Abstract

Wastewater treatment plants (WWTP) are required to meet increasingly stringent effluent quality standards as well as to improve process sustainability in terms of energy efficiency, in line with the call for a paradigm shift towards the more sustainable concept of wastewater resource recovery facility (WRRF). In this context, optimised Instrumentation, Control and Automation (ICA) systems as well as process and plant-wide modelling have become key tools for optimising economic and environmental costs. The present work reports on the successfull integration of an innovative on-line continuous titrimeter and plant-wide modelling as a support tool for the optimisation of the nitritification unit in a large-scale industrial WWTP. The information gathered from the on-line titrimeter allowed for real-time estimation of the Ammonia Oxidation Rate of the activated sludge and, ultimately, of the nitrification residual capacity of the plant. Results on the titrimeter long-term operation and historical data modelling supported plant managing decisions, such as lowering the dissolved oxygen (DO) set-point of the oxidation unit, straightforwardly resulting in energy saving.

Graphical abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Conventional Activated Sludge (CAS) systems are still the most widely adopted in wastewater treatment plants across Europe, implementing the coupled system of nitrification–denitrification as the typical combination of aerobic and anaerobic biological processes to remove organic matter and nitrogen from wastewater. In such systems, aeration contributes significantly to the overall energy consumption of WWTPs. According to Longo et al. (2016), the average energetic consumption for oxygen supply is between 0.18 and 0.80 kWh/m3, accounting for more than 45% of the total energy demand in WWTPs, with peaks up to 75%. The optimisation of the aeration process could offer considerable savings in terms of environmental and economic costs but also requires efficient control systems, possibly coupled with models able to properly represent the behaviour of the wastewater treatment plant, especially under highly variable influent characteristics (Mannucci et al. 2020). In particular, nitrification is commonly assumed to be the bottleneck in nitrogen removal processes, because nitrifiers have lower growth kinetics and affinity for oxygen, and they are more sensitive to a wider variety of inhibitors compared to heterotrophic biomass (Fiocchi et al. 2008). The optimisation of the biological nitrification is a key-factor to ensure stable treatment efficiency and energy saving (Mannucci et al. 2020).

In the last decades, mathematical modelling emerged as a powerful tool able to increase process understanding and to support plant operator’s decisions. Comprehensive activated sludge models (ASMs) were proposed and validated to describe the two-step biological nitrification in which both Ammonia (AOB) and Nitrite (NOB) Oxidising Bacteria growth were described through Monod-like kinetics limited by oxygen and substrate (Munz et al. 2011).

Control strategies for reducing energy consumption related to oxygen supply evolved in parallel with the state of the art of sensors and monitoring techniques (Yuan et al. 2019). More recently, phosphate, nitrate, nitrite and ammonia sensors became available on the market showing high potential for energy saving; however, these probes are far less reliable and require more frequent maintenance than simpler sensors such as dissolved oxygen (DO), pH, flow and level probes (Yuan et al. 2019).

Also, growing attention has been paid on monitoring instruments for biological activity estimation, as respirometers and titrimeters (Mora 2014). These instruments allow for the measurement of Oxygen Uptake Rate (OUR) and alkalinity production (or consumption) and can be used for the estimation of kinetic and stoichiometric parameters of the involved processes (Gernaey et al. 2001).

The applicability of pH/DO-stat titration for monitoring biological processes which affect pH or dissolved oxygen concentration has been widely demostrated in the literature (Badoer et al. 2015).

In particular, pH/DO-stat titration are used for monitoring conventional N-removal processes, since the first step of nitrification (the oxidation of ammonium to nitrite) is a pH-affecting process. This technique allows to assess the toxicity and/or inhibitory effects on the biomass by estimating biomass treatment capacity in terms of Ammonia Oxidation Rate (AOR).

