Abstract

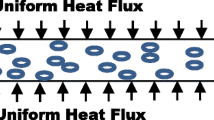

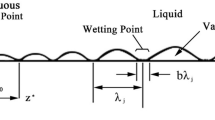

In this paper, subcooled flow boiling heat transfer was experimentally and numerically investigated to determine the temperature distribution, outlet temperature, and heat transfer coefficient in a vertical annulus with laminar upward flow of water as a working fluid. Experiments were developed in a way that the effect of different parameters such as fluid mass flux (26, 35 and 44 kg m−2 s−1), fluid inlet temperature (333 and 343 K), and heat flux (40–90 kW m−2) to be clarified. A mathematical model was then developed to determine the temperature distribution (in r and z directions), and the heat transfer coefficient along the heat transfer surface with the help of the asymptotic model, predicting more accurate results in comparison with Chen’s model. The advantage of this model over the empirical correlations is that it can predict the surface and bulk temperatures according to the operational conditions of the problem and use the obtained temperatures to calculate the thermal parameters of the system along the heat transfer surface, so, there is no need to obtain time-consuming and expensive experimental data. The maximum values of the contribution of nucleate boiling heat transfer mechanism to the total heat transfer were determined about 0.5 to 0.7 with the concept of nucleate boiling fraction. Moreover, the thermal boundary layer thickness was theoretically calculated over the heat transfer surface. The results showed that the maximum boundary layer thickness developed from 0.003 to 0.01 m when the mass flux decreases from 44 to 2.6 kg m−2 s−1. Effect of increasing mass flux and decreasing heat flux on the location of onset of nucleate boiling (ONB) demonstrated that ONB location shifted to the right from 0.017 to 0.043 m in z direction which implied the subcooled flow boiling incipience at the distance lower than 0.05 m from the beginning of the heat transfer surface.

Similar content being viewed by others

Abbreviations

- A :

-

Surface area (m2)

- C p :

-

Specific heat (J kg−1 K−1)

- d :

-

Diameter (m)

- d h :

-

Hydraulic diameter (m)

- f :

-

Friction factor

- F :

-

Enhancement factor

- h :

-

Heat transfer coefficient, a tuning parameter used in B.C. #1 (W m−2 K−1)

- I :

-

Current (A)

- k :

-

Fluid conductivity (W m−1 K−1)

- L :

-

Length (m)

- \(\dot{m}\) :

-

Fluid mass flux (kg s−1)

- Nu:

-

Nusselt number

- p :

-

Pressure (pa)

- \({p}^{*}\) :

-

Reduced pressure (dimensionless)

- Ph:

-

Phase change number

- Pr:

-

Prandtl number

- q :

-

Heat flux (W m−2)

- q exp :

-

Experimental heat flux (W m−2)

- \({q}_{\mathrm{loss}}^{\prime}\) :

-

Heat loss to the ambient (W)

- \({q}_{\mathrm{nominal}}^{\prime}\) :

-

Heat supplied by heater (W)

- Q :

-

Mass flux (kg m−2 s−1)

- R i :

-

Inner radius (m)

- R o :

-

Outer radius (m)

- Re:

-

Reynolds number

- R a :

-

Center line average roughness used in Gorenflo correlation (µm)

- r :

-

Radial direction

- S :

-

Suppression factor

- T :

-

Temperature (K)

- u :

-

Numerical uncertainty

- U :

-

Overall heat transfer coefficient

- ν:

-

Velocity (m s−1)

- V :

-

Voltage

- X :

-

Vapor phase fraction

- X tt :

-

Martinelli parameter

- α :

-

Heat transfer coefficient (W m−2 K−1)

- λ w :

-

Wall conductivity (W m−1 K−1)

- ρ :

-

Density (kg m−3)

- \(\Delta x\) :

-

Distance between thermocouple location and heat transfer surface (m)

- µ :

-

Viscosity (kg m−1 s−1)

- asy:

-

Asymptotic model

- b:

-

Bulk

- Calc.:

-

Calculation

- exp.:

-

Experimental

- fb:

-

Flow boiling

- fc:

-

Forced convection

- In:

-

Inlet

- j:

-

Numerator

- L:

-

Liquid

- Lam:

-

Laminar

- nb:

-

Nucleate boiling

- o:

-

Outlet

- tp:

-

Two phase

- tur:

-

Turbulent

- V:

-

Vapor

- w:

-

Wall/Surface

- z:

-

Axial direction

References

Chen CA, Wanga J, Wen-KenLi FL, Yande W-M. Bubble characteristics during alternating subcooled flow boiling with oscillated refrigerant flow rates—an experimental. Int Commun Heat Mass Transfer. 2021;129:105726.

