Abstract

Deglaciation due to warming climate has left a great amount of glacial tills in ravine slopes and channels in southern Tibet, which can lead to destructive debris flows and pose great threats to downstream residents and infrastructures. The mechanical properties and grain size characteristics of glacial tills are key factors that influence the initiation and development of these debris flows. In this work, a series of consolidated undrained (CU) triaxial compression tests under different confining pressures were carried out on Zelongnong glacial tills at various relative densities of 9.2%, 49.5%, 69.0% and 88.7%. The grain size distribution change before and after the CU tests was also determined. Results show that the glacial tills at relative densities of 9.2%, 49.5% and 69.0% exhibited a remarkable strain-softening and contractive behaviour during shearing, while those at a relative density of 88.7% presented a dilatant behaviour. As the relative density increased, the shear strength, elastic modulus and shearing friction angle increased, reducing the liquefaction potential. Based on the increasing rate of mechanical resistance with the increasing relative density, a critical value of 69.0% was identified to appreciate the distinct mechanical responses of the specimens. From the grain size distributions before and after CU tests, the content of grains with a diameter larger than 0.85 mm decreased due to the grain breakage while that of grains smaller than 0.3 mm increased. The higher the specimen relative density, the larger the grain breakage ratio owing to the increasing friction resistance. This grain breakage in turn causes a downward shift of the critical state line on the plane of void ratio and mean effective stress.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

In North America, Europe and Asia, a large area of Earth's land surface is covered by glaciers and permafrost [2, 37]. These alpine glaciers and permafrost are vulnerable to active tectonic movements and warming climate conditions, and associated catastrophic glacial debris flows occur frequently [24, 31]. Eventually, a large amount of loose glacial tills deposited on ravine slopes and channels [44, 51, 52]. When subsequent glaciers or landslide materials fall at a high elevation, the detached materials travel on the deposit, entrain a large amount of saturated glacial tills along the path and transform into a massive glacial debris flow. Such debris flows in alpine regions can cut off roads, block rivers and destroy facilities downstream [19, 21]. To improve debris flow hazard prevention and risk management, it becomes essential to systematically investigate the transport and disposition properties of the glacial tills.

Glacial tills can be classified into five types according to their deposition mode: lodgement tills, melt-out tills, flow tills, deformation tills and sublimation tills [13, 18, 39]. As the most common types, lodgement tills are featured by the lodgement of soil particles on the glacier bed and the fragile bonding between ice and soil particles, while melt-out tills are produced by ice melting, either from the top or from the bottom [13, 22, 39]. Dreimanis and Vagners [23] statistically determined the distribution of glacial till fragments and indicated that coarse mode was predominant close to the debris source while fine mode prevailed with increasing transport distance.

In addition to the geometry and grain size characteristics, the physical and mechanical properties of glacial tills have also been studied by Allred [2], Cao et al. [11], Chen et al. [13], Fu et al. [24] and others. Chen et al. [13] carried out a series of compression tests on lodgement and melt-out tills from Tianmo Gully of Tibet and demonstrated that the glacial tills had smaller compression index and secondary consolidation coefficient values than conventional sand and clays. Cao et al. [11] determined the unit weight, water content, shear strength, deformation modulus, consolidation parameters and shear wave velocity of a glacial till deposit in Toronto, Canada, and proposed correlations between the standard penetration test value, pressuremeter modulus and soil friction angle. Allred [2] examined the engineering properties of glacial tills with fractures and indicated that the presence of fractures significantly increased the saturated hydraulic conductivity and consolidation potential, but reduced the shear strength of glacial tills.

The soil physical and mechanical properties depend on its geometry and grain size characteristics [3, 60, 61]. In the past decades, the soil particle breakage during compression has been reported by many researchers. Several attempts have been made by proposing a breakage index based on the particle size distribution change and relating the proposed breakage index to the mechanical parameters [26, 29, 47, 50, 57]. Compared to the common geomaterials, such as river sand and gravels, glacial tills are usually more angular and sharp as they have undergone little abrasion [16]. Boulton [9] and Boulton et al. [10] pointed out that the glacial tills could be broken into smaller ones while suffering significant crushing or abrasion during the transport and deposition processes. This comminution of glacial tills and the variation of grain size due to crushing and abrasion would in turn influence the transport and deposition processes. In previous works, the grain size change because of breakage during compression or shearing under relatively high stresses and the response of the mechanical properties to grain breakage have been largely investigated on carbonate sand [17, 41, 54], quartz sand [29, 42], biocemented sand [56], tailings [57] and rockfill materials [38]. However, the feedback mechanisms of mechanical behaviour and grain breakage of glacial tills have not yet been studied.

