Abstract

A review on the hydrogen reduction kinetics of NiO, NiCO3, and Ni(OH)2 hydrogen was conducted, and the most significant experimental values and results were summarized from the past two decades. Isothermal hydrogen reduction experiments of NiO, NiCO3, and, Ni(OH)2 experiments were carried out at 300 °C, 400 °C, and 500 °C, and the obtained data were fitted to multiple different solid-state kinetic models in order to compare the suitability of the models. Non-isothermal reduction in H2 (0 °C\(\to \) 900 °C) showed the decomposition of NiCO3 at a temperature range of 230 °C to 300 °C and Ni(OH)2 at 220 °C to 300 °C. The calculated Ea values for NiCO3, Ni(OH)2, and NiO varied between 30 and 35, 36 and 37, and 21 and 26 kJ/mol, respectively. Most of the used models were well fitted making the choice of unequivocally the best suitable model difficult and the identification of the mechanism behind the reaction. It was concluded that an increase in temperature accelerates the reduction process, and the reaction rate-controlling mechanism requires more extensive investigation.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Pure nickel powders are mostly used in the production of alloys, such as low-carbon steels to improve mechanical properties such as ductility and tensile strength. Nickel powders also provide corrosion resistance, high strength, and good toughness in the wide temperature range in alloys designed for demanding applications like jet engine components and turbines.[1] Nickel powders can also be found in batteries, coatings, capacitors, electrodes composite materials, and as catalysts in metallurgical processes.[2]

In addition to the improvement of functional nickel powders of high quality, the concern about carbon dioxide emissions has driven the development of more environmentally friendly ways to produce nickel powders. Multiple countries have committed to decrease greenhouse gas emissions through emission limits which requires metal production to take significant steps towards carbon neutrality. The usage of hydrogen as a reducing agent has been proven to provide extraction of very pure fine metal powders with water vapor as the only liberated gas emission. Pure hydrogen used to reduce pure nickel compounds provides good gas-solid contact resulting in lower reaction times in moderate temperatures.[3,4]

Hydrogen reduction and reaction kinetics of NiO have been studied widely by multiple authors[2,5,14,18,19,20,21,22,23,24,25,26,27,28,29,30,31,32,33,34,35,36,37,38,39,40,41,42,43,44,45] with varying methods, parameters, and source material characteristics as well as the application of different kinetic models. Regarding other nickel compounds, such as NiCO3 and Ni(OH)2, less information about the reduction kinetics is available when hydrogen is used as a reducing agent. In this work, hydrogen reduction experiments of NiCO3 and Ni(OH)2 are carried out alongside NiO to compare the kinetic behavior of different nickel compounds. A detailed literature review is executed regarding the hydrogen reduction of NiO in order to obtain information about kinetic models that have been used to describe the reduction phenomenon. The aim is to fit the experimentally acquired isothermal data to different solid-state kinetic models collected from the literature to obtain kinetic models describing the hydrogen reduction of NiCO3 and Ni(OH)2 in addition to NiO. Hancock & Sharp method is applied to obtain preliminary information about the reduction mechanism. Furthermore, a non-isothermal reduction experiment in hydrogen atmosphere for each compound is performed to investigate the decomposition and reduction behavior under non-isothermal conditions.

