Abstract

The growth of microalgae under alkaline conditions ensures an ample supply of CO2 from the atmosphere, with a low risk of crashing due to contamination and predators. The present study investigated the mixotrophic cultivation of two alkaliphilic microalgae (Tetradesmus obliquus and Cyanothece sp.) using cheese whey as an organic carbon source. The variation in cheese whey concentration (0.5–4.5% (v/v)), culture pH (7–11), and NaNO3 concentrations (0–2 gL−1) was evaluated using central composite design in response to biomass productivity and the contents of lipids, total proteins, and soluble carbohydrates. Both investigated microalgae effectively utilized cheese whey as an organic carbon source. The optimum conditions for simultaneously maximizing biomass and lipid productivity in T. obliquus were 3.5% (v/v) whey, pH 10.0, and 0.5 g L−1 NaNO3. Under these conditions, the biomass, lipid, soluble carbohydrate, and protein productivities were 48.69, 20.64, 7.02, and 10.97 mg L−1 day−1, respectively. Meanwhile, Cyanothece produced 52.78, 11.42, 4.31, and 7.89 mg L−1 day−1 of biomass, lipid, carbohydrate, and protein, respectively, at 4.5% (v/v) whey, pH 9.0, and 1.0 g L−1 NaNO3. The lipids produced under these conditions were rich in saturated fatty acids (FAs) and monounsaturated FAs, with no polyunsaturated FAs in both microalgae. Moreover, several biodiesel characteristics were estimated, and results fell within the ranges specified by international standards. These findings indicate that the mixotrophic cultivation of alkaliphilic microalgae could open new avenues for promoting microalgae productivity through low-cost biofuel production.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Microalgae are a versatile group of microorganisms widely utilized as a source of biodiesel. They are also exploited for their main biochemical constituents such as pigments, carbohydrates, and proteins. Microalgae with high lipid productivity are suitable for biodiesel production, while those with high carbohydrate productivity could be fermented to produce other biofuels, such as bioethanol and biohydrogen (Gomaa et al. 2023). Biofuels are renewable energy sources that have been employed to overcome the worldwide energy problems associated with fossil fuels, which are mainly non-renewable. Promoting microalgae biomass and lipid productivities and facilitating their CO2 biofixation from the atmosphere are essential factors that allow for the economical production of biodiesel (Gomaa and Ali 2021; Gomaa et al. 2023).

The cultivation mode of microalgae directly influences microalgal biomass production and several cellular biochemical constituents. Microalgae exhibit different modes of nutrition, including photo-autotrophism, heterotrophism, and mixotrophism (Abreu et al. 2022). During photo-autotrophic growth, the cells can fix inorganic carbon (CO2 and bicarbonate) through light energy and photosynthesis. In contrast, under heterotrophic cultivation, the microalgal cells utilize organic compounds as both carbon and energy sources. Mixotrophy combines both photosynthesis and oxidation of organic carbons, taking advantage of both photo-autotrophic and heterotrophic mechanisms (Fawzy and Gomaa 2020). Autotrophy has the disadvantage of high CO2 supply costs and low biomass and lipid productivities. Heterotrophy or mixotrophy can promote lipid productivities compared to autotrophy, but the high cost of using organic carbon and susceptibility to microbial contamination are drawbacks. Generally, mixotrophic nutrition is preferred, as microalgal biomass productivity under mixotrophy exceeds that under autotrophy and heterotrophy (Abreu et al. 2022).

To reduce costs associated with mixotrophic cultivation, low-cost natural wastes have been used to promote microalgae growth and lipid productivity (Gomaa and Ali 2021). Additionally, cultivating microalgae under alkaline conditions can reduce microbial contamination (Chowdhury et al. 2019). For example, 2.0 × 10−5, 8.0 × 10−5, 7.0 × 10−4, and 7.0 × 10−3 mol CO2 per one liter of water are dissolved from the air (0.04 vol% CO2) at pH values of 6.0, 7.0, 8.0, and 9.0, respectively (Kikuchi et al. 2024). Consequently, alkaline conditions enhance CO2 scavenging from the atmosphere and CO2 biofixation rates, leading to higher microalgal growth (Vadlamani et al. 2017). However, most microalgae cannot thrive under alkaline conditions. For example, the freshwater microalgae Chlamydomonas reinharditii and Auxenochlorella protothecoides exhibited a marked reduction in cell growth at pH 8.5 and 9.0, respectively (Ochoa‐Alfaro et al. 2019; Andeden et al. 2021). As a result, one possible strategy for effectively sequestering CO2 from the atmosphere is to employ alkaliphilic microalgal strains. Additionally, an alkaline pH lengthens the time it takes for the cell cycle to complete and indirectly increases the generation of triacylglycerols (Andeden et al. 2021). Alkaliphilic algae, which thrive at high pH values (pH > 9), are considered promising candidates for large-scale growth and biofuel production (Vadlamani et al. 2017; Chowdhury et al. 2019).

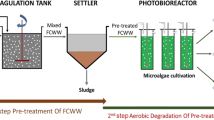

Whey, a byproduct from dairy industries, causes serious environmental problems when discharged without proper treatment. The high lactose content in whey supports mixotrophic cultivation of several microalgae and cyanobacteria (Girard et al. 2014; Pereira et al. 2019; Abril Bonett et al. 2020). However, no attempts have been made to utilize cheese whey in the mixotrophic cultivation of alkaliphilic microalgae under different pH and NaNO3 concentrations. Additionally, there has been less research done on the effects of pH and NaNO3 on the lipid, protein, and carbohydrate in microalgae under mixotrophic feeding.

The present study aims to optimize the mixotrophic growth of two alkaliphilic microalgae (Tetradesmus obliquus and Cyanothece sp.) by varying cheese whey concentrations, culture pH, and NaNO3 levels. We investigate the effects of these factors on biomass productivity and the contents of main biochemical constituents (lipids, proteins, and carbohydrates). Furthermore, treatments with maximum lipid productivities are evaluated as potential biodiesel feedstock based on fatty acid composition and biodiesel characteristics.

Materials and methods

Microalgae and growth conditions

Tetradesmus obliquus and Cyanothece sp. (Fig. S1) were isolated from El-Ibrahimiya canal and River Nile at Assiut, Egypt, respectively. The microalgae were isolated, purified, and cultivated on a synthetic medium containing (g L–1): NaNO3, 2.5; K2HPO4, 0.5; K2SO4, 1.0; NaCl, 1.0; MgSO4·7H2O, 0.2; CaCL2·2H2O, 0.04; FeSO4·7H2O, 0.01; Na2-EDTA·2H2O, 0.08; H3BO3, 2.86 × 10−3; ZnSO4·7H2O, 2.22 × 10−4; NaMoO4·2H2O, 3.9 × 10−4; CuSO4·5H2O, 7.9 × 10−5, MnCl2·4H2O, 1.81 × 10−3; and Co(NO3)·6H2O, 4.94 × 10−5 in 1.0 L of distilled water. Algal cultivation occurred in 500-mL glass bottles under continuous illumination (48.4 μmol m−2s−1) at 25 ºC with air bubbling.