In this study, a series of consolidated undrained triaxial compression (CU) tests were performed on Tibetan glacial tills at various initial effective confining pressures and relative densities, and the effect of relative density on the stress–strain relation, undrained shear strength, Young’s modulus, instability line and friction angle was determined. The grain size distributions of glacial tills were also determined before and after CU tests to enable the interpretation of feedback mechanisms of mechanical behaviour and grain breakage of glacial tills.

2 Materials and experimental methods

2.1 Materials

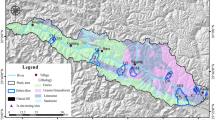

The studied area is the Zelongnong Ravine on the southeast of the Tibetan Plateau (Fig. 1). It is located at the western slope of Namcha Barwa and the right bank of the Yarlung Tsangpo Grand Canyon where several key infrastructural projects are located. Like most of the tributaries in this rugged and mountainous area, Zelongnong Gully is quite steep. The respective highest and lowest elevations of the basin are 7782 m at the Namjagbarwa mountain and 2810 m at Zhibai Village at the convergence into the Yarlung Tsangpo, and the elevation difference is up to 4972 m. The length of the main channel is about 12 km, and the mean gradient is 41.4% [59]. The headwater area of Zelongnong Gully is largely glaciated, and massive glacial tills are deposited at the front of the glaciers. The glacial tills mainly consist of granite gneiss, marble, intercalated with monoclinic gabbro, marble, garnet amphibolite, kyanite monzogneiss and other high-pressure granulite intercalations in the Zhibai formation of the Namcha Barwa group [44]. Since 1950, debris flows frequently took place in the Zelongnong Ravine due to the warming climate. Recently, on 10 September 2020, an active glacier detached under a low-intensity rainfall condition and evolved into a large-scale debris flow, damaging the Zhibai Bridge and partially blocking the Yarlung Tsangbo (Fig. 2).

Photograph showing (a) the outlet of Zelongnong Gully and (b) sample location (after Peng et al. [44])

Given the friability of glacier tills, obtaining a large quantity of intact glacial tills was difficult and the test specimens were re-constituted in the laboratory. The glacial tills were collected from the gully near the Zhibai bridge, as shown in Fig. 2b. The water content of the collected glacial tills is 5.5%. Figure 3 shows the grain size distribution of the site glacial tills. The site glacial tills are poorly graded and sorted, with 57.3% gravel and 42.7% sand [6]. The uniformity coefficient and the coefficient of curvature are 81.25 and 0.14, respectively. In this work, a triaxial compression system with a specimen diameter of 50 mm was adopted. According to the recommendation of Pedro [43] and Wang et al. [50], the triaxial compression test specimen should be 5 times larger than the maximum grain diameter to minimise the specimen size effect. Thus, the grain size of test glacial tills should be less than 10 mm. Prior to the mechanical tests, the grain size distribution of the test glacial tills was transited from that of the site glacial tills based on the parallel gradation method. For the correlative grain sizes sharing the same grain percentage, the grain sizes of the test and site glacial tills are correlated using Eq. (1):

where Dmax, Dmin and D refer to the maximum grain size, the minimum grain size and a given grain size, respectively; the superscripts s and t stand for the site and test glacial tills; and A is a scale ratio. In this work, a maximum grain size of 5 mm was adopted according to the commonly used sieve size and aforementioned allowable grain size range, and the corresponding scale ratio is 12.1. Following the above procedure, the grain size distribution of the test glacial tills was determined, as presented in Fig. 3. To obtain the test glacial tills, the mass proportion of each grain group was firstly calculated. Then, the site glacial tills of various groups were thoroughly mixed using a large mixer to constitute to the test glacial tills. The physical properties of the test glacial tills are summarised in Table 1. The maximum and minimum void ratios were measured according to ASTM [4, 5], equal to 0.710 and 0.332, respectively.

2.2 Experimental methods

Since the failure process of glacial tills lasts for a short time and does not allow dissipation of pore water pressure, CU tests were performed on the test glacial tills. The cylindrical triaxial specimens were prepared using the moist tam** method. Test glacial tills were first humidified by spraying deionised water to reach a natural water content of 5.5%. For each specimen, the wet glacial tills were divided into 5 parts, each part being compacted to 20 mm thick in a split mould with an inner diameter of 50 mm. The target diameter and height of cylindrical specimen were 50 and 100 mm, respectively, and the ratio of height to diameter was 2. The void ratios of the prepared specimens were 0.675, 0.523, 0.449 and 0.347, and the relative densities (Dr) are 9.2, 49.5, 69.0 and 88.0%, corresponding to loose, medium dense, dense and very dense states, respectively (Table 2). After the compaction, the triaxial cap was placed at the top of specimens and the split mould was then dismantled. Next, the cell wall was installed and the cell pressure was increased to 20 kPa to prevent specimen collapse.

