Abstract

Industrialized aquaculture is an essential trend for aquaculture development in China, owing to its considerable advantages in lower water consumption, higher productivity, and sustainability. However, information on its current status has been scarce up to now. This paper reviewed the current status and has identified existing problems as well as proposing possible solutions for the development of industrialized aquaculture in China. This field is still at an early stage of development and is mainly distributed in coastal regions. Major constraints on industrialized aquaculture include high capital and operational costs, the uncompetitive market price of aquatic products, uneven distribution of production and farming areas, a lack of suitably experienced managers and operators for recirculating aquaculture systems, and the coronavirus disease 2019 (COVID-19) pandemic. Possible solutions to these problems include technological innovations in systems optimization, the use of renewable energy sources and biofloc technology, the pollution-free certification of industrial aquaculture products, increased numbers of professionals in water quality control and waste management, and the financial assistance to companies and farmers along the aquaculture industrial chain.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

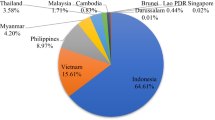

Fish are a valuable source of nutrients (e.g., protein, essential fatty acids, and trace elements) for human nutrition and play an essential role in global food security (Tacon and Metian 2013). According to the Food and Agriculture Organization (FAO), fish provided 17% of animal proteins and 7% of all proteins for the global population in 2017 (FAO 2020). Aquaculture has been the main supplier of fish for human consumption since 2014, accounting for 52% of the total in 2018 (FAO 2020). China is the world’s largest aquaculture producer: in 2020, it produced 49.90 million tonnes of aquaculture fish, accounting for 57.03% of the global total (FAO 2022). However, the development of Chinese aquaculture has been confronted with many problems due to excessive use of traditional culture systems (e.g., ponds and cages), such as disease outbreaks, environmental pollution, and food safety concerns (Cao et al. 2014).

Industrialized aquaculture is an important future trend for aquaculture development in China, owing to its advantages in saving water and land resources and promoting higher productivity and sustainability. However, little information on its current status has been available up to now. This paper reviews the current status of industrialized aquaculture in China and summarizes the main issues in its development, as well as proposing possible solutions for its future direction.

Definition of industrialized aquaculture in China

Industrialized aquaculture usually refers to land-based industrialized (indoor-tank) farming (Gui et al. 2018). It controls the water quality and water temperature for aquaculture through machinery or automation equipment following the principles of continuity and flow of the process; forms an independent system for fish breeding, fish hatchery, and commercial fish production; and makes it possible to carry out continuous nonseasonal production with high efficiency (FBMA 2021). According to government statistics, industrialized aquaculture systems can be defined as circulating filter type, warm drainage type, ordinary flow type, and warm water type (FBMA 2021).

Compared with traditional culture methods (e.g., ponds and cages), industrialized aquaculture systems have the following advantages:

-

(1)

They have more controllable conditions, higher culture density, and more extended production periods. Industrialized aquaculture systems can achieve high-density culture, free aquaculture from climatic constraints, and prolong the fish growth period by controlling the physical and chemical factors (e.g., water temperature and dissolved oxygen) that are required for the optimal growth of fish.

-

(2)

They save land and water resources: compared with conventional aquaculture systems, some industrialized aquaculture systems (e.g., recirculating aquaculture systems) use 90–99% less water and less than 1% of the land area (Ebeling and Timmons 2012).

-

(3)

Their construction sites are more flexible. Conventional aquaculture systems need to be built close to the water source and are generally far from the aquatic products markets. However, owing to the systems’ highly efficient utilization rate of water resources, industrialized aquaculture can be constructed in places where water resources are not abundant and are close to the aquatic products markets. This helps in cutting the cost of aquatic products distribution.

-

(4)

They improve feed utilization and reduce pollutant emissions. The feed conversion ratio value in industrialized aquaculture systems ranges from 0.8 to 1.1 (Ahmed and Turchini 2021), while in conventional culture systems, it is between 1.3 and 1.7 (Naylor et al. 2021). Compared with traditional culture systems, industrialized aquaculture improves feed utilization and reduces the detrimental effects of aquaculture effluents on the environment.

