Abstract

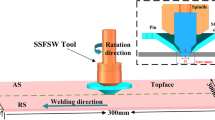

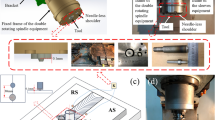

The effect of stationary shoulder friction stir welding (SSFSW) on temperature gradient and material flow was investigated to optimize the SSFSW process. A three-dimensional numerical model of heat generation and material flow was established by using computational fluid dynamics, and thermo-physical phenomena of SSFSWed Ti-6Al-4V were quantitatively analyzed in terms of heat generation, heat transfer, material flow and viscosity. The temperature gradient was more uniform in a narrow stir zone produced by the SSFSW process. The distribution of velocity was studied, and instantaneous velocity center of tool was divided into two different velocity regions to study the material flow. The simulation results were verified by experimental thermal cycles of calculated position of model, which was in accordance with the experimental results.

Similar content being viewed by others

References

Fratini L, Buffa G (2005) CDRX modelling in friction stir welding of aluminum alloys. Int J Mach Tools Manuf 45:1188–1194. https://doi.org/10.1016/j.ijmachtools.2004.12.001

Banerjee D, Williams JC (2013) Perspectives on titanium science and technology. Acta Mater 61:844–879. https://doi.org/10.1016/j.actamat.2012.10.043

Liu H, Fujii H, Maeda M, Nogi K (2003) Tensile properties and fracture locations of friction-stir welded joints of 6061–T6 aluminum alloy. J Mater Sci Lett 22:1061–1063. https://doi.org/10.1023/A:1024970421082

He X, Gu F, Ball A (2014) A review of numerical analysis of friction stir welding. Prog Mater Sci 65:1–66. https://doi.org/10.1016/j.pmatsci.2014.03.003

Meng X, Huang Y, Cao J, Shen J, dos Santos JF (2021) Recent progress on control strategies for inherent issues in friction stir welding. Prog Mater Sci. https://doi.org/10.1016/j.pmatsci.2020.100706

Zhou L, Liu HJ, Liu QW (2010) Effect of rotation speed on microstructure and mechanical properties of Ti-6Al-4V friction stir welded joints. Mater Des 31:2631–2636. https://doi.org/10.1016/j.matdes.2009.12.014

Zhou L, Liu HJ, Liu QW (2010) Effect of process parameters on stir zone microstructure in Ti-6Al-4V friction stir welds. J Mater Sci 45:39–45. https://doi.org/10.1007/s10853-009-3881-1

Zhou L, Liu HJ, Liu P, Liu QW (2009) The stir zone microstructure and its formation mechanism in Ti–6Al–4V friction stir welds. Scripta Mater 61:596–599. https://doi.org/10.1016/j.scriptamat.2009.05.029

Jiang X, Wynne BP, Martin J (2018) Variant selection in stationary shoulder friction stir welded Ti-6Al-4V alloy. J Mater Sci Technol 34:198–208. https://doi.org/10.1016/j.jmst.2017.11.024

Jiang X, Wynne BP, Martin J (2015) Microstructure and texture evolution of stationary shoulder friction stir welded Ti6Al4V alloy. Sci Technol Weld Joining 20:594–600. https://doi.org/10.1179/1362171815y.0000000043

Davies PS, Wynne BP, Rainforth WM, Thomas MJ, Threadgill PL (2011) Development of microstructure and crystallographic texture during stationary shoulder friction stir welding of Ti-6Al-4V. Metall Mater Trans A-Phys Metall Mater Sci 42A:2278–2289. https://doi.org/10.1007/s11661-011-0606-2

Bai Y, Jiang X, Chen S, Jiang W, Han Y, Yuan T, Wang X (2021) Microstructure and properties of electrically assisted stationary shoulder friction stir welded Ti6Al4V. Sci Technol Weld Joining 26:377–388. https://doi.org/10.1080/13621718.2021.1923441

Li D, Yang X, Cui L, He F, Zhang X (2015) Investigation of stationary shoulder friction stir welding of aluminum alloy 7075–T651. J Mater Process Technol 222:391–398. https://doi.org/10.1016/j.jmatprotec.2015.03.036

