Abstract

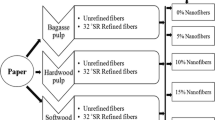

Cellulose nanofiber (CNF) is becoming a topic of great interest among the industrial and academic communities, mainly due to their potential applications in very well-differentiated industrial sectors. Among this wide range of applications, papermaking is one of the most accepted and studied. However, it is widely known that the papermaking sector is forced to compete in markets where products do not have huge added value and production margins are very low. Therefore, papermakers are constantly looking for new technologies that balance efficiency and production costs. In line with this, the present work attempts to assay the enzymatic hydrolysis of cellulose fibers to obtain CNFs. Accordingly, pH, pulp consistency, treatment time, enzyme dosage and temperature were varied to find a combination of parameters that could lead to highly efficient CNF in terms of the mechanical properties of paper enhancement and production costs. For this, CNFs were applied to unrefined and refined bleached kraft pulps and their properties were assessed. The obtained results demonstrated that it is possible to obtain highly efficient CNFs from bleached pulp at affordable costs for papermakers. Moreover, it was found that the treatment time has a key role during the production of this CNF but at low enzyme dosages since the obtained results, in terms of intrinsic properties and reinforcing potential, for high enzyme charges did not vary significantly as time was increased. In sum, the present work offers a cost-efficient solution for the application of CNF in the production of paper from bleached pulp as well as a promising alternative to those conventional processes from a technical point of view.

Similar content being viewed by others

References

Ankerfors M (2015) Microfibrillated cellulose: energy-efficient preparation techniques and applications in paper. Ph.D. Thesis, doctoral, Royal Institute of Technology (KTH)

Ansari F, Galland S, Johansson M, Plummer CJG, Berglund LA (2014) Cellulose nanofiber network for moisture stable, strong and ductile biocomposites and increased epoxy curing rate. Compos A Appl Sci Manuf 63:35–44

Battista OA (1975) Microcrystal polymer science. McGraw-Hill, New York

Besbes I, Alila S, Boufi S (2011a) Nanofibrillated cellulose from TEMPO-oxidized eucalyptus fibres: effect of the carboxyl content. Carbohydr Polym 84(3):975–983

Besbes I, Vilar MR, Boufi S (2011b) Nanofibrillated cellulose from alfa, eucalyptus and pine fibres: preparation, characteristics and reinforcing potential. Carbohydr Polym 86(3):1198–1206

Carrasco F, Mutje P, Pelach M (1996) Refining of bleached cellulosic pulps: characterization by application of the colloidal titration technique. Wood Sci Technol 30(4):227–236

Chaker A, Alila S, Mutje P, Vilar MR, Boufi S (2013) Key role of the hemicellulose content and the cell morphology on the nanofibrillation effectiveness of cellulose pulps. Cellulose 20(6):2863–2875

Charani PR, Dehghani-Firouzabadi M, Afra E, Blademo Å, Naderi A, Lindström T (2013a) Production of microfibrillated cellulose from unbleached kraft pulp of Kenaf and Scotch Pine and its effect on the properties of hardwood kraft: microfibrillated cellulose paper. Cellulose 20(5):2559–2567

Charani PR, Dehghani-Firouzabadi M, Afra E, Shakeri A (2013b) Rheological characterization of high concentrated MFC gel from kenaf unbleached pulp. Cellulose 20(2):727–740

Delgado-Aguilar M, González I, Pèlach MA, De La Fuente E, Negro C, Mutjé P (2015a) Improvement of deinked old newspaper/old magazine pulp suspensions by means of nanofibrillated cellulose addition. Cellulose 22(1):789–802

Delgado-Aguilar M, Tarrés Q, Pèlach MÀ, Mutjé P, Fullana-i-Palmer P (2015b) Are cellulose nanofibers a solution for a more circular economy of paper products? Environ Sci Technol 49(20):12206–12213

Delgado-Aguilar M, Tarrés Q, Puig J, Boufi S, Blanco Á, Mutjé P (2015c) Enzymatic refining and cellulose nanofiber addition in papermaking processes from recycled and deinked slurries. BioResources 10(3):5730–5743

Delgado-Aguilar M, Tovar IG, Tarrés Q, Alcalá M, Pèlach MÀ, Mutjé P (2015d) Approaching a low-cost production of cellulose nanofibers for papermaking applications. BioResources 10(3):5345–5355

Ek M, Gellerstedt G, Henriksson G (2009) Wood chemistry and wood biotechnology. Walter de Gruyter, Berlin

Espinosa E, Tarrés Q, Delgado-Aguilar M, González I, Mutjé P, Rodríguez A (2016) Suitability of wheat straw semichemical pulp for the fabrication of lignocellulosic nanofibres and their application to papermaking slurries. Cellulose 23(1):837–852

Ferrer A, Quintana E, Filpponen I, Solala I, Vidal T, Rodríguez A, Laine J, Rojas OJ (2012) Effect of residual lignin and heteropolysaccharides in nanofibrillar cellulose and nanopaper from wood fibers. Cellulose 19(6):2179–2193

Fukuzumi H, Saito T, Iwata T, Kumamoto Y, Isogai A (2008) Transparent and high gas barrier films of cellulose nanofibers prepared by TEMPO-mediated oxidation. Biomacromolecules 10(1):162–165

Gamelas JAF, Pedrosa J, Lourenco AF, Mutje P, Gonzalez I, Chinga-Carrasco G, Singh G, Ferreira PJT (2015) On the morphology of cellulose nanofibrils obtained by TEMPO-mediated oxidation and mechanical treatment. Micron (Oxford, England : 1993) 72:28–33