To ensure satisfactory saturation, the specimens were saturated by injecting CO2 through them under a low pressure of about 10 kPa for 10 min to dissolve air bubbles. De-aired water was then injected to saturate the specimens. Prior to the CU tests, a back pressure of 200 kPa was applied to increase the saturation degree, and correspondingly, the cell pressure was increased to 210 kPa. After that, the Skempton’s B value was taken, larger than 0.98 for all tests. The cell pressure was increased to the designed values of 250, 300, 400 and 500 kPa (corresponding to initial effective confining pressures of 50, 100, 200 and 300 kPa). The consolidation was believed to end when the expelled water volume was less than 0.005 mL/h, and it was also confirmed by the pore pressure equilibrium between the base and top of the specimen. Subsequently, the strain-controlled shearing was performed at a constant strain rate of 1.0% per minute. This strain rate value was slow enough to ensure the equilibria of the pore water pressure change throughout the specimen. The shearing tests were ended at 20% axial strain. In this work, all the tests were conducted at an ambient temperature of 20 ± 1 °C.

To clarify the grain size change during the CU tests, the grain size distributions of the specimens with various initial relative densities after the shearing under different initial effective confining pressures were also determined using dry-sieving methods.

3 Experimental results

3.1 Stress–strain behaviour

Figure 4 displays the evolutions of deviator stress (q) with axial strain (\(\varepsilon_{a}\)) for the loose, medium dense, dense and very dense specimens under various initial effective confining pressures of 50, 100, 200 and 300 kPa. It could be observed that the deviator stress for all the specimens increased quickly at the beginning. On the whole, the higher the initial effective confining pressure and the specimen relative density, the larger the deviator stress value and the increasing rate of deviator stress, which was similar to phenomenon reported by Benahmed [7] on HN31 sand. After that, the deviator stress reached a peak value (qmax), then decreased and finally approached the steady state, exhibiting the limited liquefaction behaviour, especially for the specimens with low relative densities (Fig. 4a, b).

For the undrained triaxial compression tests, the excess pore water pressure (\(\Delta u\)) is another key indicator reflecting the contractive (\(\Delta u\) > 0) and dilatant responses (\(\Delta u\) < 0). Figure 5 depicts the evolution of excess pore water pressure with axial strain for the specimens with various relative densities and under different initial effective confining pressures. For the specimens with low relative densities (loose, medium dense and dense states), the excess pore water pressure increased monotonously and tended to stabilise without any drop, indicating a pure contractive response (Fig. 5a, b, c). The larger the initial effective confining pressure, the higher the excess pore water pressure. The increase in initial effective confining pressure gave rise to the fast generation of excess pore water pressure. Under the same confining pressure, the specimens at loose and medium dense states exhibited a similar excess pores pressure and this value was obviously higher than that at dense state due the occurrence of liquefaction. In the case of very dense state, very little void space remained within the specimens and the strong rolling and sliding resistance between soil grains would facilitate the dissipation of excess pore water pressure during compression. The excess pore water pressure started with a fast increase followed by a peak value (\(\Delta u_{\max }\)) and then declined to a stable value (Fig. 5d). A more significant peak was observed for the specimen with a larger initial effective confining pressure, thanks to the suppressing effect on dilatancy. At the end of tests, because of the occurrence of cavitation, all excess pore water pressure curves approached a constant value of about − 190 kPa, which was generally related to the applied back pressure.

3.2 Peak deviator stress and Young’s modulus

The peak deviator stresses of the specimens with various relative densities and initial effective confining pressures are summarised in Fig. 6. As expected, the peak shear stress increased with the increasing initial effective confining pressure for the specimens with the same initial void ratio (Fig. 6a). In Fig. 6b, the peak deviator stress is replotted against the relative density for various initial effective confining pressures. Under a given initial effective confining pressure, the specimens at loose and medium dense states exhibited a small peak deviator stress and the shear strength kept almost constant as the relative density increased from 9.2 to 49.5%. This is attributed to the generation of high excess pore water pressure and the occurrence of significant liquefaction for the specimens at low relative densities (Fig. 5a, b). This excess pore water pressure decreased the effective stress between particles, and thus, a small shear stress was required during triaxial compression. Consequently, similar shear strengths were identified on specimens at loose and medium dense states. As the relative density increased, the peak deviator stress increased slightly at high relative densities less than 69.0% and then significantly at relative densities larger than 69.0% owing to the increasing contact area between the grains. The increasing trend of peak deviator stress with relative density followed a nearly bilinear pattern with the distinct slopes for \(D_{r} \le 69.0\%\) and for \({\text{D}}_{\text{r}}\text{ > 69.0\%}\).