Whey sampling and clarification

The whey (white cheese-whey from buffalo’s milk) was collected from a local dairy processing plant located et al.-Sharqia, Egypt. It was transported immediately to the laboratory in plastic bottles under refrigeration. The whey underwent heat treatment at 95 ºC for 90 min to clarify it. The precipitated material was removed by filtration (Pereira et al. 2019). The filtrate was collected and autoclaved separately before use to eliminate microbes and avoid growth of potential pathogens (Nazos et al. 2023). The concentrations of reducing sugars, total sugars, proteins, and lipids in the clarified cheese whey were estimated using 3,5-dinitrosalycylic acid method (Miller 1959), UV-H2SO4 method (Albalasmeh et al. 2013), Lowry method (Lowry et al. 1951), and phosphovanillin method (Mishra et al. 2014).

Experimental design

The microalgal cells at exponential growth were inoculated into 200-mL sterilized synthetic medium in 500-mL glass bottles and supplemented with different concentrations of clarified whey. The synthetic medium was prepared as described in “Microalgae and growth conditions”. A central composite design (CCD) was applied to investigate the effects of whey concentration (0.5–4.5% (v/v)), initial pH (7–11), and NaNO3 concentration (0–2 g L–1) on the biomass productivity and cellular components. The three independent factors were investigated at five levels each and a total of 20 experiments including six replicates at the center point. The initial pH of the medium was adjusted prior to autoclaving. Microalgal cells’ initial concentration was set to 0.1 based on optical density at 750 nm. Cultures were incubated at 25 ± 2 °C, under continuous illumination (48.4 μmol m−2 s−1) and air bubbling (0.5 vvm) for 10 days. The following generalized form of a second-order polynomial equation was fitted to the experimental data:

where the factors under investigation are Xi and Xj, Y represents the expected response, and the regression, linear, quadratic, and interaction coefficients are, respectively, βo, βi, βii, and βij.

Estimation of the microalgal growth and biomass productivity

A spectrophotometer (JENWAY 7315 Vis) was used to measure the optical density (OD) of the cultures at 750 nm in order to assess the microalgal growth. With the help of a standard curve (OD vs. dry cell weight, g L−1) unique to each alga, the OD data were converted into dry biomass weight. Thus, series of microalgal cultures were collected using centrifugation (4000 g, 15 min) with varying optical densities. The pellet was then oven-dried at 60 ºC to yield the corresponding dry cell weights. Using the following formula, the biomass productivity (BP, mg L−1 day−1) was determined (Gomaa et al. 2023):

where Xt is the algal biomass at the end of experiment (mg L−1). X0 is the initial biomass concentration (mg L−1), and Δt is the total duration of batch cultivation (day).

Determination of lipids

Centrifugation was used to concentrate the microalgal cells, and they were then resuspended in a predetermined amount of distilled water. After adding 2 mL of concentric H2SO4 to 200 µL of concentrated microalgal cells, the mixture was heated for 10 min at 100 ºC in a water bath. Then, 5 mL of the phosphovanillin reagent was added to each tube (Mishra et al. 2014; Gomaa and Ali 2021). The absorbance was measured spectrophotometrically at 530 nm after 15 min. As a standard, sunflower oil was utilized.

Determination of total proteins

According to Fawzy and Gomaa (2020), total proteins were extracted using 2 mL NaOH (1M) from 1 mL of concentrated cells at 100 ºC for 2 h. Following centrifugation, the supernatant was used to measure total proteins using the Lowry method (Lowry et al. 1951), with bovine serum albumin as the standard.

Determination of soluble sugars

Distilled water was used to extract the soluble carbohydrates from the concentrated algal cells at 100 °C, 2 h. Using glucose as a standard, the phenol–sulfuric acid method was employed to quantify the soluble sugars in the supernatant following centrifugation (DuBois et al. 1956).

Determination of FAME

The total lipids from the investigated microalgae under optimum growth conditions were extracted using chloroform/methanol (2:1) and converted into fatty acid methyl esters (FAME) as described previously (Johnson and Wen 2009). The FAME profile was identified using gas chromatography/mass spectrophotometry (GC/MS) in the Analytical Chemistry Unit, Faculty of Science, Assiut University, Egypt using the method reported previously (Fawzy et al. 2022).

Biodiesel characteristics

The FAME profile of the T. obliquus and Cyanothece sp. was used for the estimation of several biodiesel characteristics using the following equations (Sarin et al. 2009; Ramírez-Verduzco et al. 2012):

where MW stands for molecular weight, D for the number of double bonds, N for the percentage of FAME, MUFA for monounsaturated fatty acids, and PUFA for polyunsaturated fatty acids.

Statistical analysis

CCD analyses were performed using Chemoface v 1.65 (Nunes et al. 2012). The Pareto chart and response surface plots were generated using the same statistical program.

Results

Characterization of whey

The cheese whey sample contained reducing sugars, mainly lactose (6.67 g L–1), lipids (0.07 g L–1), protein (1.56 g L–1), and total carbohydrates (35.12 g L–1) (Table S1).

Central composite design

The mixotrophic cultivation of the investigated microalgae using cheese whey at different pH and NaNO3 concentrations was optimized using central composite design (CCD), and the results are listed in Tables 1 and 2. For each alga, four second-order polynomial equations were obtained by the CCD to describe the relationship between the investigated variables and the responses (Table S2).

All the equations exhibited high coefficient of determination (R2) values (R2 > 0.85, Table S2), implying the accuracy of the applied models. These results indicated that most of the variability in the responses could be attributed to the investigated variables.

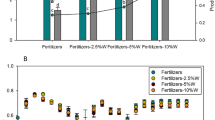

Effect of the investigated factors on biomass productivity

The Pareto chart was applied to detect the significance of the investigated factors and their effects (positive or negative). As depicted in Fig. 1a, pH and NaNO3 significantly influenced (p < 0.05) the biomass productivity (BP) of T. obliquus, while for Cyanothece, whey and NaNO3 concentrations played a significant role (Fig. 2a). Furthermore, the mutual interaction between the three investigated factors also had significant effects on the BP of both microalgae (Figs. 1a and 2a). Specifically, pH and the interaction between whey concentration and pH had the greatest impact on the BP of T. obliquus, whereas in the case of Cyanothece, the highest effects were related to whey and NaNO3 concentration (Figs. 1a and 2a).

