Abstract

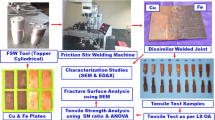

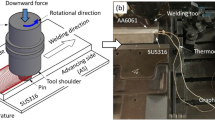

In this work, a new Double Rotating Shoulder (DRS) tool is designed to create a preheating effect and promote material flow in the shoulder-affected area during friction stir welding (FSW). A comparative study of the temperature field, strain field and material flow of AA 6061 aluminium alloy during FSW using a DRS tool and a conventional tool was carried out using numerical simulation. The model was verified according to the actual temperature field in both cases. Further, the macroscopic morphology and mechanical properties of both joints were investigated. The results showed that the simulated temperature field during FSW using a DRS tool has a good correlation with the actual temperature field. The DRS tool does lead to different macroscopic profiles but has almost no impact on mechanical properties.

Similar content being viewed by others

References

Thomas W M, Nicholas E D, Needham J C, Murch M G, Temple-Smith P, and Dawes C J, International patent number PCT/GB92/02203 and GB patent application number 9125978.9 (1991)

Mishra R S, and Ma Z Y, Mat Sci Eng R 50 (2005) 1. https://doi.org/10.1016/j.mser.2005.07.001

Kayode O, and Akinlabi E T, Mater Res Express 6 (2019) 112005. https://doi.org/10.1088/2053-1591/ab3262

Cao F, Huang G, Hou W, Ni R, Sun T, Hu J, Shen Y, and Gerlich A P, J Mater Process Technol 307 (2022) 117660. https://doi.org/10.1016/j.jmatprotec.2022.117660

Cao F, Sun T, Hu J, Hou W, Huang G, Shen Y, Ma N, Geng P, Hu W, and Qu X, Mater Des 225 (2023) 111492. https://doi.org/10.1016/j.jmatdes.2022.111492

Fei X, ** X, Ye Y, **u T, and Yang H, Mater Sci Eng A 653 (2016) 43. https://doi.org/10.1016/j.msea.2015.11.101

Yaduwanshi D K, Bag S, and Pal S, Mater Des 92 (2016) 166. https://doi.org/10.1016/j.matdes.2015.12.039

Kaushik P, and Dwivedi D K, Mater Today 46 (2021) 1091. https://doi.org/10.1016/j.matpr.2021.01.438

Li J Q, and Liu H J, Int J Adv Manuf Technol 66 (2013) 623. https://doi.org/10.1007/s00170-012-4353-3

Widener C A, Talia J E, Tweedy B M, and Burford D A, High-rotational speed friction stir welding with a fixed shoulder, Proceedings of the 6th International Symposium on Friction Stir Welding, Montreal (2006)

Li J Q, and Liu H J, Mater Des 43 (2013) 299. https://doi.org/10.1016/j.matdes.2012.07.011

Li J Q, Liu H J, and Duan W J, Int J Adv Manuf Tech 64 (2013) 1685. https://doi.org/10.1007/s00170-012-4132-1

Barbini A, Carstensen J, and dos Santos J F, J Mater Sci Technol 34 (2018) 119. https://doi.org/10.1016/j.mst.2017.10.017

Sinhmar S, and Dwivedi D K, J Mater Process Technol 277 (2020) 116482. https://doi.org/10.1016/j.jmatprotec.2019.116482

Saravana Sundar A, Kar A, Mugada K K, and Kumar A, Mater Charact 203 (2023) 113148. https://doi.org/10.1016/j.matchar.2023.113148

Thomas W M, Threadgill P L, and Nicholas E D, Sci Technol Weld Join 4 (1999) 365.

Mitsuo H, Friction agitation joining method and Frictional Agitation joining device’ Patent Abstracts of Japan, Publication number 2000-094156, Date of publication of application 04.04.2000

Thomas W M, Braithwaite A B M, and John R, Skew-Stir™ Technology, Proceedings of the 3rd International Symposium on Friction Stir Welding, Port Island, Japan (2001)

Thomas W M, Norris I M, Smith I J, and Staines D G, Reversal stir welding—Re-stir™—feasibility study, Proceedings of the 4th International Symposium on Friction Stir Welding, Park City, Utah, USA (2003)

Thomas W M, Norris I M, Staines D G, and Watts E R, Friction stir welding—process Developments and Variant Techniques, The SME Summit, Oconomowoc, Milwaukee, WI (2005)

Kumari K, Pal S K, and Singh S B, J Mater Process Technol 215 (2015) 132. https://doi.org/10.1016/j.jmatprotec.2014.07.031

Jaina R, Kumari K, Pal S K, and Singh S B, J Mater Process Technol 255 (2018) 121. https://doi.org/10.1016/j.jmatprotec.2017.11.043

Zhao P-F, Ren G-S, Guang-Sheng, Xu C-G, and Shen Z, J Plast Eng 04 (2006) 79.

Zhang Y, Cao X, Larose S, and Wanjara P, Can Metall Q 51 (2012) 250.

Li J Q, and Liu H J, J Mater Sci Technol 31 (2015) 375e383. https://doi.org/10.1016/j.jmst.2014.07.020

Kwang-** L, and Eui-Pyo K, Trans Nonferrous Met Soc China 24 (2014) 2374. https://doi.org/10.1016/S1003-6326(14)63359-8

Moreira P M G P, Santos T, Tavares S M O, Richter-Trummer V, Vilaça P, and de Castro P P M S T, Mater Des 30 (2009) 180. https://doi.org/10.1016/j.matdes.2008.04.042

Jamshidi Aval H, Serajzadeh S, and Kokabi A H, Mater Sci Eng A 528 (2011) 8071. https://doi.org/10.1016/j.msea.2011.07.056

Chen Y, Hu H, Huang C, Friction stir welding technology, CHINA MACHINE PRESS, May 2018, (2018), p 62, Paperback ISBN: 9787111595458, https://www.cmpbook.com

Acknowledgements

All authors were involved in the study conceptualization and design, all commented on previous versions of the manuscript, and all authors read and approved the final manuscript. Tao Sun contributed to methodology, investigation and reviewing; Zhenkui liang helped in sample testing; Yongqi Yang helped in reviewing and editing; **aomei Feng done resources and editing; Yifu Shen helped in funding acquisition, resources and supervision.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wu, J., Sun, T., Liang, Z. et al. Simulation and Experimental Analysis of Double Rotating Shoulder Friction Stir Welding. Trans Indian Inst Met (2024). https://doi.org/10.1007/s12666-024-03356-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12666-024-03356-2