Abstract

The use of agricultural waste to produce biofuel is challenging for waste management. This study investigated the biogas including methane production, and chemical oxygen demand (COD) removal efficiency by anaerobic digestion (AD) from mixed pineapple pulp and peel (MPP). Two-stage of anaerobic digestion system was configured as a continuously stirred tank reactor (CSTR) installed with an anaerobic hybrid reactor (AHR). Total solids (TS) of MPP loading at 4% (w/v) was used with four different hydraulic retention times (HRT) to investigate the subsequent effects, such as pH, alkalinity, biogas and methane production, and COD removal efficiency. The overall pH in CSTR was more acidic than the AHR system and exhibited less stability of the AD process by highly volatile acids. The highest biogas production (0.39 v/v-d) was obtained at HRT 7 with the biogas yield of 0.43 m3/kg COD removed and COD removal efficiency of 67.05% in the AHR system. The separated acidogenic and methanogenic stages in the two-stage system improved the digestion performance. The methane yields in the AHR system remained stable except for the lowest HRT condition (HRT5). Biogas production from pineapple wastes by two-stage anaerobic digestion systems was elucidated and could be applied for a larger digestion scale.

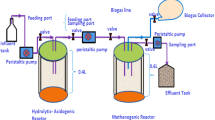

Graphical abstract

Similar content being viewed by others

Abbreviations

- ABR:

-

Anaerobic baffled reactor

- AD:

-

Anaerobic digestion

- AHR:

-

Anaerobic hybrid reactor

- AnMBR:

-

Anaerobic membrane bioreactor

- ASBR:

-

Anaerobic sequencing batch reactor

- COD:

-

Chemical oxygen demand

- CSTR:

-

Continuous stirred tank reactor

- HRT:

-

Hydraulic retention time

- MPP:

-

Mixed pulp and peel

- OLR:

-

Organic loading rate

- PSW:

-

Pineapple solid wastes

- TS:

-

Total solids

- VFA:

-

Volatile fatty Acids

- VSS:

-

Volatile suspended solids

References

Food and Agriculture Organization of the United Nations (FAO): Faostat (2020). https://www.fao.org/faostat/en/#data/QI. Accessed 5 Dec 2021

IndexBox: Asia’s canned pineapples market—Thailand holds the lion’s share of exports (2019). https://www.globaltrademag.com/asias-canned-pineapples-market-thailand-holds-the-lions-share-of-exports/. Accessed 10 Dec 2021

Sukruansuwan V, Napathorn SC (2018) Use of agro-industrial residue from the canned pineapple industry for polyhydroxybutyrate production by cupriavidus necator strain a-04. Biotechnol Biofuels 11:202. https://doi.org/10.1186/s13068-018-1207-8

Johnston HJ, Mueller W, Steinle S, Vardoulakis S, Tantrakarnapa K, Loh M, Cherrie JW (2019) How harmful is particulate matter emitted from biomass burning? A19hailandd perspective. Curr Pollut Rep 5:353–377. https://doi.org/10.1007/s40726-019-00125-4

Intharathirat R, Abdul Salam P (2016) Valorization of msw-to-energy in19hailandd: status, challenges and prospects. Waste Biomass Valoriz 7:31–57. https://doi.org/10.1007/s12649-015-9422-z

Nguyen TVT, Unpaprom Y, Manmai N, Whangchai K, Ramaraj R (2020) Impact and significance of pretreatment on the fermentable sugar production from low-grade longan fruit wastes for bioethanol production. Biomass Convers Biorefin. https://doi.org/10.1007/s13399-020-00977-7

Bardiya N, Somayaji D, Khanna S (1996) Biomethanation of banana peel and pineapple waste. Bioresour Technol 58:73–76. https://doi.org/10.1016/S0960-8524(96)00107-1

Kawata Y, Md Yusoff F, Khong NMH, Umi DWA (2021) The economic feasibility assessment of using tropical fruit wastes in production of fish feed for the Malaysian mahseer, Tor tambroides (Bleeker, 1854). J Mater Cycles Waste Manage 23:1026–1036. https://doi.org/10.1007/s10163-021-01190-y