The BP of T. obliquus fluctuated between 26.39 and 48.69 mg L–1 day–1 (Table 1). The BP of this microalga exhibited non-significant variations under the investigated whey concentrations. However, increasing the initial pH of the culture medium of T. obliquus markedly enhanced its BP, especially at higher whey concentrations (Figs. 1a and 3a). Therefore, pH and its mutual interaction with whey concentration showed positive effects on the BP of T. obliquus (Fig. 3a). Similarly, NaNO3 concentration exhibited positive effects on the BP of T. obliquus, but its mutual interactions with whey concentration and pH were negative (Fig. 1a and 3a).

On the other hand, the cyanobacterium Cyanothece failed to grow under nitrogen-deprived conditions, resulting in a drastic decline in growth. Consequently, its BP showed negative values at 0.0 g L–1 of NaNO3 (Table 2; Fig. 4a). However, in the presence of nitrate at different culture conditions, the BP of Cyanothece ranged from 8.20 to 52.78 mg L–1 day–1 (Table 2). Increasing the initial concentration of NaNO3 exhibited positive effects on its BP (Figs. 2a and 4a). Similarly, increasing whey concentration positively influenced the cyanobacterium’s growth. Nevertheless, the three investigated factors exhibited antagonistic mutual interactions on the BP of Cyanothece (Figs. 2a and 4a).

Effect of the investigated factors on lipid contents

The lipid content (LC) of T. obliquus fluctuated between 18.74% w/w (run 11) and 42.39% w/w (run 7), corresponding to lipid productivity of 4.93 and 20.64 mg L–1 day–1, respectively (Table 1). Meanwhile, the LC within Cyanothece cells ranged from 3.17% w/w (run 14) to 21.65% w/w (run 10), with corresponding lipid productivity of 0.67 and 11.42 mg L–1 day–1, respectively (Table 2).

The three investigated factors significantly affected the LC of T. obliquus (Fig. 1b). In contrast, the LC of Cyanothece was notably influenced by pH and whey concentration (Fig. 2b). The most prominent effects on the LC of T. obliquus and Cyanothece were related to nitrogen concentration and pH, respectively (Figs. 1b and 2b). However, the LC exhibited a drastic decrease with increasing the initial concentration of NaNO3 in T. obliquus culture, especially at higher whey concentration and pH (Fig. 3b). Consequently, negative effects on LC of T. obliquus were observed for NaNO3 concentration and its mutual interaction with whey and pH (Fig. 1b). Additionally, initial culture pH exhibited significant positive effects on the LC content of T. obliquus at low nitrate concentration (Fig. 1b). The interaction between initial culture pH and nitrate concentration was also negative (Fig. 3b).

On the other side, increasing the initial pH during Cyanothece cultivation adversely affected its LC (Fig. 2b). Conversely, the LC was significantly increased at higher whey concentrations, but antagonistic interactions between whey concentration and culture pH were observed (Figs. 2b and 4b).

Effect of the investigated factors on SCC

The soluble carbohydrate contents (SCC) of T. obliquus ranged from 7.58 to 17.77% (w/w) (Table 1), while in Cyanothece, the SCC fell within the range 5.11–20.60% (w/w) (Table 2). The three investigated factors exhibited significant effects on SCC of both microalgae (Figs. 1c and 2c). Increasing NaNO3 concentration had prominent positive effects on SSC of Cyanothece (Fig. 2c), but negative effects in the case of T. obliquus (Fig. 1c). Additionally, pH showed negative effects on SCC of both microalgae. However, increasing whey concentration in T. obliquus culture had positive effects on SCC, although its interaction with pH and nitrate resulted in significant negative effects (Figs. 1c and 3c). Notably, the mutual whey and nitrate interaction had the greatest impact on the SCC of T. obliquus (Figs. 1c and 3c). Furthermore, pH significantly interacted antagonistically with NaNO3 concentration regarding the SSC of Cyanothece (Figs. 2c and 4c).

Effect of the investigated factors on TPC

The total protein contents (TPC) for T. obliquus and Cyanothece, as assessed by the Pareto diagram, indicated that the three variables under consideration were statistically significant (p < 0.05) (Figs. 1d and 2d). The TPC of T. obliquus ranged from 13.90 to 28.49% (w/w), while for Cyanothece sp., it fell within the range of 8.85 to 22.04% (w/w) (Tables 1 and 2, respectively).

In T. obliquus, whey concentration exerted the greatest influence on TPC, whereas in the case of Cyanothece, the highest effects were associated with the initial NaNO3 (Figs. 1d and 2d). Interestingly, increasing whey concentration had a positive effect on the TPC in T. obliquus (positive effects) (Fig. 1d), but the opposite trend was observed in Cyanothece (Fig. 2d). Both microalgae exhibited increased TPC at nitrogen replete conditions, with NaNO3 showing positive linear effects on TPC (Figs. 1d and 2d).

However, higher pH values in the culture medium were not conducive to cellular protein accumulation in either T. obliquus or Cyanothece (Figs. 1d and 2d). Notably, these negative effects of pH were exacerbated at higher NaNO3 concentrations in T. obliquus (Fig. 3d) and at low NaNO3 concentrations in Cyanothece (Fig. 4d). Consequently, the mutual interaction between pH and NaNO3 regarding TPC was antagonistic in T. obliquus (Fig. 1d) but synergistic in Cyanothece (Fig. 2d). Additionally, a negative mutual interaction between pH and whey was observed in T. obliquus (Fig. 1d).

FAME composition and biodiesel properties

The treatments with the highest lipid productivity (treatment no. 7 for T. obliquus and treatment no. 10 for Cyanothece sp.) were analyzed to identify the fatty acid methyl esters (FAME) and their corresponding biodiesel characteristics. The FAME profile indicated higher percentages of saturated fatty acids (SFAs), which contributed to 56.96% and 79.38% of the total percentage of fatty acids (FAs) in T. obliquus and Cyanothece sp., respectively (Table S3). The remaining percentage was related to monounsaturated fatty acids (MUFAs), and no polyunsaturated fatty acids (PUFAs) were detected for both microalgae.

In T. obliquus, the percentage of palmitic acid reached 53.92%, followed by oleic acid (18.08%) and cis-vaccenic acid (14.56%). Meanwhile, in Cyanothece sp., the percentage of palmitic acid was 65.98%, followed by n-capric acid (13.41%), oleic acid (10.31%), and cis-vaccenic acid (10.31%) (Table S3).