Young’s modulus, defined as the ratio of deviator stress to axial strain from 0 to 0.5% [46], was also determined for all the specimens. The variations of calculated Young’s modulus with initial effective confining pressure and relative density are shown in Fig. 7. For the specimens with the same relative density, the Young’s modulus increased with the increasing initial effective confining pressure due to the increase in the shear resistance. Under a given initial effective confining pressure, a bilinear fitting could also be applied to represent the change of Young’s modulus with relative density. This also defines a characteristic relative density of 69.0% regardless of initial effective confining pressure, which agrees well with the above observation while dealing with the variation of peak deviator stress with relative density in Fig. 6b.

3.3 Effective stress paths

Figure 8 presents the effective stress path of the specimens with various relative densities on the plane of effective stress (\({\text{p}}{\prime}\)) and deviator stress (q). For the loose, medium dense and dense specimens with contractive behaviour, undrained shearing led to a rapid decrease in the shear stress subsequent to a peak on the effective stress paths (Fig. 8a, b and c). Lade [32] indicated that the stress state at which instability occurs corresponds to the top of the current yield surface. The instability line can be obtained by linearly connecting the peaks of effective stress paths with the origin of axes [32,33,34]. At a given initial relative density, the specimens under different initial effective confining pressures achieved the same instability line. For the very dense specimens with dilatant behaviour, the effective stress paths of CU tests increased monotonically and approached a constant stress ratio line (Fig. 8d). Following the suggestions of Chu et al. [15] and Wanatowski et al. [48], the instability conditions for very dense specimens were determined by the constant stress ratio line. For comparison, the typical instability lines for the loose, medium dense, dense and very dense under initial effective confining pressures of 50 and 300 kPa are replotted in Fig. 9. The instability lines are not unique for the specimens with various initial relative densities. A anticlockwise rotation can be observed with the increase in the relative density for the instability line on the \(\it {\text{p}}{\prime}\)-q plane. For further quantification of liquefaction potential, the slopes of instability lines were determined. The mobilised angle \(\emptyset_{inst}^{\prime }\) could be calculated by the following equation:

where \({\text{M}}_{\text{inst}}\) is the stress ratio represented by the slope of instability line. Figure 10 displays the variation of mobilised angle with the relative density. With the increase in the relative density, the mobilised angle increases sharply from 22.5° owing to increasing contact surface area between grains. While the relative density reaches a threshold value of about 69.0%, the increasing trend becomes less remarkable for a higher relative density, which is consistent with the observation by Chu and Leong [14] on a Singapore marine-dredged sand. Note that this threshold value is close to that observed on peak deviator stress (see Fig. 6b), reconfirming the distinct mechanical responses of glacial tills depending on their relative densities.

3.4 Grain size change after CU tests

After the CU tests, the grain size distributions of the test glacial tills were also determined. In general, the grain breakage increased with the increasing initial effective confining pressure. As an example, Fig. 11 illustrates the representative specimen cross sections after the CU triaxial texts under an initial effective confining pressure of 300 kPa. The large grains reduced significantly with the increase in the initial dry density, especially in the middle part where potential shear bands are located. Figure 12 depicts the typical grain size distributions of specimens with various relative densities before and after CU triaxial texts under an initial effective confining pressure of 300 kPa. Figure 12a shows that the grain size distribution curves of the specimens after the CU tests were above that before tests. Furthermore, the grain size distribution curves after the CU tests were well ordered with respect to the relative density: the curve for a higher relative density lied above that for a lower one. To further clarify the grain size changes before and after the CU tests, the grain contents of all groups before and after CU tests are summarised in Fig. 12b. It appeared that the contents of large gains with diameters of 3.35–5, 2–3.35 and 0.85–2 mm decreased with the increase in the relative density while those of small grains with diameters of 0.125–0.3 and 0.063–0.125 mm increased. Regarding the grains with a diameter of 0.3–0.85 mm, their content variation was due to the combined effect of the breakage of larger grains and themselves. When the content of broken grains with a diameter larger than 0.85 mm was close to that of the broken grains with diameter 0.125–0.85 mm, no significant change in the content of grains with a diameter of 0.125–0.85 mm was observed after the CU tests.