Farmed species in industrialized aquaculture in China

Farmed aquaculture species in China have similarities and differences when compared with developed countries (Table 1). Farmed species in European countries are concentrated on sturgeon (order Acipenseriformes), Atlantic salmon (Salmo salar), Arctic char (Salvelinus alpinus), rainbow trout (Oncorhynchus mykiss), European eel (Anguilla anguilla), Nile tilapia (Oreochromis niloticus), pike perch (Stizostedion lucioperca), and European lobster (Homarus gammarus). North American aquaculture focuses on oyster mussel (Epioblasma capsaeformis), Arctic char (Salvelinus alpinus), yellow perch (Perca flavescens), hybrid striped bass (Morone chrysops x M. saxatilis), and tilapia. Industrialized aquaculture in Japan focuses on Japanese eel (Anguilla japonica), pejerrey (Odontesthes bonariensis), Japanese flounder (Paralichthys olivaceus silver), kuruma shrimp (Marsupenaeus japonicus), white shrimp (Penaeus vannamei), and abalone (Haliotis sp.). Farmed species in China include grouper (Epinephelus sp.), large yellow croaker (Pseudosciaena crocea), half-smooth tongue sole (Cynoglossus semilaevis), giant river prawn (Macrobrachium rosenbergii), white shrimp, turbot (Scophthalmus maximus), and starry flounder (Platichthys stellatus); of these, turbot and half-smooth tongue sole are the main cultured species in industrialized aquaculture (Wang et al. 2013).

Industrialized aquaculture models in China

The development of industrialized aquaculture in China has been a process of gradual change over time. In the 1970s, industrialized aquaculture models were dominated by still water and flowing water aquaculture. In the 1980s, China introduced foreign recirculating aquaculture systems and began to develop recirculating aquaculture; however, the introduced facilities were not widely applied due to the high capital and operating costs (**g et al. 2018). At the end of the twentieth century, industrialized flowing water aquaculture characterized by “utility sheds + underground seawater” was widely promoted and applied; its advantages included economic efficiency, reduced environmental impact, and high yield (Lei 2010). In the twenty-first century, with the strategic demand for the benefits of a circular economy, energy-saving, and emissions reduction, the closed recirculating aquaculture model was developed in China (Fan and Fang 2020; Wang et al. 2013). At present, industrialized aquaculture models in China can be divided into three models: flowing water systems, recirculating aquaculture systems (RAS), and aquaponics systems (Fig. 1) (Cang 2019; Chen et al. 2009; Li et al. 2021). A series of strategies have been recommended to deal with these problems, such as the support of free legal advice and financial assistance to companies and farmers along the aquaculture industrial chain (Chang et al. 2022; Yuan et al. 2022).

Conclusion

Industrialized aquaculture is an environmentally friendly and sustainable culture model, possessing considerable advantages over traditional culture systems in saving water and resources, increasing production and food security of aquatic products, and reducing pollutant emissions. At present, industrialized aquaculture is still at an early stage of development and is mainly distributed in coastal regions. The development of industrialized aquaculture is restricted by high capital and operational costs, the uncompetitive market price of fish, uneven distribution of industrialized aquaculture, a lack of suitably experienced RAS managers and operators, and the COVID-19 pandemic. Possible solutions to these problems include technological innovations in systems optimization, the use of renewable energy sources and biofloc technology, the pollution-free certification of industrialized aquaculture products, more trained professionals in water quality control and waste management, and the financial assistance to companies and farmers along the aquaculture industrial chain.

Data availability

The data that support the findings of this study are available from the corresponding author upon reasonable request.

