Abstract

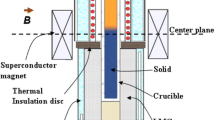

To understand the effects of convection and a temperature gradient on solidification behavior, Ti–6Al–4V alloy samples were melted and solidified using three levitation methods: electrostatic levitation (ESL), electromagnetic levitation (EML) with severe convection, and aerodynamic levitation (ADL) with a large temperature gradient. Titanium carbide (TiC) particles were added to Ti–6Al–4V as heterogeneous nucleation site particles to make differences in microstructures obvious. The cross sections of the levitated samples were analyzed using electron backscatter diffraction (EBSD) to obtain prior-β grain maps. The grains in the ESL sample were relatively isotropic in shape, whereas the grains and dendrite structures of the EML sample were radially arranged throughout the cross section. Therefore, under significant convection, such as in the EML sample, as grain growth is suppressed downstream, grain growth in the direction perpendicular to the melt flow is accelerated. In the ADL sample with a large temperature gradient in a vertical direction, columnar and equiaxed grains were formed in the lower and upper parts of the sample, respectively. Therefore, during unidirectional solidification due to a large temperature gradient, the shape of the grains changes from columnar to equiaxed as constitutional undercooling increases.

Similar content being viewed by others

References

M. Založnik and B. Šarler: Mater. Sci. Eng. A, 2005, vol. 413–14, pp. 85–91.

D. Zhang, A. Prasad, M.J. Bermingham, C.J. Todaro, M.J. Benoit, M.N. Patel, D. Qiu, D.H. Stjohn, M. Qian, and M.A. Easton: Metall. Mater. Trans. A, 2020, vol. 51A, pp. 4341–59.

C. Han, R. Babicheva, J.D.Q. Chua, U. Ramamurty, S.B. Tor, C.-N. Sun, and K. Zhou: Addit. Manuf., 2020, vol. 36, p. 101466.

C. Landron, X. Launay, J.C. Rifflet, P. Echegut, Y. Auger, D. Ruffier, J.P. Coutures, M. Lemonier, M. Gailhanou, M. Bessiere, D. Bazin, and H. Dexpert: Nucl. Instrum. Methods Phys. Res. B, 1997, vol. 124, pp. 627–32.

T. Usui, S. Shiratori, K. Tanimoto, S. Ozawa, T. Ishikawa, S. Suzuki, H. Nagano, and K. Shimano: Int. J. Microgravity Sci. Appl., 2023, vol. 40, p. 400302.

R.W. Hyers: Meas. Sci. Technol., 2005, vol. 16, pp. 394–401.

D.M. Herlach, R.F. Cochrane, I. Egry, H.J. Fecht, and A.L. Greer: Int. Mater. Rev., 1993, vol. 38, pp. 273–347.

H. Yasuda: Solidification of Containerless Undercooled Melts, 1st ed. Wiley-VCH, Berlin, 2012, pp. 305–20.

X. Ge, X. Xu, Q. Hu, W. Lu, L. Yang, S. Cao, M. **a, and J. Li: J. Mater. Sci. Technol., 2019, vol. 35, pp. 1636–43.

M. Mojib, R. Pahuja, M. Ramulu, and D. Arola: Proc. ASME, 2020, IMECE2020-24194.

X. Wang, G. Han, J. Ye, and C. Zhang: Proc. 2019 IEEE, 2019, pp. 1382–86.

Y. Watanabe, M. Sato, T. Chiba, H. Sato, N. Sato, S. Nakano, and S. Suzuki: J. Jpn. Laser Process. Soc., 2019, vol. 26, pp. 46–50.

Y. Watanabe, M. Sato, T. Chiba, H. Sato, N. Sato, and S. Nakano: Metall. Mater. Trans. A, 2020, vol. 51A, pp. 1345–52.

Y. Watanabe, S. Yamada, T. Chiba, H. Sato, S. Miura, K. Abe, and T. Kato: Materials, 2023, vol. 16(17), p. 5974.

S. Yamamoto, N. Date, Y. Mori, S. Suzuki, Y. Watanabe, S. Nakano, and N. Sato: Metall. Mater. Trans. A, 2019, vol. 50A, pp. 3174–85.