Based on the FAME profile, several biodiesel characteristics were calculated, and the results are listed in Table 3. The saponification values (SV), representing the amount of potassium hydroxide required to saponify 1 g of oil, were 208.03 mg KOH g−1 fat for T. obliquus and 228.53 mg KOH g−1 fat for Cyanothece. Notably, the iodine values for both microalgae were low and significantly lower than the limit specified in the European standard (EN 14214). Similarly, the cetane number (CN) values for both microalgae exceeded the limits set by EN 14214, American standard (ASTM D6751), and Indian standard (IS 15607).

In terms of unsaturation, the degree of unsaturation (DU) in Cyanothece biodiesel reached 10.31 wt.%, contrasting with 43.04 wt.% in T. obliquus. The oxidation stability (OS) values for both microalgae complied with international standards, exceeding a value of 6. Additionally, the cold filter plugging point (CFPP) estimates were 0.46 °C and 4.25 °C, aligning with the limits specified by the EN 14214 standard and IS 15607. Both microalgae exhibited cloud point (CP) and pour point (PP) values above 18 °C.

Furthermore, the kinematic viscosity (υ) and density (ρ) fell within the limits specified by international standards. Lastly, the higher heating values (HHV) were 39.41 MJ kg−1 for T. obliquus and 40.11 MJ kg−1 for Cyanothece sp.

Discussion

The growth behavior and accumulation of value-added metabolites in two microalgae were investigated at varying organic carbon, nitrogen, and pH concentrations. Importantly, increasing culture pH enhances CO2 uptake rates from the atmosphere and provides a higher supply of bicarbonate as well as it reduces culture crashes due to contamination or the establishment of predators (Vadlamani et al. 2017). The microalga is considered alkalitolerant when it prefers to grow under neutral conditions, with significantly less growth observed at alkaline pH. In contrast, alkaliphilic microalgae thrive optimally at pH 9–10 (Gimmler and Degenhard 2001). Notably, the significant positive effects of pH on the biomass productivity of T. obliquus indicated its alkaliphilic nature, with optimal growth at pH 9–10. In contrast, the growth of the cyanobacterium Cyanothece sp. was not inhibited at alkaline pH, further confirming its alkaliphilic characteristics. However, its biomass production exhibited insignificant effects upon increasing culture pH. Alkaliphilic microalgae and cyanobacteria can efficiently utilize bicarbonate as a carbon source, facilitated by the action of carbonic anhydrase. The higher CO2 biofixation rates and increased biomass productivity observed in alkaliphilic microalgae compared to neutralophilic species offer economic and environmental advantages.

During mixotrophic cultivation, both investigated microalgae effectively utilized cheese whey as a source of organic carbon, aligning with previous studies (Girard et al. 2014; Pereira et al. 2019; Tharani and Ananthasubramanian 2020; Bentahar and Deschênes 2022). In this nutritional mode, microalgal cells benefit from both inorganic and organic carbon sources, promoting simultaneous growth and the production of certain metabolites (Gomaa and Yousef 2020; Gomaa and Ali 2021).

The growth of microalgae on cheese whey necessitates the biosynthesis of β-galactosidase, which enables the conversion of lactose in the whey into glucose and galactose. This mechanism has been previously confirmed in various microalgae, including T. obliquus and Cyanothece sp. (Suwal et al. 2019; Zanette et al. 2019; Chenebault et al. 2020; Bentahar and Deschênes 2022). A detailed comparison of the growth and biochemical composition of the investigated microalgae in relation to previous studies regarding mixotrophic cultivation using cheese whey is listed in Table S4. In the present study, the mixotrophic cultivation was performed under alkaline conditions using low concentration of cheese whey. This is advantageous for large-scale production to minimize microbial contamination and culture crashing. The biomass and lipid productivity of the investigated microalgae were comparatively higher than those reported for Chlorella vulgaris (Salati et al. 2017; Melo et al. 2018), Desmodesmus sp. (Salah et al. 2023), Chlamydomonas sp. (Mondal et al. 2021), and Spirulina platensis (Pereira et al. 2019).

The results of the current study indicated that, at low cheese whey concentrations, the supply of bicarbonate through an increase in culture pH becomes more critical for sustaining T. obliquus growth than higher whey concentrations. Specifically, raising the culture pH from 8 to 10 at 1.5% (v/v) whey and 0.5 gL−1 NaNO3 led to an enhancement of biomass productivity of T. obliquus from 30.22 to 36.91 mg L−1 day−1. Interestingly, at slightly alkaline pH conditions (pH 8), increasing the cheese whey concentration to 3.5% (v/v) did not significantly affect the biomass productivity of T. obliquus (31.61 mg L−1 day−1). These effects may be related to the variation of β-galactosidase production and activity under different culture conditions. For example, Bentahar et al. reported that increasing lactose concentration in T. obliquus culture did not elevate the specific activity of β-galactosidase (Bentahar et al. 2019). However, the culture pH plays a crucial role, as β-galactosidase activity is enhanced at alkaline pH in microalgae (Zanette et al. 2019).

The present results indicated that cheese whey concentration had non-significant linear effects on the biomass productivity of T. obliquus, while culture pH exhibited remarkable positive effects. However, synergistic significant effects of whey concentration and culture pH were observed. This implies that better biomass production of T. obliquus occurs at high whey concentration and pH, utilizing both inorganic and organic carbon. Consequently, the highest biomass productivity of 48.69 mg L−1 day−1 was observed at 3.5% (v/v) of whey, pH 10, and 0.5 g L−1 NaNO3. This value was approximately 1.6–1.8 times higher than those observed at pH 7 and 8.

Similarly, Zhang et al. reported optimal growth of Scenedesmus obliquus at pH 10 under autotrophic conditions (Zhang et al. 2019). In another study, mixotrophic cultivation of S. obliquus using disperse orange‑2RL Azo dye induced high biomass production under alkaline conditions (pH 11) (Hamouda et al. 2022). The shift of culture pH toward alkalinity can lead to different gene expression in the microalgal cells compared to neutral pH. For instance, 1432 genes in alkali-tolerant Chlorella sp. BLD were relatively upregulated at pH 10 compared to pH 7.5 (Qu and Miao 2021). The upregulation of genes related to CO2 fixation and photosynthesis ensures higher algal growth under alkaline conditions (Qu and Miao 2021).