References

Ahmed N, Turchini GM (2021) Recirculating aquaculture systems (RAS): environmental solution and climate change adaptation. J Clean Prod 297:126604. https://doi.org/10.1016/j.jclepro.2021.126604

Arifa BMK, Lalon RM, Alam ABMS, Rahman MS (2022) Economic feasibility of Pabda and stinging catfish culture in recirculating aquaculture systems (RAS) in Bangladesh. Aquacult Int 30:445–465. https://doi.org/10.1007/s10499-021-00807-1

Aubin J, Papatryphon E, Van der Werf HMG, Petit J, Morvan YM (2006) Characterisation of the environmental impact of a turbot (Scophthalmus maximus) re-circulating production system using Life Cycle Assessment. Aquaculture 261:1259–1268. https://doi.org/10.1016/j.aquaculture.2006.09.008

Badiola M, Basurko OC, Piedrahita R, Hundley P, Mendiola D (2018) Energy use in recirculating aquaculture systems (RAS): a review. Aquacult Eng 81:57–70. https://doi.org/10.1016/j.aquaeng.2018.03.003

Badiola M, Mendiola D, Bostock J (2012) Recirculating aquaculture systems (RAS) analysis: main issues on management and future challenges. Aquacult Eng 51:26–35. https://doi.org/10.1016/j.aquaeng.2012.07.004

Cang P (2019) Comprehensive economic analyses of turbot farming industry transformation from the environment-friendly perspective. Dissertation, Shanghai Ocean University

Cang P, Yang Z, Duan Y (2018) The economies of scale of turbot industrial running water aquaculture system in China: a case from Shandong province. Turk J Fish Aquat Sc 18:167–173. https://doi.org/10.4194/1303-2712-v18_1_19

Cao L, Wang W, Yang Y, Yang C, Yuan Z, **ong S, Diana J (2007) Environmental impact of aquaculture and countermeasures to aquaculture pollution in China. Environ Sci Pollut R 14:452–462. https://doi.org/10.1065/espr2007.05.426

Chang Y-C, Zhang X, Khan MI (2022) The impact of the COVID-19 on China’s fisheries sector and its countermeasures. Ocean Coast Manage 216:105975. https://doi.org/10.1016/j.ocecoaman.2021.105975

Chang Z-Q, Neori A, He Y-Y, Li J-T, Qiao L, Preston SI, Liu P, Li J (2020) Development and current state of seawater shrimp farming, with an emphasis on integrated multi-trophic pond aquaculture farms, in China – a review. Rev Aquacult 12:2544–2558. https://doi.org/10.1111/raq.12457

Chen J, Xu H, Ni Q, Liu H (2009) The study report on the development of China industrial recirculating aquaculture. Fishery Modernization 36:1–7

Colt J, Summerfelt S, Pfeiffer T, Fivelstad S, Rust M (2008) Energy and resource consumption of land-based Atlantic salmon smolt hatcheries in the Pacific Northwest (USA). Aquaculture 280:94–108. https://doi.org/10.1016/j.aquaculture.2008.05.014

Crab R, Avnimelech Y, Defoirdt T, Bossier P, Verstraete W (2007) Nitrogen removal techniques in aquaculture for a sustainable production. Aquaculture 270:1–14. https://doi.org/10.1016/j.aquaculture.2007.05.006

Cripps SJ, Bergheim A (2000) Solids management and removal for intensive land-based aquaculture production systems. Aquacult Eng 22:33–56. https://doi.org/10.1016/S0144-8609(00)00031-5

Dalsgaard J, Lund I, Thorarinsdottir R, Drengstig A, Arvonen K, Pedersen PB (2013) Farming different species in RAS in Nordic countries: current status and future perspectives. Aquacult Eng 53:2–13. https://doi.org/10.1016/j.aquaeng.2012.11.008

De Schryver P, Crab R, Defoirdt T, Boon N, Verstraete W (2008) The basics of bio-flocs technology: the added value for aquaculture. Aquaculture 277:125–137. https://doi.org/10.1016/j.aquaculture.2008.02.019

Ebeling JM, Timmons MB (2012) Recirculating aquaculture systems. In: Tidwell JH (ed) Aquaculture production systems. John Wiley & Sons, Inc., New Delhi, India, pp 245–277. https://doi.org/10.1002/9781118250105.ch11