Fang X, Chen C, Qi Wu, Tian Lu. A method for develo** correlations for subcooled flow boiling heat transfer and its application to water. Fusion Eng Des. 2018;129:286–90.

Bergles AE, Rohsenow WM. The determination of forced-convection surfaceboiling heat transfer. J Heat Transfer. 1964;86:365–72.

Liu Z, Winterton RHS. A general correlation for saturated and subcooled flow boiling in tubes and annuli, based on a nucleate pool boiling equation. Int J Heat Mass Transfer. 1991;34:2759–66.

Bjorg RW, Hall GR, Rohsenow WM. Correlation of forced convection boiling heat transfer data. Int J Heat Mass Transfer. 1982;25:753–7.

McAdams WH, Kennel WE, Minden CS, Carl R, Picornell PM, Dew JE. Heat transfer at high rates to water with surface boiling. Ind Eng Chem. 1949;41(9):1945–53.

Jens WH, Lottes PA. Pressure drop and density date for high-pressure water, analysis of heat transfer, Burnout. Argonne National Lab. Report, ANL-4627; 1951.

Thom JRS, Walker WM, Fallon TAGFS. Reising, boiling in subcooled water during flow up heated tubes or annuli, Presented at the symposium on boiling heat transfer in steam generating units and heat exchangers. Institute of Mechanical Engineers; 1965.

Fang X, Yuan Y, Xu A, Tian L, Wu Q. Review of correlations for subcooled flow boiling heat transfer and assessment of their applicability to water. Fusion Eng Des. 2017;122:52–63.

Kandlikar SG. Heat transfer characteristics in partial boiling, fully developed boiling, and significant void flow regions of subcooled flow boiling. J Heat Transfer. 1998;120(2):395–401.

Sarafraz M, Peyghambarzadeh SM, Marahel A. Mathematical modeling of air duct heater using the finite difference method. Pol J Chem Technol. 2011;13:47–52.

Bejarano ED. A reaction engineering approach to modelling of crude oil fouling deposits: analysis, monitoring and cleaning. A thesis submitted for the degree of Doctor of Philosophy in Chemical Engineering, 2016; pp. 1–102.

Fernandez-Seara J, Uhia FJ, Sieres J. Labratory practices with the wilson plot method. Exp Heat Transfer. 2007;20:123–35.

Bird RB, Stewart WE, Lightfoot N. Transport phenomena. New York: Wiley; 2002. (chapter 2).

Filonenko G. Hydraulic resistance in pipes. Teplonergetika. 1954;1:40–4.

Najibi SH, Muller-Steinhagen H, Jamialahmadi M. Mixed salt crystalization fouling. Chem Eng Process. 1992;52(8):1256–84.

Yan J, Bi Q, Liu Z, Zhu G, Cai L. Subcooled flow boiling heat transfer of water in a circular tube under high heat fluxes and high mass fluxes. Fusion Eng Des. 2015;100:406–18.

Baburajan PK, Bisht GS, Gupta SK, Prabhu SV. Measurement of subcooled boiling pressure drop and local heat transfer coefficient in horizontal tube under LPLF conditions. Nacl Eng Des. 2013;255:169–79.

Fazel A, Ali S, Jamialahmadi M, Safekordi AK. Experimental investigation in pool boiling heat transfer of pure/binary mixtures and heat transfer correlations. Iran Chem Eng J. 2008;27:135–49.

Peyghambarzadeh S, Vatani A, Jamialahmadi M. Application of asymptotic model for the prediction of fouling rate of calcium sulfate under subcooled flow boiling. Appl Therm Eng. 2012;39:105–13.