Choonut A, Saejong M, Sangkharak K (2014) The production of ethanol and hydrogen from pineapple peel by Saccharomyces cerevisiae and Enterobacter aerogenes. Energy Proc 52:242–249. https://doi.org/10.1016/j.egypro.2014.07.075

Kainthola J, Kalamdhad AS, Goud VV (2019) A review on enhanced biogas production from anaerobic digestion of lignocellulosic biomass by different enhancement techniques. Process Biochem 84:81–90. https://doi.org/10.1016/j.procbio.2019.05.023

Pramanik SK, Suja FB, Zain SM, Pramanik BK (2019) The anaerobic digestion process of biogas production from food waste: prospects and constraints. Bioresour Technol Rep 8:100310. https://doi.org/10.1016/j.biteb.2019.100310

de Diego-Díaz B, Duran A, Álvarez-García MR, Fernández-Rodríguez J (2019) New trends in physicochemical characterization of solid lignocellulosic waste in anaerobic digestion. Fuel 245:240–246. https://doi.org/10.1016/j.fuel.2019.02.051

Mao C, Feng Y, Wang X, Ren G (2015) Review on research achievements of biogas from anaerobic digestion. Renew Sustain Energy Rev 45:540–555. https://doi.org/10.1016/j.rser.2015.02.032

Boe K, Angelidaki I (2009) Serial cstr digester configuration for improving biogas production from manure. Water Res 43:166–172. https://doi.org/10.1016/j.watres.2008.09.041

Hans M, Kumar S (2019) Biohythane production in two-stage anaerobic digestion system. Int J Hydrogen Energy 44:17363–17380. https://doi.org/10.1016/j.ijhydene.2018.10.022

Jürgensen L, Ehimen EA, Born J, Holm-Nielsen JB (2018) A combination anaerobic digestion scheme for biogas production from dairy effluent—cstr and abr, and biogas upgrading. Biomass Bioenergy 111:241–247. https://doi.org/10.1016/j.biombioe.2017.04.007

Varol A, Ugurlu A (2017) Comparative evaluation of biogas production from dairy manure and co-digestion with maize silage by CSTR and new anaerobic hybrid reactor. Eng Life Sci 17:402–412. https://doi.org/10.1002/elsc.201500187

Jitpupakdee J, Namsree P, Suvajittanont W, Sillapacharoenkul B, Rungdsardthong V (2010) Effect of hydraulic retention time on biogas production using CSTR and hybrid reactor. In: The 3rd technology and innovation for sustainable development international conference (TISD 2010). Royal Mekong Nongkhai Hotel, Nong Khai, Thailand, March 4–6, 2010, pp 607–611

AOAC (2000) Official methods of analysis, 17th edn. Association of Official Analytical Chemists International, Gaithersburg

Browning BL (1967) Methods of wood chemistry. Interscience, New York

Nelson N (1944) A photometric adaptation of the Somogyi method for the determination of glucose. J Biol Chem 153:375–380

Somogyi M (1937) A reagent for the copper-iodometric determination of very small amounts of sugar. J Biol Chem 117:771–776

APHA, AWWA, WEF (1995) Standard methods for the examination of water and wastewater, 19th edn. American Public Health Association, American Water Works Association, Water Environment Federation, Baltimore, MD

Pattharaprachayakul N, Kesonlam N, Duangjumpa P, Rungsardthong V, Suvajittanont W, Lamsal B (2021) Optimization of hydraulic retention time and organic loading rate in anaerobic digestion of squeezed pineapple liquid wastes for biogas production. Appl Sci Eng Prog. https://doi.org/10.14416/j.asep.2021.04.004

Wang Y, Zhang Y, Wang J, Meng L (2009) Effects of volatile fatty acid concentrations on methane yield and methanogenic bacteria. Biomass Bioenergy 33:848–853. https://doi.org/10.1016/j.biombioe.2009.01.007

Khan MU, Ahring BK (2019) Lignin degradation under anaerobic digestion: Influence of lignin modifications—a review. Biomass Bioenergy 128:105325. https://doi.org/10.1016/j.biombioe.2019.105325