Nevertheless, pH/DO-stat titration tests take a rather long time period (a few hours), and they are almost always offline test, requiring a preliminary sampling phase of the mixed liquors which may not be fully representative of the actual conditions and do not provide real-time information about the process. Instead, when applied in continuous conditions, it can provide important data on the evolution of the nitrification process, offering new and useful information on process performance to plant operators, especially in industrial WWTPs in which significant influent load and toxicity variations occur (Fiocchi et al. 2008). In this work, an innovative system to optimise nitrification control was implemented. An on-line differential titrimeter (ODT), developed in previous works (Mannucci et al. 2020), was installed in the large industrial WWTP managed by Consorzio Cuoiodepur S.p.A. (Pisa, IT) and provided real-time AOR estimates over about 1-year operation, acting as an effective biosensor. ODT outcomes were integrated with plant-wide modelling, offering an innovative decision support tool for nitrification control and optimisation. Modelling of the biological unit was implemented in SUMO®, and a 5-year historical dataset was elaborated to simulate long-term dynamic operation, on a monthly average base.

Materials and methods

Cuoiodepur WWTP

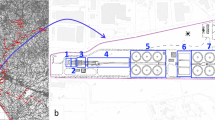

Cuoiodepur WWTP treats vegetable tannery wastewater produced in the Tuscan leather-industry district of Santa Croce sull’Arno (PI). Municipal wastewaters from the surrounding area also are treated in the plant. The industrial stream is characterised by high organic carbon and nitrogen load, high salinity, sulphur compounds, biorefractory and nitrification inhibiting compounds, such as syntetic or natural tannins used in the production line. Municipal flowrate accounts for almost 40% of the total influent flowrate but its contribution in terms of carbon and nitrogen incoming load is less than 2%. In addition, the plant is subject to strong temporal variations in terms of industrial contaminant loads due to seasonal and market-related production fluctuations. Cuoiodepur water treatment line is presented in Fig. 1.

Ammonia oxidising bacteria (AOB) are reported to be very sensitive to salinity fluctuations and inhibiting conditions in tannery wastewaters, and low maximum growth rates have been observed (Moussa et al. 2006). Salinity and inhibitory compounds, such as tannins are tipically acknowledged as the main disturbing agents for AOB activity. Thereby, in Cuoiodepur WWTP, the conventional activated sludge unit is operated at very high sludge retention time (SRT = 55 days, on average) in order to promote nitrification even in case of significant nitrifiers inhibition. High-SRT operation is also conducive for the degradation of the biorefractory organic fractions, thereby maximising the overall carbon removal. The most critical conditions for nitrification instability occur at industrial activity resume after long period of inactivity, i.e. typically after summer break or Easter and Christmas holidays. Indeed, significant nitrogen and inhibiting agents loads are faced by nitrifiers after weeks of moderate load conditions. After Christmas holidays, low temperature futher decreases activity of nitrifiers and potential nitrification instability could be faced.

In order to ensure efficient and stable nitrification, AOB response to such remarkable dynamic conditions should be capable of maintaining sufficient system nitrification capacity, even during fast transition phases. If such a minimum condition is not ensured, AOB washout and ammonia accumulation in the effluent might occurs. Thereby, it is primary interest of the industrial plant operators to be able to monitor nitrification stability and prevent events of ammonia discharge above the regulation limits.

Online differential titrimeter

The ODT is an innovative instrument for real-time estimation of the Ammonium Oxidation Rate (AOR) in WWTPs. The ODT consists of two identical 2-L jacketed Continuous Stirred Tank Reactors (CSTR), reactor 1 (R1) and reactor 2 (R2), equipped with pum** system for reagents and sludge dosing and sensors for DO, pH and T monitoring (Fig. 2).

Operational conditions and data acquisition are controlled by a centralised PLC. Activated sludge is continuously withdrawn from the nitrification tank of Cuoiodepur WWTP, pumped in the two reactors and then returned back to the plant unit. The hydraulic retention time (HRT) is set to 1 h. Withdrawing point of the mixed liquor sludge is located at the ending part of the nitrification tank, so that only residual ammonia and biodegradable organic matter are present.

