Abstract

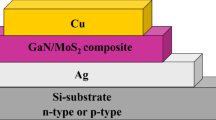

In this study, we present the fabrication and characterization of a thin film based on 1 T-MoS2 pn photodiode for the purpose of quick response photodetection application. The photodiode was fabricated using RF-sputtering process. The scanning electron microscopy (SEM) and Fourier-transform infrared spectroscopy (FTIR) techniques were employed to investigate the surface topology and structural characteristics of the nanostructured MoS2 thin film. The electrical properties of the photodiode that was produced were examined by conducting measurements of its current–voltage (I-V) characteristics across a range of bias voltages spanning from − 2 to + 2 V. The external quantum efficiency (EQE) of the pn photodiode that was produced was determined to be as high as 9.8%. Additionally, the internal quantum efficiency (IQE) was found to be as high as 10.5%. Furthermore, a time response of 1.748 ms was observed. The findings of this study illustrate the capability of MoS2 photodiodes in facilitating rapid response photodetection applications.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The appeal of low dimensional materials, particularly 2-D layered materials, stems from their ability to provide access to new physical phenomena. Additionally, their distinct chemical, mechanical, optical, and electrical properties make them highly desirable from a technological perspective. Graphene, along with other 2-D layered materials like hexagonal boron nitride (h-BN) and recently discovered 2-D nanostructures of Bi2Se3 and Bi2Te3 (known as topological insulator materials), exhibit great potential as candidates for a wide range of nanoelectronics applications in the future [1,2,3,4,5]. The family of transition metal di-chalcogenides (TMDC), which include compounds such as MoS2, WS2, WSe2, and others, is a distinct category of two-dimensional materials that has garnered growing attention within the scientific community [6,7,8,9,10,11,12]. While graphene exhibits the maximum measured mobility of over 100,000 cm2/Vs [13] among this group, its electrical band structure lacks a band gap, making it unsuitable for certain applications. However, this characteristic has paved the way for the exploration of semiconducting 2D materials such as MoS2 and others [14, 15]. The material known as MoS2 has the characteristic of being a semiconductor, and it possesses the quality of tunability of its bandgap based on its thickness. In its bulk form, MoS2 has an indirect bandgap value of 1.2 eV. The bilayer form of MoS2 demonstrates an initial indirect bandgap of 1.3 eV, which transitions to a direct bandgap of 1.8 eV in its monolayer counterpart. Additionally, it possesses an electron affinity of 4.0 eV [16, 17]. In addition, the intrinsic high absorption coefficients, exceeding 5 × 107 m−1 in the visible spectrum, position MoS2 as a material with significant potential for improving the efficacy of optical detection. The photodetection efficiency of 2D photodetectors utilising MoS2 was enhanced at specific wavelength ranges by modifying its exceptional features [18,19,20,21,22,2.3 Fabricated photodiode figures of merit measurements The primary component of the indoor arrangement for characterizing the IV photodiode is the halogen lamp. The CMP6 pyranometer/reference sensor and the Device Under Test (DUT) are securely mounted on an automated stage. The generated beam was directed towards the CMP6 pyranometer and the DUT in an alternating manner, as shown in Fig. 2. The measurement of the current–voltage (I-V) characteristics of a photodiode involves varying the load voltage while maintaining a constant irradiance (G) of 100 mW/cm2 and a fixed temperature of DUT at 25 °C. The CMP6 pyranometer is a thermopile detector used for measuring irradiance. It is classified as a First-Class instrument according to ISO 9060:1990 standards. The reaction time (63%) of the pyranometer is less than 6 s and it is capable of detecting radiation throughout the spectral range of 285–2800 nm [31]. The direct current voltage was applied to the DUT. The voltage across the DUT and the voltage across a reference shunt resistor of 100 Ω were measured using two Keithley 2010 multimeters in order to obtain the current measurement [32, 33]. IV characteristic system measurements. 