Abstract

Accurately monitoring Canopy Nitrogen Concentration (CNC) is a prerequisite for precision nitrogen (N) fertiliser management at the farm scale with carbon and N budgeting across the landscape and ecosystems. While many spectral indices have been proposed for CNC monitoring, their applicability and accuracy are often adversely affected by confounding factors such as aboveground biomass (AGB), crop type, growth stages, and environmental conditions, limiting their broader application and adoption; with AGB being one of the most dominant signals and confounding factors at canopy scale. The confounding effect can become more challenging as AGB is also physiologically linked with CNC across the growth stages. Additionally, the interplay between index form, selection of optimal wavebands and their bandwidths remains poorly understood for CNC index design. This study proposes robust and cost-effective 2- and 4-waveband multispectral (MS) CNC indices applicable across a wide range of crop conditions. We collected 449 canopy reflectance spectra (400–980 nm) together with corresponding CNC and AGB measurements across four growth stages of ryegrass (winter and summer), and five growth stages of barley (winter-spring) in Victoria, Australia, in 2018 and 2019. All possible waveband (400–980 nm) combinations revealed that the best combination varied between seasons and crop types. However, the visible spectrum, particularly the blue region, presented high and consistent performance. Bandwidths of 10–40 nm outperformed either very narrow (2 nm) or very broad bandwidths (80 nm). The newly developed 2-waveband index (416 and 442 nm with 10-nm bandwidth; R2 = 0.75 and NRMSE = 0.2) and 4-waveband index (512, 440, 414 and 588 nm with 40-nm bandwidth; R2 = 0.81 and NRMSE = 0.17) exhibited the best performance, while validation with an independent dataset (from a different growing period to those used in the model development) obtained NRMSE values of 0.25 and 0.24, respectively. The 4-waveband index provides enhanced performance and permits use of broader bandwidths than its 2-waveband counterpart.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The mismatch between the available soil nitrogen (N) and the N requirements of the crop is often the major limiting factor in crop productivity. N fertilisers are the primary external source of soil N. Traditionally, N fertiliser is uniformly applied across a field without considering the dynamic nature of crop N requirements, which can vary both spatially within a field and temporally with plant phenological development and environmental conditions. This can often lead to suboptimal fertilisation.

Under-fertilisation can cause a significant reduction in crop yield. At the same time, over-fertilisation can result in a high cost of crop production, including fertiliser cost, time and energy involved in fertilisation, to the farmers. In addition, over-fertilisation is often linked to ecological adversities such as groundwater pollution, eutrophication of water bodies and greenhouse gas emissions. Canopy nitrogen concentration (CNC) has been found to be linked to both the crop N status (Chen et al., 2010; Yoder & Pettigrew-Crosby, 1995) and the availability of soil N (Ollinger et al., 2002). Therefore, the accurate and regular monitoring of CNC in fine spatial resolution during crop growth is a vital monitoring task for the implementation of site-specific variable rate N fertiliser application strategies.

Traditionally, CNC is measured from laboratory-based tissue analysis, which is slow, destructive, and expensive. On the other hand, remote sensing-based CNC monitoring provides a rapid, non-destructive, non-invasive, and spatially continuous and consistent means of assessing canopy N status. These advantages of remote sensing become more pronounced when repeated assessments of CNC are required, such as for variable rate N fertilisation, carbon stock and N cycle modeling, at the landscape and ecosystem scale. Many published works have shown the usefulness of remote sensing in estimating CNC over a wide range of crops, including wheat (Cammarano et al., 2014; Chen et al., 2010; Fitzgerald et al., 2010; He et al., 2016), rice (Nguyen & Lee, 2006; Stroppiana et al., 2009; Tian et al., 2011; Zha et al., 2020), maize (Bausch & Diker, 2001; Chen et al., 2010; Gabriel et al., 2017; Li et al., 2014a), grass (Adjorlolo et al., 2014; Baghzouz et al., 2006; Lamb et al., 2002; Patel et al., 2021, 2023), broccoli (El-Shikha et al., 2007), cotton (Barnes et al., 2000; El-Shikha et al., 2008) and barley (Boegh et al., 2002; Kleman & Fagerlund, 1987; Patel et al., 2020, 2023; Xu et al., 2014) using a range of spectral indices.

Many previously proposed spectral indices for monitoring CNC are either only showing the relationship to CNC for a specific growth stage and/or crop type, or the relationship between the index and CNC varies with growth stage (Li et al., 2014a; Patel et al., 2021). This limitation can significantly hinder the adoption and applicability of CNC indices in decision support systems across various growth stages. The use of growth/crop-specific CNC indices in real-world conditions, which are typically heterogeneous, requires two steps: first, to detect the crop type and growth stage, and second, to apply the respective CNC indices. However, this crop type and growth stage classification is subject to their own errors, which can further introduce compounding errors in the final CNC estimates.

The studied crop types in this study, ryegrass and barley, belong to the grass family. Their structural attributes are similar in early growth stages but become markedly different in later growth stages. An interesting factor highlighted by Patel et al. (2021) and Stroppiana et al. (2009) is that some growth stages exhibit a high correlation (up to 0.90) between CNC and aboveground biomass (AGB)/leaf area index (LAI) (one of the most dominating factors at canopy scale reflectance (Ollinger, 2011)). Another crop physiological factor is that CNC decreases as a negative power function with AGB (also called ‘CNC dilution curve’ (Greenwood et al., 1990)) across growth stages (e.g., coefficient of determination (R2) of 0.76 between CNC and AGB in rice (Stroppiana et al., 2009)).

The corollary of growth stage-specific high CNC-AGB correlation and CNC dilution is that the CNC model may unintendedly rely on more dominant AGB/LAI attributes rather than subtle CNC signals, especially at canopy scale. This can mask the subtle and relevant CNC features in models despite accommodating variances in CNC and AGB across the growth stages. Additionally, growth stage-specific indices may be responding to factors other than CNC, as many structural attributes show strong covariance with CNC at specific growth stages (Ollinger, 2011; Patel et al., 2021; Stroppiana et al., 2009), reducing model robustness to changing conditions.

It is thus essential to develop CNC indices that are as robust as possible to changing conditions (other than CNC), including growth stage and crop type. Once proven to be effective across growth stages and seasons, CNC indices can be applied beyond paddock-scale fertiliser management to the ecosystem-level carbon and N stock modeling (Evans & Clarke, 2019; Kokaly et al., 2009; Ollinger et al., 2002; Smith et al., 2002). A robust CNC sensing model that is applicable across growth stages can improve the economic and environmental gains resulting from its application (Hank et al., 2019).

Many CNC monitoring indices have been proposed based on both multispectral (MS) and hyperspectral (HS) sensors. An important strength of the HS sensor is a contiguous spectrum with a high spectral resolution that can extract narrow absorption features (e.g., 1–6 nm), such as chlorophyll. However, data from HS sensors can be voluminous and feature strong cross-correlation between adjacent wavebands. In contrast, MS sensors can be deployed and manufactured at relatively lower costs and have modest data flow, making them more user-friendly. However, sparsely ill-positioned central wavebands and averaging over wavelengths in coarse bandwidth in the MS sensor can lead to loss of critical spectral information required for CNC map**.

Considering the advantages and disadvantages of both MS and HS sensing, one practical approach proposed by many studies is to explore information-rich HS data to identify the most sensitive set of wavebands for the target biochemical attribute of the crops, CNC in this case (Hansen & Schjoerring, 2003; He et al., 2020; Li et al., 2014b; Thenkabail et al., 2002; Tian et al., 2011, 2014; Zhao et al., 2007). By selecting appropriate wavebands from the pool of HS data and index formulation, it is possible to reduce the influence of extraneous factors other than the target canopy property. For example, Li et al. (2021) developed a three-waveband index capable of map** N uptake, which minimises the effects of crop type changes and is applicable across wheat and corn canopies simultaneously. Similarly, He et al. (2016) modified the normalised difference vegetation index (NDVI) index and proposed a new CNC index applicable across the multi-angular reflectance data. Therefore, HS data can be instrumental in identifying wavebands that are sensitive to a target biophysical/biochemical variable, minimising influence from extraneous factors.

A desirable aspect of any CNC index is its applicability across a wide range of crops and crop growth conditions. The predictive skills of existing CNC indices are influenced by factors other than CNC, such as AGB, phenological stages, background soil, crop type and environmental conditions (Asner, 1998; Boegh et al., 2002; Daughtry et al., 2000; Haboudane et al., 2002; Li et al., 2010; Ollinger, 2011; Patel et al., 2021; Stroppiana et al., 2009; Van Leeuwen & Huete, 1996; Yoder & Pettigrew-Crosby, 1995). Therefore, many indices show variable relationships with CNC when evaluated across the growth stages. For example, when evaluated across the growth stages, Li et al. (2014a) reported up to 48% and 74% decline in the CNC model’s R2 for normalised difference red edge (NDRE) and canopy chlorophyll content index (CCCI), respectively. We aimed to develop a model that is robust to variable application conditions through using a diverse data set containing (a) two different crop types, (b) several different fertilisation levels, and (c) a variety of growth stages.