Non-limiting DO concentrations (5 ± 1 mgO2 L−1) in the two reactors are achieved by controlled dosage of hydrogen peroxide (0.65 M H2O2), which is rapidly converted to water and oxygen by the activity of the catalase enzyme. This enzyme is produced by almost all organisms to prevent the build-up of excessive levels of H2O2 which is detrimental to living cells naturally produced by the biomass (Ficara et al. 2000). Temperature is controlled by the continous recirculation of tempered water in the reactor’s jacket and set at the actual temperature observed in the plant’s nitrification tank by mean of a thermostat. Both reactors are continuously fed with ammonium solution at concentrations that ensure non-limiting and non-inhibiting conditions for the biological activity of nitrifiers (ca. 30 mgN_NH4+ L−1, in both reactors). Nitrification is inhibited in reactor 1 by continuously dosing Alliltiourea (ca. 30 mgATU L−1). The system PLC allows for continuous data acquisition on operational condition as well as solutions dosing (ammonia, hydrogen peroxide and acid/base), in the two reactors. Provided that operational conditions are identical in the two reactors and that constant pH is maintained, the differential dosage of the base solution is proportional to the acidity production due to nitrification only (occurring in R2 and not in R1), and it enables to calculate the AORMAX of the non-inhibited reactor (R2). Real-time AORMAX is straightfarwardly calculated by such a diffential dosage through system algoritms. AORMAX was monitored over a nine-month period, from April to December 2019. Data referring to January, February and March 2019 were not considered, since important modifications of ODT hardware and software were conducted, and the corresponding AORMAX results were considered not reliable. Temperature correction to 20 °C was applied to AORMAX values through Arrhenius equation (θ = 1.07), in order to easily compare outcomes over the year.

When needed, the ODT equipment can also be used in batch-mode, as an offline respirometer/titrimeter, as presented in the following sections.

Plant-wide modelling

A plant-wide model of the biological unit of Cuoiodepur WWTP was implemented in SUMO software (Dynamita, Canada). The library model Sumo2S (Hauduc et al. 2017) was adopted in order to include processes related to the sulphur cycle. The model was partially modified in order to better suit with some peculiar characteristics observed in activated sludge processed applied to tannery wastewaters. The main modifications were based on the evidence that in WWTP operating at very high SRT (> 50 days), as it is the case of Cuoiodepur WWTP, volatile suspended solids (VSS) and total suspended solids (TSS) concentration are often overestimated applying conventional ASM models (Lubello et al. 2009). This is due to the fact that complex particulate compounds, typically not reactive at normal SRT, are ultimately (though slowly) hydrolysed or degraded. Thereby, a low-rate conversion process was introduced for the conversion of the variable XU (unbiodegradable particulate COD, non-reactive by default) into the variable XB (slowly biodegradable particulate COD). Also, a low-rate hydolysis process was introduced for the hydrolysis of the variable XI (inert suspended solids, non-reactive by default) into the variable SI (inert dissolved solids). Both the new processes were modelled with first order kinetics, introducing the conversion/hydrolisis rates, Kconv_XU and Khyd_XI for the two processes, respectively (Lubello et al. 2009).

A new variable was introduced in the model to describe the rate of ammonium removal due to the nitrification only: AOR_AOB. Non-nitrifying biomass assimilation, N removal by anammox and precipitation processes were excluded.

where YAOB is the growth yield factor for AOB [ −], iN is the specifc uptake for synthesis [gN gCODnew biomass−1], XAOB is the concentration of AOB [gCOD m−3].

rAOB is the AOB growth rate [d−1], rAOB is calculated by SUMO according to Monod-like saturation functions for substrates and AOB concentration.