On the other hand, the growth variation of Cyanothece sp. was primarily influenced by the supply of organic carbon through cheese whey, rather than variations in pH. Consequently, the maximum biomass productivity of Cyanothece sp. reached 52.78 mg L−1 day−1 at 4.5% (v/v) whey, pH 9, and 1.0 gL−1 NaNO3. Remarkably, this value was 2.3-fold higher than that obtained at low whey concentration (1.0% v/v) under the same conditions. These observations suggest that the assimilation of cheese whey by Cyanothece sp. as a carbon source is more effective for biomass production, in contrast to the results observed for T. obliquus. These variations may be related to the variation in β-galactosidase production and activity in microalgae (Zanette et al. 2019).

During mixotrophic cultivation, the availability of sufficient carbon not only influences microalgae growth but also impacts their biochemical composition (Gomaa and Ali 2021). Multiple correlation analysis revealed that treatments with higher biomass production of T. obliquus exhibited significant correlations with increased cellular lipid content (R = 0.493, p = 0.027). This relationship is advantageous for ensuring higher lipid productivity for biodiesel synthesis. However, non-significant correlations (p > 0.05) were observed between lipid, protein, and carbohydrate in the case of T. obliquus. These observations suggest that incorporating cheese whey into T. obliquus culture provided sufficient carbon for both cellular division and the synthesis of lipids, proteins, and carbohydrates. Consequently, our results indicated a significant increase in lipid, protein, and carbohydrate contents with increasing cheese whey concentration during mixotrophic cultivation.

In contrast, the lipid content of Cyanothece sp. was not directly related to its biomass production but showed an inverse relationship with carbohydrate content (R = − 0.572, p = 0.01). Furthermore, protein and carbohydrate contents in Cyanothece sp. exhibited a positive correlation (R = 0.542, p = 0.017). These observations suggest that Cyanothece cells effectively utilized cheese whey as a carbon source, allocating it primarily to lipid synthesis. Consequently, our results indicated a significant increase in lipid content in Cyanothece cells, accompanied by a decrease in protein and carbohydrate contents with increasing whey concentration in the culture medium. Interestingly, the growth of Spirulina platensis on cheese whey led to the accumulation of protein content at the expense of reduced carbohydrate synthesis (Pereira et al. 2019).

Microalgal metabolism is greatly influenced, either directly or indirectly, by the culture pH. Increasing the culture pH led to higher lipid accumulation in the case of T. obliquus, but it lowered the lipid content in Cyanothece cells. Previous studies have also observed triacylglyceride accumulation in T. obliquus cells when culture pH was increased, especially under nitrogen-deprived conditions (Gardner et al. 2011; Breuer et al. 2013; Andeden et al. 2021).

In our current study, we observed a remarkable increase in lipid content in T. obliquus under high initial pH conditions and low NaNO3 concentrations. Specifically, the highest lipid content of 42.39% (w/w) was obtained at 3.5% (v/v) cheese whey, pH 10, and NaNO3 0.5 g L–1. Under these conditions, lipid productivity reached 20.64 mg L–1 day–1. However, this value was nearly halved when the initial culture pH was set to 8.0 or NaNO3 concentration was increased to 1.5 g L–1. These results align with the effects of alkaline conditions on lipid synthesis in Chlorella sp. (Qu and Miao 2021).

The increase in lipid content in T. obliquus can be attributed to the elevation of acetyl-coenzyme A, a precursor for fatty acid (FA) biosynthesis. This elevation occurs due to pyruvate accumulation from CO2 fixation, as well as protein and carbohydrate hydrolysis (Qu and Miao 2021). Consequently, the decrease in soluble carbohydrates and total proteins resulting from increasing the initial culture pH in the investigated microalgae may be related to the upregulation of genes responsible for starch and protein hydrolysis, as reported previously (Qu and Miao 2021).

The decrease in lipid contents of Cyanothece cells at high pH agreed with previous observations on the cyanobacterium Leptolyngbya foveolarum (Singh and Kumar 2021). Unfortunately, Cyanothece sp. was characterized by low lipid accumulation compared to T. obliquus, which reached a maximum value of 21.65% (w/w) and 11.42 mg L−1 day−1 at 4.5% (v/v) cheese whey, pH 9.0, and NaNO3 1.0 g L−1. However, the obtained results for lipid contents were relatively higher than those reported in several cyanobacterial species belonging to genera Oscillatoria, Phormidium, Lyngbya, Leptolyngbya, Nostoc, Spirulina, and Synechococcus, where the lipid contents fluctuated between 2.3% and 10.6% (Mathimani et al. 2018; Yadav et al. 2021).

Nitrogen concentration in the growth medium is a fundamental factor that affects microalgal growth and biosynthesis of cellular metabolites. Increasing NaNO3 concentrations supported the growth of both T. obliquus and Cyanothece sp. However, a complete inhibition of Cyanothece sp. growth was observed under nitrogen-deprived conditions, which contradicts the behavior of T. obliquus. Previous studies have reported similar trends: a decline in the growth of the cyanobacterium Aphanocapsa sp. under nitrogen starvation (Gomaa and Ali 2021) and nitrogen starvation-induced growth inhibition in the cyanobacterium Synechocystis sp. through the downregulation of genes associated with photosynthesis, protein biosynthesis, and energy metabolism (Huang et al. 2013). Under nitrogen-starved or limited conditions, several microalgae tend to hyperaccumulate lipids and increase carbohydrate synthesis while decreasing protein contents (Nagappan et al. 2020).

In the case of T. obliquus, the present results indicated a significant increase in lipid and carbohydrate contents, with a concomitant decrease in protein contents, by decreasing NaNO3 concentration in the medium. Conversely, increasing nitrate concentrations in the culture of Cyanothece sp. significantly increased carbohydrate and protein contents, but without significant effects on lipid contents. The optimum growth conditions for obtaining higher biomass, lipid, protein, and carbohydrate productivities from T. obliquus were 3.5% (v/v) cheese whey, pH 10.0, and 0.5 g L−1 NaNO3. Under these conditions, the biomass, lipid, protein, and carbohydrate productivities were 48.69, 20.64, 7.02, and 10.97 mg L−1 day−1, respectively. On the other hand, at 4.5% (v/v) cheese whey, pH 9.0, and 1.0 g L−1 NaNO3, Cyanothece exhibited a higher biomass of 52.78 mg L−1 day−1 and lipid productivities of 11.42 mg L−1 day−1. To increase carbohydrate and protein productivities from Cyanothece sp., the cheese whey concentration should be reduced to 2.5% (v/v) at the same pH and NaNO3 concentration. Consequently, the carbohydrate and protein productivities would increase to 8.10 and 8.77 mg L−1 day−1.