Sun GD, Zhou L, Liu YN, Yang HF, Jiang JT, Li GA (2022) Microstructure characterization and evaluation of mechanical properties in 2A97 aluminum-lithium alloys welded by stationary shoulder friction stir welding. J Market Res 16:416–432. https://doi.org/10.1016/j.jmrt.2021.12.004

Buffa G, Fratini L, Impero F, Masnata A, Scherillo F, Squillace A (2020) Surface and mechanical characterization of stationary shoulder friction stir welded lap joints: experimental and numerical approach. IntJ Mater Form 13:725–736. https://doi.org/10.1007/s12289-020-01574-9

Iqbal MP, Tripathi A, Jain R, Mahto RP, Pal SK, Mandal P (2020) Numerical modelling of microstructure in friction stir welding of aluminum alloys. Int J Mech Sci. https://doi.org/10.1016/j.ijmecsci.2020.105882

Chen GQ, Feng ZL, Chen J, Liu L, Li H, Liu Q, Zhang S, Cao X, Zhang G, Shi QY (2017) Analytical approach for describing the collapse of surface asperities under compressive stress during rapid solid state bonding. Scripta Mater 128:41–44. https://doi.org/10.1016/j.scriptamat.2016.10.015

Chen G, Ma Q, Zhang S, Wu J, Zhang G, Shi Q (2018) Computational fluid dynamics simulation of friction stir welding: a comparative study on different frictional boundary conditions. J Mater Sci Technol 34:128–134. https://doi.org/10.1016/j.jmst.2017.10.015

Wang X, Gao Y, Liu X, McDonnell M, Feng Z (2021) Tool-workpiece stick-slip conditions and their effects on torque and heat generation rate in the friction stir welding. Acta Mater. https://doi.org/10.1016/j.actamat.2021.116969

Chen S, Han Y, Jiang X, Li X, Yuan T, Jiang W, Wang X (2021) Study on in-situ material flow behavior during friction stir welding via a novel material tracing technology. J Mater Process Technol. https://doi.org/10.1016/j.jmatprotec.2021.117205

Ulysse P (2002) Three-dimensional modeling of the friction stir-welding process. Int J Mach Tools Manuf 42:1549–1557. https://doi.org/10.1016/s0890-6955(02)00114-1

Colegrove PA, Shercliff HR (2003) Experimental and numerical analysis of aluminum alloy 7075–T7351 friction stir welds. Sci Technol Weld Joining 8:360–368. https://doi.org/10.1179/136217103225005534

Nandan R, DebRoy T, Bhadeshia H (2008) Recent advances in friction-stir welding - process, weldment structure and properties. Prog Mater Sci 53:980–1023. https://doi.org/10.1016/j.pmatsci.2008.05.001

Nandan R, Lienert TJ, DebRoy T (2008) Toward reliable calculations of heat and plastic flow during friction stir welding of Ti-6Al-4V alloy. Int J Mater Res 99:434–444. https://doi.org/10.3139/146.101655

Wu CS, Su H, Shi L (2018) Numerical simulation of heat generation, heat transfer and material flow in friction stir welding. Acta Metall Sin 54:265–277. https://doi.org/10.11900/0412.1961.2017.00294

Shi L, Chen J, Wu CS, Fu L (2021) Analysis of heat and mass transfer in ultrasonic vibration-enhanced friction stir welding of 2195 Al–Li alloy. Sci Technol Weld Joining 26:363–370. https://doi.org/10.1080/13621718.2021.1917748

Su H, Wang T, Wu C (2021) Formation of the periodic material flow behavior in friction stir welding. Sci Technol Weld Joining 26:286–293. https://doi.org/10.1080/13621718.2021.1902605

Zhao W, Wu C, Su H (2020) Numerical investigation of heat generation and plastic deformation in ultrasonic assisted friction stir welding. J Manuf Process 56:967–980. https://doi.org/10.1016/j.jmapro.2020.05.047

Yang C, Wu C, Shi L (2020) Modeling the dissimilar material flow and mixing in friction stir welding of aluminum to magnesium alloys. J Alloys Compd. https://doi.org/10.1016/j.jallcom.2020.156021

Su Y, Li W, Liu X, Gao F, Yu Y, Vairis A (2020) Strengthening mechanism of friction stir welded alpha titanium alloy specially designed T-joints. J Manuf Process 55:1–12. https://doi.org/10.1016/j.jmapro.2020.03.032