Engle CR, Kumar G, van Senten J (2020) Cost drivers and profitability of U.S. pond, raceway, and RAS aquaculture. J World Aquacult Soc 51:847–873. https://doi.org/10.1111/jwas.12706

Fan Y, Fang C (2020) Circular economy development in China-current situation, evaluation and policy implications. Environ Impact Asses 84:106441. https://doi.org/10.1016/j.eiar.2020.106441

FAO (2020) The state of world fisheries and aquaculture 2020. Sustainability in action. Food and Agriculture Organization of the United Nations, Rome

FAO (2022) FishstatJ, a tool for fishery statistical analysis. global fishery and aquaculture production 1950–2020. Rome, Italy. https://www.fao.org/fishery/en/topic/166235

Farghally HM, Atia DM, El-madany HT, Fahmy FH (2014) Control methodologies based on geothermal recirculating aquaculture system. Energy 78:826–833. https://doi.org/10.1016/j.energy.2014.10.077

FBMA (Fisheries Bureau of the Ministry of Agriculture of the People's Republic of China) (2021) China fishery statistical yearbook-2020. China Agriculture Press, Bei**g, China

FBMA (Fisheries Bureau of the Ministry of Agriculture of the People's Republic of China) (2022) China fishery statistical yearbook-2021. China Agriculture Press, Bei**g, China

Feng G, Zhuang P, Zhang L, Zhang T, Huang X, Zhao F (2004) Status quo and prospects of sturgeon aquaculture in China. Marine Fisheries 26:317–320

Fuller RJ (2007) Solar heating systems for recirculation aquaculture. Aquacult Eng 36:250–260. https://doi.org/10.1016/j.aquaeng.2006.12.005

Goddek S, Delaide B, Mankasingh U, Ragnarsdottir KV, Jijakli H, Thorarinsdottir R (2015) Challenges of sustainable and commercial aquaponics. Sustainability 7:4199–4224. https://doi.org/10.3390/su7044199

Gui J-F, Tang Q, Li Z, Liu J, De Silva SS (2018) Aquaculture in China: success stories and modern trends. John Wiley & Sons, Oxford UK

Gutierrez-Wing MT, Malone RF (2006) Biological filters in aquaculture: trends and research directions for freshwater and marine applications. Aquacult Eng 34:163–171. https://doi.org/10.1016/j.aquaeng.2005.08.003

Han J, Su S (2022) A review of research progress and application of biofloc technology. Fisheries Science 41:491–503. https://doi.org/10.16378/j.cnki.1003-1111.20228

Hu Z, Lee JW, Chandran K, Kim S, Khanal SK (2012) Nitrous oxide (N2O) emission from aquaculture: a review. Environ Sci Technol 46:6470–6480. https://doi.org/10.1021/es300110x

**g Q, Wang Z, Huang B, Guan C, Jia Y (2018) Development of the different aquaculture models for marine fishes. Open Journal of Fisheries Research 5:37–44. https://doi.org/10.12677/ojfr.2018.52006

Jones JW, Mair RA, Neves RJ (2005) Factors affecting survival and growth of juvenile freshwater mussels cultured in recirculating aquaculture systems. N Am J Aquacult 67:210–220. https://doi.org/10.1577/A04-055.1

Khanjani MH, Sharifinia M (2020) Biofloc technology as a promising tool to improve aquaculture production. Rev Aquacult 12:1836–1850. https://doi.org/10.1111/raq.12412

Kuhn DD, Boardman GD, Lawrence AL, Marsh L, Flick GJ (2009) Microbial floc meal as a replacement ingredient for fish meal and soybean protein in shrimp feed. Aquaculture 296:51–57. https://doi.org/10.1016/j.aquaculture.2009.07.025

Lei J (2010) Strategy consideration for industry construction of Chinese marine culture. J Fish Sci China 17:600–609