Review on the Hydrogen Reduction Kinetics of Ni Compounds

The first investigations of hydrogen reduction of NiO were executed by Benton and Emmett already in 1924, and some of their conclusions are still relevant: (a) reduction takes place at the interface of NiO and previously reduced Ni, (b) there is so-called “autocatalytic” effect, i.e., reduction rate is proportional to the interfacial area, (c) induction period (nucleation) occurs and is dependent on the temperature and sample characteristics and, (d) added water increases induction period and reduces the reduction rate.[5] Since Benton’s and Emmett’s work, several studies about the kinetics of NiO reduction by H2 have been concluded with varying reduction conditions (temperature, gas composition, H2 flow) and NiO particle size. As in solid-state reactions generally, many models have been suggested based on the assumed reaction mechanism derived from the reduction experiment results. These models are theoretical, mathematical descriptions of experimental occurrences; a specific reaction type is described by a specific mathematical model translating it to a rate equation. The individual reaction steps are usually difficult to identify in solid-state reactions, and it requires techniques such as microscopy, spectroscopy, X-ray diffraction, etc. The conclusion about the reaction mechanism is based on the kinetic model that gives the best correspondence with the experimental results. In general, the classification of the models is based on the graphical shape of isothermal curves of the reduction (x vs t or d/dt vs x, x is the conversion fraction) or on the assumptions about the reaction mechanism.[6] Solid-state reaction mechanisms include reaction-order models (F), diffusion-limited models (D), geometrical contraction models (R), nucleation models (AE)[7,8,9,10] which are illustrated in Figure 1 and in addition, random pore model (RPM),[11] Ŝesták-Berggren function (SB)[12] and Prout-Tompkins (PT)[13] models. The different reaction models are presented in Table I divided into groups based on the assumed mechanisms behind the model. Reaction-order models (F) are usually applied when the reaction is homogenous.[14] Diffusion-based models (D) assume that the rate-controlling factor is the transportation of reactants and/or products to/from the active interface when gas permeates into the solid lattice.[15] Geometrical contraction models (R) are examples of the shrinking core model where a solid particle is consumed by a reaction occurring on the phase boundary. Reaction is limited by the formation of products that interfere gas diffusion to the product surface. The shrinkage or growth can be two (R2) or three dimensional (R3).[16] Nucleation models (AE) assume reaction occurring in the forming (nucleation) and growing nuclei.[17] The models described before are considered as basic models. Other models (PT, RPM, SB) are more specific and less relevant when considering the hydrogen reduction of nickel compounds, hence, not taken into consideration in this work.

Reaction mechanism behind (a) reaction-order model (F), (b) geometrical contracting model (R), (c) diffusion model, and (d) Avrami–Erofe’ev model. Adapted with permission from Ref. [14]

The most relevant studies regarding hydrogen reduction and kinetics of unsupported NiO are listed in Table II including the most important process parameters, used model, and calculated Ea values. As seen from the Table, different models have been suggested to describe the reaction, and derived Ea values vary from 3.5 to 120 kJ/mol. Multiple authors have concluded the following: (1) the induction period decreases with increasing temperature, (2) the reduction degree increases with increasing temperature up to 600 °C, slowing down between 600 °C and 900 °C, before increasing again after 950 °C. Yet the mechanism behind the reduction reaction is uncertain, and the conclusions by different authors suggest nucleation and growth (AE) or diffusion (D) being the prevalent mechanisms. Erri and Varma[18] applied isoconversional Friedman method to thermogravimetric experimental data to demonstrate the importance of diffusional effects. They concluded that the presence of internal and external mass-transfer limitations explains the variation of activation energy values and must be taken into consideration more extensively.[18] Jeangros et al.[19] used environmental TEM to monitor the structural and chemical evolution of NiO during hydrogen reduction. They observed nuclei forming and concluded the consistency with Avrami nucleation models.[19] Chatterjee et al.[20] studied the kinetics of hydrogen reduction of NiO powder and single pellet interpreting that within a temperature range of 300° C to 600 °C, the rate-controlling factor is diffusion through gas film, and the reduction rate increases with increasing temperature and hydrogen flow rate.[20] Zhou et al.[14] used Hancock and Sharp method and statistical analysis[21] to explore the one suitable solid-state model for NiO reduction experimental data found from the literature.[22,23,29] They concluded that the Avrami-Erofe’ev model represents the reduction of NiO even at higher temperatures.[14] In more recent studies, Lee and Min[22] examined the influence of NiO particle size on the reduction. They concluded that the influence of particle size increases with increasing temperature and that the 2nd-order Avrami is the best suitable model.[22] Manykyan et al.[23] reported kinetic data for NiO reduction at relatively low temperatures (270 °C to 500 °C) and high temperatures (900 °C to 1320 °C) concluding that Avrami nucleation models describe the mechanism in both cases. At higher temperatures, the induction period cannot be detected, and the reduction occurs in seconds forming a fine extremely porous product. They also pointed out the complexity of structural transformation during reduction stating that the mechanism relies on both nucleation and outward diffusion of water molecules.[23] Plascencia G[24] revisited previous data[25,26,27] from reduction of three different nickel oxides. He observed that variation in activation energies between the samples is due to the differences in chemical composition, structure, and morphology of the samples.[24]