4 Interpretation and discussion

4.1 Quantification of grain breakage during shearing

As marked earlier, the shearing process led to a significant grain breakage. Many grain breakage indices have been proposed to characterise the degree of particle breakage and energy dissipation [27, 33, 54]. Among them, Hardin’s grain breakage ratio was most used in the geotechnical research community. For comparison, the Hardin grain breakage ratio is used to describe the grain breakage behaviour during the CU tests [28]. A schematic diagram of the determination of grain breakage ratio is shown in Fig. 13a. The grain breakage is represented by the area of the shaded zone (Areashaded) surrounded by the grain size distribution curves before and after the CU tests. The grain breakage ratio is defined as the ratio of the shaded zone area to the area of the zone above the grain size distribution curve before the CU tests (AreaABC):

The calculated results are summarised in Table 3. For comparison, the shearing-induced grain breakage ratios of different types of soils were also compiled. The grain breakage is strongly related to the soil type, initial grain size distribution, void ratio and test condition. Compared to some typical crushable geomaterials, such as calcareous sands, dam rockfill materials and riverbed gavels, the glacial tills are relatively more crushable under similar conditions. This implied the importance of grain breakage of glacial tills to their transport and disposition. The variation of grain breakage ratio with relative density is depicted in Fig. 13b. As the relative density increased from 9.2 to 88.7%, the grain breakage ratio increased from 5.0 to 16.7%. Additionally, a larger increasing rate was observed when the relative density was larger than 69%, which was similar to the variation of the peak shear resistance with the relative density (Fig. 6b). This phenomenon suggested that grain breakage was highly related to the applied stress. When the specimens were subjected to shearing, rolling and sliding were the main manners for the relative movement between grains due to the least amount of energy required to mobilise. Once the rolling and sliding were suppressed by the increasing friction resistance of the specimens with high relative densities, soil grain asperities would break during shearing. Moreover, the higher the relative density, the larger the peak shear strength and the more grains were broken after triaxial compression.

4.2 Effect of grain breakage on the critical state

Soil grain gradation change because of breakage can in turn influence its basic constitutive properties such as critical states and stress–strain relations [12]. When particulate soils are sheared at a constant stain rate, they can reach a critical state at which the volume, shear stress and mean effective stress remain unchanged [25]. In general, the critical state locus can be described using a unique three-dimensional spatial curve for a given soil regardless of the initial void ratio. In this study, the critical state points were obtained for all the specimens when both the deviator stress and excess pore pressure became steady at the end of shear tests. Figure 14 summarises the critical state points of specimens with various relative densities and under different initial effective confining pressures projected on the \({\text{p}}{\prime}\)-q and \({\text{p}}{\prime}\)-e planes. In Fig. 14a, under a given initial effective confining pressure, a larger critical deviator stress was observed for the specimen with a higher relative density, suggesting that the increase in the relative density enhanced the undrained shear resistance of glacial tills. For all the specimens, there was an almost unique relationship between the critical deviator stress and the mean effective stress. The critical stress ratio of the Zelongnong glacial tills is 1.39, corresponding to a critical friction angle of 34.4°. In Fig. 14b, the relationships between void ratio and mean effective stress after consolidation and shearing are compared. Note that the void ratio of glacial tills is kept constant during triaxial compression. It appeared that the undrained shearing led to a significant contractive behaviour for the specimens at relative densities of 9.2%, 49.5% and 69.0% and a dilatant behaviour for the specimens at a relative density of 88.7%, which was consistent with the observation on the excess pore water pressure evolution (Fig. 5d). In the critical state, the effect of grain breakage on critical stress ratio is insignificant and the critical deviator stress is solely dependent on the mean effective stress. The critical state lines for all the specimens are no longer unified on the plane of void ratio and logarithm of mean effective stress (Fig. 14b). The critical state line of specimens with a larger relative density lies below that for the specimens with a smaller relative density. During the triaxial compression, the broken grain asperities would fill the void space and no longer sustain the external load, leading to a decrease in the soil skeleton volume [25]. As a result, the critical state line shifts downward after grain breakage [20, 40]. Moreover, the larger the grain breakage ratio, the more significant the critical state line shifts. In this work, a preliminary attempt was made to model the mechanical behaviour. Futures studies will be conducted to further understand the mechanical behaviour of glacial tills, and an associated constitutive model will be proposed for glacial tills with particle breakage.