Lei J, Huang B, Liu B, Xu Z, Yan K, Zhai J (2014) Strategic research on the construction of high-end farming industry in China based on the concept of aquatic animal welfare. Strategic Study of CAE 16:14–20

Lekang OI (2013) Aquaculture Engineering. Blackwell, London

Li J, Hou J, Zhang P, Liu Y, **a R, Ma X (2016) Influence on water quality and microbial diversity in fish pond by Ipomoea aquatica floating-bed. China Environ Sci 36:3071–3080

Li X, Li J, Wang Y, Fu L, Fu Y, Li B, Jiao B (2011) Aquaculture industry in China: current state, challenges, and outlook. Rev Fish Sci 19:187–200. https://doi.org/10.1080/10641262.2011.573597

Liu X, Steele JC, Meng X-Z (2017) Usage, residue, and human health risk of antibiotics in Chinese aquaculture: a review. Environ Pollut 223:161–169. https://doi.org/10.1016/j.envpol.2017.01.003

Liu Y, Wang X (2022) Promoting competitiveness of green brand of agricultural products based on agricultural industry cluster. Wirel Commun Mob Com 2022:7824638. https://doi.org/10.1155/2022/7824638

Losordo TM, Masser MP, Rakocy J (1998) Recirculating aquaculture tank production systems an overview of critical considerations. SRAC Publication 451:1–6

Love DC, Fry JP, Genello L, Hill ES, Frederick JA, Li X, Semmens K (2014) An international survey of aquaponics practitioners. PLoS ONE 9:1–10. https://doi.org/10.1371/journal.pone.0102662

Martins CIM, Eding EH, Verdegem MCJ, Heinsbroek LTN, Schneider O, Blancheton JP, d’Orbcastel ER, Verreth JAJ (2010) New developments in recirculating aquaculture systems in Europe: a perspective on environmental sustainability. Aquacult Eng 43:83–93. https://doi.org/10.1016/j.aquaeng.2010.09.002

Mohammad T, Moulick S, Mukherjee CK (2018) Economic feasibility of goldfish (Carassius auratus Linn.) recirculating aquaculture system. Aquac Res 49:2945–2953. https://doi.org/10.1111/are.13750

Murray F, Bostock J, Fletcher D (2014) Review of recirculation aquaculture system technologies and their commercial application. University of Stirling Aquaculture, Scotland UK

Naylor RL, Hardy RW, Buschmann AH, Bush SR, Cao L, Klinger DH, Little DC, Lubchenco J, Shumway SE, Troell M (2021) A 20-year retrospective review of global aquaculture. Nature 591:551–563. https://doi.org/10.1038/s41586-021-03308-6

Pham N, Meuwissen M, Le CT, Bosma RH, Verreth J, Oude Lansink A (2016) Economic feasibility of recirculating aquaculture systems in pangasius farming. Aquacult Econ Manag 20:185–200. https://doi.org/10.1080/13657305.2016.1156190

Piedrahita RH (2003) Reducing the potential environmental impact of tank aquaculture effluents through intensification and recirculation. Aquaculture 226:35–44. https://doi.org/10.1016/S0044-8486(03)00465-4

Shao M, Che B, Sun C, ** H, Zhang H, Xu S (2021) Cost benefit analysis of industrialized culture of Penaeus vannamei: take Shandong province as an example. Ocean Dev Manag 38:15–23

Shen L, Shi Y, Zou YC, Zhou XH, Wei QW (2014) Sturgeon Aquaculture in China: status, challenge and proposals based on nation-wide surveys of 2010–2012. J Appl Ichthyol 30:1547–1551. https://doi.org/10.1111/jai.12618

Summerfelt ST, Wilton G, Roberts D, Rimmer T, Fonkalsrud K (2004) Developments in recirculating systems for Arctic char culture in North America. Aquacult Eng 30:31–71. https://doi.org/10.1016/j.aquaeng.2003.09.001

Tacon AG, Metian M (2013) Fish matters: importance of aquatic foods in human nutrition and global food supply. Rev Fish Sci 21:22–38. https://doi.org/10.1080/10641262.2012.753405