Rhamdhani et al.[28,29] investigated structural and phase changes during hydrogen reduction of NiCO3 in a temperature range of 110 °C to 900 °C. They detected (1) removal of entrained water, (2) decomposition of carbonate above 200 °C and formation of NiO, (3) reduction of NiO from around 340 °C to 400 °C, (4) 400 °C to 500 °C agglomeration of Ni particles, and (5) above 700 °C significant sintering/densification of Ni particles. Due to these observations, reduction temperature was suggested to maintain under 600 °C, and high H2 partial pressure is favored.[28,29] Nguyen and Nguyen[2] synthesized nanosized nickel powder from Ni(OH)2 observing two stages: (1) removal of structural water within a temperature range of 210 °C to 280 °C and (2) formation of metallic Ni from NiO within a temperature range of 280 °C to 300 °C. They suggested a temperature increase in order to accelerate the reduction process.[2] The direct reduction experiments concluded of direct hydrogen reduction of NiCO3 and Ni(OH)2 are listed in Table III.

Experimental Techniques

Materials

Hydrogen reduction experiments were executed to three different commercially available nickel compounds, nickel oxide (NiO), nickel carbonate (NiCO3), and nickel hydroxide (Ni(OH)2, supplied by Alfa Aesar. The basic characteristics of the source materials are presented in Table IV.

Reduction Method

The non-isothermal and isothermal reduction experiments were carried out with Netzsch STA 449 F3 thermal analyzer (TGA) combined with Netzsch QMS 403D mass spectrometer detecting and recording the mass loss of the reducing samples. The main parts of the reduction system are the balance system measuring the mass of the sample, furnace heating the sample, heating elements measuring the system temperature, and gas supply unit monitoring the gas atmosphere. The system is connected to a recording unit that collects and analyzes the received data.

In the first experimental part, NiCO3, Ni(OH)2, and NiO samples (100 mg) were reduced in 5 vol pct H2 in Ar non-isothermally with heating rate of 5 °C/min to 900 °C to examine the differences of the reduction processes of the three different Ni compounds (Figure 2). The isothermal reduction experiments of the nickel samples were executed in three different temperatures, 300 °C, 400 °C, and 500 °C that were chosen based on the non-isothermal studies of the compounds. Approximately 100 mg of the sample was weighed to an Al2O3 cylindrical crucible (V = 6.4 cm3) which was placed into the sample carrier inside the thermogravimetry. Sample was quickly heated (20 °C/min) to the target temperature in Ar. When target temperature was reached, inert atmosphere was kept for 10 min following introduction of reducing gas (10 pct H2 + Ar) with a flow rate of 0.02 l/min. The sample was kept in reductive conditions for 1 h, and cooling was performed in Ar with rate of 40 °C/min. Ar flow during heating was 0.18 l/min and reduced to 0.16 l/min after introduction of H2 and kept in this state until the end of cooling. The isothermal test series presented in Table V was performed to all three nickel compounds.

The reaction routes for the source materials are following:

Reduction starts when hydrogen is introduced to the system. The initial step, induction period, is controlled by hydrogen partial pressure. As mentioned in chapter II, NiCO3 has been detected to decompose to basic NiO when temperature increases over 200 °C. In case of Ni(OH)2, increase in temperature causes evaporation of the structural water and formation on water vapor.

Model-Free Method – Hancock & Sharp

One simple method for identification of solid-state kinetic mechanisms in isothermal conditions was proposed by Hancock & Sharp[46] who used classical equation analysis of nucleation-and-growth process to distinguish reaction mechanism in decomposition of kaolinite, brucite, and BaCO3. Zhou et al.[14] used the same method as a diagnostic tool to obtain preliminary information about the reaction mechanism behind H2 reduction of supported and unsupported NiO. The nucleation model can be expressed as following:

where \(x\) is solid conversion, a is frequency factor of nuclei formation and crystalline growth, t is the reaction time, and n is the Avrami-Erofe’ev exponent which are listed for every model in Table I. The most suitable kinetic model can be identified from the slope n of the plot \(\text{ln}\left(-\text{ln}\left(1-x\right)\right)\) vs \(\text{ln}t\) when conversion values are limited to range between 0.15 to 0.5. This limitation erases the effects of geometrical factors, experimental inaccuracy, and the errors at t = 0.[14,46] This method provides information that can be used as a directional tool in distinguishing reaction mechanisms, and it should be noted that corresponding n values of different models are very close to each other indicating suitability of various models.[14]

