Abstract

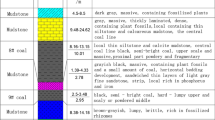

Owing to the influence of advancing speed, the movement characteristics of roof are special, and there exists a risk of pressure frame and roof fall. To understand the influence of the advancing speed on the strata pressure distribution of the fully mechanized top-coal caving roadway during the transition period, this study takes the 301 fully mechanized top-coal caving face of Changchun **ng coal mine as the engineering background. The influence of the advancing speed on the distribution of the abutment pressure is analyzed on the basis of the elastic foundation beam theory, and the characteristics of strata pressure display are verified by both numerical simulation and field measurement. The results show that when the advancing speed of the working face increases, the value of the bearing pressure at the azimuth position in front of the working face also increases. Within a certain range, the peak value of the bearing pressure at the front of the working face is proportional to the advancing speed, and the position of the peak value of the supporting pressure in advance is closer to the working face. The conclusions obtained can provide technical support for stop and end surrounding rock control measures in similar working faces.

Similar content being viewed by others

References

An BF, Zhang JX, Li M et al (2016) Stability of pillars in backfilling mining mining face to recover room mining standing pillars. J Min Saf Eng 33(2):238–243

Baldi A (2014) Residual stress measurement using hole drilling and integrated digital image correlation techniques. Exp Mech 54(3):379–391

Chang ZG, Zhang JM, Chen YJ et al (2016) Research on triangle-coal recycling amount in parallel open pit coal mine with total inner dum** covering end slope. J Coal Eng 48(9):54–56

Ding XP, Li SC, Wang J et al (2013) Optimization of underground mining development direction about end slope coal pillar recovery of open-pit coal mine. J China Coal Soc 38(11):1923–1928

Dong HN (2015) Study of numerical simulation on strata behavior sat rotary mining face. J Coal Technol 34(9):30–32

Ghasemi E, Shahriar K (2012) A new coal pillars design method in order to enhance safety of the retreat mining in room and pillar mines. Saf Sci 50(3):579–585

Golebiowski T, Zogala B, Mendecki M et al (2018) Application of rock-bolts as the electrodes for ERT surveys in mining conditions. J Appl Geophys 155:122–130

Huang JY, Zou XZ (2003) Analysis of rotary mining technology for fully mechanized mining face. J Min Saf Eng 20(1):87–88

Jiang FX (2004) Mining pressure and strata control. Coal Industry Press, Bei**g

Liu RC, Li JH, Xu CC et al (2012) Rotating mining in irregular mechanized coal mining face. J Liaoning Tech Univ 5:138–141

Liu HL, Yang TH, Zhang BH et al (2017) Influence factors of overlying coal strata falling and mine pressure behaviours in western coal mines. J China Coal Soc 42(2):460–469

Lu W, Yang K, Pan GR (2003) Analysis of pressure characteristics of revolving fully mechanized coal mine in three soft thick seam with big dip angle. J China Coal 20(1):87–88

Lu W, Yang K, Yang XJ et al (2014) Rotary mining technology of fully-mechanized coal mining face in deep inclined thick seam with soft roof, soft coal and soft floor. J Coal Sci Technol 42(7):18–21

Pu ZQ (2013) The study on strata behavior laws in rotational adjustment oblique roadway. J Saf Coal Mines 44(4):46–48

Shi CY (2014) Application research on rotary mining of L type isolated island coal pillar under complex conditions. J Hebei Univ Eng

Tu SH, Hao MK, **e YS (2004) Key technology of rotary mining in fully mechanized coal mining face of Gudao coal pillar. J China Univ Min Technol 33(5):520–523

Wang DY (2014) Study of impact of mining rate on abutment pressure of stope. J Coal Technol 33(3):94–96

Wang Q, Zhao MZ (2009) Technology and application of multi continuous rotary mining to fully mechanized longwall coal mining face. J Coal Sci Technol 6:14–16

Wang E, He X, Liu X et al (2011) A non-contact mine pressure evaluation method by electromagnetic radiation. J Appl Geophys 75(2):338–344

Xu T, Wang F, Liu ZF (2011) Strata behavior of revolving mining in “three soft” coal seam. J Coal Technol 30(2):130–131

Yang K, Lu W, Pan GR et al (2003) Investigation into strata behaviours and ground control of high height rotary longwall mining in large inclined angle coal seam under complicated geological conditions. J Min Saf Eng 20(1):87–88

Yang K, Kong XY, Lu W et al (2015a) Study on the regularity of mining pressure in the mining of large inclined thick coal seam under the near mined out area. J Rock Mech Eng S2:4278–4285

Yang JH, Sun SL, Kong DZ (2015) Effect of mining face length and advancing speed on strata behaviors in high-intensity mining. J Rock Soil Mech (s2)

Yang K, He X, Liu S et al (2016) Rib spalling mechanism and control with fully mechanized longwall mining in large inclination “three-soft” thick coal seam under closed distance mined gob. J Min Saf Eng 33(4):611–617

Yu BJ, Fu SJ (2017) Reserch on technology feasible of high cutting fully—mechanized coal mining under complicated geological condition. J Coal Sci Technol 45(7):33–38

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Li, L., He, X., Chen, Yq. et al. Influence of Different Propulsion Speeds on the Characteristics of Mine Pressure in the Fully Mechanized Caving Face During Rotary Stage. Geotech Geol Eng 37, 3937–3947 (2019). https://doi.org/10.1007/s10706-019-00883-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10706-019-00883-4