Abstract

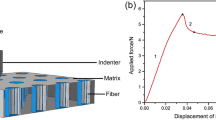

In order to investigate the effect of different matrices on the bending properties and fracture behavior of the continuous W-core-SiC fiber-reinforced aluminum matrix (SiCf/Al) composites, 30 vol.% SiCf/2024Al and 30 vol.% SiCf/6061Al composites were prepared via matrix coating and hot isostatic pressing. Samples from these composites were subjected to the push-out test and three-point bending test with in situ SEM. The microstructure of the SiCf/Al composites was examined by SEM and TEM. Results showed that there were coarse AlCuFeMn and Al2Cu phases in the matrix of the SiCf/2024Al composite, and needle-like Al4C3 phase at the interface between fiber and matrix. For the SiCf/6061Al composite, there were no coarse second phase in the matrix and no Al4C3 phase at the interface between fiber and matrix. The interfacial shear strength of the SiCf/2024Al composite (~ 37 MPa) was relatively larger than that of the SiCf/6061Al composite (~ 34 MPa), indicating a relatively strong interface bonding for the SiCf/2024Al composite. The bending strength of the SiCf/6061Al composite (1091 MPa) was superior to that of the SiCf/2024Al composite (968 MPa). For 30 vol.% SiCf/2024Al composite, cracks were initiated at the edge of the coarse second phase under bending load and propagated along the grain boundary of matrix. The crack passed directly through SiC fibers due to the strong interface bonding and needle-like Al4C3 phases formed by interfacial reaction, and the propagation rate was fast. For 30 vol.% SiCf/6061Al composite, the crack was initiated at the interface between fiber and matrix when the plastic deformation of matrix was retarded at the first SiC fiber. Then, the crack passed around SiC fibers and propagated in forms of crack bridging and deflection due to the suitable interface bonding, and the propagation rate was slow.

Similar content being viewed by others

References

H. Taguch, CVD-Continuous Silicon Carbide Fiber and Its Composites, J. Japan Soc. Powder Powder Metall., 1992, 39(6), p 455–458

V.V. Astanin, O.A. Kaibyshev, L.A. Imayeva, and A.A. Sirenko, Fabrication of Metal-Matrix Composites by Application of the Superplasticity Effect, J. Mater. Eng. Perform., 1997, 6(4), p 461–468

C. Wang, H. Li, P. Zhang, and H. Zhao, Effect on Corrosion Resistance of Ce-Rich-Sealed Ni-P Coatings on Cf/Al Composite Surface, J. Mater. Eng. Perform., 2013, 22(2), p 624–631

Z.X. Guo and B. Derby, Solid-State Fabrication and Interfaces of Fibre Reinforced Metal Matrix Composites, Prog. Mater Sci., 1995, 39(4–5), p 411–495

H.X. Peng, F.P.E. Dunne, K.H. Baik, and P.S. Grant, Fibre Re-arrangement and Matrix Softening Phenomena in Matrix-Coated Fibre (MCF) Composites During Vacuum Hot Pressing Consolidation, Mater. Sci. Eng. A, 2003, 346(1–2), p 246–253

A. Alten, E. Erzi, Ö. Gürsoy, G.H. Ağaoğlu, D. Dispinar, and G. Orhan, Production and Mechanical Characterization of Ni-Coated Carbon Fibers Reinforced Al-6063 Alloy Matrix Composites, J. Alloy. Compd., 2019, 787, p 543–550

A.K. Somayaji and N. Marakala, Effect of T6 Heat Treatment on Hardness Wear and Fatigue Behaviour of Nickel Coated Carbon Fiber Reinforced Al-7079 MMC, Int. J. Mech. Prod. Eng. Res. Dev., 2019, 9(2), p 253–264

K. Yu, V. Dollhopf, and R. Kochendorfer, CVD SiC/Al Composites Produced by a Vacuum Suction Casting Process, Compos. Sci. Technol., 1993, 46(1), p 1–6

A. Vassel, Continuous Fibre Reinforced Titanium and Aluminium Composites: A Comparison, Mater. Sci. Eng. A, 1999, 263(2), p 305–313

H.E. Déve and C. McCullough, Continuous-Fiber Reinforced Al Composites: A New Generation, JOM, 1995, 47(7), p 33–37