That being said, often studies have either used single growth stage or selective growth stages from a season, mono-crop data or N uptake for index development. In this study, ryegrass and barley crops are used to develop the CNC models. Ryegrass is the most common and nutritious forage and pasture crop for animal feed in the dairy industry worldwide. At the same time, barley is the fourth most common cereal crop globally for food, feeding and malting purposes. To the best of our knowledge, no studies have been conducted using ryegrass and barley data across multiple growth stages and seasons for develo** a common robust CNC MS index.

Many studies have attempted to develop customised 2-waveband normalised difference formulations for sensing canopy N-related attributes using exhaustive searches across a range of crops, such as Hansen and Schjoerring (2003) and Li et al. (2010) for wheat; Inoue et al. (2012), Stroppiana et al. (2009), Tian et al., (2011, 2014) and Yu et al. (2013) for rice; and (Zhao et al., 2016 demonstrated that the 4-waveband angular insensitivity vegetation index (AIVI) exhibited a 14% and 10% increase in correlation with CNC compared to the 2-waveband soil adjusted vegetation index (SAVI) and 3-waveband enhanced vegetation index (EVI-1), respectively.

Locating the CNC-sensitive central wavebands from HS data is an essential part of designing a new index, but it also involves the selection of the most optimum bandwidth around those central wavebands. Hansen and Schjoerring (2003) found that the locations of the central wavebands for estimating CNC and LAI indices change with the bandwidth. Narrowband vs. broadband index is a much-debated topic in remote sensing as some studies (Broge & Mortensen, 2002; Hansen & Schjoerring, 2003; Marshall & Thenkabail, 2015; Sun et al., 2017; Thenkabail et al., 2000) reported improved performance in applying the narrow waveband indices as much as 24% (Thenkabail et al., 2002), whereas some showed no difference in performance (Broge & Leblanc, 2001; Li et al., 2014a; Lu et al., 2019) and even reported a decrease (Li et al., 2020). The bandwidth effect on CNC index performance has been given limited attention to date. Therefore, the choice of suitable bandwidth warrants further analysis together with finding the best waveband combinations.

With reference to the recent publications (e.g., Berger et al., 2020 and Bossung et al., 2022), machine learning (ML), deep learning (DL) and radiative transfer model (RTM)-based approaches have shown promising results for CNC retrieval. Retrieving canopy biophysical and/or biochemical attributes, including CNC, from RTM inversion is an ill-posed problem and can even become more challenging when compounded with model and site-specific variable (e.g., leaf angle distribution) uncertainties (Berger et al., 2020; Combal et al. 2003; Ollinger, 2011). Nonetheless, ML, DL and RTM approaches are complex and pose high computational load; therefore, they have increasingly large inference time with high-resolution images compared to simple 2–4 waveband simple vegetation indices. The large inference time is a hindrance to their real-time application. This is not a criticism of these models but rather a limitation for specific tasks. The development of simple 2–4 waveband indices for CNC is the focus of this study.

This paper proposes the optimal configuration (waveband locations and bandwidth) for a robust canopy reflectance-based MS CNC sensor by utilising the rich spectral information from the HS data. The scope of this study, therefore, includes the following principal research objectives combining a contrasting range of growth stage data from rainfed barley (winter-spring) and irrigated ryegrass in two seasons (winter and summer). (1) To develop a new 2–4 waveband index capable of monitoring CNC across a range of contrasting growth conditions for ryegrass and barley. This includes the determination of the best waveband combinations and the corresponding bandwidths. (2) To analyse the influence of the most dominating perturbing factor, AGB, on the newly developed indices. (3) To compare the performance of the newly developed indices with the traditional CNC indices. (4) To assess the uncertainty and the effects of different bandwidths in the selection of the best candidate wavebands for the CNC index using random resampling (bootstrap** analysis) across the growth stages, seasons, fertiliser treatments and crop types from the entire calibration dataset. (5) To validate the CNC models using an independent dataset from a different growing period not used in the model development stages.

Measurement program and methods

Study area and experimental design

There were two experimental sites used for this study, one with ryegrass (Lolium perenne) at Allansford, near Warrnambool and the other one with barley (Hordeum vulgare) at Kaniva, both in Victoria, Australia (Fig. 1). To obtain a range of CNC in crops, the experimental ryegrass site had nine different levels of N treatment applied, and corresponding CNC, AGB and canopy reflectance data were acquired over two seasons, winter (May–June 2018) and summer (January–February 2019). For the barley crop, corresponding CNC, AGB and canopy reflectance data were acquired for three different N treatments in winter-spring (July–October 2019).

A and B show the location of the study site in Victoria, Australia, C shows the experimental design at the barley site in Kaniva, Victoria and D shows the experimental design at the ryegrass site in Allansford, Victoria. On the ryegrass plots, U, EEF and C symbolise urea, enhanced efficiency fertiliser and control treatments, respectively (bottom left). The number indicates the application rate (kg-N/ha) after the treatment group symbol. The spatial distribution of urine treatment was not uniform on the plots; therefore, we limited our data collection to the remaining plots, i.e., 40 plots with U, EEF and C treatments. On the barley plots, FN, 2N and 0N indicate the farmer’s rate, two times farmer’s rate and the no fertiliser treatment, respectively. The barley experimental plot image was created using Google Earth image, whereas the ryegrass experimental plot image is from an unmanned aerial vehicle (UAV) image collected on 19 February 2019

Ryegrass

We scheduled the data collection to cover four canopy conditions (CC), in increasing order of AGB, in each season, dispersed across the harvest-growth-harvest cycle. Of the four measurements, the first and fourth data collection campaigns were close to the first and second harvests, while the remaining two were performed in-between, leading to a wide range of AGB conditions (Table 1). For clarity, we note here that we use AGB as the proxy for the growth stage-driven changes in canopy structural attributes and CNC in crops. The ryegrass experimental site (29 m × 23 m) had four main N treatment classes, urea (U, 46% N), enhanced efficiency fertiliser (EEF, green Urea NV™), urine and control (no fertiliser,C). Each treatment class had five replicates for each application rate (20, 40, 60, 80 kg/ha for U; 10, 20, 40 for EEF; Urine and C). Urine plots were excluded from data collection as the treatment was not uniform over the plots. Plots were 3 m × 3 m in size. In total, there were 40 plots for data collection and subsequent analysis after excluding urine plots. Data collection occurred in winter 2018 and summer 2019 (Table 1).

These four CCs, various N application rates and the two seasons ensured a wide range of CNC and AGB, which is advantageous for develo** robust regression-based CNC indices (see Sect. “CNC index development”). Each plot was further divided into 0.3 m × 0.3 m area (0.09 m2) for ground truth collection and spectroradiometer measurements (see Sect. “Radiometric data collection”). This sampling area was randomly selected, excluding areas close to the plot corners and previously sampled patches. Soil moisture was maintained at the optimum level using a center-pivot irrigation system. The irrigation system broke down after 14 January 2019; therefore, it was not possible to obtain a complete set of four sampling times, and the next growth cycle was sampled (Table 1).

Barley

The winter-spring barley (cv. Sparticus) was sown on 5 May 2019 on a farm near Kaniva, Victoria, with a row width of 0.3 m. Over the period from early growth to harvest, five measurement campaigns were conducted (Table 1). There were three N treatment groups: the farmer's rate (36.8 kg N/ha on 11 June and again on 21 July) (FN), two times the farmer’s rate (73.6 kg/ha N on 11 June and 46 kg N/ha on 21 July) (2N) and no fertilisation (0N) with respective strips for data collection within the field (Fig. 1). A transect along each N treatment strip was sampled at nine different sites in a 1-m length along two adjacent rows, i.e. two rows × 1 m (0.6 m2, considering 0.6 m row-row spacing), for spectral and ground truth data collection (Fig. 1). Therefore, each measurement date contains 27 samples, both radiometric and corresponding ground truths, except for the GS 25–31 stage. At that stage, only 21 measurements were obtained due to time constraints (first five transects along the east–west direction and two transects (8 and 9 for 2N, 17 and 18 for 0N, and 26 and 27 for FN) out of the four remaining ones for each N treatment group). Unlike the ryegrass, barley growth was supported by rainfall only.

Radiometric data collection

Canopy level sunlit reflectance was measured using an ASD HandHeld-2 field spectroradiometer (Analytical Spectral Devices, Inc., Boulder, CO, USA) with the default optics setting of 25° field of view (FOV) in the spectral range 325–1075 nm at 1.5 nm spectral sampling interval (< 3 nm spectral resolution at 700 nm) between 11:00 and 14:35 local time. The built-in algorithm in the spectroradiometer subsamples the spectral reflectance to 1-nm intervals. For the ryegrass and barley, 25–30 scans were performed and averaged at two measuring heights corresponding to 15 and 30 cm diameter footprints at the top of the canopy within the ground truth sampling area (i.e. 0.3 m × 0.3 m in ryegrass and two rows (0.6 m) × 1 m in barley). These were averaged to reduce the measurement variability. Frequent calibration using reflection from a Spectralon panel (Labsphere, Inc., North Sutton, NH, USA) was undertaken to account for radiation changes. Due to coastal weather conditions at Allansford, the data collection was mostly performed under part cloud to full cloud conditions, whereas at Kaniva, this was mostly under clear sky conditions (except for the partly cloudy condition on 28 July 2019). Therefore, to counter the influence of cloud conditions on spectral data, we employed a frequent (from ~ 30 s to 2 min, depending on the prevailing cloud condition) normalisation of canopy spectral reflectance using a Spectralon panel. Due to the low signal-to-noise ratio and high scattering/absorption observed below 400 nm and above 980 nm, the candidate spectral waveband pool was reduced to 400–980 nm.