1. Halogen lamp; 2. Motorized stage; 3. CMP6 Pyranometer/reference photodetector; 4. DUT; 5. Keithley 2010 (voltage reading); 6. Keithley 2010 (voltage drop across reference shunt resistance); 7. Keithley 2002 for irradiance measurement; 8. dc load power supply; 9. Personal Computer; 10. Power supply for halogen lamp Figure (3) schematically shows the experimental setup for measuring the spectral responsivity. The fabricated photodiodes spectral responsivity has been evaluated using different Light Emitting diodes (LED) at certain wavelengths (430 nm, 463 nm, 481 nm, 535 nm, 545 nm, 645 nm, 650 nm, 744 nm, 769 nm) as an optical source. As shown in Fig. (3), The reference detector measures the power at the chosen wavelengths; this is followed by the DUT measuring the signal in its focus. DUT measures dark current when the shutter is closed, and when it is opened the signal is measured. By means of a transitional stage the reference detector is allowed to detect the dark current and the signal level at the same wavelength as DUT, at the previously stated wavelengths of LED the process is repeated [34]. DUT spectral responsivity RDUT(λ) has been calculated by analogy with the reference detector [35,36,37], by the aid of (1): The symbol SDUT (λ) represents the signal photocurrent of the DUT at a certain wavelength (λ). SREF (λ) denotes the signal photocurrent measured by the reference detector, while RREF (λ) represents the spectral responsivity data of the reference detector in units of amperes per watt (A/W). In our particular situation, the amplifier's gain is denoted by G and has a value of 1. The diameter of the incident beam on the detector was approximately adjusted to 3 mm. The photocurrent response of both the reference detector and the detector under calibration was recorded at each wavelength. The measurements were conducted in the laboratory facilities of NIS, where the temperature of the detector under examination was maintained at 23.0 °C ± 1.0 °C. The temperature sensor included within the transfer detector was utilized to regulate the reading process. The temperature was controlled using the thermoelectric cooler (TEC) and recorded both prior to and following each measurement at a certain wavelength. Adequate time was allowed to ensure that the detector and the device under test (DUT) reached thermal equilibrium. The structure Fig. (4) is intended to obtain the fast response time for an MSM type photodetector by providing a directional current path. A fast response time to light is one of the essential factors for evaluating a photodetector, using a mechanical chopper adjusted at 25 Hz as an optic modulator. Quantum efficiency (Q.E.) is a quantifiable measure of the effectiveness of incident radiant flux in producing measurable quantities, such as temperature or current, within a sensor. The effects under consideration can be categorized as either internal quantum efficiency (IQE) or external quantum efficiency (EQE), depending on the specific portion of light involved in their manifestation. IQE of a photodiode refers to the ratio of the number of electron–hole pairs generated to the number of absorbed photons. On the other hand, EQE represents the ratio of the number of electron–hole pairs formed to the number of incident photons [38]. QE is commonly represented as a mathematical function that relates to certain characteristics such as wavelength, absorption coefficient, frequency, and so on. Furthermore, in the scenario where incident photons are fully absorbed and all resulting minority carriers actively participate in the current generation process at a certain wavelength, QE is considered to be equal to one. The parameters that contribute to QE reduction below unity include optical reflection losses, carrier recombination, defects, passivating layer thickness, and do** level [39]. Incident radiant flux on a photodiode undergoes reflectance, absorbance and transmittance events. The percentage of the incident photons that influence to photocurrent is expressed as \({\eta }_{e}\) [38, 40, 41] and is calculated using Eq. (2), where, \(R\left(\lambda \right)\) is the responsivity, h is Planck’s constant, \(\lambda \) is the wavelength, e is the electronic charge Is obtained by the aid of responsivity and reflectance [40] as given by Eq. (3), where, \(\rho \left(\lambda \right)\) is the reflectance of the photodiode.2.3.1 I-V characteristics of the fabricated pn-photodiode