Koch K, Lübken M, Gehring T, Wichern M, Horn H (2010) Biogas from grass silage—measurements and modeling with adm1. Bioresour Technol 101:8158–8165. https://doi.org/10.1016/j.biortech.2010.06.009

Liew LN, Shi J, Li Y (2011) Enhancing the solid-state anaerobic digestion of fallen leaves through simultaneous alkaline treatment. Bioresour Technol 102:8828–8834. https://doi.org/10.1016/j.biortech.2011.07.005

Brown D, Li Y (2013) Solid state anaerobic co-digestion of yard waste and food waste for biogas production. Bioresour Technol 127:275–280. https://doi.org/10.1016/j.biortech.2012.09.081

Santos LA, Valença RB, Silva LCS, Holanda SHB, Silva AFV, Jucá JFT, Santos AFMS (2020) Methane generation potential through anaerobic digestion of fruit waste. J Clean Prod 256:120389. https://doi.org/10.1016/j.jclepro.2020.120389

Cavinato C, Bolzonella D, Pavan P, Fatone F, Cecchi F (2013) Mesophilic and thermophilic anaerobic co-digestion of waste activated sludge and source sorted biowaste in pilot- and full-scale reactors. Renew Energy 55:260–265. https://doi.org/10.1016/j.renene.2012.12.044

Gemmeke B, Rieger C, Weiland P, Schröder J (2009) Biogas-messprogramm ii, 61 biogasanlagen im vergleich. Guelzow-Pruezen: Fachagentur Nachwachsende Rohstoffe

Timur H, Özturk I (1999) Anaerobic sequencing batch reactor treatment of landfill leachate. Water Res 33:3225–3230. https://doi.org/10.1016/S0043-1354(99)00048-2

Herrmann C, Ramm P, Murphy JD (2018) The relationship between bioreactor design and feedstock for optimal biogas production. In: Liao Q, Chang J-S, Herrmann C, **a A (eds) Bioreactors for microbial biomass and energy conversion. Springer Singapore, Singapore, pp 163–197

Azevedo A, Gominho J, Duarte E (2021) Performance of anaerobic co-digestion of pig slurry with pineapple (ananas comosus) bio-waste residues. Waste Biomass Valoriz 12:303–311. https://doi.org/10.1007/s12649-020-00959-w

Peces M, Astals S, Jensen PD, Clarke WP (2018) Deterministic mechanisms define the long-term anaerobic digestion microbiome and its functionality regardless of the initial microbial community. Water Res 141:366–376. https://doi.org/10.1016/j.watres.2018.05.028

Gonzalez-Tineo PA, Durán-Hinojosa U, Delgadillo-Mirquez LR, Meza-Escalante ER, Gortáres-Moroyoqui P, Ulloa-Mercado RG, Serrano-Palacios D (2020) Performance improvement of an integrated anaerobic–aerobic hybrid reactor for the treatment of swine wastewater. J Water Process Eng 34:101164. https://doi.org/10.1016/j.jwpe.2020.101164

Kong Z, Wu J, Rong C, Wang T, Li L, Luo Z, Ji J, Hanaoka T, Sakemi S, Ito M, Kobayashi S, Kobayashi M, Qin Y, Li Y-Y (2021) Large pilot-scale submerged anaerobic membrane bioreactor for the treatment of municipal wastewater and biogas production at 25°C. Bioresour Technol 319:124123. https://doi.org/10.1016/j.biortech.2020.124123

Sunil Kumar G, Gupta SK, Singh G (2007) Biodegradation of distillery spent wash in anaerobic hybrid reactor. Water Res 41:721–730. https://doi.org/10.1016/j.watres.2006.11.039

Ebrahimi A, Hashemi H, Eslami H, Fallahzadeh RA, Khosravi R, Askari R, Ghahramani E (2018) Kinetics of biogas production and chemical oxygen demand removal from compost leachate in an anaerobic migrating blanket reactor. J Environ Manage 206:707–714. https://doi.org/10.1016/j.jenvman.2017.10.038