The model layout of Cuoiodepur biological unit is presented in Fig. 3. The denitrification and oxidation units (11,000 and 26,000 m3, respectively) are simulated through 4 compartments in series in order to represent the plug-flow-like condition of the real plant. Namely: DEN_1, DEN_2, DEN_3 and DEN_4 for the denitrification unit, and NIT_1, NIT_2, NIT_3 and NIT_4 for the nitrification one. A further anoxic volume is placed as post-denitrification tank, consistently to Cuoiodepur layout. Two model input streams were considered: (1) the effluent of the primary sedimentation tank was considered as industrial influent; (2) the domestic wastewater, entering the system upstream of the denitrification unit, consistenly with the real plant layout. Wastage sludge was dynamically obtained, according to SRT set at 55 d. The secondary settler was considered as a reactive tank and simulated by a point-settler tank and an anoxic reactor, with a volume equal to 0.8 times the real settler volume, fed with settled sludge. A high recycle rate (10 times the industrial flowrate) was applied between the point settler and the reactive settler unit. Such a modification was supported by the evidence that a further aliquot of nitrate is consumed in Cuoiodepur sedimentation tank.

Five-year historical data, on influent and effluent quality as well as operational conditions, were processed and simulated in SUMO, on a monthly-average base. The reference period comprised the years 2015–2019. Prior to the dynamic simulation, yearly average values of the reference year 2015 were used as constant input for steady state calculation in order to define initial conditions for state variables. Historical data produced during regular plant monitoring were provided by Cuoiodepur WWTP. The main analites of interest for modelling purpose were: COD, ammonia, nitrite, nitrate, total nitrogen, chloride, sulphide, hydrogen sulphide, volatile suspended solids (VSS) and total suspended solids (TSS). Beside municipal/industrial influent and secondary settler effluent, historical data were processed also for strategic plant units, such as primary sedimentation tank effluent and oxidation tank. COD and N fractionation of industrial and domestic influents were characterised according to chemico-physical analysis as well as respirometric techniques, on multiple 24-h composite samples collected over the year 2019. Specifically, the primary effluent was filtered at 0.45 and 0.1 µm in order to differentiate the particulate, soluble and colloidal fractions. Colloidal solids were considered as those retained at 0.1µ filtration, after 0.45µ filtration. Biodegradability of each fraction was then assessed through respirometric test in the ODT operated in batch-mode. The respirometric tests were performed similarly to Munz et al. (2008). COD balance over the exogenous OUR returned the biodegradable share of the injected COD (non filtered, filtered at 0.45 µ and filtered at 0.1 µ). A similar procedure was adopted for the characterisation of the civil influent. According to personal communication with the plant process engineer, the main characteristics of industrial and municipal influents can be considered constant over the 5-year period of interest, since no significant variations in terms of industrial activity nor local population occurred. Thereby, influent fractionations were assumed constant throughout the years. Monthly average values of temperature and DO concentration in the aeration tank (terminal part) as well as influent, effluent and recirculation flowrates were also introduced as dynamic variables in the modell. Specific measurement campaigns were performed in order to assess: (i) the actual flowrate of mixed liquor recirculation (QML), (ii) the nitrate load removed in the post denitrification unit and secondary tank, (iii) the DO concentration profile over the longitudinal axes of the nitrification tanks.

Chlorides are present at concentrations as high as 5–6 gCl−L−1 in the industrial influent (around 3 gCl−L−1, in the biological unit due to mixing with domestic influent) and are typically representative of the industrial activity, i.e. the higher the chlorides the higher the tanneries production. Chlorides were also selected as non-reactive compounds, and their concentration was measured over the manhole entering the biological units as well as the primary sludge effluent, in the first measuring campaign. Points A, B and C as presented in Fig. 1, were monitored, and chloride mass balance allowed for QML assessment. The second measuring campaign was performed over the post-treatment unit following the nitrification tank, comprising a post-denitrification and post-aeration tank, and the secondary tank effluent. Ammonia, nitrite and nitrate concentrations were measured, and mass balance performed. Moreover, DO profile over the nitrificaton unit length was measured in the third measurement campaing.