2.3.2 Spectral power responsivity.

2.3.3 Response Time measurement

2.3.4 Quantum efficiency (Q.E.)

2.3.4.1 External quantum efficiency \(\left({{\varvec{\eta}}}_{{\varvec{e}}}\right)\)

2.3.4.2 Internal quantum efficiency \(\left({{\varvec{\eta}}}_{{\varvec{i}}}\right)\)

3 Results and discussion:

3.1 Characterization of (DUT) fabricated photodiode

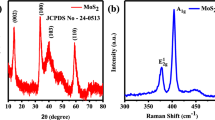

3.1.1 FTIR analysis

Optical characterization of the DUT was performed with FTIR as shown in Fig. 5. FTIR represents different peaks that are attributed to the different layer compositions of DUT. It shows small peak range between 3113 and 3370 cm−1 attributed to Si- wafer substrate [42]. As well silicon lattice phonons assigned at ~ 480 cm−1 [43]. The small peak ranged at ~ 2130 cm−1 attributed to middle Ag-layer [44]. However, the upper layer content MoS2 was attributed by broad band ranged at 860–1300 cm−1 representing stretching vibration bond of MoS2 and two peaks at 1616, 1424 cm−1 which may be ascribed to presence of 1T-MoS2 phase [45].

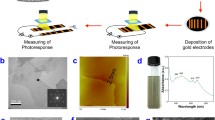

3.1.2 SEM and map**

Scanning electron microscopy (SEM) was utilized to characterize the surface morphology of the investigated films, fig. (6:a→c) shows a representative SEM image of nanostructured MoS2 thin film deposited by RF-magnetron sputtering Also, the fine quality of the deposited MoS2 layer was clearly verified when going down to 1 μm scale bar. Thickness was measured and was shown in Fig. 6b, 6c. SEM investigation also verifies that the film has smooth surface without pinholes, the particles are distributed uniformly throughout the MoS2 thin film, which indicates a homogeneous film surface. RF-sputtering offers a smooth shiny surface observed by the eye. Elemental constituents of the deposited thin film is confirmed by map** analysis Fig. (7) and Table (1). Table (1) shows the concentration percentage of materials in all thin film layers, the concentration depends mainly on the thickness of each layer.

3.2 Fabricated photodiode performance parameters

3.2.1 I-V characteristics

Figure 8 illustrates the current–voltage (I-V) characteristics of a MoS2 pn-photodiode with a Cu top electrode (referred to as the Cu-device) under reverse bias conditions. The Ag electrode is negatively biased in both the absence of light (dark condition) and when the device is illuminated. It is observed that the magnitude of electric currents is significantly greater when the system is exposed to illumination compared to when it is in a dark environment. As an illustration, when the voltage (Vd) across the device is 3.9 V, the current (Idark) in the absence of illumination is measured to be 0.56 mA. Conversely, when the device is exposed to an illumination intensity of 100 mW/cm2, the current (Iillumination) is found to be 2.54 mA, which is 4.5 times greater than the dark current. The primary factor influencing the current in the presence of light illumination and a specific reverse bias voltage is the density of charge carriers created by photons. In conditions of low light intensities, characterized by a low density of photo carriers, it is seen that only shallow traps are occupied, resulting in a correspondingly low trapped charge density. Consequently, the rate at which the photocurrent increases with increasing light intensity is found to be high. Nevertheless, when the intensity of light grows, the density of photo charge carriers also increases. Consequently, deep traps become occupied, resulting in trapped charge limiting conduction. As a result, the rate at which the photocurrent increases with light intensity is attenuated [46, 47].

3.2.2 Device spectral responsivity

Photoresponse curve for the fabricated pn-photodiode Fig. (9) is presented and it was found that its maximum responsivity was \(42.21{\text{mA}}/{\text{W}}\) @ 535nm and this is attributed to huge amount of charge carriers accumulated upon the silver layer by surface plasmon resonance (SPR) by the collective oscillation of conduction band electrons that are in resonance with the oscillating electric field of incident light when illuminating the top layer of the upper electrode with the selected wavelengths. This will produce energetic plasmonic electrons through non-radiative excitation that in turn enhances the current flow after the (e–h) pair recombination.

3.2.3 Time response measurement

The photoresponse time refers to the duration it takes for a photosensitive material or device to exhibit a measurable reaction to incident light. The response of \({\tau }_{response}\) is dependent on the rise time (τrise) and fall time (τfall), which represent the durations for the photocurrent to grow from 0 to 90% of maximum photocurrent and decrease from 100 to 0% of maximum photocurrent accordingly. The measurement of \({\tau }_{response}\) for a thin film pn-photodiode based on MoS2 was conducted at a switching frequency of 3 s and a power density of 0.8 mW/cm2, as depicted in Fig. 10. The obtained value for \({\tau }_{response}\) was determined to be 1.748 ms. The sensitivity of the response time of atomically thin MoS2 to surface interaction and defect states is widely acknowledged in the scientific community. The reduction in carrier lifespan will result in a significant decrease in response time. There is a significant improvement in response time of our device compared to previously prepared MoS2 devices. The rapid reaction of the manufactured pn-photodiode can be attributed to the electron cloud generated by the silver layer underlying the MoS2 layer. This electron cloud generates a significant number of holes, resulting in a downward shift of the Fermi level. In addition, this phenomenon will result in a change in the threshold voltage and a decrease in the carrier lifetime, ultimately leading to the suppression of its inherent n-type characteristics [42].