Penalva ML, Otaegi A, Pujana J, Rivero A (2009) Development of a new joint geometry for FSW, 3rd manufacturing-engineering-society international conference (MESIC 2009), Alcoy, Spain, pp 1–11

He W, Liu J, Hu W, Wang G, Chen W (2019) Controlling residual stress and distortion of friction stir welding joint by external stationary shoulder. High Temp Mater Process 38:662–671. https://doi.org/10.1515/htmp-2019-0005

Su Y, Li W, Patel V, Vairis A, Wang F (2019) Formability of an AA5083 aluminum alloy T-joint using SSFSW on both corners. Mater Manuf Process 34:1737–1744. https://doi.org/10.1080/10426914.2019.1669799

Yang H, Zhao H, Xu X, Zhou L, Zhao H, Liu H (2021) Effect of stirring pin rotation speed on microstructure and mechanical properties of 2A14-T4 alloy T-joints produced by stationary shoulder friction stir welding. Materials. https://doi.org/10.3390/ma14081938

Silva YC, Oliveira Júnior FJV, Marcondes F, Silva CC (2020) Analysis of viscosity function models used in friction stir welding. J Braz Soc Mech Sci Eng. https://doi.org/10.1007/s40430-020-02504-1

Cho HH, Hong ST, Roh JH, Choi HS, Kang SH, Steel RJ, Han HN (2013) Three-dimensional numerical and experimental investigation on friction stir welding processes of ferritic stainless steel. Acta Mater 61:2649–2661. https://doi.org/10.1016/j.actamat.2013.01.045

Nandan R, Roy GG, Debroy T (2006) Numerical simulation of three-dimensional heat transfer and plastic flow during friction stir welding. Metall Mater Trans A-Phys Metall Mater Sci 37A:1247–1259. https://doi.org/10.1007/s11661-006-1076-9

Sheppard T, Wright DS (1979) Determination of flow-stress.1. constitutive equation for aluminum-alloys at elevated-temperatures. Metals Technol 6:215–223. https://doi.org/10.1179/030716979803276264

Bruschi S, Poggio S, Quadrini F, Tata ME (2004) Workability of Ti–6Al–4V alloy at high temperatures and strain rates. Mater Lett 58:3622–3629. https://doi.org/10.1016/j.matlet.2004.06.058

Yu ZZ, Zhang W, Choo H, Feng ZL (2012) Transient heat and material flow modeling of friction stir processing of magnesium alloy using threaded tool. Metall Mater Trans A-Phys Metall Mater Sci 43A:724–737. https://doi.org/10.1007/s11661-011-0862-1

Shi L, Wu CS, Padhy GK, Gao S (2016) Numerical simulation of ultrasonic field and its acoustoplastic influence on friction stir welding. Mater Des 104:102–115. https://doi.org/10.1016/j.matdes.2016.05.001

Huang Y, **e Y, Meng X, Lv Z, Cao J (2018) Numerical design of high depth-to-width ratio friction stir welding. J Mater Process Technol 252:233–241. https://doi.org/10.1016/j.jmatprotec.2017.09.029

Huang Y, **e Y, Meng X, Li J, Zhou L (2019) Joint formation mechanism of high depth-to-width ratio friction stir welding. J Mater Sci Technol 35:1261–1269. https://doi.org/10.1016/j.jmst.2019.01.016

Jiang W, Jiang XQ, Yuan T, Chen SJ, Liu YY, Liu XS (2022) Material flow and viscous slips during stationary shoulder friction stir welding of Ti6Al4V. Sci Technol Weld Join 27:220–227. https://doi.org/10.1080/13621718.2022.2036573

Acknowledgements

This work was funded by the National Natural Science Foundation of China (Grant No. 51604015).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

We declare that we do not have any commercial or associative interest that represents a conflict of interest in connection with the work submitted.

Additional information

Handling Editor: P. Nash.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

**aoqing, J., Wang, J., Tao, Y. et al. Numerical simulation of the stationary shoulder friction stir welding of Ti-6Al-4V. J Mater Sci 57, 7367–7383 (2022). https://doi.org/10.1007/s10853-022-07116-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-022-07116-9