Kinetic Analysis: Model-Fitting Method

Isothermal thermogravimetric analysis is based on the change of the sample mass as a function of time when temperature is constant. The progression of the reaction, e.g., conversion \(x\) for gravimetric measurement can be defined by

where \({m}_{0}\) (mg) is the initial weight, \({m}_{t}\) (mg) is the weight at time \(t\), and \({m}_{\infty }\)(mg) is the final weight of the solid.[6] The differential form of kinetic equation is following:

where t (s) is time, T (K) is the temperature, and \(f(x)\) is the reaction model, for which different equations are presented in Table I (chapter 2). The correlation between temperature and rate constant can be expressed by replacing \(k\left(T\right)\) with the Arrhenius equation, which gives

where \(A\) is the frequency factor, \({E}_{a} \)(J/mol) is the activation energy, R is the gas constant, T (K) is the absolute temperature, and \(x\) is solid conversion rate.[6] Equation 7 assumes a single-step reaction, where reaction rate is only function of temperature when conversion degree is constant (isoconversional method).

Based on the previous kinetic studies concluded with hydrogen reduction of NiO, different models were applied to compare results found from the literature. Reduction of chosen nickel compound with respect to hydrogen can be expressed as follows:

where \(k\) is the temperature-dependent reaction rate, \({p}_{{H}_{2}}\) is the partial pressure of hydrogen, and \(g\left(x\right)\) is the differential form of chosen kinetic model (also presented in Table I).[6,22] The apparent rate constant \({k}_{0}\) can be derived from the slope of \(g\left(x\right)\) vs time graph, where t = 0 when hydrogen is introduced to the system and \(g\left(x\right)\) values are plotted until conversion degree reaches 1. The actual rate constant is received by diving \({k}_{0}\) with hydrogen partial pressure \({p}_{{H}_{2}}\).

Arrhenius equation can be expressed in a graph with the relation between \(ln(k)\) and \(1/t\). By combining Eqs. [9] and [10][6,22]

The Ea values can be calculated from the Arrhenius plot:

where \({k}_{s}\) is the slope of the \(ln(k)\) vs \(1/T\) graph.

Results and Discussion

Conversion rates for the hydrogen reduction of NiO, NiCO3, and Ni(OH)2 in temperatures 300 °C, 400 °C, and 500 °C are shown in Figures 3(a), (b), and (c). Studied compounds reached full conversion within the reduction cycle (1 hour) and is observed that reduction to metallic nickel takes notable more time at the lowest temperature of 300 °C compared to reduction at 400 °C and 500 °C. Increase in the operating temperature accelerates the process substantially, and full reduction of the oxide is achieved considerable faster, especially in case of NiCO3 and Ni(OH)2. NiO reduction to Ni occurred slower compared to the other two tested compounds. Mass loss of NiCO3 and Ni(OH)2 during heating and in reductive atmosphere is presented in Tables VI and VII. Mass loss occurs during heating because of decomposition of NiCO3 and Ni(OH)2 and evaporation of structural water, as discussed before (Eqs. 2 and 3). In both cases, the mass loss during heating and reduction was concordant with the theoretical mass loss of assumed decomposition reactions. The mass loss of NiO in all operated temperatures was approximately 21 wt pct from the original weight, which is in consensus with theoretical mall loss wt pct of 21.4 wt pct and with previous experiments found from the literature. The non-isothermal thermogravimetric curve (Fig 2.) shows that the evaporation of structural water in NiCO3 starts in around 60 °C, decomposition of the compound in around 230 °C, and ending in around 300 °C. In case of Ni(OH)2, the decomposition of water starts in around 220 °C reaching the peak fast in 250 °C. The non-isothermal curve also indicates that the reduction of all the compounds starts in around 250 °C, and reduction of NiCO3 and Ni(OH)2 to metallic Ni is faster compared to NiO.

