Abstract

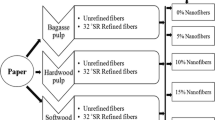

During their recycling, cellulosic fibres suffer irreversible damage caused by repeated wetting and drying cycles, beating stages and bleaching reactions. This damage decreases the mechanical properties of the paper prepared from recycled pulp. Soft beating of the pulp is a simple way to partially recover the original mechanical properties, but it is limited by the high degradation of fibres, fines generation and decrease in drainage rate that recycled fibres already present. The present research studies the use of nanofibrillated cellulose (CNF) as an alternative to mechanical beating to improve the strength properties of paper produced from a deinked recycled pulp obtained by disintegration and flotation of a mixture of old newspapers and magazines. Different percentages of CNF were added to this mixture with a retention aid. A fraction of the same pulp without CNF was also beaten at different intensities in a PFI mill. Morphological properties of both beaten and CNF-reinforced pulp suspensions, as well as structural and mechanical properties of handsheets made thereof, were analysed and their results compared. Paper containing 1.5 % of CNF presented a higher tensile strength and stiffness than paper from beaten pulp with similar freeness and water retention values. A higher amount of CNF further improved the mechanical properties, up to double the tensile index, which opens new possibilities of use for recycled paper.

Similar content being viewed by others

References

Ackermann C, Göttsching L, Pakarinen H (2000) Papermaking potential of recycled fibre. In: Göttsching L, Pakarinen H (eds) Recycled fibre and deinking, papermaking sci. technol. ser, vol 10. Fapet Oy, Helsinki, pp 358–438

Ahola S, Österberg M, Laine J (2008) Cellulose nanofibrils adsorption with poly(amideamine) epichlorohydrine studied by QCM-D and application as a paper strength additive. Cellulose 15:303–314

Alcalá M, González I, Boufi S, Vilaseca F, Mutjé P (2013) All-cellulose composites from unbleached hardwood kraft pulp reinforced with nanofibrillated cellulose. Cellulose 20:2909–2921

Batchelor WJ, He J (2005) A new method for determining the relative bonded area. Tappi J 4(6):23–28

Batchelor WJ, Kibblewhite RP (2006) Calculation of the relative bonded area and scattering coefficient from sheet density and fibre shape. Holzforschung 60(3):253–258

Besbes I, Alila S, Boufi S (2011) Nanofibrillated cellulose from TEMPO-oxidized eucalyptus fibres: effect of the carboxyl content. Carbohydrate Polymers 84(3):975–983

Borodulina S, Kulachenko A, Galland S, Nygards M (2012) Stress-strain curve of paper revisited. Nordic Pulp and Paper Research 27(2):318–328

Cao B, Tschirner J, Ramaswamy S (1999) Study of changes in wet-fibre flexibility and surface of recycled fibres. PaperijaPuu/Paper Timber 81(2):117–122

Carrasco F, Mutjé P, Pèlach MA (1996) Refining of bleached cellulosic pulps: characterization by application of the colloidal titration technique. Wood Sci Technol 30(4):227–236

Carrasco F, Mutjé P, Pèlach MA (1998) Control of retention in paper-making by colloid titration and zeta potential techniques. Wood Sci Technol 32:145–155

Carrasco F, Pèlach MA, Mutjé P (1999) Deinking of high-quality offset papers: influence of consistency, agitation speed and air flow rate in the flotation stage. Tappi J 82(3):125–129

Dasgupta S (1994) Mechanism of paper tensile-strength development due to pulp beating. Tappi J 77(6):158–166

González I, Boufi S, Pèlach MA, Alcalà M, Vilaseca F, Mutjé P (2012) Nanofibrillated cellulose as paper additive in eucalyptus pulps. BioResources 7(4):5167–5180

González I, Alcalà M, Arbat G, Vilaseca F, Mutjé P (2013a) Suitability of rapeseed chemithermomechanical. Pulp as raw material in papermaking. Bioresources 8(2):1697–1708

González I, Vilaseca F, Alcalá M, Pèlach MA, Boufi S, Mutjé P (2013b) Effect of the combination of biobeating and CNF on the physico-mechanical properties of paper. Cellulose 20(3):1425–1435

Henriksson M, Berglund LA, Isaksson P, Lindström T, Nishino T (2008) Cellulose nanopaper structures of high toughness. Biomacromolecules 9:1579–1585

Howard RC (1995) The effects of recycling on pulp quality. Technology of paper recycling, RWJ McKinney (ed.), Blackie Academic, London, Ch. 6, 180-203

Hubbe M (2014) Prospects for maintaining strength of paper and paperboard products while using less forest resources: a review. BioResources 9(1):1634–1763

Hubbe M, Heitmann JA (2007) Review of factors affecting the release of water from cellulosic fibres during paper manufacture. Bioresources 2(3):500–533

Hubbe M, Venditti RA, Rojas OJ (2007) What happens to cellulosic fibres during papermaking and recycling? A Review. Bioresources 2(4):739–788