A detailed comparison of the main fatty acids in the investigated microalgae with other microalgae under mixotrophic cultivation is listed in Table S5. The biodiesel obtained from the investigated microalgae was characterized by a higher percentage of SFAs, followed by MUFAs, and no PUFAs were detected. Lipids with high contents of SFAs and MUFAs can produce high-quality biodiesel (Gomaa et al. 2023). The FAME profile for both microalgae was rich in C16 and C18 FAs (Table S5). Under mixotrophic conditions, lipids rich in SFAs and MUFAs were produced, but PUFAs were not detected in both microalgae. Consequently, the produced biodiesel exhibited low IV and DU, along with high OS, indicating stable biodiesel suitable for long-term storage (Gomaa and Ali 2021). Under the optimized conditions, the present microalgae produced biodiesel with lower IV and higher CN than those reported for other microalgae (Table 3).

The CN reflects the ignition efficiency of the engine, and the obtained values for both microalgae could ensure better engine performance. The biodiesel produced by Cyanothece sp. showed better CN, DU, IV, and OS compared to that of T. obliquus under the optimized conditions. The ν (kinematic viscosity) values were related to the flow performance of the biodiesel in the engine. Generally, ν increases with increasing long-chain FAs, DU, and trans-oriented FAs. Accordingly, the biodiesel from T. obliquus had higher ν values than Cyanothece sp., but both were within the limits specified by international standards.

The CP (cloud point), PP (pour point), and CFPP (cold filter plugging point) were indicative of biodiesel flow properties in cold climates. While PP and CP were not specified in international standards, the IS standard indicated a minimum of three and 15 for PP during winter and summer, respectively. The values obtained in the present study indicated better performance of T. obliquus biodiesel in cold climates compared to Cyanothece sp. Furthermore, the CFPP values for both microalgae agreed with international limits. The HHV (higher heating value) defines the amount of heat produced after combustion of 1 g of biodiesel. Although not identified by international standards, HHV usually ranges between 39 and 41 MJ kg−1 for microalgal-derived fuel (Demirbas 2009), which aligns with the findings of this study.

Conclusion

The present study evaluated the mixotrophic growth and productivity of two alkaliphilic microalgae using cheese whey as a cheap, environmentally benign, and sustainable organic carbon source. We investigated algal biomass productivity and the contents of lipids, total proteins, and soluble carbohydrates under different concentrations of cheese whey, nitrate, and culture pH. Incorporating cheese whey into the culture medium of T. obliquus had positive effects on lipid, carbohydrate, and protein contents, enabling higher biomass productivity at elevated culture pH. Similarly, the culture of Cyanothece exhibited higher biomass productivity and lipid contents at high concentrations of cheese whey, albeit with a concomitant decrease in protein and soluble carbohydrate contents. Increasing culture pH supported higher biomass productivity with elevated cellular lipid contents in T. obliquus, but protein and carbohydrate levels decreased. Conversely, increasing culture pH during Cyanothece cultivation significantly decreased its lipid and protein contents, with no significant effects on biomass production. Nitrate deficiency increased lipid and soluble carbohydrate contents in T. obliquus during mixotrophic cultivation, but biomass productivity decreased simultaneously. Nitrate was crucial for supporting Cyanothece growth and increasing cellular protein and carbohydrate contents. Accordingly, the optimum conditions to promote biomass and lipid productivity in T. obliquus were 3.5% (v/v) cheese whey, initial pH 10.0, and 0.5 g L−1 NaNO3. Under these conditions, the biomass, lipid, soluble carbohydrate, and protein productivities were 48.69, 20.64, 7.02, and 10.97 mg L−1 day−1, respectively. Meanwhile, at 4.5% (v/v) cheese whey, initial pH 9.0, and 1.0 g L−1 NaNO3, Cyanothece exhibited biomass, lipid, soluble carbohydrate, and protein productivities of 52.78, 11.42, 4.31, and 7.89 mg L−1 day−1, respectively. Furthermore, the biodiesel produced under these conditions exhibited favorable characteristics that aligned with international standards. Overall, this study highlights the promising utilization of alkaliphilic microalgae in biofuel production through cost-effective mixotrophy.

Data availability

The datasets used and/or analyzed during the current study are available from the corresponding author on reasonable request.

References

Abreu AP, Morais RC, Teixeira JA, Nunes J (2022) A comparison between microalgal autotrophic growth and metabolite accumulation with heterotrophic, mixotrophic and photoheterotrophic cultivation modes. Renew Sustain Energy Rev 159:112247. https://doi.org/10.1016/j.rser.2022.112247

Abril Bonett JE, de Sousa GP, Cardoso PG, de Freitas CF, Duarte WF (2020) Isolation of freshwater microalgae and outdoor cultivation using cheese whey as substrate. Biocatal Agric Biotechnol 29:101799. https://doi.org/10.1016/j.bcab.2020.101799

Albalasmeh AA, Berhe AA, Ghezzehei TA (2013) A new method for rapid determination of carbohydrate and total carbon concentrations using UV spectrophotometry. Carbohydr Polym 97:253–261. https://doi.org/10.1016/j.carbpol.2013.04.072

Andeden EE, Ozturk S, Aslim B (2021) Effect of alkaline pH and nitrogen starvation on the triacylglycerol (TAG) content, growth, biochemical composition, and fatty acid profile of Auxenochlorella protothecoides KP7. J Appl Phycol 33:211–225. https://doi.org/10.1007/s10811-020-02311-0

Bentahar J, Deschênes J (2022) Influence of sweet whey permeate utilization on Tetradesmus obliquus growth and β-galactosidase production. Can J Chem Eng 100:1479–1488. https://doi.org/10.1002/cjce.24245

Bentahar J, Doyen A, Beaulieu L, Deschênes J-S (2019) Investigation of β-galactosidase production by microalga Tetradesmus obliquus in determined growth conditions. J Appl Phycol 31:301–308. https://doi.org/10.1007/s10811-018-1550-y

Breuer G, Lamers PP, Martens DE, Draaisma RB, Wijffels RH (2013) Effect of light intensity, pH, and temperature on triacylglycerol (TAG) accumulation induced by nitrogen starvation in Scenedesmus obliquus. Bioresour Technol 143:1–9. https://doi.org/10.1016/j.biortech.2013.05.105

Chenebault C, Diaz-Santos E, Kammerscheit X, Görgen S, Ilioaia C, Streckaite S, Gall A, Robert B, Marcon E, Buisson D-A, Benzerara K, Sassi J-F, Cassier-Chauvat C, Chauvat F (2020) A genetic toolbox for the new model cyanobacterium Cyanothece PCC 7425: a case study for the photosynthetic production of limonene. Front Microbiol 11. https://doi.org/10.3389/fmicb.2020.586601