N. Date, S. Yamamoto, Y. Watanabe, H. Sato, S. Nakano, N. Sato, and S. Suzuki: Metall. Mater. Trans. A, 2021, vol. 52A, pp. 3609–27.

Y. Watanabe, H. Sato, M. Mihara-Narita, and S. Sekiyama: Metallic Powder for Directed Energy Deposition and Its Fabrication Method, Japanese Patent Application No. 2023-201358, 2023.

C. Hanada, H. Aoki, Y. Ueda, K. Kadoi, Y. Mabuchi, K. Yoneda, M. Yamada, H. Sato, Y. Watanabe, Y. Harada, S. Ozawa, S. Nakano, C. Koyama, H. Oda, T. Ishikawa, Y. Watanabe, T. Shimaoka, and S. Suzuki: Int. J. Microgravity Sci. Appl., 2023, vol. 40, p. 400301.

C. Mayer-Laigle, C. Gatumel, and H. Berthiaux: Chem. Eng. Res. Des., 2015, vol. 95, pp. 248–61.

T. Ishikawa, C. Koyama, Y. Nakata, Y. Watanabe, and P. Paradis: J. Chem. Thermodyn., 2021, vol. 163, p. 106598.

Y. Mabuchi, C. Hanada, Y. Ueda, K. Kadoi, Y. Kushiya, H. Aoki, R. Saguchi, K. Yoneda, M. Yamada, H. Sato, Y. Watanabe, S. Ozawa, S. Nakano, C. Koyama, H. Oda, T. Ishikawa, Y. Watanabe, T. Shimaoka, and S. Suzuki: Int. J. Microgravity Sci. Appl., 2024, vol . 41, p. 41020.

S. Ozawa, Y. Nagasaka, M. Itakura, K. Sugisawa, and Y. Seimiya: J. Appl. Phys., 2021, vol. 130, p. 135101.

Y. Seimiya, Y. Kudo, R. Shinazawa, Y. Watanabe, T. Ishikawa, and S. Ozawa: Metals, 2022, vol. 12, p. 1129.

Y. Seimiya, R. Shinazawa, T. Katsumi, and S. Ozawa: Int. J. Microgravity Sci. Appl., 2024, vol. 41, p. 410102.

M.V. Kumar, T. Ishikawa, B. Basavalingu, J.T. Okada, and Y. Watanabe: J. Appl. Phys., 2013, vol. 113, p. 193503.

W.G. Burgers: Physica, 1934, vol. 1, pp. 561–86.

C. Cayron, B. Artaud, and L. Briottet: Mater. Charact., 2006, vol. 57, pp. 386–401.

M. Humbert and N. Gey: J. Appl. Crystallogr., 2002, vol. 35, pp. 401–05.

M. Watanabe, M. Adachi, and H. Fukuyama: J. Mol. Liq., 2021, vol. 324, p. 115138.

Y. Mabuchi, C. Hanada, Y. Ueda, K. Kadoi, H. Aoki, R. Saguchi, M. Yamada, H. Sato, Y. Watanabe, S. Ozawa, S. Shiratori, S. Nakano, C. Koyama, H. Oda, T. Ishikawa, Y. Watanabe, and S. Suzuki: Int. J. Microgravity Sci. Appl., 2024, vol. 41, p. 410101.