Ramstorfer F, Steiner H, Brenn G, Kormann C, Rammer F. Subcooled boiling flow heat transfer from plain and enhanced surfaces in automotive applications. J Heat Transfer. 2008;130(1): 011501.

Peyghambarzadeh SM, Sarafraz M, Ameri N, Vatani A, Jamialahmadi M. force convective and subcooled flow boiling heat transfer to pure water and n-heptane in an annular heat exchanger. Ann Nucl Energy. 2013;53:401–10.

Saikia K, Basu DN, Pandeya M. Numerical characterization of thermalhydraulics of subcooled flow boiling through the annular core of a test facility. Ann Nucl Energy. 2022;167: 108836.

Bergman L, Lavine AS. Fundamentals of heat and mass transfer. 8th ed. New York: Wiley; 2017.

Jamialahmadi M, Muller-Steinhagen H, Abdollahi H, Shariati A. Experimental and theoretical studies on subcooled flow boiling of pure liquids and multicomponent mixtures. Int J Heat Mass Transfer. 2008;51(2):482–2593.

Steiner H, Kobor A, Gebhard L. A wall heat transfer model for subcooled boiling flow. Int J Heat Mass Transf. 2005;48:4161–73.

Maurus R, Sattelmayer T. Bubble and boundary layer behaviour in subcooled flow boiling. Int J Therm Sci. 2006;45:257–68.

Lucic A, Emans M, Mayinger F, Zenger C. Inteferometric and numerical study of the temperature field in the boundary layer and heat transfer in subcooled flow boiling. Int J Heat Fluid Flow. 2004;25:180–95.

Chen CA, Li KW, Lin TF, Li W-K, Yan W-M. Study on heat transfer and bubble behavior inside horizontal annuli: experimental comparison of R-134a, R-407C, and R-410A subcooled flow boiling. Case Stud Therm Eng. 2021;24: 100875.

Hsieh YY, Chiang LJ, Lin TF. Subcooled flow boiling heat transfer of R-134a and the associated bubble characteristics in a vertical plate heat exchanger. Int J Heat Mass Transf. 2002;45:1791–806.

Zhang T, Liu Y. Numerical investigation of flow and heat transfer Characteristics of subcooled boiling in a single rod channel with/without spacer grid. Case Stud Therm Eng. 2020;20:10064.

Warrier GR, Dhir VK. Heat transfer and wall heat flux partitioning during subcooled flow nucleate boiling—a review. J Heat Transf. 2006;128:1243–56.

Eraghubi M, Di Marco P, Robinson AJ. Low mass flux upward vertical forced flow boiling of HFE7000. Exp Therm Fluid Sci. 2019;102:291–301.

Vadlamudi SRG, Nayak A. Review of literature on departure from nucleate boiling in subcooled flow boiling. Multiph Sci Technol. 2018;30(4):247–66.

Wang S, Bi X. boiling heat transfer in small rectangular channels at low Reynolds number and mass flux. Exp Themal Fluid Sci. 2016;77:234–45.

Hua S, Huang R, Li Z, Zhou P. Experimental study on the heat transfer characteristics of subcooled flow boiling with cast iron heating surface. Appl Therm Eng. 2015;77:180–91.

Li Z, Huang R, Wang Z. Subcooled boiling heat transfer modelling for internal combustion engine applications. Proc Inst Mech Eng, Part D. 2012;226(3):301–11.

Vasudevan S, Etemad S, Davidson L, Villar GM. Numerical model to estimate subcooled flow boiling heat flux and to indicate vapor bubble interaction. Int J Heat Mass Transf. 2021;170: 121038.

Khoshnevis A, Sarchami A, Ashgriz N. Effect of nucleation bubble departure diameter and frequency on modeling subcooled flow boiling in an annular flow. Appl Therm Eng. 2018;138:280–8.

Najibi SH, Muller-Steinhagen H, Jami al ahmadi M. Calcium sulafate scale formation during subcooled flow boiling. Chem Eng Sci. 1996;52:1265–84.

Thorncroft GE, Klausner JF, Mei R. An experimental investigation of bubble growth and detachment in vertical upflow and downflow boiling. Int J Heat Mass Transfer. 1998;41:3857–71.