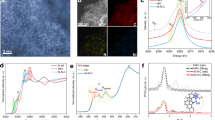

Results of model-free method and model-fitting method based on thermogravimetric data of H2 reduction of NiCO3, Ni(OH)2, and NiO are presented in Figures 4 through 10. Figures 4 through 6, present the Hancock & Sharp plots and derived Avrami-Erofe’ev exponents for each compound. The Arrhenius plots between ln k and 1/T for each compound are presented in Figure 7(a), (b), and (c). Figures 8 through 10 present the conversion predictions of some models compared to the experimental data of hydrogen reduction of NiCO3, Ni(OH)2 and NiO in three operated temperatures.

The Ea values calculated using different solid-state kinetic models are presented in Tables VIII through X together with slope equation and adjusted R-squared (R2) value indicating the “goodness” of the plot. Adjusted R2 considers only the independent variables that affect on the dependant variables and, therefore, to the performance of the model. The Ea values vary between 29.4 and 45.3 kJ/mol regarding NiCO3, 35.7 to 50.2 kJ/mol for Ni(OH)2 and 19.4 to 75.5 kJ/mol for NiO when different kinetic models were used to calculate the activation energy values.

As shown in Figure 8(a), the Avrami-Erofe’ev models predict the reduction of NiCO3 satisfyingly at the lowest temperature (300 °C) although model-free method indicated that the controlling mechanism is F3. This may be due to the overlap** reactions of decomposition and reduction causing non-linear plot. The Hancock & Sharp method indicates that the mechanism approaches phase-boundary-controlled reaction (R2, R3) when NiCO3 reduction is performed at 400 °C or 500° C. In both cases, experimental data are in good correlation with R2 and R3 model predictions at the beginning of the reaction, but the final phase does not follow any of the model predictions. In case of Ni(OH)2, Hancock & Sharp method suggests that reaction mechanism at 300 °C approaches nucleation and growth (AE1) and at higher temperatures phase-boundary-controlled reactions (R2, R3).

Model-fitting method confirms good fit of R2 model to experimental data at higher temperatures, but discrimination between AEn and R3 models at 300 °C cannot be concluded. It should be noted that the Hancock & Sharp plot at 300 °C is not linear, and in reaction phase between conversion 0.15 and 0.5, reaction may be interfered by decomposition of the hydroxide and formation of water vapor.

Nguyen and Nguyen[2] used AE1 model to calculate Ea value (54 kJ/mol) for H2 reduction of Ni(OH)2 at lower-temperature range (210 °C to 300 °C). Results derived from these experiments suggest that R2 model is preferable when temperature is raised to 300 °C and up. None of the models describe the reduction of NiO in 300 °C accurately, but when temperature is increased to 400 °C, AE models give a good fit in comparison to experimental data. At 500 °C, both AE models and R3 provide an average fit although neither of predictions are accurate throughout the reduction. Overall, the best models describing the reduction of the studied compounds are models based on nucleation (AE) and phase-boundary-controlled reaction (R2, R3) depending on the reduction temperature. The model-fitting method did not indicate unequivocally which model describes the reduction reactions of the compounds accurately. This indicates that the hydrogen reduction reaction rate-controlling factor depends on the process parameters and particle characteristics and may alternate throughout the reaction. The competing reaction mechanisms are nucleation and growth (AEn) and geometrical contracting models R2 and R3 at operating temperatures between 300 °C and 500 °C.