5 Conclusions

In this study, the effects of relative density and initial effective confining pressure on the mechanical behaviour of the glacial tills from Zelongnong Gully in Tibet were experimentally determined by a series of CU tests under various initial effective confining pressures. Additionally, the grain size distributions before and after CU tests were also measured, allowing the relevance between the mechanical behaviour and grain breakage characteristics during shearing to be analysed. The following conclusions can be drawn:

-

1)

The glacial tills exhibited an obvious strain-softening behaviour during shearing. Additionally, this strain-softening was more significant due to their angularity and sharpness compared to common river sand and gravels. Regarding the excess pore water change, a contractive behaviour was observed for the specimens in loose state, medium dense and dense state, while a dilatant behaviour was observed for those in very dense state.

-

2)

The mechanical resistance increased slowly with the increase in the relative density as the relative density was lower than 69.0%. When the relative density was larger than 69.0%, the increasing rate of the mechanical resistance started to rise rapidly due to the increasing contact surface area. A threshold value of 69.0% was identified to characterise the distinct mechanical responses of the specimens with various relative densities.

-

3)

From the grain size distributions before and after CU tests, the content of grains with a diameter larger than 0.85 mm decreased while that of the grains with a diameter smaller than 0.3 mm increased. Hardin’s grain breakage ratio was introduced to describe the grain size change during the shearing. The increase in the relative density led to an increase in the grain breakage owing to the increasing friction resistance and the grain breakage would in turn shift downward the critical state line due to the decreasing soil skeleton volume.

Notably, the evolutions of particle fracture, fractal dimension, particle shape and coordination number during the triaxial shearing were not considered in this study. The particle size and shape, and spatial distribution of glacial tills will be investigated using X-ray microtomography in future studies, allowing the breakage behaviour and potential shear band, and their influence on the mechanical behaviour of glacial tills to be further analysed.

Data availability

The data that support the findings of this study are available on request from the corresponding author.

References

Abbas SM (2003) Testing and modelling the behavior of riverbed and quarried rockfill materials. PhD Thesis. Delhi, India: Indian Institute of Technology.

Allred BJ (2000) Survey of fractured glacial till geotechnical characteristics: hydraulic conductivity, consolidation, and shear strength (1). Ohio J Sci 45:63–63

Altuhafi F, Baudet BA (2011) A hypothesis on the relative roles of crushing and abrasion in the mechanical genesis of a glacial sediment. Eng Geol 120(1–4):1–9

ASTM. (2014a). Standard test methods for maximum index density and unit weight of soils using a vibratory table. ASTM standard D4253–14, West Conshohocken. American Society for Testing Materials, Pennsylvania.

ASTM. (2014b). “Standard test methods for minimum index density and unit weight of soils and calculation of relative density. ASTM standard D4254–14, West Conshohocken. American Society for Testing Materials, Pennsylvania.

ASTM (2017) Standard practice for classification of soils for engineering purposes (Unified Soil Classification System). ASTM standard D2487–17. West Conshohocken. American Society for Testing Materials, Pennsylvania.

Benahmed N (2001) Comportement mecanique d’un sable sous cisaillement monotone et cyclique: application aux phenomenes de liquefaction et de mobilite cyclique [Ph. D thesis Ecole]. Nationale Des Ponts et Chaussees.

Bishop AW (1966) Strength of soils as engineering materials. 6th Rankine lecture. Géotechnique 16:89–130

Boulton GS (1996) Theory of glacial erosion, transport and deposition as a consequence of subglacial sediment deformation. J Glaciol 42(140):43–62

Boulton GS, Dent DL, Morris EM (1974) Subglacial shearing and crushing, and the role of water pressures in tills from south-east Iceland. Geogr Ann 56A(3–4):135–145

Cao L, Peaker S, Ahmad S (2015) Engineering characteristic of glacial tills in GTA. Proceedings of GeoQuebec.