The ryegrass data collection was performed during the two seasons, winter (mean daily maximum temperature 15 °C) and summer (mean daily maximum temperature 24 °C) (Fig. 2). Winter was relatively wet compared to the summer season. Whereas the weather during the barley growing season ranged from typical winter to spring conditions, with daily recorded maximum temperature reaching as low as 0 °C and as high as 37 °C (Fig. 2).

CNC and AGB determination

Immediately after the spectral measurements in the ryegrass field and within 0–2 days in the barley field, crops were cut for laboratory determination of the CNC and AGB. The ryegrass was cut at the typical grazing height (~ 5–7 cm above the soil) from the ground truth sampling area (0.3 m × 0.3 m in ryegrass and 0.6 m × 1 m row in barley), while barley was cut just above the soil level. These samples included all vegetation above the cutting height within the sampling area. Samples were stored inside a cool box and transported to the laboratory facility. Immediately after obtaining the fresh biomass weights, samples were oven-dried at 70 °C until they attained constant dry weight (~ 72–96 h). The AGB (g/m2) was determined from the dried biomass samples. To obtain CNC (100 × g-N/g-AGB, %), entire dried AGB samples were ground and then analysed using the Dumas Combustion—LECO Trumac method at a furnace temperature of around 1350°C for ryegrass. CNC for the barley was determined by a commercial lab (APAL, https://www.apal.com.au/Home.aspx) using the Dumas method. The observed CNC and AGB sample statistics for ryegrass in winter and summer, and the barley growing season have been listed in Table 2.

CNC index development

The overall approach to CNC index development was to undertake an exhaustive search in the calibration dataset (Table 1) for robust waveband combinations using two different index forms which are introduced below. In doing this, bootstrap** was used to ensure the waveband selection was as robust as possible. A variety of bandwidths was also considered.

One of the most commonly used spectral index formulations in remote sensing is a normalised difference of two appropriate wavebands \({R}_{\lambda 1}\) and \({R}_{\lambda 2}\) (e.g., NDVI), where R denotes canopy reflectance and λn indicates waveband number. To avoid any confusion with NDVI, we designate the expression for the normalised difference using 2-wavebands as ND2:

Previous studies have reported that ND2 commonly has a plateau response (saturation) for regression relationships at high growth stages/AGB (Thenkabail et al., 2000; Viña et al., 2011). Gitelson (2004), Huete (1988) and Rondeaux et al. (1996) have shown that the insertion of a constant coefficient in the normalised difference index can effectively improve the sensitivity both at low and high LAI values. Inspired, He et al. (2016) recently developed the angular insensitive vegetation index (AIVI) formula by adding a ratio of two additional wavebands, λ3 and λ4, that modifies the simple waveband difference in the ND2 numerator to a scaled difference. Therefore, we employed the functional form of AIVI, with 4-wavebands (ND4) with the aim of improving the sensitivity to CNC. The ND4 index is defined as:

Equation (2) can be rearranged as follows:

Other types of 2- or 3-waveband combinations based on the functional forms of double-peak canopy nitrogen index (DCNI), MERIS terrestrial chlorophyll index (MTCI) and a range of other options suggested by Tian et al. (2011) were also considered, but preliminary analyses showed no significant performance improvement over the simple ND2 index.

As mentioned in Li et al. (2014a) and Patel et al. (2021), the growth stage-specific performance can be misleading in selecting a spectral index to estimate CNC across a wide range of growth and phenological stages. In order to address this issue, all the growth stages were collated into different groups for all possible waveband combinations and the respective predictive model calibrations. Individual data sets were created by grou** into ryegrass winter, ryegrass summer, ryegrass (winter + summer), barley, and finally, collating all the groups into one (ryegrass + barley) as shown in Table 1. The best 2-waveband (ND2) and 4-waveband (ND4) indices were then applied separately to these groups using the spectral data and corresponding ground truth CNC data from the calibration dataset (Table 1) to analyse the variability of the candidate wavebands across the groups (see flowchart in Fig. 3).

Flowchart of 2- and 4-waveband index development and robustness analysis using calibration data only (Table 1). The R2, λ, Δλ and ND2BS/ND4BS stand for the coefficient of determination, waveband, bandwidth, and bootstrap sampling-based ND2/ND4 indices, respectively

The optimal waveband combinations and bandwidth for ND2 and ND4 indices as predictors of CNC, were obtained using the two-step approach. In the first step, all possible combinations of λ1 and λ2 in the spectral range of 400–980 nm for ND2 were evaluated using linear regression. For ND4, a similar evaluation for λ1, λ2, λ3 and λ4 wavebands over the entire spectrum (400–980 nm) would be computationally very expensive; thus, a two-stage search was implemented. In the first stage, a rough/broader search at a step size of 10 nm from 400 to 980 nm was conducted to narrow the search area into a few candidate spectral regions using linear regression. In the second stage, a more refined search with a 2-nm step size was performed within the candidate spectral region (< 650 nm in this case) found in the first stage. We used samples from all growth stages, seasons and crop types (all the calibration data) since a robust CNC index is the aim of this study.

In the second step, step 1 was repeated on 2, 10, 20, 30, 40 and 80 nm bandwidths to optimise ND2 and ND4 over 400–650 nm at an optimum bandwidth. To resample hyperspectral reflectance (\(R\)) to a specific bandwidth Δλ nm at the central waveband \(C\) nm, the following rule was applied at any given central waveband \({R}_{\Delta \lambda C}\) nm, which is similar to the approximately rectangular radiance spectral response function of Landsat-8 OLI wavebands (Barsi et al., 2014):

The analysis mentioned above to formulate the CNC index has been performed in MATLAB 2017b (MathWorks) software, and the code can be made available on request to authors.

Robustness analysis

It is also important to evaluate the robustness of wavebands selected for ND2 and ND4 by analysing the selection of wavebands and the effects of a wide range of bandwidths on different randomly generated training samples across the growth stages, seasons, fertiliser treatments and crop types. Thus, we repeated the above-described step 2 at a 10 nm step size for 200 bootstrap samples (approximately 63% of the unique samples with repetitions) from the entire calibration dataset (Table 1). We designated the ND2 and ND4 indices calculated from each bootstrap sample as ND2BS and ND4BS, respectively, to avoid confusion with all the calibration data-based ND2 and ND4 indices, as discussed in Sect. “CNC index development”. This bootstrap analysis is implemented on the identical spectral range of 400–650 nm (similar to the search range in ND2 and ND4 best waveband combination found in step (1)) to investigate the shift in the best wavebands for the individual bootstrap samples. This bootstrap** gives the variability in waveband location in ND2BS and ND4BS indices as well as their performance (R2) across the bandwidths and bootstrap samples. We made 200 bootstrap** and a non-parametric probability density estimation using the Gaussian kernel approach as the basis to simulate the probability density function (PDF). These PDFs will aid in comparing and visualising the bootstrap results in a concise way.

Comparison with commonly used N indices

We used some known CNC indices (Table 3) to compare the newly developed ND2 and ND4 indices for CNC sensing. In addition to a selection of one-dimensional indices (e.g. NDVI and PRI), a two-dimensional planar domain index, the canopy chlorophyll content index (CCCI) (derived from NDRE (surrogate for CNC status) and NDVI (a surrogate for canopy cover)) (Barnes et al., 2000; Fitzgerald et al., 2010), is also included in Table 3 for the comparative analysis. All published indices are calculated at 10 nm bandwidth in Table 3 (except for PRI, which was estimated at 3 nm bandwidth (Trotter et al., 2002)). A range of relationships was explored from linear to nonlinear between the published indices and the crop variables (CNC and AGB).

Independent model validation

The established regression models from the calibration data were validated with an independent dataset of spectral and the related CNC data, collected from the ryegrass field at a different time period (on 03 and 14 January 2019) (Table 1). We calculated the performance metrics, coefficient of determination (R2), root mean square error (RMSE) and normalised RMSE (NRMSE, dimensionless), to assess the various regression models on the calibration and the independent data. These performance metrics were calculated by applying the following formulas:

where Y, Ypredicted and \(\overline{Y }\) are the observed CNC, predicted CNC (from optimised regression model), and arithmetic mean of CNC, respectively. The number of observations and parameters in a regression model are denoted by n and m in Eq. (6), respectively. The relationship between observed CNC and AGB was evaluated using the Spearman rank correlation.

Results

Characteristics of the observed CNC and AGB data

The changes in CNC and AGB across the sampling growth stages, seasons and crops, induced by different N treatments, growth stages and seasons are illustrated in Fig. 4. Substantial variability in CNC and AGB was observed as a result of variable N treatment in both experimental fields. As reported by Greenwood et al. (1990) and Lemaire et al. (2008), overall CNC declined with increasing AGB, which is also referred to as the ‘CNC dilution curve’ (Fig. 4). The CNC dilution is mainly attributed to the ontogenetic changes in leaf area, and physiologically driven N allocation and remobilisation within the plants as they grow (Greenwood et al., 1990; Lemaire et al., 2008). This ‘CNC dilution curve’ becomes more evident when individual N treatment groups are observed across the growth stages (Fig. 4c,d,e). When analysis of individual sampling days is considered, both CNC and AGB increased almost linearly with the N application rate (Fig. 4a,b).