Choi H-J (2016) Dairy wastewater treatment using microalgae for potential biodiesel application. Environ Eng Res 21:393–400. https://doi.org/10.4491/eer.2015.151

Chowdhury R, Keen PL, Tao W (2019) Fatty acid profile and energy efficiency of biodiesel production from an alkaliphilic algae grown in the photobioreactor. Bioresour Technol Reports 6:229–236. https://doi.org/10.1016/j.biteb.2019.03.010

de Melo RG, de Andrade AF, Bezerra RP, Correia DS, de Souza VC, Brasileiro-Vidal AC, de Viana Marques AD, Porto ALF (2018) Chlorella vulgaris mixotrophic growth enhanced biomass productivity and reduced toxicity from agro-industrial by-products. Chemosphere 204:344–350. https://doi.org/10.1016/j.chemosphere.2018.04.039

Demirbas A (2009) Progress and recent trends in biodiesel fuels. Energy Convers Manag 50:14–34. https://doi.org/10.1016/j.enconman.2008.09.001

DuBois M, Gilles KA, Hamilton JK, Rebers PA, Smith F (1956) Colorimetric method for determination of sugars and related substances. Anal Chem 28:350–356. https://doi.org/10.1021/ac60111a017

Fawzy MA, Gomaa M (2020) Pretreated fucoidan and alginate from a brown seaweed as a substantial carbon source for promoting biomass, lipid, biochemical constituents and biodiesel quality of Dunaliella salina. Renew Energy 157:246–255. https://doi.org/10.1016/j.renene.2020.05.065

Fawzy MA, El-Naeb EH, Hifney AF, Adam MS, Gomaa M (2022) Growth behavior, phenol removal and lipid productivity of microalgae in mixotrophic and heterotrophic conditions under synergistic effect of phenol and bicarbonate for biodiesel production. J Appl Phycol 34:2981–2994. https://doi.org/10.1007/s10811-022-02845-5

Gardner R, Peters P, Peyton B, Cooksey KE (2011) Medium pH and nitrate concentration effects on accumulation of triacylglycerol in two members of the chlorophyta. J Appl Phycol 23:1005–1016. https://doi.org/10.1007/s10811-010-9633-4

Gimmler H, Degenhard B (2001) Alkaliphilic and alkali-tolerant algae. Algal Adaptation to Environmental Stresses. Springer, Berlin Heidelberg, Berlin, Heidelberg, pp 291–321

Girard J-MM, Roy M-LL, Ben HM, Gagnon J, Faucheux N, Heitz M, Tremblay R, Deschênes J-SS (2014) Mixotrophic cultivation of green microalgae Scenedesmus obliquus on cheese whey permeate for biodiesel production. Algal Res 5:241–248. https://doi.org/10.1016/j.algal.2014.03.002

Gomaa M, Ali MMA (2021) Enhancement of microalgal biomass, lipid production and biodiesel characteristics by mixotrophic cultivation using enzymatically hydrolyzed chitin waste. Biomass Bioenerg 154:106251. https://doi.org/10.1016/J.BIOMBIOE.2021.106251

Gomaa M, Yousef N (2020) Optimization of production and intrinsic viscosity of an exopolysaccharide from a high yielding Virgibacillus salarius BM02: study of its potential antioxidant, emulsifying properties and application in the mixotrophic cultivation of Spirulina platensis. Int J Biol Macromol 149:552–561. https://doi.org/10.1016/j.ijbiomac.2020.01.289

Gomaa M, Fawzy MA, El-Sheekh MM (2023) Microalgae-based biofuel synthesis. In: Shah MP (ed) Green Approach to Alternative Fuel for a Sustainable Future. Elsevier, 89–105. https://doi.org/10.1016/B978-0-12-824318-3.00023-0

Hamouda RA, El-Naggar NE, Abou-El-Souod GW (2022) Simultaneous bioremediation of Disperse orange-2RL Azo dye and fatty acids production by Scenedesmus obliquus cultured under mixotrophic and heterotrophic conditions. Sci Rep 12:20768. https://doi.org/10.1038/s41598-022-22825-6

Huang S, Chen L, Te R, Qiao J, Wang J, Zhang W (2013) Complementary iTRAQ proteomics and RNA-seq transcriptomics reveal multiple levels of regulation in response to nitrogen starvation in Synechocystis sp. PCC 6803. Mol Biosyst 9:2565. https://doi.org/10.1039/c3mb70188c

Johnson MB, Wen Z (2009) Production of biodiesel fuel from the microalga Schizochytrium limacinum by direct transesterification of algal biomass. Energy Fuels 23:5179–5183. https://doi.org/10.1021/ef900704h

Kikuchi Y, Kanai D, Sugiyama K, Fujii K (2024) Biogas upgrading by wild alkaliphilic microalgae and the application potential of their biomass in the carbon capture and utilization technology. Fermentation 10:134. https://doi.org/10.3390/fermentation10030134

Lowry OH, Rosebrough NJ, Farr AL, Randall RJ (1951) Protein measurement with the Folin phenol reagent. J Biol Chem 193:265–275

Mathimani T, Uma L, Prabaharan D (2018) Formulation of low-cost seawater medium for high cell density and high lipid content of Chlorella vulgaris BDUG 91771 using central composite design in biodiesel perspective. J Clean Prod 198:575–586. https://doi.org/10.1016/j.jclepro.2018.06.303

Miller GL (1959) Use of dinitrosalicylic acid reagent for determination of reducing sugar. Anal Chem 31:426–428. https://doi.org/10.1021/ac60147a030

Mishra SK, Suh WI, Farooq W, Moon M, Shrivastav A, Park MS, Yang J-WW (2014) Rapid quantification of microalgal lipids in aqueous medium by a simple colorimetric method. Bioresour Technol 155:330–333. https://doi.org/10.1016/j.biortech.2013.12.077

Mondal M, Khan AA, Halder G (2021) Estimation of biodiesel properties based on fatty acid profiles of Chlamydomonas sp. BTA 9032 and Chlorella sp. BTA 9031 obtained under mixotrophic cultivation conditions. Biofuels 12:1175–1181. https://doi.org/10.1080/17597269.2019.1600453

Nagappan S, Devendran S, Tsai P-C, Jayaraman H, Alagarsamy V, Pugazhendhi A, Ponnusamy VK (2020) Metabolomics integrated with transcriptomics and proteomics: evaluation of systems reaction to nitrogen deficiency stress in microalgae. Process Biochem 91:1–14. https://doi.org/10.1016/j.procbio.2019.11.027