G.D. Zhang and R. Chen, Effect of the Interfacial Bonding Strength on the Mechanical Properties of Metal Matrix Composites, Compos. Interfaces, 1993, 1(4), p 337–355

K.S. Chan, Fracture Mechanisms and Properties of Metal-Matrix Composites, Key Eng. Mater., 1995, 104–107, p 791–798

M. Suéry, G. L’Espérance, B.D. Hong, L.N. Thanh, and F. Bordeaux, Development of Particulate Treatments and Coatings to Reduce Silicon Carbide Degradation by Liquid Aluminum, J. Mater. Eng. Perform., 1993, 2(3), p 365–373

B. Leszczyńska-Madej, D. Garbiec, and M. Madej, Effect of Sintering Temperature on Microstructure and Selected Properties of Spark Plasma Sintered Al-SiC Composites, Vacuum, 2019, 164, p 250–255

L. **e, T. Sun, C. He, J. Deng, H. Yi, X. Yang, Q. Qin, and Q. Peng, Enhancement of Toughness of SiC Through Compositing SiC-Al Interpenetrating Phase Composites, Nanotechnology, 2019, 31(13), p 135706

K.T.V. Rao, S.C. Siu, and R.O. Ritchie, Failure Mechanisms in SiC-Fiber Reinforced 6061 Aluminum Alloy Composites Under Monotonic and Cyclic Loading, Metall. Mater. Trans. A, 1993, 24(3), p 721–734

H. She, D. Shu, W. Chu, J. Wang, and B.-D. Sun, Effects of Fe and Si Impurities on the Microstructure and Properties of 7 × × × High Strength Aircraft Aluminum Alloys, J. Mater. Eng., 2013, 6, p 92–98

Y. Zhao, D. Song, B. Lin, C. Zhang, D. Zheng, S. Inguva, T. Li, Z. Sun, Z. Wang, and W. Zhang, 3D Characterization of Ultrasonic Melt Processing on the Microstructural Refinement of Al-Cu Alloys Using Synchrotron X-ray Tomography, Mater. Charact., 2019, 153, p 354–365

H.K. Kamga, D. Larouche, M. Bournane, and A. Rahem, Mechanical Properties of Aluminium-Copper B206 Alloys with Iron and Silicon Additions, Int. J. Cast Met. Res., 2012, 25(1), p 15–25

B. Yao, Z. Zhou, L. Duan, and Z. Chen, Characterization of Three-Point Bending Properties of Metal–Resin Interpenetrating Phase Composites, RSC Adv., 2018, 8(29), p 16171–16177

C.J. Yang, S.M. Jeng, and J.M. Yang, Interfacial Properties Measurement for SiC Fiber-Reinforced Titantum Alloy Composites, Scr. Metall. Mater., 1990, 24(3), p 469–474

F. Bocher, H.M. Flower, and M.P. Ryan, The Effect of Microstructure on Localized Corrosion in Creep Age-Formable Aluminum Alloys: Identification of Intermetallic Particles and Pit Initiation Sites, J. Electrochem. Soc., 2006, 153(12), p B551–B554

M. Wu, C. Wu, and S. Gao, Effect of Ultrasonic Vibration on Fatigue Performance of AA 2024-T3 Friction Stir Weld Joints, J. Manuf. Process., 2017, 29, p 85–95

A.L. Ning, Z.Y. Liu, and S.M. Zeng, Effect of Large Cold Deformation on Characteristics of Age-Strengthening of 2024 Aluminum Alloys, Trans. Nonferrous Met. Soc. China, 2006, 16(5), p 1121–1128

Y.Q. Jiang, J.H. Liu, and X.B. Wu, A Measure of Interfacial Frictional Shear Strength of MMC, Chin. J. Mater. Res., 1994, 8(4), p 378–380

Acknowledgments

The authors gratefully acknowledge the financial support of the National Natural Science Foundation of China, Grant Nos. U1537212, 51471019.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Chu, D., Ma, Y., Li, P. et al. Bending Properties and Failure Mechanism of Continuous W-Core-SiC Fiber-Reinforced 2024 and 6061 Aluminum Matrix Composites. J. of Materi Eng and Perform 29, 6295–6306 (2020). https://doi.org/10.1007/s11665-020-05119-8

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-020-05119-8