The combination of different treatment rates and growth stages leads to a wide scatter between CNC and AGB (Fig. 4), particularly for ryegrass (Fig. 4a). This in-field and across-field variability are advantageous for develo** a robust and more widely applicable spectral model for measuring CNC, which is one of the main objectives of this study. Additionally, weather conditions also affect CNC, as seen in Fig. 4a, where CNC is lower in summer ryegrass than in winter ryegrass, linked to physiological changes associated with warmer growth conditions (Reich & Oleksyn, 2004; Woods et al., 2003). The correlation between CNC and AGB for ryegrass combined across seasons (Table 4) was lower in magnitude than the correlation specific to individual growth stages (as high as 0.90, see Table S1 in supplementary material). However, the barley data still has a significant (r = − 0.67, p value < 0.01) correlation after combining the growth stages. This is due to the low scatter observed in the CNC-AGB relationship across growth stages, attributed to the only three N application rates and variation in soil and water across the field (Fig. 4e). Since the barley crop included a much greater contribution of the stalk in the AGB, leading to a much (~ five times) higher AGB than ryegrass, therefore, combining the ryegrass and barley AGB was not reasonable for the analysis of AGB in Table 4.

Relationship of canopy nitrogen concentration (CNC) and aboveground biomass (AGB) in (a) ryegrass and (b) barley crop irrespective of the N treatments with black and blue markers to distinguish winter and summer seasons in ryegrass crop. For illustrative purpose, three N treatment groups (U80, U20 and C in ryegrass; 2N, 0N and FN in barley) are tracked across the growth in winter (c), summer (d) ryegrass and (e) barley crop. The solid lines in (c), (d), and (e) depict the ‘CNC dilution curve’, which follows a negative power function (Lemaire et al., 2008) for a specific N treatment group. Note: Symbols UX and C indicate urea X kg/ha and control treatment (no N application) groups in ryegrass while FN, 2N and 0N indicate farmer’s rate, two times farmer’s rate and no N application treatment groups in barley

Optimal wavebands and bandwidths

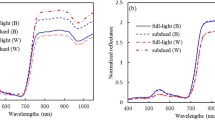

The performance (R2 and NRMSE) of all possible waveband combinations is presented in Fig. 5 and Table 5 for winter ryegrass, summer ryegrass, all ryegrass, barley, and all data combined, respectively, for ND2 and ND4 indices. The results illustrate the several well-performing spectral regions (blue areas) in each case, except for winter ryegrass (Fig. 5). The results highlighted the importance of visible spectrum wavebands in map** CNC (Fig. 5, Table 5), with the best combinations indicated by an asterisk (*) in Fig. 5. The lower R2 for the winter ryegrass ND2 index can be explained by the low CV (0.14) observed for CNC (Table 2 and Fig. 5a). It is evident that the location of the optimal wavebands and their respective bandwidths changed between seasons (winter and summer in ryegrass) and crop types (ryegrass and barley) for both ND2 and ND4 indices (Fig. 5, Table 5). For example, the best combination of ND2_winter wavebands was primarily in the blue region (416 and 424 nm) in winter and shifted to green–red (514 and 605 nm) in summer (ND2_summer) for ryegrass (Fig. 5a,b).

Coefficient of determination (R2) and normalised root mean square error (NRMSE) for all the possible waveband combinations using ND2 index with the best Δλ nm bandwidth around central wavebands, λ1 and λ2 nm for CNC in a) winter ryegrass (ND2_winter) b) summer ryegrass (ND2_summer) c) ryegrass (winter + summer, ND2_ryegrass) d) barley (ND2_barley) and e) all data (ryegrass + barley, ND2). *indicates the location of the optimum waveband combination. + indicates the location of the photochemical reflectance index (PRI) wavebands, which are selected because of their performance in a wide range of ryegrass conditions (Patel et al., 2021). Due to symmetry, only the lower triangular waveband combinations are shown in the matrix plot. Note λ and Δλ indicate waveband location and bandwidth, respectively

What stands out from Fig. 5 is that the blue waveband (400–500 nm) consistently displayed high sensitivity to CNC across seasons and crop types. Interestingly, a very narrow region around 670—720 nm (red to the red-edge region) revealed some high-performing waveband combinations exist in some cases; however, their performance was not as strong as the candidate wavebands in the blue region of the spectrum in ND2 (Fig. 5).

Summary results in Table 5 indicate that 4-waveband ND4 indices are superior in predicting CNC than their 2-waveband counterparts (Fig. 5) across all crop groups. Overall, ND4 indices demonstrated a min 8% and max 23% decrease in NRMSE compared to ND2 across the crop groups (Table 5).

The performance of ND2 and ND4 formula-based spectral indices across the crop groups is presented in Table 6. The exhaustive search using all possible waveband combinations clearly resulted in the best indices for each crop group (e.g., ND4_winter for winter ryegrass). However, some of the indices developed for specific groups had difficulty estimating CNC for other groups. For example, ND2_summer's NRMSE increased by 83% when evaluated against all ryegrass data (Table 6). This highlights the importance of considering a wide range of conditions in develo** a robust CNC index. ND4 indices performed better than their ND2 counterparts for their respective crop groups (Table 6).

Comparison of ND2 and ND4 with published indices for CNC

The results presented in Fig. 6 and Table 7 demonstrate that the ND2 and ND4 indices developed in this study perform better than published indices, such as NDVI, MTCI, AIVI, CCCI, NDRE, and mSR, in estimating CNC for both ryegrass and barley. The ND2 and ND4 indices show the least scatter and highest linearity when compared to the published indices, indicating that the optimum wavebands for CNC estimation have been successfully located. The ND4 index, in particular, shows the best CNC prediction skills and consistent performance across different crop groups (Fig. 6i and Table 7).

Relationship of newly developed (ND2, ND4) and published indices with canopy nitrogen concentration (CNC) in ryegrass winter (n = 160), summer (n = 160) and barley (n = 129) crops in the calibration data. Relationships shown for two new indices (ND2 and ND4) and the best-published index (PRI, photochemical reflectance index) are from the error metrics for the fitted relationships (readers refer to Fig. S1 for regression equations of all the indices). The X-axis has the values of the index indicated inside the respective plot

Among the published indices, an exception is PRI (Fig. 6b) which showed a reasonably consistent (0.20 ≤ NRMSE ≤ 0.33) but nonlinear relationship with CNC. This nonlinearity results in the PRI’s close to plateau response at high CNC values (Fig. 6b). In addition, high clustering around PRI's low values indicates reduced sensitivity of PRI for low barley CNC values (corresponding to GS 80 when heads were visible). We found that NDVI showed a strong saturation effect even at intermediate values of CNC (Fig. 6a). Moreover, except PRI, all the published indices showed low performance (R2 ≤ 0.33; 0.20 ≤ NRMSE ≤ 0.65) and separate clusters of responses for ryegrass and barley CNC (Fig. 6). This shows that a single CNC model based on any of these published indices is unable to independently map CNC across the crop types. Even the 4-waveband AIVI and 3-waveband mSR indices did not improve the CNC estimation (Table 7).

Relationship with AGB

Table S2 summarises all the relationships between the indices and AGB. It is important to note that the AGB measured in barley was five times greater than in ryegrass (Table 4). Therefore, the regression attributes for the pooled ryegrass and barley AGB data are an artefact of this scale difference and therefore are considered to be unreliable and are excluded (Table S2).

PRI exhibited a moderate correlation with AGB in ryegrass groups and barley (R2 < 0.44 and R2 = 0.51, respectively) (Table S2). NDVI had a low to moderate correlation (0.27 ≤ R2 ≤ 0.47) with AGB across the groups. Overall, AIVI and mSR performed consistently (0.29 ≤ R2 ≤ 0.41) across the groups with AGB in ryegrass and barley (Table S2). Regarding NRMSE, similar associations of MTCI, mSR, NDRE and AIVI with AGB were found across the groups. ND2 and ND4 indices exhibited low correlation (R2 ≤ 0.32) in ryegrass and moderate correlation (R2 = 0.50) in barley AGB. However, the indices still showed a moderate correlation with barley AGB due to the high correlation (r = − 0.67, p value < 0.01) between CNC and AGB (Table 4).

CNC model validation

After the establishment of the regression equations between the best spectral indices and CNC in the previous section (Fig. 6b,h,i), the independent data (neither used to derive the optimal waveband combinations nor to calibrate the regression models) from the ryegrass field, collected on 03 and 14 January 2019 (Table 1), was used to validate the three best predictive models obtained from PRI, ND2 and ND4 in Fig. 7. The predictive accuracy (NRMSE in the validation data (NRMSE_val)) of PRI, ND2, and ND4 was found to be similar. Although there is a slight decrease in NRMSE_val from PRI to ND2 to ND4, the scatter around the 1:1 line is noteworthy (Fig. 7). The smaller scatter in ND4 establishes it as the most reliable CNC indicator in this study (Fig. 7c).