Conclusions

Commercially available NiO, NiCO3, and Ni(OH)2 samples were reduced in three different temperatures under hydrogen atmosphere to investigate the kinetic behavior of the compounds. The obtained data were fitted to different solid-state kinetic models to gain information about the reaction mechanisms and activation energies of different Ni compounds. Based on the derived results, it is difficult to state which model describes the hydrogen reduction process of these compounds the best, but the model prediction curves suggested Avrami-Erofe’ev models and phase-boundary-controlled reaction models R2 and R3 to have the best fit compared to experimental data. The Avrami-Erofe’ev exponents derived from Hancock & Sharp plots indicated similar results and stated that controlling reaction mechanisms are nucleation and growth and phase-boundary-controlled reactions. Based on this, the activation energies vary between 30 and 35, 36 and 37 and 21 and 26 kJ/mol for NiCO3, Ni(OH)2, and NiO, respectively. The calculated Ea values are lower compared to the values found from the literature although they are similar to the values derived by Placencia and Utigard.,[27] Chatterjee et al.,[41] and Sokić et al.[37] Increase in temperature accelerates the reduction process which is in consensus with multiple studies concluded about the hydrogen reduction of Ni compounds. The studied reactions require more detailed analysis, knowledge about the sample characteristics, especially after decomposition of NiCO3 and Ni(OH)2, and understanding the effect of the process parameters such as hydrogen flow and gas composition, heating rate, and temperature to the reduction process. Moreover, the sample size (100 mg) was small so the affect of a bigger sample to the reaction mechanism and activation energy should be investigated. These matters require different experimental setups and analysis of different stages during the reaction, and characterization of the end products. These results explain the inconsistency in previous experiments and provide more experimental data about the hydrogen reduction of NiO, NiCO3, and Ni(OH)2.

References

L. Koehler and Koehler Associates: AMS handbook. 2015. vol. 7, pp. 673–81.

V.M. Nguyen and T.H. Nguyen: Metallurgist, 2021, vol. 65, pp. 206–13.

S. Luidold and H. Antrekowitsch: Min. Metals Mater. Soc., 2007, vol. 59(6), pp. 20–26.

S. Luidold and H. Antrekowitsch: Min. Metals Mater. Soc., 2007, vol. 59(6), pp. 58–62.

A.F. Benton and J. Emmett: Am. Chem. Soc., 1924, vol. 46, pp. 2728–37.

A. Khawam and D.R. Flanagan: J. Phys. Chem. B, 2006, vol. 101, pp. 17315–28.

M. Avrami: J. Chem. Phys., 1939, vol. 7, p. 1103.

M. Avrami: J. Chem. Phys., 1940, vol. 8, p. 212.

M. Avrami: J. Chem. Phys., 1941, vol. 9, p. 177.

B.N. Erofeev: Dokl AN SSSR., 1946, vol. 52, p. 515.

S.K. Bhatia and D.D. Perlmutter: AlChE J., 1980, vol. 26, pp. 379–86.

J. Šesták and G. Berggren: Thermochim. Acta, 1971, vol. 3, pp. 1–2.

E.G. Prout and F.C. Tompkins: Trans. Faraday Soc., 1944, vol. 40, pp. 488–98.

Z. Zhou, L. Han, and G.M. Bollas: Int. J. Hydrogen Energy, 2014, vol. 39, pp. 8535–56.

A.K. Galwey and M.E. Brown: Stud. Phys. Theoret. Chem., 1999, vol. 1, p. 75.

J.W. Evans, S. Song, and C.E. Leon-Sucre: Metall. Mater. Trans. B, 1976, vol. 7B, pp. 55–65.

I.H. Leubner: Curr. Opin. Colloid Interface Sci., 2000, vol. 5, pp. 151–59.

P. Erri and A. Varma: Ind. Eng. Chem. Res., 2009, vol. 48, pp. 4–6.

Q. Jeangros, T.W. Hansen, J.B. Wagner, C.D. Damsgaard, R.E. Dunin-Borkowski, C. Hébert, J. Van Herle, and A. Hessler-Wyser: J. Mater. Sci., 2013, vol. 48, pp. 2893–2907.

R. Chatterjee, B. Sabyasachi, B. Sayan, and G. Dinabandhu: Trans. Indian Inst. Met., 2012, vol. 65, pp. 265–73.

J.D. Hancock and J.H. Sharp: J. Am. Ceram. Soc., 1973, vol. 55(2), pp. 74–77.

D.S. Lee and D.J. Min: Met. Mater. Int., 2019, vol. 25, pp. 982–90.

K. Manykyan, A.G. Avetisyan, C.E. Shuck, H.A. Chatilyan, S. Rouvimov, S.L. Kharatyan, and A.S. Mukasyan: J. Phys. Chem. C, 2015, vol. 119, pp. 16131–38.