Eslami H, Hashemi H, Fallahzadeh RA, Khosravi R, Fard RF, Ebrahimi AA (2018) Effect of organic loading rates on biogas production and anaerobic biodegradation of composting leachate in the anaerobic series bioreactors. Ecol Eng 110:165–171. https://doi.org/10.1016/j.ecoleng.2017.11.007

Namsree P, Suvajittanont W, Puttanlek C, Uttapap D, Rungsardthong V (2012) Anaerobic digestion of pineapple pulp and peel in a plug-flow reactor. J Environ Manage 110:40–47. https://doi.org/10.1016/j.jenvman.2012.05.017

Li W, Loh K-C, Zhang J, Tong YW, Dai Y (2018) Two-stage anaerobic digestion of food waste and horticultural waste in high-solid system. Appl Energy 209:400–408. https://doi.org/10.1016/j.apenergy.2017.05.042

Lee E, Oliveira DSBL, Oliveira LSBL, Jimenez E, Kim Y, Wang M, Ergas SJ, Zhang Q (2020) Comparative environmental and economic life cycle assessment of high solids anaerobic co-digestion for biosolids and organic waste management. Water Res 171:115443. https://doi.org/10.1016/j.watres.2019.115443

Begum S, Anupoju GR, Sridhar S, Bhargava SK, Jegatheesan V, Eshtiaghi N (2018) Evaluation of single and two stage anaerobic digestion of landfill leachate: effect of ph and initial organic loading rate on volatile fatty acid (vfa) and biogas production. Bioresour Technol 251:364–373. https://doi.org/10.1016/j.biortech.2017.12.069

Brémond U, Bertrandias A, de Buyer R, Latrille E, Jimenez J, Escudié R, Steyer J-P, Bernet N, Carrere H (2021) Recirculation of solid digestate to enhance energy efficiency of biogas plants: strategies, conditions and impacts. Energy Convers Manage 231:113759. https://doi.org/10.1016/j.enconman.2020.113759

Chaiyapong P, Chavalparit O (2016) Enhancement of biogas production potential from Acacia leaf waste using alkaline pre-treatment and co-digestion. J Mater Cycles Waste Manage 18:427–436. https://doi.org/10.1007/s10163-016-0469-0

Zou H, Jiang Q, Zhu R, Chen Y, Sun T, Li M, Zhai J, Shi D, Ai H, Gu L, He Q (2020) Enhanced hydrolysis of lignocellulose in corn cob by using food waste pretreatment to improve anaerobic digestion performance. J Environ Manage 254:109830. https://doi.org/10.1016/j.jenvman.2019.109830

Ahmadi-Pirlou M, Gundoshmian TM (2018) The effect of substrate ratio and total solids on biogas production from anaerobic co-digestion of municipal solid waste and sewage Sludge. J Mater Cycles Waste Manage 23:1938–1946. https://doi.org/10.1007/s10163-021-01264-x

Anita A, Ibrahim MG, Fujii M, Ookawara S, Nasr M (2022) Dual biogas/biochar production from anaerobic co-digestion of petrochemical and domestic wastewater: a techno-economic and sustainable approach. Biomass Convers Biorefin. https://doi.org/10.1007/s13399-022-02944-w

Acknowledgements

We would like to express our sincere thanks to the Thailand Graduate Institute of Science and Technology (TGIST) and Graduate Fund, and the National Research Council of Thailand (KMUTNB-BasicR-65-46) for their financial support.

Author information

Authors and Affiliations

Contributions

JJ: methodology, data curation, validation. NP: writing—original draft. VR: funding acquisition, conceptualization, supervision, writing—review and editing. WS: supervision. DU: supervision.

Corresponding author

Ethics declarations

Conflict of interest

The authors have no relevant financial or non-financial interests to disclose.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Jitpupakdee, J., Pattharaprachayakul, N., Rungsardthong, V. et al. Enhancement of biogas production from industrial solid pineapple wastes by two-stage anaerobic digestion systems. J Mater Cycles Waste Manag 25, 3734–3746 (2023). https://doi.org/10.1007/s10163-023-01790-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10163-023-01790-w