Abstract

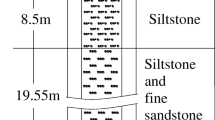

To master the laws of strong strata behavior of Tashan coal mine under Carboniferous coal mining process, the laws of strong strata behavior in 8107 working face was measured and analyzed. It was shown that the average initial weighting step of 8107 working face was 59.4 m. The average periodic weighting step of main roof was 16.2 m. The maximum working resistance during periodic weighting was 14,711.1 kN. The maximum working resistance during non-periodic weighting was 11,339.9 kN. The average dynamic load factor K during periodic weighting was 1.31. The stress of coal column on the side of the goaf could be divided into four zones (stress stabilization zone, stress slow-increasing zone, significant—increasing stress zone, stress reduction zone) along the strike of 8107 working face. There was a peak of lateral support pressure along the trend of 8107 working face. And the peak position was biased to the side of return airway roadway. With the increase of the distance from the down-side of return airway, the pressure peak of the inner coal body along the strike of 8107 the working face increased and the peak position decreased from the coal wall. The peak stress of coal column tended to be close to the up-side of return airway. And the distance from the down-side of return airway for the peak of inner coal was larger than that for the peak of coal pillar. The peak position of abutment pressure of hard roof was in the range of 10–25 m in front of 8107 working face under full mechanized mining extra thickness coal seam conditions. The relative stress concentration coefficient of k was 1.3–6.5. The range of 10–25 m from the front of the working face to coal wall was stress reduction zone. And the influence range of abutment pressure was about 80 m. It was of great significance to the control and practice of the surrounding rock of the stope for the mining of the hard extra-thick coal seam.

Similar content being viewed by others

References

Cheng YH, Jiang FX, Pang JL (2012) Research on lateral strata pressure characteristic in goaf of top coal caving in extra thick coal seam and its application. J China Coal Soc 37(7):1088–1093 (in Chinese)

Kong LH, Jiang FX, Wang CW (2010) Study of reasonable working resistance of support in fully-mechanized sublevel caving face in extra-thick coal seam. Chin J Rock Mech Eng 29(11):2312–2318 (in Chinese)

Ning RF (2018) Measurement of pressure behavior in fully mechanized mining face of thick seam in **qu mine. Coal Mine Mod 1:56–58 (in Chinese)

Qi J, Liu BL (2017) Measurement analysis and simulation study on advanced ground pressure laws of two roadways at 22303 working face in Bulianta coal mine. Saf Coal Mine 48(s1):10–14 (in Chinese)

Shi ZP, Song GY, Wang QZ (2015) Front abutment pressure evolution law of thick coal seam working face with hard roof. Coal Technol 34(3):6–8 (in Chinese)

Wang SM (2006) A brief review of the methods determining the height of permeable fracture zone. Hydrogeol Eng Geol 30(1):64–66

Wu YP, Gao XC, Duan WS (2009) Strata behavior features of fully mechanized top coal caving mining face in ultra thick seam with hard roof in binchang mining area. Coal Sci Technol 37(1):59–61 (in Chinese)

**e GX, Yang K, Liu QM (2006) Study on distribution laws of stress in inclined coal pillar for fully-mechanized top-coal caving face. Chin J Rock Mech Eng 25(3):545–549 (in Chinese)

Yang JX, Lu Y, Liu CY, Yang Y (2013) Analysis on the rock failure and strata behavior characteristics under the condition of hard and thick roof. J Min Saf Eng 30(2):211–217 (in Chinese)

Yu B (2010) Study on fully mechanized coal mining technology in passed 40 years in Datong mining area. J China Coal Soc 35(11):1772–1777 (in Chinese)

Yu B, Chen Y, Han J, Liu JR (2013) Study of the relationship between the Kouquan fault and strong ground pressure in Tongxin coal mine. J China Coal Soc 38(1):73–77 (in Chinese)

Yu B, Liu CY, Yang JX et al (2014) The mechanism of strong pressure reveal under the influence of mining dual system of coal pillar in Datong mining area. J China Coal Soc 39(1):40–46 (in Chinese)

Zhao DS, Chen F, Wang ZC (2011) The experimental study on the failure of soft overburden in mining of thick coal seam. J Guangxi Univ Nat Sci Ed 36(1):177–181

Acknowledgements

This work was supported by 2017 Key Technologies of Prevention and Control of Serious and Major Accidents in Safety Production (liaoning-0005-2017AQ) and the National Natural Science Foundation of China (51774199).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, Z., Guo, X. & Wang, C. Measurement of the Strong Pressure Appearance Laws with Hard Roof and Full Mechanized Mining Extra Thick Coal Seam. Geotech Geol Eng 36, 3399–3409 (2018). https://doi.org/10.1007/s10706-018-0541-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10706-018-0541-8