Predictive performance of the best among published indices (PRI, photochemical reflectance index) and newly developed 2- and 4-waveband indices (ND2 and ND4) on the independent canopy nitrogen concentration (CNC) data (n = 80, red colour) (all the calibration data (n = 449) in the background, grey colour). NRMSE_val indicate normalised root mean square error (NRMSE) values for the independent validation data from the respective indices

Bootstrap** model performance and waveband selection

Apart from comparing the performance of ND2 and ND4 indices in CNC map** (Fig. 5 and Table 5), it is also important to evaluate the robustness of the central waveband selection and the influence of the bandwidth. The study implemented 200 bootstrap analyses on the complete calibration (across seasons and crop type) dataset to assess the robustness of the candidate waveband selection and the corresponding CNC estimation accuracy for various bandwidths (2, 10, 20, 30, 40 and 80 nm) in ND2BS and ND4BS indices. The bootstrap** was performed on the most informative waveband range (400–650 nm, identified in Fig. 5 and Table 5) at a sparser 10 nm search step. On average, both λ1 and λ2 of the ND2BS index shifted as the bandwidth changed, as illustrated by the PDF (Fig. 8a, b). However, regardless of this shift, λ1 and λ2 remained within the blue region of the spectrum, mainly with λ < 500 nm (Fig. 8a, b). λ2 is slightly red-shifted compared to λ1.

Comparison of probability density function (PDF) of the optimum waveband locations in 200 bootstrap (BS) samples for 2-waveband (ND2BS) (a, b) and 4-waveband (ND4BS) (c, d, e, f) indices. The BS was conducted over the spectral range of 400–650 nm at a step size of 10 nm across the bandwidths (Δλ nm)

The impact of bandwidths on the ND4BS index performance was also evaluated across the bootstrap samples (Fig. 8c–f). We found that the four optimum wavebands in the ND4BS index were swap** among the bootstrap samples. For this reason, they were sorted in ascending order, resulting in four groups of wavebands (namely, group-1, 2, 3 and 4) for the comparison between bootstrap samples. The four resulting regions after sorting are illustrated by their respective PDFs (Fig. 8c–f).

In addition to the shifts in the central waveband locations, there is also a shift in the R2 values for bootstrap samples across the bandwidths. Generally, R2 increases with bandwidth from 2 to 40 nm and then decreases from 40 nm to a much broader bandwidth of 80 nm in both the ND2BS and the ND4BS index (Fig. 9). The change in R2 with bandwidth is smaller for ND4BS indices than ND2BS.

Corresponding to Fig. 8, the coefficient of determination (R2) of 200 bootstrap (BS) samples for 2-waveband (ND2BS) (left) and 4-waveband (ND4BS) (right) indices across the bandwidths (Δλ nm). PDF stands for the probability density function

To examine the robustness of the waveband selected, the study compares the performance (R2) of the best 2-waveband (ND2BS) and 4-waveband (ND4BS) index obtained from individual bootstrap samples against the R2 obtained using ND2 and ND4 indices identified in Table 5 (Fig. 10). The scatter points are systematically shifted above the 1:1 line in Fig. 10, indicating better performance for the ND2 and ND4 index over their respective counterparts ND2BS and ND4BS across the bandwidths. This is likely due to the broader search step size of 10 nm used in bootstrap**, which has overlooked the very best waveband combinations.

Discussion

One of this study's main objectives was to identify the robust waveband and bandwidth combinations for a low-cost CNC sensor, by incorporating the data spanning a wide range of growth conditions in irrigated ryegrass (in winter and summer) and rainfed barley (winter-spring). Considering the real-world heterogeneities in cropland, in terms of AGB growth, seasons, fertiliser management and crop type, growth stage-dependent models are less useful and may be subject to higher error when underlying crop conditions change. That being said, the presence of a strong correlation (as high as 0.90, Table S1) between ground CNC and AGB data may pose challenges in develo** a CNC index independent of AGB (Ollinger, 2011; Patel et al., 2021).

Another confounding factor for the development/evaluation of CNC indices is the ‘CNC dilution curve’, which shows that CNC varies as a negative power function with AGB across the growth stages (Greenwood et al., 1990; Lemaire et al., 2008). Therefore, any model using an index that responds mainly to green biomass and relies on a CNC-AGB relationship (‘CNC dilution curve’) will be poor where crop conditions change (e.g., ryegrass in Fig. 4 and Table 4). To address these challenges, all growth stages across fertiliser treatments, growth/phenological conditions, seasons, and crop types were grouped to identify more robust CNC-sensitive wavebands for use in ND2 and ND4-based indices. This approach helped to counter the condition-specific CNC-AGB correlation, and increase the robustness of the MS index for CNC sensing. Nevertheless, to develop CNC models that are truly transferrable (across growth stages, seasons, crop types, range of fertiliser applications and regions) requires the development of a very diverse database of ground truth samples and corresponding radiometric reflectance spectra.

ND2 and ND4 spectral waveband positions

The results revealed that blue wavebands in the range of 400–450 nm were consistently present as sensitive wavebands for CNC in both ND2 and ND4, regardless of the crop groups. Additionally, the best candidate indices for ND4 also included green and red wavebands. These findings align with previous research, which has found the importance of the visible spectrum for CNC across a wide range of ecological conditions and crop types (Hansen & Schjoerring, 2003; Read et al., 2002; Stroppiana et al., 2009; Tian et al., 2011, 2014). The presence of blue wavebands in ND2 and ND4 can be attributed to the absorption of chlorophyll a and b pigments, which have exclusive and separate absorption peaks in the blue and red regions of the spectrum. Chlorophyll has been found to have a linkage with CNC (Bassi et al., 2018; Daughtry et al., 2000; Evans, 1989; Hansen & Schjoerring, 2003; Yoder & Pettigrew-Crosby, 1995), which likely explains the selection of these wavebands for CNC indices. However, the scaling of indices using blue wavebands for airborne/spaceborne sensors needs to be carefully assessed due to the increased atmospheric attenuation of the blue wavebands.

Furthermore, regarding the selection of green and red wavebands in ND4, it is based on the strong absorption peaks of chlorophyll in the blue (400–460 nm) and red regions (640–670 nm). However, research by Gitelson et al. (1996) has shown that the inverse of reflectance around 520–630 nm range is more sensitive to a wide range of chlorophyll concentrations than the red region, due to its saturation at high chlorophyll values. This finding can justify the inclusion of wavebands close to that range (512 nm and 588 nm), in addition to the blue wavebands (414 and 440 nm) in ND4. This inclusion results in a more robust linearity in ND4 and ND2 for both ryegrass and barley CNC, even at the highest CNC values (i.e. > 4%, Fig. 6b,c). A practical implication of this finding is the potential development of a common MS-CNC sensor, which would facilitate seamless CNC map** without the need for switching to a crop-specific model via crop classification algorithms for ryegrass and barley, reducing lag and computational cost.