Vosough A, Peyghambarzadeh SM, Assari MR. Influence of thermal shock on mitigation of calcium sulfate crystallization fouling under subcooled flow boiling condition. Appl Therm Eng. 2020;164: 114434.

Paakkonen TM, Riihimaki M, Simonson CJ, Muurinen E, Keiski RL. Modelling CaCo3 crystalization fouling on a heat exchanger surface-definition of fouling layer prperties and model parameters. Int J Heat Mass Transf. 2015;83:84–98.

Levy SC. Forced convection subcooled boiling-prediction of vapor volumetric fraction. Int J Heat Mass Transfer. 1967;10:951–65.

Gnielinski V. New equations for heat and mass transferin turbulent pipe and channel flow. Int Chem Eng. 1976;16:359–68.

Moffa RJ. Using uncertainty analysis in the planning of an expriment. J Fluids Eng. 1985;107:173–8.

Chen JC. A correlation for boiling heat transfer to saturated fluids in convective flow. Ind Eng Chem Process Design Dev. 1966;5(3):322–9.

Kutateladze SK. Boiling heat transfer. Int J Heat Mass Transfer. 1961;4:3–45.

Gorenflo D. State of the art in pool boiling heat transfer of new refrigerants. Int J Refrig. 2001;24:6–14.

Liu W. Prediction of critical heat flux for subcooled flow boiling in annulus and transient surface temperature change at CHF. Fluids. 2022;7:230.

Massey BS. Mechanics of fluids. 8th ed. New York: Taylor & Francis; 2006.

Gorenflo D, Sokol P. Prediction method of pool boiling heat transfer with cryogenic liquids. Int J Refrig. 1988;11:315–20.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendices

Appendix A

Wilson plot technique for calculation of \(\frac{\Delta x}{{\uplambda }_{\mathrm{w}}}\)

The actual surface temperature can be calculated using Fourier’s conduction equation, as follows:

The value of \(\Delta x/\lambda_{{\text{w}}}\) is obtained for thermocouples using Wilson plot technique. The main goal of Wilson plot technique is calculation of convection coefficient of the fluid or any other thermal resistance participated in the overall thermal resistance. The overall thermal resistance of the system can be expressed as the sum of two thermal resistances corresponding to the stainless steel wall and convection from surface to the fluid bulk.

Equation (42) can be simplified to Eq. (43):

where U denotes the overall thermal heat transfer coefficient, and \(\alpha\) is heat transfer coefficient. For estimating \( \frac{\Delta x}{{\lambda_{{\text{w}}} }}\), the value of heat transfer coefficient is necessary. Mathematical relationship of heat transfer coefficient to some measurable values like friction factor (f) and velocity (v) can be presented as follows [37]:

The friction factor related to Reynolds number according to Blasius’s correlation [52].

Combination of Eqs. (44) and (45) yields Eq. (46).

where

By combining Eqs. (46) and (47) and inserting into Eq. (43) as well as bringing together all the constants as “C1”, Eq. (48) is obtained:

Equation (48) shows that the plot of 1/U versus 1/v0.75 for each thermocouple gives the values of \(\frac{\Delta x}{{\lambda_{{\text{w}}} }}\) as the intercept of the line. A sample figure, Fig.

16 is plotted for one of the thermocouples to show the variation of overall thermal resistance (U−1) against ν−0.75. As can be seen from Fig. 16, the value of \(\frac{\Delta x}{{\lambda_{{\text{w}}} }}\) is estimated about 6 \(\times\) 10–4 m2 K W−1 and applied to modify the surface temperature using Eq. (41).

Appendix B

The temperature dependent physical properties of water used in Eq. (10):

Appendix C

Algorithm used for calculation of tuning parameters of α0 and n based on the experimental data applied in Chen and asymptotic models.

Appendix D

Algorithm used in this research to solve the equation in the subcooled flow boiling region.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Dashtban, M., Peyghambarzadeh, S.M., Alavi Fazel, S.A. et al. Mathematical modeling and experimental validation of heat transfer during upward subcooled flow boiling in a vertical annulus. J Therm Anal Calorim 148, 13519–13541 (2023). https://doi.org/10.1007/s10973-023-12657-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-023-12657-5