G. Plascencia: Arch. Metall. Mater., 2018, vol. 63, pp. 781–89.

T.A. Utigard, G. Plascencia, T. Marin, J. Liu, A. Vahed, and M. Muinonen: Can. Met. Q., 2005, vol. 44, pp. 421–28.

T.A. Utigard, M. Wu, G. Plascencia, and T. Marin: Chem. Eng. Sci., 2005, vol. 60, pp. 2061–68.

G. Plascencia and T. Utigard: Chem. Eng. Sci., 2009, vol. 64, pp. 3879–88.

M.A. Rhamdhani, E. Jak, and P.C. Hayes: Metall. Mater. Trans. B, 2008, vol. 39B, pp. 218–33.

M.A. Rhamdhani, E. Jak, and P.C. Hayes: Metall. Mater. Trans. B, 2008, vol. 39B, pp. 234–45.

A. Rashed and Y. Rao: Chem. Eng. Commun., 1997, vol. 156, pp. 1–30.

J.-S. Lee and B.-S. Kim: Mater. Trans., 2001, vol. 42, pp. 1607–12.

J. Richardson, R. Scates, and M. Twigg: Appl. Catal. A: Gen., 2003, vol. 246, pp. 137–50.

J. Richardson, R. Scates, and M. Twigg: Appl. Catal. A: Gen., 2004, vol. 267, pp. 35–46.

B. Janković: J. Phys. Chem. Solids, 2007, vol. 68, pp. 2233–46.

B. Janković, B. Adnadević, and S. Mentus: Thermochim. Acta, 2007, vol. 456, pp. 48–55.

B. Janković, B. Adnadević, and S. Mentus: Chem. Eng. Sci., 2008, vol. 63, pp. 567–75.

B. Adnadević and B. Janković: Physica B, 2008, vol. 403, pp. 4132–38.

T. Hidayat, M.A. Rhamdhani, E. Jak, and P.C. Hayes: Metall. Mater. Trans. B, 2009, vol. 20B, pp. 474–89.

S.S.A. Syed-Hassan and C.-Z. Li: Appl. Catal. A: Gen., 2011, vol. 398, pp. 187–94.

S.S.A. Syed-Hassan and C.-Z. Li: Int. J. Chem. Kin., 2011, vol. 43, pp. 667–76.

M. Sokić, Ž Kamberović, V. Nikolić, B. Marković, M. Korać, Z. Anić, and M. Gavrilovski: Sci. World J., 2015, vol. 2015, pp. 1–9.

M. Abdollahi, M. Sameezadeh, and M. Vaseghi: Mater. Manuf. Process., 2018, vol. 33, pp. 856–62.

J.-R. Lee, N. Hasolli, S.-M. Jeon, K.-S. Lee, K.-D. Kim, Y.-H. Kim, K.-Y. Lee, and Y.-O. Park: Korean J. Chem. Eng., 2018, vol. 35, pp. 2321–26.

A.V. Fedorov, R.G. Kukushkin, P.M. Yeletsky, O.A. Bulavchenko, Y.A. Chesalov, and V.A. Yakolev: J. Alloys Compd., 2020, vol. 844, pp. 1–3.

L. Bai, J. Fan, P. Hu, F. Yuan, J. Li, and Q. Tang: J. Alloys Compd., 2009, vol. 481, pp. 563–67.

J.D. Hancock and J.H. Sharp: J. Am. Chem. Soc., 1972, vol. 55, pp. 74–77.

Acknowledgments

This research is a part of Business Finland funded Towards Carbon Neutral Metals (TOCANEM:41700/31/2020:) project. The authors wish to thank the project partners involved in the research and the staff of the Process Metallurgy Research Unit in the University of Oulu. The authors would like to thank Ilkka Vesavaara from the University of Oulu Fibre and Particle Engineering unit for completing the nickel content analysis of the Ni compounds. We also like to thank Prof. Timo Fabritius from the University of Oulu Process Metallurgy Research Group for all the support and comments.

Funding

Open Access funding provided by University of Oulu (including Oulu University Hospital).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Pöyhtäri, S., Ruokoja, J., Heikkinen, EP. et al. Kinetic Analysis of Hydrogen Reduction of Nickel Compounds. Metall Mater Trans B 55, 251–265 (2024). https://doi.org/10.1007/s11663-023-02955-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-023-02955-6