Our exhaustive search did not suggest candidate waveband combinations within red-edge and near-infrared (NIR) regions of the spectrum, contradictory to the selections in Tian et al. (2011) for rice, Li et al. (2014b) and Feng et al. (2016) for wheat, and Wang et al. (2016; Li et al., 2014b; Tian et al., 2011; Wang et al., Effects of bandwidth Bandwidth has a significant impact on waveband selection and the sensitivity of indices to CNC, which has practical implications in the trade-off between spatial and spectral resolution when designing sensors (Cao et al., 2019; Hansen & Schjoerring, 2003; Thenkabail et al., 2002). Using wider bandwidths can enhance the robustness and applicability of CNC indices across different spectral instruments, minimising the effect of varying sensitivity across their spectral range and any small spectral shift in canopy CNC absorption features (Knox et al., 2010). Similar changes in the best central waveband locations have been observed as bandwidth varies from very narrow (2 nm) to broad (80 nm), as reported by Thenkabail et al. (2002) and Hansen and Schjoerring (2003) in their exhaustive waveband searches for spectral index development. The predictive abilities (R2) of the ND2BS and ND4BS indices also vary with bandwidth, showing first improvement as bandwidth increases from very narrow (Δλ = 2 nm) up to some intermediate bandwidths (e.g., Δλ = 10–40 nm) before drop** at very broad bandwidths (Δλ = 80 nm) (Fig. 9). This effect is stronger for ND2BS than ND4BS (Fig. 9). The permissible broader bandwidth in ND4 can facilitate high spatial resolution that is a prerequisite for assessing individual crop canopy N status and, therefore, can be instrumental in site-specific N fertiliser management. The published indices that were evaluated in this study have performed poorly in comparison to the ND2 and ND4 indices for CNC (Fig. 6). This is in contrast to the encouraging performance reported for indices such as AIVI (He et al., 2016) and CCCI (Fitzgerald et al., 2010) in wheat, and NDRE in cotton (Barnes et al., 2000). One index that explicitly aims to separate canopy cover and CNC is CCCI, which uses a planar domain approach and employs one index (e.g. NDVI) to control for canopy cover and another index (e.g. NDRE) to capture the CNC signal, essentially using four wavebands. Despite this nuanced approach, CCCI also showed the lowest association (R2 = 0.09) with all CNC data (Fig. 6e, Table 7). There are two reasons that can explain the poor performance of these published indices, (1) the indices respond more consistently to AGB than CNC (Table S2), and (2) there is a crop-dependent response to CNC as evidenced by clustering of ryegrass and barley in Fig. 6. The waveband search method used for ND2 and ND4 effectively rewards independence from AGB, environmental factors, phenological stages and crop type due to the wide range of conditions in the development dataset. While ND2 and ND4 have broader applicability, it can be argued that some previous indices, such as CCCI have been developed to predict CNC at a specific growth stage and perform well, provided their use is constrained to the conditions they were developed under. Nevertheless, CNC indices capable of continuous sensing are particularly advantageous for tracking spatial as well as temporal patterns of N and carbon stocks over crop growth cycles (Kokaly et al., 2009; Smith et al., 2002). Among the published indices considered, PRI was the most robust indicator of CNC. However, the nonlinear relationship between PRI and CNC causes a decline in sensitivity at high and low CNC values (i.e. around < 1.5% and > 4%, Fig. 6b and Fig. 7a). It should be noted that PRI was not originally developed for CNC sensing; however, previous studies have found close links between PRI and a variety of attributes, including light use efficiency (LUE) (Gamon et al., 1992; Jia et al., 2018), chlorophyll: carotenoid ratio (Gamon et al., 2015) and LAI (Barton & North, 2001; Gitelson et al., 2017), and the relationship may also change depending on the temporal scale of measurement (Gamon et al., 2015). Further research focusing on understanding the drivers of PRI’s response to CNC across growth/phenological stages is required. The findings in this study have important implications for the use of ND2 and ND4 indices in airborne and satellite remote sensing of CNC across the wide range of CNC values (Fig. 6h,i). The blue wavebands used for ND2 and ND4 are more susceptible to being attenuated when collected from airborne and spaceborne platforms due to atmospheric scattering (Curran, 1989). Therefore, the utility of the ND2 and ND4 indices may depend on the effectiveness of atmospheric correction algorithms. Nonetheless, ND2 and ND4 can offer the best and most robust CNC sensing capability at proximal to low-altitude sensing, where the atmosphere has minimal interference. In addition, the suitability of these indices for different bandwidths used by UAV, airborne and spaceborne spectroradiometers must also be considered. For example, if an NRMSE of 0.25 can be used as a threshold accuracy of CNC estimation, then ND4 can reach this threshold with a bandwidth of up to 95 nm, while similar accuracy can be achieved at around 70 nm bandwidth for ND2 (Fig. 11). The advantage of having a broad permissible bandwidth is that it would be easier to construct a fine spatial resolution and high signal-to-noise ratio equipped, tailored MS sensor with either ND4 or ND2 wavebands on board. Moderate Resolution Imaging Spectroradiometer (MODIS) has blue wavebands (waveband-8 and -9 close to ND2 and ND4) and green wavebands (waveband-4 and -11, not optimally close to green wavebands of ND4) around the best CNC index wavebands found in this study. However, the spatial resolution (i.e. ≥ 500 m) may be too coarse for CNC sensing at the field scale for variable rate N application. The growing number of hyperspectral satellite missions such as PRISMA (PRecursore IperSpettrale della Missione Applicativa, Italy; 400–2500 nm at 10 nm and 30 m) (Loizzo et al., 2018), EnMAP (Environmental Map** and Analysis Program, Germany; 400–2500 nm at 6.5–10 nm and 30 m) (Guanter et al., 2015) and SHALOM (Spaceborne Hyperspectral Applicative Land and Ocean Mission; 400–2500 nm at 10 nm and 10 m) (Feingersh & Dor, 2015) have the potential of utilising the proposed indices for CNC monitoring at paddock to ecosystem-level monitoring given the spatial resolution (≤ 30 m). It is important to note that this study is limited in its analysis to the spectral range of 400–980 nm (visible-NIR, VNIR). N taken up by plants is also substantially invested in proteins (non-pigment compounds), in addition to chlorophyll. These proteins have absorption peaks in the short-wave infrared (SWIR) region (Curran, 1989; Kokaly, 2001). Therefore, future studies should explore the possibility of incorporating the SWIR wavebands along with VNIR wavebands for CNC index development (Berger et al., 2020; Hallik et al., 2009). A comprehensive approach that includes both VNIR and SWIR wavebands may provide a more robust and accurate index for CNC sensing.Why did the published indices tested perform poorly?

Implications for airborne/satellite remote sensing

Conclusion

This study has demonstrated that normalised difference-based indices exhibit promising capability for CNC estimation using canopy reflectance. The present study has gone some way towards develo** a robust MS CNC sensor by optimising waveband and bandwidth configuration across a wide range of conditions, including seasons, irrigation conditions and N fertiliser treatments in two crops; ryegrass and barley. The key findings of this study are as follows:

(1) The selection of optimal wavebands and bandwidths, as well as the structure of the index, is crucial for develo** a CNC index. The ND4 index formulation was found to provide more robust linearity across a range of CNC values, and avoid a plateau response at high CNC.

(2) While the best waveband selection varies with crop type and season, an optimal spectral region exists that enables consistently high CNC estimation performance in both ryegrass and barley. The visible spectrum, particularly blue wavebands, was critical for estimating CNC, and neither red-edge nor NIR wavebands were selected among the candidate waveband combinations. This work has proposed two new CNC indices, 2-waveband ND2 (416, 442 nm with Δλ = 10 nm) and 4-waveband ND4 (512, 440, 414, 588 nm with Δλ = 40 nm).

(3) The 4-waveband (ND4) index minimised the loss of predictive skill that occurred for the 2-waveband (ND2) index with a change in crop type and bandwidth.

(4) Overall, ND4 and ND2 are applicable (at NRMSE = 0.25) even at broader (70–95 nm) bandwidths. This consistency supports their potential application for broadband proximal, airborne and satellite CNC monitoring platforms.

In conclusion, the results of this study support the strong potential of the newly developed indices for consistent CNC map** across growing seasons in ryegrass and barley. The benefits of consistent CNC map** can enable these indices to assist in site-specific management of the economically and ecologically expensive N fertilisers. This consistent CNC sensing capability of ND2 and ND4, when coupled with permissible broad bandwidth (70–95 nm), can also assess carbon and N storage across the crop growth cycle at landscape to ecosystem scale. More research using diverse crop and ecological conditions is necessary to further evaluate the efficacy and robustness of ND2 and ND4 for CNC prediction.

References

Adjorlolo, C., Mutanga, O., & Cho, M. A. (2014). Estimation of canopy nitrogen concentration across C3 and C4 grasslands using WorldView-2 multispectral data. IEEE Journal of Selected Topics in Applied Earth Observations and Remote Sensing, 7, 4385–4392.

Asner, G. P. (1998). Biophysical and biochemical sources of variability in canopy reflectance. Remote Sensing of Environment, 64, 234–253.

Baghzouz, M., Devitt, D. A., & Morris, R. L. (2006). Evaluating temporal variability in the spectral reflectance response of annual ryegrass to changes in nitrogen applications and leaching fractions. International Journal of Remote Sensing, 27, 4137–4157.

Barnes, E.M., Clarke, T.R., Richards, S.E., Colaizzi, P.D., Haberland, J., Kostrzewski, M., Waller, P., Choi C., R.E., Thompson, T., Lascano, R.J., Li, H., Moran, M.S., 2000. Coincident detection of crop water stress, nitrogen status and canopy density using ground based multispectral data, in: Proc. 5th Int. Conf. Precis Agric. pp. 1–15.

Barsi, J. A., Lee, K., Kvaran, G., Markham, B. L., & Pedelty, J. A. (2014). The spectral response of the Landsat-8 operational land imager. Remote Sensing., 6, 10232–10251.

Barton, C. V. M., & North, P. R. J. (2001). Remote sensing of canopy light use efficiency using the photochemical reflectance index: Model and sensitivity analysis. Remote Sensing of Environment, 78, 264–273.

Bassi, D., Menossi, M., & Mattiello, L. (2018). Nitrogen supply influences photosynthesis establishment along the sugarcane leaf. Science and Reports, 8, 1–13.

Bausch, W. C., & Diker, K. (2001). Innovative remote sensing techniques to increase nitrogen use efficiency of corn. Communications in Soil Science and Plant Analysis, 32, 1371–1390.

Berger, K., Verrelst, J., Féret, J.-B., Wang, Z., Wocher, M., Strathmann, M., Danner, M., Mauser, W., & Hank, T. (2020). Crop nitrogen monitoring: Recent progress and principal developments in the context of imaging spectroscopy missions. Remote Sensing of Environment, 242, 111758.

Boegh, E., Soegaard, H., Broge, N., Hasager, C. B., Jensen, N. O., Schelde, K., & Thomsen, A. (2002). Airborne multispectral data for quantifying leaf area index, nitrogen concentration, and photosynthetic efficiency in agriculture. Remote Sensing of Environment, 81, 179–193.

Bossung, C., Schlerf, M., & Machwitz, M. (2022). Estimation of canopy nitrogen content in winter wheat from Sentinel-2 images for operational agricultural monitoring. Precision Agriculture, 23, 2229–2252.

Broge, N. H., & Leblanc, E. (2001). Comparing prediction power and stability of broadband and hyperspectral vegetation indices for estimation of green leaf area index and canopy chlorophyll density. Remote Sensing of Environment, 76, 156–172.

Broge, N. H., & Mortensen, J. V. (2002). Deriving green crop area index and canopy chlorophyll density of winter wheat from spectral reflectance data. Remote Sensing of Environment, 81, 45–57.