Chen C, Zhang LM, Shen P (2020) Influence of mineral dissolution on the mechanical behaviour of a granular assembly under complex stress states. Int J Rock Mech Min Sci 136:104546

Chen LL, Zhou GD, Mu QY, Cui KFE, Song DR (2019) Compression characteristics of saturated re-compacted glacial tills in Tianmo Gully of Tibet. China J Mt Sci 16(7):1661–1674

Chu J, Leong WK (2002) Effect of fines on instability behaviour of loose sand. Géotechnique 52(10):751–755

Chu J, Leroueil S, Leong WK (2003) Unstable behaviour of sand and its implication for slope instability. Can Geotech J 40(5):873–885

Clarke BG (2018) The engineering properties of glacial tills. Geotech Res 5(4):262–277

Coop MR, Sorensen KK, Freitas TB, Georgoutsos G (2004) Particle breakage during shearing of a carbonate sand. Geotechnique 54(3):157–163

Cui ZJ (2013) Diamicton and environment. Science and Technology Press, Hebei, pp 117–127. (in Chinese)

Cui P, Ge Y, Li S, Li Z, Xu X, Zhou GG, Chen H, Wang H, Lei Y, Zhou L, Yi S (2022) Scientific challenges in disaster risk reduction for the Sichuan-Tibet Railway. Eng Geol 309:106837

Daouadji A, Hicher PY, Rahma A (2001) An elastoplastic model for granular materials taking into account grain breakage. Eur. J. Mech. A Solids 20:113–137

Deng M, Chen N, Liu M (2017) Meteorological factors driving glacial till variation and the associated periglacial debris flows in Tianmo Valley, south-eastern Tibetan Plateau. Nat Hazards Earth Syst Sci 17(3):345–356

Dreimanis A (1989) Tills: their genetic terminology and classification. Genet Classif Glacigenic Deposit 45:17–83

Dreimanis A, Vagners UJ (1971) Bimodal distribution of rock and mineral fragments in basal tills. In: Goldthwait RP (ed) Till: a symposium. Ohio State University Press Columbus, Ohio, pp 237–250

Fu Y, Jiang Y, Wang J, Liu Z, Lu X (2021) Mechanical properties of frozen glacial tills due to short periods of thawing. Front Earth Sci 12:1306

Ghafghazi M, Shuttle DA, DeJong JT (2014) Particle breakage and the critical state of sand. Soils Found 54(3):451–461

Guo WL, Chen G (2022) Particle breakage and gradation evolution of rockfill materials during triaxial shearing based on the breakage energy. Acta Geotech 17(11):5351–5358

Gupta AK (2016) Effects of particle size and confining pressure on breakage factor of rockfill materials using medium triaxial test. J Rock Mech Geotech Eng 8(3):378–388

Hardin BO (1985) Crushing of soil particles. J Geotech Eng 111(10):1177–1192

Irani N, Lashkari A, Tafili M, Wichtmann T (2022) A state-dependent hyperelastic-plastic constitutive model considering shear-induced particle breakage in granular soils. Acta Geotech 17(11):5275–5298

Kikumoto M, Wood DM, Russell A (2010) Particle crushing and deformation behaviour. Soils Found 50(4):547–563

Kumar A, Bhambri R, Tiwari SK, Verma A, Gupta AK, Kawishwar P (2019) Evolution of debris flow and moraine failure in the Gangotri Glacier region, Garhwal Himalaya: Hydro-geomorphological aspects. Geomorphology 333:152–166

Lade P (1992) Static instability and liquefaction of loose fine sandy slopes. J Geotech Eng 118(1):51–71

Lade P (1993) Initiation of static instability in the submarine Nerlerk Berm. Can Geotech J 30(6):895–904

Lade P, Yamamuro J (1997) Effects of nonplastic fines on static liquefaction of sands. Can Geotech J 34(6):918–928

Lade PV, Yamamuro JA, Bopp PA (1996) Significance of particle crushing in granular materials. J Geotech Eng 122(4):309–316

Liu J, Zou D, Kong X, Liu H (2016) Stress-dilatancy of Zi**pu gravel in triaxial compression tests. Sci China Technol Sci 59(2):214–224

Liu Z, Liu J, Li X, Fang J (2019) Experimental study on the volume and strength change of an unsaturated silty clay upon freezing. Cold Reg Sci Technol 157:1–12. https://doi.org/10.1016/j.coldregions.2018.09.008

Ma G, Zhou W, Chang XL (2014) Modeling the particle breakage of rockfill materials with the cohesive crack model. Comput Geotech 61:132–143

van der Meer JJ, Menzies J, Rose J (2003) Subglacial till: the deforming glacier bed. Quat Sci Rev 22(15–17):1659–1685

Muir Wood D, Maeda K (2008) Changing grading of soil: effect on critical states. Acta Geotech 3:3–14

OuYang H, Dai G, Qin W, Zhang C, Zhu W, Gong W (2022) Experimental study on the mechanical behaviors and particle breakage characteristics of calcareous sand from South China Sea under repeated one-dimensional impacts. Acta Geotech 63:1–20

Ovalle C, Dano C, Hicher PY, Cisternas M (2015) Experimental framework for evaluating the mechanical behavior of dry and wet crushable granular materials based on the particle breakage ratio. Can Geotech J 52(5):587–598

Pedro L (2004) De l'étude du comportement mécanique de sols hétérogènes modèles à son application au cas des sols naturels. Ph.D. thesis. Ecole Nationale des Ponts et Chaussées, Université Paris-Est.