T. Ishikawa, J.T. Okada, P.-F. Paradis, and Y. Watanabe: Jpn. J. Appl. Phys., 2011, vol. 50, p. 11RD03.

L. Bolzoni, M. **a, and N.H. Babu: Sci. Rep., 2016, vol. 6, p. 39554.

H. Miura, E. Yokoyama, K. Nagashima, K. Tsukamoto, and A. Srivastava: J. Appl. Phys., 2010, vol. 108, p. 114912.

Y. Mabuchi, C. Hanada, H. Aoki, K. Kadoi, Y. Ueda, Y. Kushiya, R. Saguchi, K. Yoneda, M. Yamada, H. Sato, Y. Watanabe, S. Ozawa, S. Nakano, H. Oda, C. Koyama, T. Ishikawa, Y. Watanabe, and S. Suzuki: Metall. Mater. Trans. B. Published online in May 29, 2024.

Y. Chong, R. Gholizadeh, K. Yamamoto, and N. Tsuji: Scripta Mater., 2023, vol. 203, p. 115397.

B. Skallerud, T. Iveland, and G. Härkegård: Eng. Fract. Mech., 1993, vol. 44, pp. 857–74.

O.E. Okorafor: Trans. Jpn. Inst. Met., 1986, vol. 27, pp. 463–68.

S.F. Hussainy, M. Mohiuddin, P. Laxminarayana, S. Sundarrajan, and A. Krishnaiah: J. Manuf. Sci. Prod., 2016, vol. 16, pp. 1–9.

D.M. Matson, L. Battezzati, P.K. Galenko, C.-A. Gandin, A.K. Gangopadhyay, H. Henein, K.F. Kelton, M. Kolbe, J. Valloton, S.C. Vogel, and T. Volkmann: NJP Microgravity, 2023, vol. 65, pp. 1–14.

S. Berry, R.W. Hyers, B. Abedian, and L.M. Racz: Metall. Mater. Trans. B, 1998, vol. 31B, pp. 171–78.

X. **ao, R.W. Hyers, and D.M. Matson: Int. J. Heat Mass Transf., 2019, vol. 136, pp. 531–42.

J. Lee, D.M. Matson, S. Binder, M. Kolbe, D. Herlach, and R.W. Hyers: Metall. Mater. Trans. B, 2014, vol. 45B, pp. 1018–23.

A. Jakhar, A. Bhattacharya, P. Rath, and S.K. Mahapatra: J. Therm. Sci. Eng. Appl., 2019, vol. 11, p. 051010.

C. Beckermann, H.-J. Diepers, I. Steinbach, A. Karma, and X. Tong: J. Comput. Phys., 1999, vol. 154, pp. 468–96.

A. Kao, L.V. Toropova, I. Krastins, G. Demange, D.V. Alexandrov, and P.K. Galenko: JOM, 2020, vol. 72, pp. 3123–31.

H. Soltani, G. Reinhart, M.C. Benoudia, F. Ngomesse, M. Zahzouh, and H. Nguyen-Thi: J. Cryst. Growth, 2020, vol. 548, p. 125819.

H. Li, K. Wang, G. Xu, H. Jiang, Q. Wang, and Y. Wang: J. Magnes. Alloy, 2021, pp. 1–14.

Acknowledgments

This study was conducted under the preliminary experiments of Hetero-3D Mission using the Japanese experiment module “Kibo” on the ISS. Furthermore, this work was conducted using research equipments (G1001, G1011, G1017, G1023, G1039, G1054, and G1055) with the help of the Joint Research Center for Environmentally Conscious Technologies in Materials Science, Kagami Memorial Research Institute for Materials Science and Technology, Waseda University (JPMXP0723833151). Furthermore, we appreciate Kimura Foundry Co., Ltd. for its financial support. The work done at Nagoya Institute of Technology (NITech) was supported by Adaptable and Seamless Technology Transfer Program through Target-Driven R&D (A-STEP) from Japan Science and Technology Agency (JST) Grant Number JPMJTR23R3.

Conflict of interest

The authors declare that there are no conflicts of interest.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix

Appendix

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Hanada, C., Mabuchi, Y., Kadoi, K. et al. Elucidation of Solidification Behavior of Ti–6Al–4V under Convection and a Temperature Gradient Using Levitation Methods. Metall Mater Trans B (2024). https://doi.org/10.1007/s11663-024-03148-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11663-024-03148-5