3.2.4 Specular reflectance measurement ρ(λ) and Q.E.

Specular reflectance for the fabricated device Fig. (11) was measured using UV–VIS-NIR scanning spectrophotometer (UV-3101PC) and maximum peaks was determined for pn photodiode to be @ 421nm, 653 nm also \({\eta }_{e}\) and \({\eta }_{i}\) for the fabricated photodiode was determined Figs. (12, 13) as the largest E.Q.E was 9.8% @ λ = 535 nm and largest I.Q.E. was 10.5% @ λ = 535 nm.

4 Conclusion

A photodiode utilising a p–n junction has been successfully manufactured using MoS2 as the semiconductor material which formed by RF-sputtering PVD method yielded 1T metallic phase. This phase has a tetragonal symmetry with octahedral coordination and a one-layer unit cell. 1T MoS2 exhibits great potential as a material for electrical devices and energy conversion processes. A comprehensive evaluation has been conducted to examine the performance and properties of the fabricated device. The measured dark current \(\left({I}_{d}\right)\) at a voltage Vd of 3.9 V was found to be 0.56 mA. The measured value of the illumination current \(\left({I}_{illumination}\right)\) was 2.54 mA. The highest recorded responsivity was 42.21 mA/W at a wavelength of 535nm. Additionally, the measured response time \(\left({\tau }_{response}\right)\) was found to be 1.748 ms, resulting in an external quantum efficiency (Q.E) of up to 9.8% at a wavelength (λ) of 535 nm, and an internal quantum efficiency of up to 10.5% at the same wavelength (λ = 535 nm). The measured transient period was found to be relatively small. This observation was attributed to the building of free electron clouds caused by the surface plasmonic phenomena generated by the Ag thin film layer beneath the MoS2 thin film. This accumulation induces a large number of holes and results in a downward shift of the Fermi level. In addition, this phenomenon will result in a shift in the threshold voltage and a decrease in the carriers’ lifetime.

Data availability

Raw data were generated at the [Cairo University] large-scale facility. Derived data supporting the findings of this study are available from the corresponding author upon request.

References:

K.S. Novoselov et al., Proc. Natl. Acad. Sci. U.S.A. 102, 10451 (2005)

S. Kim et al., Appl. Phys. Lett. 94, 062167 (2009)

A. Lipp et al., J. Eur. Ceram. Soc. 5, 3 (1989)

P. Avouris, Nano Lett. 10, 4285 (2010)

H. Zhang et al., Nat. Phys. 5, 438 (2009)

J. Per et al., Mater. Res. Bull. 21, 457 (1986)

J.A. Wilson et al., Adv. Phys. 18, 193 (1969)

B. Radisavljevic et al., Nat. Nanotechnol. 6, 147 (2011)

W.S. Hwang et al., Appl. Phys. Lett. 101, 013107 (2012)

H. Fang et al., Nano Lett. 12, 3788 (2012)

B. Radisavljevic et al., ACS Nano 5, 9934 (2011)

H. Wang et al., Nano Lett. 12, 4674 (2012)

K.I. Bolotin et al., Solid State Commun. 146, 351 (2008)

Y. Yoon et al., Nano Lett. 11, 3768 (2011)

C. Chang et al., Nano Lett. 12, 1538 (2012)

S.W. Han et al., Phys. Rev. B 84, 045409 (2011)

J. Salmani et al., 2011 International Semiconductor Device Research Symposium (ISDRS) (IEEE, 2011)

H.S. Lee et al., Nano Lett. 12, 3695 (2012)

Z. Yin et al., ACS Nano 6, 74 (2012)

S.H. Yu et al., ACS Nano 8, 8285 (2014)