Cammarano, D., Fitzgerald, G. J., Casa, R., & Basso, B. (2014). Assessing the robustness of vegetation indices to estimate wheat N in Mediterranean environments. Remote Sens., 6, 2827–2844.

Cao, Z., Ma, R., Duan, H., & Xue, K. (2019). Effects of broad bandwidth on the remote sensing of inland waters: Implications for high spatial resolution satellite data applications. ISPRS Journal of Photogrammetry and Remote Sensing, 153, 110–122.

Chen, P., Haboudane, D., Tremblay, N., Wang, J., Vigneault, P., & Li, B. (2010). New spectral indicator assessing the efficiency of crop nitrogen treatment in corn and wheat. Remote Sensing of Environment, 114, 1987–1997.

Combal, B., Baret, F., Weiss, M., Trubuil, A., Mace, D., Pragnere, A., Myneni, R., Knyazikhin, Y., & Wang, L. (2003). Retrieval of canopy biophysical variables from bidirectional reflectance: Using prior information to solve the ill-posed inverse problem. Remote Sensing of Environment, 84, 1–15.

Curran, P. J. (1989). Remote sensing of foliar chemistry. Remote Sensing of Environment, 30, 271–278.

Dash, J., & Curran, P. J. (2004). The MERIS terrestrial chlorophyll index. International Journal of Remote Sensing, 25, 5403–5413.

Daughtry, C. S. T., Walthall, C. L., Kim, M. S., De Colstoun, E. B., & McMurtrey Iii, J. E. (2000). Estimating corn leaf chlorophyll concentration from leaf and canopy reflectance. Remote Sensing of Environment, 74, 229–239.

El-Shikha, D. M., Barnes, E. M., Clarke, T. R., Hunsaker, D. J., Haberland, J. A., Pinter, P. J., Jr., Waller, P. M., & Thompson, T. L. (2008). Remote sensing of cotton nitrogen status using the canopy chlorophyll content index (CCCI). Transactions of the ASABE, 51, 73–82.

El-Shikha, D. M., Waller, P., Hunsaker, D., Clarke, T., & Barnes, E. (2007). Ground-based remote sensing for assessing water and nitrogen status of broccoli. Agricultural Water Management, 92, 183–193.

Evans, J. R. (1989). Photosynthesis and nitrogen relationships in leaves of C 3 plants. Oecologia, 78, 9–19.

Evans, J. R., & Clarke, V. C. (2019). The nitrogen cost of photosynthesis. Journal of Experimental Botany, 70, 7–15.

Feingersh, T. & Dor, E. B. (2015). SHALOM–A commercial hyperspectral space mission. In Optical payloads for space missions (pp. 247–263).

Feng, W., Zhang, H.-Y., Zhang, Y.-S., Qi, S.-L., Heng, Y.-R., Guo, B.-B., Ma, D.-Y., & Guo, T.-C. (2016). Remote detection of canopy leaf nitrogen concentration in winter wheat by using water resistance vegetation indices from in-situ hyperspectral data. Field Crops Research, 198, 238–246.

Fitzgerald, G., Rodriguez, D., & O’Leary, G. (2010). Measuring and predicting canopy nitrogen nutrition in wheat using a spectral index—The canopy chlorophyll content index (CCCI). Field Crops Research, 116, 318–324.

Gabriel, J. L., Zarco-Tejada, P. J., López-Herrera, P. J., Pérez-Martín, E., Alonso-Ayuso, M., & Quemada, M. (2017). Airborne and ground level sensors for monitoring nitrogen status in a maize crop. Biosystems Engineering, 160, 124–133.

Gamon, J. A., Kovalchuck, O., Wong, C. Y. S., Harris, A., & Garrity, S. R. (2015). Monitoring seasonal and diurnal changes in photosynthetic pigments with automated PRI and NDVI sensors. Biogeosciences, 12, 4149–4159.

Gamon, J. A., Penuelas, J., & Field, C. B. (1992). A narrow-waveband spectral index that tracks diurnal changes in photosynthetic efficiency. Remote Sensing of Environment, 41, 35–44.

Gitelson, A. A. (2004). Wide dynamic range vegetation index for remote quantification of biophysical characteristics of vegetation. Journal of Plant Physiology, 161, 165–173.

Gitelson, A. A., Gamon, J. A., & Solovchenko, A. (2017). Multiple drivers of seasonal change in PRI: Implications for photosynthesis 2 Stand Level. Remote Sensing of Environment, 190, 198–206.

Gitelson, A. A., Kaufman, Y. J., & Merzlyak, M. N. (1996). Use of a green channel in remote sensing of global vegetation from EOS-MODIS. Remote Sensing of Environment, 58, 289–298.

Greenwood, D. J., Lemaire, G., Gosse, G., Cruz, P., Draycott, A., & Neeteson, J. J. (1990). Decline in percentage N of C3 and C4 crops with increasing plant mass. Annals of Botany, 66, 425–436.

Guanter, L., Kaufmann, H., Segl, K., Foerster, S., Rogass, C., Chabrillat, S., Kuester, T., Hollstein, A., Rossner, G., & Chlebek, C. (2015). The EnMAP spaceborne imaging spectroscopy mission for earth observation. Remote Sensing, 7, 8830–8857.

Haboudane, D., Miller, J. R., Tremblay, N., Zarco-Tejada, P. J., & Dextraze, L. (2002). Integrated narrow-band vegetation indices for prediction of crop chlorophyll content for application to precision agriculture. Remote Sensing of Environment, 81, 416–426.

Hallik, L., Kull, O., Niinemets, Ü., & Aan, A. (2009). Contrasting correlation networks between leaf structure, nitrogen and chlorophyll in herbaceous and woody canopies. Basic and Applied Ecology, 10, 309–318.

Hank, T. B., Berger, K., Bach, H., Clevers, J. G. P. W., Gitelson, A., Zarco-Tejada, P., & Mauser, W. (2019). Spaceborne imaging spectroscopy for sustainable agriculture: Contributions and challenges. Surveys in Geophysics, 40, 515–551.

Hansen, P. M., & Schjoerring, J. K. (2003). Reflectance measurement of canopy biomass and nitrogen status in wheat crops using normalized difference vegetation indices and partial least squares regression. Remote Sensing of Environment, 86, 542–553.

He, L., Ren, X., Wang, Y., Liu, B., Zhang, H., Liu, W., Feng, W., & Guo, T. (2020). Comparing methods for estimating leaf area index by multi-angular remote sensing in winter wheat. Science and Reports, 10, 13943. https://doi.org/10.1038/s41598-020-70951-w

He, L., Song, X., Feng, W., Guo, B.-B., Zhang, Y.-S., Wang, Y.-H., Wang, C.-Y., & Guo, T.-C. (2016). Improved remote sensing of leaf nitrogen concentration in winter wheat using multi-angular hyperspectral data. Remote Sensing of Environment, 174, 122–133.

Huete, A. (1988). A soil-adjusted vegetation index (SAVI). Remote Sensing of Environment, 25, 295–309.

Inoue, Y., Sakaiya, E., Zhu, Y., & Takahashi, W. (2012). Diagnostic map** of canopy nitrogen content in rice based on hyperspectral measurements. Remote Sensing of Environment, 126, 210–221.

Jia, W., Coops, N. C., Tortini, R., Pang, Y., & Black, T. A. (2018). Remote sensing of variation of light use efficiency in two age classes of Douglas-fir. Remote Sensing of Environment, 219, 284–297.

Kleman, J., & Fagerlund, E. (1987). Influence of different nitrogen and irrigation treatments on the spectral reflectance of barley. Remote Sensing of Environment, 21, 1–14.

Knox, N. M., Skidmore, A. K., Schlerf, M., De Boer, W. F., Van Wieren, S. E., Van der Waal, C., Prins, H. H. T., & Slotow, R. (2010). Nitrogen prediction in grasses: Effect of bandwidth and plant material state on absorption feature selection. International Journal of Remote Sensing, 31, 691–704.

Kokaly, R. F. (2001). Investigating a physical basis for spectroscopic estimates of leaf nitrogen concentration. Remote Sensing of Environment, 75, 153–161.

Kokaly, R. F., Asner, G. P., Ollinger, S. V., Martin, M. E., & Wessman, C. A. (2009). Characterizing canopy biochemistry from imaging spectroscopy and its application to ecosystem studies. Remote Sensing of Environment, 113, S78–S91.

Lamb, D. W., Steyn-Ross, M., Schaare, P., Hanna, M. M., Silvester, W., & Steyn-Ross, A. (2002). Estimating leaf nitrogen concentration in ryegrass (Lolium spp.) pasture using the chlorophyll red-edge: Theoretical modelling and experimental observations. International Journal of Remote Sensing, 23, 3619–3648.

Lemaire, G., Jeuffroy, M.-H., & Gastal, F. (2008). Diagnosis tool for plant and crop N status in vegetative stage: Theory and practices for crop N management. European Journal of Agronomy, 28, 614–624.

Li, F., Elsayed, S., Hu, Y., & Schmidhalter, U. (2020). Passive reflectance sensing using optimized two-and three-band spectral indices for quantifying the total nitrogen yield of maize. Computers and Electronics in Agriculture, 173, 105403.

Li, F., Li, D., Elsayed, S., Hu, Y., & Schmidhalter, U. (2021). Using optimized three-band spectral indices to assess canopy N uptake in corn and wheat. European Journal of Agronomy, 127, 126286.