Peng DL, Zhang LM, Jiang RC, Zhang S, Shen P, Lu WJ, He X (2022) Initiation mechanisms and dynamics of a debris flow originated from debris-ice mixture slope failure in southeast Tibet, China. Eng Geol 45:106783

Rezvani R, Amin NA, Tutunchian M (2021) The effect of particle size distribution on shearing response and particle breakage of two different calcareous soils. Eur Phys J Plus 136(10):1–16

Su Y, Cui YJ, Dupla JC, Canou J (2020) Investigation of the effect of water content on the mechanical behavior of track-bed materials under various coarse grain contents. Constr Build Mater 263:120206

Tong CX, Zhai MY, Li HC, Zhang S, Sheng D (2022) Particle breakage of granular soils: changing critical state line and constitutive modelling. Acta Geotech 45:1–14

Wanatowski D, Chu J, Loke WL (2010) Drained instability of sand in plane strain. Can Geotech J 47(4):400–412

Wang HL, Cui YJ, Lamas-Lopez F, Calon N, Saussine G, Dupla JC, Canou J, Aimedieu P, Chen RP (2018) Investigation on the mechanical behavior of track-bed materials at various contents of coarse grains. Constr Build Mater 164:228–237

Wang C, Ding X, Yin ZY, Peng Y, Chen Z (2021) Mechanical characteristics and particle breakage of coral sand under one-dimensional repeated loading. Acta Geotech 13:1–14

Wang WP, Yang JS, Wang YB (2019) Dynamic processes of 2018 Sedongpu landslide in Namcha Barwa-Gyala Peri massif revealed by broadband seismic records. Landslides 17(2):409–418

Wang M, Li X, Xu X (2021) An implicit Heat-Pulse-Probe method for measuring the soil ice content. Appl Therm Eng 196:117186. https://doi.org/10.1016/j.applthermaleng.2021.117186

Wei H, Zhao T, He J, Meng Q, Wang X (2018) Evolution of particle breakage for calcareous sands during ring shear tests. Am Soc Civ Eng.

**ao Y, Liu HL, Chen QS, Ma QF, **ang YZ, Zheng YR (2017) Particle breakage and deformation of carbonate sands with wide range of densities during compression loading process. Acta Geotech 12(5):1177–1184

**ao Y, Wang C, Wu H, Desai CS (2021) New simple breakage index for crushable granular soils. Int J Geomech 21(8):04021136

**ao Y, Zhao C, Sun Y, Wang S, Wu H, Chen H, Liu H (2021) Compression behavior of MICP-treated sand with various gradations. Acta Geotech 16(5):1391–1400

Yu F (2023) State-dependent behavior of weathered sands incorporating progressive particle breakage in drained triaxial tests. Acta Geotech 12:1–22

Zhang C, Chen Q, Pan Z, Ma C (2020) Mechanical behavior and particle breakage of tailings under high confining pressure. Eng Geol 265:105419

Zhang J, Shen X (2011) Debris-flow of zelongnong ravine in tibet. J Mt Sci 8(4):535–543

Zhao HF, Zhang LM (2014) Effect of coarse content on the shear behaviour of unsaturated widely graded soils. Can Geotech J 51(12):1371–1383

Zhao HF, Zhang LM, Xu Y, Chang DS (2013) Variability of geotechnical properties of a fresh landslide soil deposit. Eng Geol 166:1–10

Acknowledgements

This work was financially supported by the Research Grants Council of the Hong Kong SAR (Grant No. 16209421), the NSFC/RGC Joint Research Scheme (G. No. N_HKUST620/20), the National Natural Science Foundation of China (42061160480) and the Project of Hetao Shenzhen-Hong Kong Science and Technology Innovation Cooperation Zone (HZQB-KCZYB-202008).

Funding

Open access funding provided by Hong Kong University of Science and Technology.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interests

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Zeng, ZX., Zhang, LM., Xu, ZD. et al. Mechanical behaviour and grain breakage characteristics of Tibetan glacial tills under triaxial compression. Acta Geotech. (2024). https://doi.org/10.1007/s11440-023-02195-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11440-023-02195-7