Nazos TT, Stratigakis NC, Spantidaki M, LagouvardouSpantidaki A, Ghanotakis DF (2023) Characterization of cheese whey effluents and investigation of their potential to be used as a nutrient substrate for Chlorella biomass production. Waste Biomass Valorization 14:3643–3655. https://doi.org/10.1007/s12649-023-02081-z

Nunes CA, Freitas MP, Pinheiro ACM, Bastos SC (2012) Chemoface: a novel free user-friendly interface for chemometrics. J Braz Chem Soc 23:2003–2010. https://doi.org/10.1590/S0103-50532012005000073

Ochoa‐Alfaro AE, Gaytán‐Luna DE, González‐Ortega O, Zavala‐Arias KG, Paz‐Maldonado LMT, Rocha‐Uribe A, Soria‐Guerra RE (2019) pH effects on the lipid and fatty acids accumulation in Chlamydomonas reinhardtii. Biotechnol Prog 35. https://doi.org/10.1002/btpr.2891

Pereira MIB, Chagas BME, Sassi R, Medeiros GF, Aguiar EM, Borba LHF, Silva EPE, Neto JCA, Rangel AHN (2019) Mixotrophic cultivation of Spirulina platensis in dairy wastewater: Effects on the production of biomass, biochemical composition and antioxidant capacity. PLoS ONE 14:e0224294. https://doi.org/10.1371/journal.pone.0224294

Qu D, Miao X (2021) Carbon flow conversion induces alkali resistance and lipid accumulation under alkaline conditions based on transcriptome analysis in Chlorella sp. BLD Chemosphere 265:129046. https://doi.org/10.1016/j.chemosphere.2020.129046

Ramírez-Verduzco LF, Rodríguez-Rodríguez JE, del Jaramillo-Jacob RA (2012) Predicting cetane number, kinematic viscosity, density and higher heating value of biodiesel from its fatty acid methyl ester composition. Fuel 91:102–111. https://doi.org/10.1016/j.fuel.2011.06.070

Salah A, Sany H, El-Sayed AE-KB, El-Bahbohy RM, Mohamed HI, Amin A (2023) Growth performance and biochemical composition of Desmodesmus sp. green alga grown on agricultural industries waste (cheese whey). Water, Air, Soil Pollut 234:770. https://doi.org/10.1007/s11270-023-06780-0

Salati S, D’Imporzano G, Menin B, Veronesi D, Scaglia B, Abbruscato P, Mariani P, Adani F (2017) Mixotrophic cultivation of Chlorella for local protein production using agro-food by-products. Bioresour Technol 230:82–89. https://doi.org/10.1016/j.biortech.2017.01.030

Sarin A, Arora R, Singh NP, Sarin R, Malhotra RK, Kundu K (2009) Effect of blends of Palm-Jatropha-Pongamia biodiesels on cloud point and pour point. Energy 34:2016–2021. https://doi.org/10.1016/j.energy.2009.08.017

Singh P, Kumar D (2021) Biomass and lipid productivities of cyanobacteria - Leptolyngbya foveolarum HNBGU001. BioEnergy Res 14:278–291. https://doi.org/10.1007/s12155-020-10170-3

Suwal S, Bentahar J, Marciniak A, Beaulieu L, Deschênes J-S, Doyen A (2019) Evidence of the production of galactooligosaccharide from whey permeate by the microalgae Tetradesmus obliquus. Algal Res 39:101470. https://doi.org/10.1016/j.algal.2019.101470

Tharani D, Ananthasubramanian M (2020) Microalgae as sustainable producers of bioplastic. In: Alam M, Xu JL, Wang Z (eds) Microalgae biotechnology for food, health and high value products. Springer, Singapore, pp 373–396.https://doi.org/10.1007/978-981-15-0169-2_11

Tsolcha ON, Tekerlekopoulou AG, Akratos CS et al (2018) A Leptolyngbya-based microbial consortium for agro-industrial wastewaters treatment and biodiesel production. Environ Sci Pollut Res 25:17957–17966. https://doi.org/10.1007/s11356-018-1989-z

Vadlamani A, Viamajala S, Pendyala B, Varanasi S (2017) Cultivation of microalgae at extreme alkaline pH conditions: a novel approach for biofuel production. ACS Sustain Chem Eng 5:7284–7294. https://doi.org/10.1021/acssuschemeng.7b01534

Yadav G, Sekar M, Kim S-H, Geo VE, Bhatia SK, Sabir JSM, Chi NTL, Brindhadevi K, Pugazhendhi A (2021) Lipid content, biomass density, fatty acid as selection markers for evaluating the suitability of four fast growing cyanobacterial strains for biodiesel production. Bioresour Technol 325:124654. https://doi.org/10.1016/j.biortech.2020.124654

Zanette CM, Mariano AB, Yukawa YS, Mendes I, RigonSpier M (2019) Microalgae mixotrophic cultivation for β-galactosidase production. J Appl Phycol 31:1597–1606. https://doi.org/10.1007/s10811-018-1720-y

Zhang Y, Ren L, Chu H, Zhou X, Yao T, Zhang Y (2019) Optimization for Scenedesmus obliquus cultivation: the effects of temperature, light intensity and pH on growth and biochemical compositioN. Microbiol Biotechnol Lett 47:614–620. https://doi.org/10.4014/mbl.1906.06005

Funding

Open access funding provided by The Science, Technology & Innovation Funding Authority (STDF) in cooperation with The Egyptian Knowledge Bank (EKB).

Author information

Authors and Affiliations

Contributions

The authors confirm contribution to the paper as follows: study conception and design were performed by M. Gomaa. Experiments and data collection were performed by A. M. Youssef. Analysis and interpretation of results were performed by M. Gomaa and A. M. Youssef. The supervision of the experiments was performed by M. Gomaa, A. K. S. H. Mohamed, and A. A. El-Shanawany. The first draft of the manuscript was written by M. Gomaa, and A. M. Youssef and all authors commented on previous versions of the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Ethics approval and consent to participate

Not applicable.

Consent for publication

Not applicable.

Competing interests

The authors declare no competing interests.

Additional information

Responsible Editor: Ta Yeong Wu

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Youssef, A.M., Gomaa, M., Mohamed, A.K.S.H. et al. Enhancement of biomass productivity and biochemical composition of alkaliphilic microalgae by mixotrophic cultivation using cheese whey for biofuel production. Environ Sci Pollut Res 31, 42875–42888 (2024). https://doi.org/10.1007/s11356-024-33877-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-024-33877-8