Li, F., Miao, Y., Feng, G., Yuan, F., Yue, S., Gao, X., Liu, Y., Liu, B., Ustin, S. L., & Chen, X. (2014a). Improving estimation of summer maize nitrogen status with red edge-based spectral vegetation indices. Field Crops Research, 157, 111–123.

Li, F., Miao, Y., Hennig, S. D., Gnyp, M. L., Chen, X., Jia, L., & Bareth, G. (2010). Evaluating hyperspectral vegetation indices for estimating nitrogen concentration of winter wheat at different growth stages. Precision Agriculture, 11, 335–357.

Li, F., Mistele, B., Hu, Y., Chen, X., & Schmidhalter, U. (2014b). Optimising three-band spectral indices to assess aerial N concentration, N uptake and aboveground biomass of winter wheat remotely in China and Germany. ISPRS Journal of Photogrammetry and Remote Sensing, 92, 112–123.

Loizzo, R., Guarini, R., Longo, F., Scopa, T., Formaro, R., Facchinetti, C., Varacalli, G., 2018. PRISMA: The Italian hyperspectral mission, in: IGARSS 2018–2018 IEEE International Geoscience and Remote Sensing Symposium. IEEE, pp. 175–178.

Lu, B., He, Y., & Dao, P. D. (2019). Comparing the performance of multispectral and hyperspectral images for estimating vegetation properties. IEEE Journal of Selected Topics in Applied Earth Observations and Remote Sensing, 12, 1784–1797.

Marshall, M., & Thenkabail, P. (2015). Advantage of hyperspectral EO-1 Hyperion over multispectral IKONOS, GeoEye-1, WorldView-2, Landsat ETM+, and MODIS vegetation indices in crop biomass estimation. ISPRS Journal of Photogrammetry and Remote Sensing, 108, 205–218.

Nguyen, H. T., & Lee, B.-W. (2006). Assessment of rice leaf growth and nitrogen status by hyperspectral canopy reflectance and partial least square regression. European Journal of Agronomy, 24, 349–356.

Ollinger, S. V. (2011). Sources of variability in canopy reflectance and the convergent properties of plants. New Phytologist, 189, 375–394.

Ollinger, S. V., Smith, M.-L., Martin, M. E., Hallett, R. A., Goodale, C. L., & Aber, J. D. (2002). Regional variation in foliar chemistry and N cycling among forests of diverse history and composition. Ecology, 83, 339–355.

Patel, M. K., Ryu, D., Western, A. W., Fitzgerald, G., Perry, E. M., Suter, H., & Young, I. (2020). Map** Canopy Nitrogen Concentration across Ryegrass and Barley Crop using Random Forest Regression. American Geophysical Union (AGU).

Patel, M. K., Padarian, J., Western, A. W., Fitzgerald, G. J., McBratney, A. B., Perry, E. M., Suter, H., & Ryu, D. (2023). Retrieving canopy nitrogen concentration and aboveground biomass with deep learning for ryegrass and barley: Comparing models and determining waveband contribution. Field Crops Research, 294, 108859.

Patel, M. K., Ryu, D., Western, A. W., Suter, H., & Young, I. M. (2021). Which multispectral indices robustly measure canopy nitrogen across seasons: Lessons from an irrigated pasture crop. Computers and Electronics in Agriculture., 182, 106000. https://doi.org/10.1016/j.compag.2021.106000

Read, J. J., Tarpley, L., McKinion, J. M., & Reddy, K. R. (2002). Narrow-waveband reflectance ratios for remote estimation of nitrogen status in cotton. Journal of Environmental Quality, 31, 1442–1452.

Reich, P. B., & Oleksyn, J. (2004). Global patterns of plant leaf N and P in relation to temperature and latitude. Proceedings of the National Academy of Sciences, 101, 11001–11006.

Rondeaux, G., Steven, M., & Baret, F. (1996). Optimization of soil-adjusted vegetation indices. Remote Sensing of Environment, 55, 95–107.

Rouse, J.W., Haas, R.H., Schell, J.A., Deering, D.W., 1973. Monitoring vegetation systems in the Great Plains with ERTS. Proc. 3rd ERTS Symp. 1, 309–317.

Sims, D. A., & Gamon, J. A. (2002). Relationships between leaf pigment content and spectral reflectance across a wide range of species, leaf structures and developmental stages. Remote Sensing of Environment, 81, 337–354. https://doi.org/10.1016/S0034-4257(02)00010-X

Smith, M.-L., Ollinger, S. V., Martin, M. E., Aber, J. D., Hallett, R. A., & Goodale, C. L. (2002). Direct estimation of aboveground forest productivity through hyperspectral remote sensing of canopy nitrogen. Ecological Applications, 12, 1286–1302.

Stroppiana, D., Boschetti, M., Brivio, P. A., & Bocchi, S. (2009). Plant nitrogen concentration in paddy rice from field canopy hyperspectral radiometry. Field Crops Research, 111, 119–129.

Sun, J., Yang, J., Shi, S., Chen, B., Du, L., Gong, W., & Song, S. (2017). Estimating rice leaf nitrogen concentration: Influence of regression algorithms based on passive and active leaf reflectance. Remote Sensing, 9, 951.

Thenkabail, P. S., Smith, R. B., & De Pauw, E. (2000). Hyperspectral vegetation indices and their relationships with agricultural crop characteristics. Remote Sensing of Environment, 71, 158–182.

Thenkabail, P. S., Smith, R. B., & De Pauw, E. (2002). Evaluation of narrowband and broadband vegetation indices for determining optimal hyperspectral wavebands for agricultural crop characterization. Photogrammetric Engineering and Remote Sensing, 68, 607–622.

Tian, Y.-C., Gu, K.-J., Chu, X., Yao, X., Cao, W.-X., & Zhu, Y. (2014). Comparison of different hyperspectral vegetation indices for canopy leaf nitrogen concentration estimation in rice. Plant and Soil, 376, 193–209.

Tian, Y. C., Yao, X., Yang, J., Cao, W. X., Hannaway, D. B., & Zhu, Y. (2011). Assessing newly developed and published vegetation indices for estimating rice leaf nitrogen concentration with ground-and space-based hyperspectral reflectance. Field Crops Research, 120, 299–310.

Trotter, G. M., Whitehead, D., & Pinkney, E. J. (2002). The photochemical reflectance index as a measure of photosynthetic light use efficiency for plants with varying foliar nitrogen contents. International Journal of Remote Sensing, 23, 1207–1212.

Van Leeuwen, W. J. D., & Huete, A. R. (1996). Effects of standing litter on the biophysical interpretation of plant canopies with spectral indices. Remote Sensing of Environment, 55, 123–138.

Viña, A., Gitelson, A. A., Nguy-Robertson, A. L., & Peng, Y. (2011). Comparison of different vegetation indices for the remote assessment of green leaf area index of crops. Remote Sensing of Environment, 115, 3468–3478.

Wang, W., Yao, X., Yao, **nFeng, Tian, Y., Liu, X., Ni, J., Cao, W., & Zhu, Y. (2012). Estimating leaf nitrogen concentration with three-band vegetation indices in rice and wheat. F. Crop. Res., 129, 90–98.

Woods, H. A., Makino, W., Cotner, J. B., Hobbie, S. E., Harrison, J. F., Acharya, K., & Elser, J. J. (2003). Temperature and the chemical composition of poikilothermic organisms. Functional Ecology, 17, 237–245.

Xu, X., Zhao, C., Wang, J., Zhang, J., & Song, X. (2014). Using optimal combination method and in situ hyperspectral measurements to estimate leaf nitrogen concentration in barley. Precision Agriculture, 15, 227–240.

Yoder, B. J., & Pettigrew-Crosby, R. E. (1995). Predicting nitrogen and chlorophyll content and concentrations from reflectance spectra (400–2500 nm) at leaf and canopy scales. Remote Sensing of Environment, 53, 199–211.

Yu, K., Li, F., Gnyp, M. L., Miao, Y., Bareth, G., & Chen, X. (2013). Remotely detecting canopy nitrogen concentration and uptake of paddy rice in the Northeast China Plain. ISPRS Journal of Photogrammetry and Remote Sensing, 78, 102–115.

Zadoks, J. C., Chang, T. T., & Konzak, C. F. (1974). A decimal code for the growth stages of cereals. Weed Research, 14, 415–421.

Zha, H., Miao, Y., Wang, T., Li, Y., Zhang, J., Sun, W., Feng, Z., & Kusnierek, K. (2020). Improving unmanned aerial vehicle remote sensing-based rice nitrogen nutrition index prediction with machine learning. Remote Sens., 12, 215.

Zhao, B., Duan, A., Ata-Ul-Karim, S. T., Liu, Z., Chen, Z., Gong, Z., Zhang, J., **ao, J., Liu, Z., & Qin, A. (2018). Exploring new spectral bands and vegetation indices for estimating nitrogen nutrition index of summer maize. European Journal of Agronomy, 93, 113–125.

Zhao, D., Huang, L., Li, J., & Qi, J. (2007). A comparative analysis of broadband and narrowband derived vegetation indices in predicting LAI and CCD of a cotton canopy. ISPRS Journal of Photogrammetry and Remote Sensing, 62, 25–33.

Acknowledgements