González I, Boufi S, Pèlach MA, Alcalà M, Vilaseca F, Mutjé P (2012) Nanofibrillated cellulose as paper additive in eucalyptus pulps. BioResources 7(4):5167–5180

González I, Vilaseca F, Alcalá M, Pèlach M, Boufi S, Mutjé P (2013) Effect of the combination of biobeating and NFC on the physico-mechanical properties of paper. Cellulose 20(3):1425–1435

González I, Alcalà M, Chinga-Carrasco G, Vilaseca F, Boufi S, Mutjé P (2014) From paper to nanopaper: evolution of mechanical and physical properties. Cellulose 21(4):2599–2609

Henriksson M, Henriksson G, Berglund L, Lindström T (2007) An environmentally friendly method for enzyme-assisted preparation of microfibrillated cellulose (MFC) nanofibers. Eur Polym J 43(8):3434–3441

Henriksson M, Berglund LA, Isaksson P, Lindstrom T, Nishino T (2008) Cellulose nanopaper structures of high toughness. Biomacromolecules 9(6):1579–1585

Hildén L, Väljamäe P, Johansson G (2005) Surface character of pulp fibres studied using endoglucanases. J Biotechnol 118(4):386–397

Hubbe MA (2014) Prospects for maintaining strength of paper and paperboard products while using less forest resources: a review. BioResources 1(9):1787–1823

Iwamoto S, Nakagaito A, Yano H, Nogi M (2005) Optically transparent composites reinforced with plant fiber-based nanofibers. Appl Phys A 81(6):1109–1112

Kibblewhite RP (1972) Effect of beating on fibre morphology and fibre surface structure. Appita J 26(3):196–202

Lavoine N, Desloges I, Dufresne A, Bras J (2012) Microfibrillated cellulose–Its barrier properties and applications in cellulosic materials: a review. Carbohydr Polym 90(2):735–764

Lindström T, Fellers C, Ankerfors M, Glad-Nordmark G (2014) On the strength mechanism of dry strengthening of paper with nanocellulose. Recent advances in Cellulose Nanotechnology Research, Trondheim

Norell M, Johansson K, Persson M (1999) Retention and drainage. In: Papermaking science and technology, Book 4: papermaking chemistry, Suomen Paperi-insinöörien Yhdistys, Technical Association of the Pulp and Paper Industry (TAPPI), pp 43–81

Okahisa Y, Yoshida A, Miyaguchi S, Yano H (2009) Optically transparent wood–cellulose nanocomposite as a base substrate for flexible organic light-emitting diode displays. Compos Sci Technol 69(11):1958–1961

Pääkkö M, Ankerfors M, Kosonen H, Nykänen A, Ahola S, Österberg M, Ruokolainen J, Laine J, Larsson P, Ikkala O (2007) Enzymatic hydrolysis combined with mechanical shearing and high-pressure homogenization for nanoscale cellulose fibrils and strong gels. Biomacromolecules 8(6):1934–1941

Page D (1969) A theory for tensile strength of paper. Tappi 52(4):674

Petroudy SRD, Syverud K, Chinga-Carrasco G, Ghasemain A, Resalati H (2014) Effects of bagasse microfibrillated cellulose and cationic polyacrylamide on key properties of bagasse paper. Carbohydr Polym 99:311–318

Rouger J, Mutjé P (1984) Correlation between the cellulose fibres beating and the fixation of a soluble cationic polymer. Br Polym J 16(2):83–86

Saito T, Kimura S, Nishiyama Y, Isogai A (2007) Cellulose nanofibers prepared by TEMPO-mediated oxidation of native cellulose. Biomacromolecules 8(8):2485–2491

Sehaqui H, Allais M, Zhou Q, Berglund LA (2011a) Wood cellulose biocomposites with fibrous structures at micro-and nanoscale. Compos Sci Technol 71(3):382–387

Sehaqui H, Zhou Q, Berglund LA (2011b) High-porosity aerogels of high specific surface area prepared from nanofibrillated cellulose (NFC). Compos Sci Technol 71(13):1593–1599

Sehaqui H, Zhou Q, Ikkala O, Berglund LA (2011c) Strong and tough cellulose nanopaper with high specific surface area and porosity. Biomacromolecules 12(10):3638–3644

Sehaqui H, Zhou Q, Berglund L (2013) Nanofibrillated cellulose for enhancement of strength in high-density paper structures. Nord Pulp Pap Res J 28(2):182

Wang W, Mozuch MD, Sabo RC, Kersten P, Zhu J, ** Y (2015) Production of cellulose nanofibrils from bleached eucalyptus fibers by hyperthermostable endoglucanase treatment and subsequent microfluidization. Cellulose 22(1):351–361

Yoo S, Hsieh JS (2010) Enzyme-assisted preparation of fibrillated cellulose fibers and its effect on physical and mechanical properties of paper sheet composites. Ind Eng Chem Res 49(5):2161–2168

Zhang H, Zhao C, Li Z, Li J (2016) The fiber charge measurement depending on the poly-DADMAC accessibility to cellulose fibers. Cellulose 23(1):163–173

Zimmermann T, Bordeanu N, Strub E (2010) Properties of nanofibrillated cellulose from different raw materials and its reinforcement potential. Carbohydr Polym 79(4):1086–1093

Acknowledgments

The authors wish to acknowledge the financial support of the Economy and Competitiveness Ministry of the Government of Spain to project CTQ2013–48090–C2–2–R.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Tarrés, Q., Saguer, E., Pèlach, M.A. et al. The feasibility of incorporating cellulose micro/nanofibers in papermaking processes: the relevance of enzymatic hydrolysis. Cellulose 23, 1433–1445 (2016). https://doi.org/10.1007/s10570-016-0889-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-016-0889-y