Takeuchi T (2017) Application of recirculating aquaculture systems in Japan. Springer Japan, Tokyo

Tidwell JH (2012) Aquaculture production systems. John Wiley & Sons, New Delhi, India

van Rijn J, Tal Y, Schreier HJ (2006) Denitrification in recirculating systems: theory and applications. Aquacult Eng 34:364–376. https://doi.org/10.1016/j.aquaeng.2005.04.004

Wei Y (2020) Research on construction and microclimate of trabeculeless solar aquaculture greenhouse with hollow membrane. Dissertation, Institute of Oceanology, Chinese Academy of Sciences

Wang F, Lei J, Gao C, Huang B, Zhai J (2013) Review of industrial recirculating aquaculture research at home and abroad. J Fish Sci China 20:1100–1111. https://doi.org/10.3724/SP.J.1118.2013.01100

Watanabe WO, Losordo TM, Fitzsimmons K, Hanley F (2002) Tilapia production systems in the Americas: technological advances, trends, and challenges. Rev Fish Sci 10:465–498. https://doi.org/10.1080/20026491051758

Whitelaw K (2004) ISO 14001 environmental systems handbook, 2ed edn. Routledge, London

**n N, Zhang S, Yang Y, **ng K (2019) Analysis on development process and current situation of Tian** industrial marine aquaculture. Fishery Modernization 46:1–6. https://doi.org/10.3969/j.issn.1007-9580.2019.02.001

Xu S, Liu J, Xu H, Liu Q, Xu G (2022) Study on nitrogen removal from industrial recirculating mariculture tail water. Environ Ecol 4:116–118

Yuan Y, Miao W, Yuan X, Dai Y, Yuan Y, Gong Y (2022) The impact of COVID-19 on aquaculture in China and recommended strategies for mitigating the impact. J World Aquacult Soc 53:933–947. https://doi.org/10.1111/jwas.12886

Zhang B, Zhao Z, Qu M, Zhang H, Tang Z, Zhai S (2020) Analysis of the status quo of industrialized aquaculture. Animals Breeding and Feed 31–34. https://doi.org/10.13300/j.cnki.cn42-1648/s.2020.01.011

Zhang Y, Tang Y, Zhang Y, Sun Y, Yang H (2021) Impacts of the COVID-19 pandemic on fish trade and the co** strategies: an initial assessment from China’s perspective. Mar Policy 133:104748. https://doi.org/10.1016/j.marpol.2021.104748

Zhao C (2015) Turbot factory circulating water aquaculture and water aquaculture economic benefit comparison research. Dissertation, Shanghai Ocean University

Zhong S, Li A, Wu J (2022) The total factor productivity index of freshwater aquaculture in China: based on regional heterogeneity. Environ Sci Pollut R 29:15664–15680. https://doi.org/10.1007/s11356-021-16504-8

Zhu R, **g Z, Tang B, Sha M (2022a) Research on the progress of industrial circulating aquaculture wastewater treatment. Heilongjiang Sci 13:4–6

Zhu J, Liu H, Cheng H, Zhang L, Chen S, Liu Y (2022b) Research and industrialization development of industrialized recirculating aquaculture technology. China Fisheries 41–49

Funding

This work was supported by the Doctoral Scientific Research Foundation of Henan University of Science and Technology (13480088; 13480087).

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design, material preparation, data collection, and analysis. The first draft of the manuscript was written by Weijun Chen, and all authors commented on previous versions of the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Ethical approval

Not applicable.

Consent to participate

Not applicable.

Consent to publish

All authors have reviewed and approved the manuscript for publication.

Competing interests

The authors have no relevant financial or nonfinancial interests to disclose.

Additional information

Responsible Editor: Philippe Garrigues

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Chen, W., Gao, S. Current status of industrialized aquaculture in China: a review. Environ Sci Pollut Res 30, 32278–32287 (2023). https://doi.org/10.1007/s11356-023-25601-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-023-25601-9