O. Lopez-Sanchez et al., Nat. Nanotechnol. 8, 497 (2013)

W. Zhang et al., Sci. Rep. 4, 3826 (2014)

F. **a et al., Nat. Photonics 8, 899 (2014)

Y.-H. Lee et al., Adv. Mater. 24, 2320 (2012)

Y. Zhan et al., Small 8, 966 (2012)

K.-K. Liu et al., Nano Lett. 12, 1538 (2012)

J. Jeon et al., Nanoscale 7, 1688 (2015)

K.O. Legg , W.D. Sproul (eds.), Opportunities for Innovation: Advanced Surface Engineering (Technomic Publishing Co., Switzerland, 1995)

R. Chen et al., Adv. Elect. Mater. 8, 2200281 (2022)

S. Aftab et al., Nanotechnology 29, 045201 (2017)

E.M. El-Mahdy, S. Abd El-Mongy, A.M. Karmalawi, IEEE Instrum. Meas. Mag 25, 22 (2022)

G. P. Leary, Thesis for M.S. degree at Montana State University, Bozeman, Montana, USA (2019)

A. Van Der Heide, Renewable Energy (2005), p. 4

L.C. Alves, et al., Spatial uniformity of the silicon photodiodes for establishment of spectral responsivity scale, 19th IMEKO World Congress 2009 (2009), p. 1218

M.S. Lima, et al., Spectral responsivity calibration of the linear pyrometer of Inmetro, in 18th IMEKO World Congress 2006: Metrology for a Sustainable Development, vol. 2 (2006), p. 1068

Y.S. Yoo et al., Metrologia 53, 1354 (2016)

K. Mahmoud et al., Appl. Opt. 52, 1263 (2013)

Ö. Bazkir, Rev. Adv. Mater. Sci. 21, 90 (2009)

P. J. Key, N. P. Fox, M. L. Rastello., Metrologia. 21, 81 (1985)

A. Ferrero et al., Appl. Opt. 44, 208 (2005)

C. Hicks et al., Appl. Opt. 42, 4415 (2003)

A. Lamberti et al., J. Atom. Mol. Opt. Phys. (2012). https://doi.org/10.1155/2012/948390

S. Hava, J. Ivri, M. Auslender, J. Opt. A Pure Appl. Opt. 3, S190 (2001)

S. Bhagyaraj, I. Krupa, Molecules 25, 435 (2020)

S. Yougbaré et al., Nanomaterials 11, 3064 (2021)

G. Konstantatos et al., Nat. Photon. 1, 531 (2007)

J.P. Clifford et al., Nat. Nanotechnol. 4, 40 (2009)

Acknowledgements

The authors would give their sincere thanks and gratefulness to NILES, Cairo University, for the encouragement, great help and endless support to come out with this study. The authors are thankful to the dean ship of scientific research at the university of Bisha for supporting this work through the Fast-Track Research support program.

Funding

Open access funding provided by The Science, Technology & Innovation Funding Authority (STDF) in cooperation with The Egyptian Knowledge Bank (EKB). Open access funding provided by The Science, Technology & Innovation Funding Authority (STDF) in cooperation with The Egyptian Knowledge Bank (EKB). The authors declare that no funds, grants, or other support were received during the preparation of this manuscript.

Author information

Authors and Affiliations

Contributions

“All authors contributed to the study conception and design. Material preparation, data collection, measurements and analysis were performed by [Ahmed Abdelhady A. Khalil], [Abdallah M. Karmalawi] and [Alaaeldin A. Abdelmageed]. The first draft of the manuscript was written by [Hamdan A. S. Al-shamiri], [Heba A. Shawkey] and all authors commented on previous versions of the manuscript. All authors read and approved the final manuscript. Revised by [Maram T. H. Abou Kana], [Hamed M. Kandel] and [Mohamed A. Swillam].

Corresponding author

Ethics declarations

Conflict of interest

The authors have no competing interests to declare that are relevant to the content of this article.

Research involving Huma/animal participants

All authors certify that research fabrication, analysis and measurement procedure steps don’t include experiments on human and/or animals.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Khalil, A.A.A., Karmalawi, A.M., Abdelmageed, A.A. et al. Fast response fabricated MoS2-photodiode based thin film. J Mater Sci: Mater Electron 35, 546 (2024). https://doi.org/10.1007/s10854-024-12204-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10854-024-12204-4