferential growth mechanism of recrystallization texture in high purity binary magnesium-rare earth alloys. Acta Mater 138:27–41. https://doi.org/10.1016/j.actamat.2017.07.038

Wang H, Zhang DT, Qiu C, Zhang WW, Chen DL (2022) Achieving superior mechanical properties in a low-alloyed magnesium alloy via low-temperature extrusion. Mater Sci Eng A 851:143611. https://doi.org/10.1016/j.msea.2022.143611

Guan D, Liu X, Gao J, Ma L, Wynne BP, Rainforth WM (2019) Exploring the mechanism of “rare earth” texture evolution in a lean Mg–Zn–Ca alloy. Sci Rep 9:7152. https://doi.org/10.1038/s41598-019-43415-z

Zeng ZR, Zhu YM, Xu SW, Bian MZ, Davies CHJ, Birbilis N, Nie JF (2016) Texture evolution during static recrystallization of cold-rolled magnesium alloys. Acta Mater 105:479–494. https://doi.org/10.1016/j.actamat.2015.12.045

Zhang Z, Zhang J, **e J, Liu S, He Y, Wang R, Fang D, Fu W, Jiao Y, Wu R (2022) Significantly enhanced grain boundary Zn and Ca co-segregation of dilute Mg alloy via trace Sm addition. Mater Sci Eng A 831:142259. https://doi.org/10.1016/j.msea.2021.142259

Zhang B, Wang Y, Geng L, Lu C (2012) Effects of calcium on texture and mechanical properties of hot-extruded Mg–Zn–Ca alloys. Mater Sci Eng A 539:56–60. https://doi.org/10.1016/j.msea.2012.01.030

Homma T, Mendis CL, Hono K, Kamado S (2010) Effect of Zr addition on the mechanical properties of as-extruded Mg–Zn–Ca–Zr alloys. Mater Sci Eng A 527:2356–2362. https://doi.org/10.1016/j.msea.2009.12.024

Xu Y, Li J, Qi M, Guo W, Deng Y (2022) A newly developed Mg–Zn–Gd–Mn–Sr alloy for degradable implant applications: influence of extrusion temperature on microstructure, mechanical properties and in vitro corrosion behavior. Mater Charact 188:111867. https://doi.org/10.1016/j.matchar.2022.111867

Niu Y, Song Z, Le Q, Hou J, Ning F (2019) Excellent mechanical properties obtained by low temperature extrusion based on Mg-2Zn-1Al alloy. J Alloy Compd 801:415–427. https://doi.org/10.1016/j.jallcom.2019.05.297

Li ZH, Gao S, Sasaki TT, Nakata T, Kamado S, Tsuji N, Hono K (2022) Discontinuous yielding phenomena triggered by Zn addition in low-alloyed Mg–Al–Ca–Mn alloys. Scr Mater 221:114967. https://doi.org/10.1016/j.scriptamat.2022.114967

Li RG, Zhao DY, Zhang JH, Li HR, Dai YQ, Fang DQ (2020) Room temperature yielding phenomenon in extruded or/and aged Mg-14Gd-2Ag-0.5Zr alloy with fine-grained microstructure. Mater Sci Eng A 787:139551. https://doi.org/10.1016/j.msea.2020.139551

Schwab R, Ruff V (2013) On the nature of the yield point phenomenon. Acta Mater 61:1798–1808. https://doi.org/10.1016/j.actamat.2012.12.003

Brindley BJ, Worthington PJ (1970) Yield-point phenomena in substitutional alloys. Metall Rev 15:101–114. https://doi.org/10.1179/mtlr.1970.15.1.101

Tian YZ, Gao S, Zhao LJ, Lu S, Pippan R, Zhang ZF, Tsuji N (2018) Remarkable transitions of yield behavior and Lüders deformation in pure Cu by changing grain sizes. Sc Mater 142:88–91. https://doi.org/10.1016/j.scriptamat.2017.08.034

Lu X, Zhao GQ, Zhou JX, Zhang CS, Chen L, Tang SQ (2018) Microstructure and mechanical properties of Mg-3.0 Zn-1.0 Sn-0.3 Mn-0.3 Ca alloy extruded at different temperatures. J Alloys Compd 732:257–269. https://doi.org/10.1016/j.jallcom.2017.10.210

Takigawa Y, Honda M, Uesugi T, Higashi K (2008) Effect of initial grain size on dynamically recrystallized grain size in AZ31 magnesium alloy. Mater Trans 49:1979–1982. https://doi.org/10.2320/matertrans.MAW200829

Kim SH, Lee JU, Kim YJ, Moon BG, You BS, Kim HS, Park SH (2017) Improvement in extrudability and mechanical properties of AZ91 alloy through extrusion with artificial cooling. Mater Sci Eng A 703:1–8. https://doi.org/10.1016/j.msea.2017.07.048

Shi Q, Wang C, Deng K, Nie K, Cao M, Gan W, Liang W (2020) Work hardening and softening behavior of pure Mg influenced by Zn addition investigated via in-situ neutron diffraction. Mater Sci Eng A 772:138827. https://doi.org/10.1016/j.msea.2019.138827

Toda-Caraballo I, Galindo-Nava EI, Rivera-Diaz-del-Castillo PEJ (2014) Understanding the factors influencing yield strength on Mg alloys. Acta Mater 75:287–296. https://doi.org/10.1016/j.actamat.2014.04.064

Acknowledgements

This work was sponsored by the Key-Area Research and Development Program of Guangdong Province (No. 2020B010186002), the Natural Science Foundation of Guangdong for Research Team (No. 2015A030312003) and National Study Abroad Fund. One of the authors (D.L. Chen) is also grateful for the financial support by Natural Sciences and Engineering Research Council of Canada (NSERC).

Author information

Authors and Affiliations

Contributions

HW: Conceptualization, Methodology, Investigation, Data curation, Writing-original draft, Writing- review & editing. DTZ: Resources, Investigation, Writing-review & editing. CQ: Software, Methodology. WWZ: Conceptualization, Methodology. DLC: Investigation, Writing-review & editing.

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Handling Editor: Sophie Primig.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wang, H., Zhang, D.T., Qiu, C. et al. Microstructure and tensile properties of a low-alloyed magnesium alloy: effect of extrusion temperature. J Mater Sci 58, 13502–13517 (2023). https://doi.org/10.1007/s10853-023-08877-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-023-08877-7