Huber P, Carré B, Petit-Conil M (2008) The influence of TMP fibre flexibility on flocculation and formation. BioResources 3(4):1218–1227

Isogai A, Saito T, Fukuzumi H (2011) TEMPO-oxidized cellulose nanofibres. Nanoscale 3:71

Kang T, Paulapuro H (2006) Effect of external fibrillation on paper strength. Pulp Paper Can 107(7/8):51–54

Lehto JH (2004) Characterisation of mechanical and chemical pulp fibres. 58th Appitaannual conference and exhibition, Canberra, ACT, Australia, 19–21 April 2004, Carlton, VIC, Australia, Appita, Paper 3A13

Marais A, Wågberg L (2012) The use of polymeric amines to enhance the mechanical properties of lignocellulosic fibrous networks. Cellulose 19(4):1437–1447

Molin U, Daniel G (2004) Effects of refining on the fibre structure of kraft pulps as revealed by FE-SEM and TEM: influence of alkaline degradation. Holzforschung 58(3):226–232

Mutjé P, Pèlach MA, García JC, Presta S, Vilaseca F, Jiménez L (2006) Comparison of cationic demand between olive Wood organosolv pulp and eucalyptus kraft pulp. Process Biochem 41:1602–1607

Nazhad MM (2005) Recycled fibre quality—a review. J Ind Eng Chem 11(3):314–329

Norell M, Johansson K, Persson M (1999) Retention and drainage. Papermaking science and technology, book 4: papermaking chemistry. Fapet Oy, Helsinki, pp 43–81

Oksanen T, Buchert J, Viikari L (1997) The role of hemicelluloses in the hornification of bleached kraft pulps. Holzforschung 51(4):355–360

Page DH (1969) A theory for tensile strength of paper. Tappi J 52(4):674

Page DH (1993) A quantitave theory of the strength of wet webs. J Pulp Paper Sci 19(4):175–176

Paradis MA, Genco JM, Bousfield DW, Hassler JC, Wildfong V (2002) Determination of drainage resistance coefficients under known shear rate”. Tappi J 1(8):12–18

Pèlach MA, Puig J, Vilaseca F, Mutjé P (2001) Influence of chemicals on deinkability of wood-free fully coated fine paper. J Pulp Paper Sci 27(10):353–358

Pèlach MA, Pastor FJ, Puig J, Vilaseca F, Mutjé P (2003) Enzymatic deinking of newspapers with cellulose. Process Biochem 38(7):1063–1067

Pöiry (2011) Average papermaking fibre furnish the world 1990-2025. Pulp RP consumption 1995–2025, World Fibre Outlook, Pöyry LLC

Saito T, Kimura S, Nishiyama Y, Isogai A (2007) Cellulose nanofibres prepared by TEMPO-mediated oxidation of native cellulose. Biomacrmolecules 8:2485–2491

Salmi J, Nypelö T, Österberg M, Laine J (2009) Layer structures formed by silica nanoparticles and cellulose nanofibrils with cationic polyacrylamide (C-PAM) on cellulose surface and thier influence on interactions. Bioresources 4(2):602–625

Sehaqui H, Allais M, Zhou Q, Berglund L (2011) Wood cellulose biocomposites with fibrous structures at micro-and nanoscale. Compos Sci Technol 71:382–387

Shao SY, Hu KT (2002) Hornification of recycled fibre. China Pulp Paper 2:57–60

Somwang O, Enomae T, Onabe F (2001) Effect of fibrehornification in recycling on bonding potential at interfibre crossings: confocal laser-scanning microscopy. Kami Pa Gikyoshi/Jap Tappi J 56(2):79–85

Taipale T, Österberg M, Nykänen A, Ruokolainen J, Laine J (2010) Effect of microfibrillated cellulose and fines on the drainage of kraft pulp suspension and paper strength. Cellulose 17:1005–1020

Wågberg L, Gustafsson E, Utsel S, Johansson E, Ankerfors C, Marais A (2012) Use of thin, tailored Layer-by-Layer (LbL) films to increase the mechanical properties of fibrous networks 11th International Biorelated Polymer Symposium/243rd National Spring Meeting of the American-Chemical-Society (ACS), San Diego, CA. Vol 243

Wang X, Maloney TC, Paulapuro H (2003) Internal fibrillation in never-dried and once-dried chemical pulps. APPITA J 56(6):455–459

Wildfong V, Genco J, Bousfield DW, Hassler J (2003) A twin wire drainage model for various blade configurations. In: Proceedings of Tappi Spring Technology Conference, pp 579–590

Acknowledgments

The authors wish to acknowledge the financial support of the Spanish Economy and Competitiveness Ministry to the referenced projects: CTQ2012-36868-C02-01 and CTM2011-28506-C02-01.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Delgado-Aguilar, M., González, I., Pèlach, M.A. et al. Improvement of deinked old newspaper/old magazine pulp suspensions by means of nanofibrillated cellulose addition. Cellulose 22, 789–802 (2015). https://doi.org/10.1007/s10570-014-0473-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-014-0473-2