ODT and modelling integration

Model calibration of the maximum growth rate of AOB (µAOB) was based on best fitting with the observed effluent ammonia concentration. Calibration was based on a trial and error iterative approach targeting least-square minimisation. Oxygen half saturation coefficient for AOB was set to 0.5 mgO2 L−1 (Mannucci et al. 2020). First order hydrolisis/conversion constants for the new processes accounting for XU and XI reactions were set as follows: Kconv_XU = 0.014 d−1 and Khyd_XI = 0.016 d−1, in line with values reported in previous works (Lubello et al. 2009). Oxygen half saturation constant for the sulphur oxidising bacteria was set to 0.1 mgO2 L−1 (Mora et al. 2016), instead of the default value of 1 mgO2 L−1. Kinetic and stoichiometric parameter referred to other biomasses were left at the default values.

Data set refferring to the period 2015–2018 was used for calibration; data set on 2019 was used for model validation instead.

AOR estimation through ODT were crossed with WWTP operational conditions and influent characteristics as well as model outcomes. Specifically, AOR profiles were correlated with: effluent chlorides (proportional to the industrial load), nitrogen load inlet, ammonium outlet and temperature. Results on AORMAX estimated from the ODT were critically compared to model outcomes.

The Maximun Nitrifying Capacity (MNC) expressed in tonN d−1 was estimated by multipling daily average values of AORMAX (at DO of 2 mgO2 L−1) and actual volumes of the oxidation tanks. The MNC profile were correlated with total nitrogen load inlet and ammonium outlet concentration.

Results and discussion

Measuring campaing and model calibration results

Table 1 shows COD fractionation according to the results of the respirometry tests; the corresponding COD concentrations for the industrial and domestic influents are referred to average concentrations for the first year of simulation (2016) as representative of the incoming flows. The industrial and domestic influents also contain ammonium, in average concentration of 213 gN-NH4+ m−3 and 24 gN-NH4+ m−3, respectively. Organic nitrogen (98 gN m−3) and sulphur compounds (106 gS-H2S m−3 and 2500 gS-SO42− m−3) were detected in the industrial influent only. Monthly average values were included as dynamic input in the model.

The ratio on the esimated QML and the primary influent flowrate was estimated as high as 10, in line with the recorded values. Such a verification was deemed necessary in order to take into account sidestream recirculation flowrate and possible inaccuracy in the flow meters, due to the high volumes pumped in the recirculation unit.

Monitoring activity over the post-denitrification unit and the secondary settler showed that a further nitrate reduction (up to 30%) was achieved after the main biological units. Data analysis revealed that a strong negative correlation was observed between the effluent nitrate concentration and the MLSS contration (correlation coefficient close to − 0.7). It is argued that secondary denitrification phenomena may occur in the sedimentation tank, especially when mixed liquor VSS (MLVSS) are particularly high (> 10 gL−1). The reactive sedimetation tank allowed for an accurate representation of the effluent nitrate concentration.

DO monitoring over the longitudinal axes of the aeration tank allowed to define the actual profile of DO consistently applied to the four nitrification units in the model. As an average profile, DO concentration were 0.6, 1.6, 2.2, 2.2 mg L−1 for NIT_1, NIT_2, NIT_3 and NIT_4, respectively.

The calibrated value for the maximum growth rate for AOB (μAOB) was 0.58 d−1, about 30% lower than the default value assumed by the software (0.85 d−1). As already described, low μAOB are reported for industrial wastewaters applications (Szpyrkowicz and Kaul 2004). The calibrated value allowed for an accurate simulation of the effluent ammonium concentration also in the validation data set on the year 2019.

Figure 4a shows the 5-year (2015–2019) simulation results in terms of effluent ammonia, nitrate and soluble COD versus the observed values. The models show good and robust fitting of the simulated outcomes versus the observed concentrations. Figure 4b shows observed and modelled MLVSS in the aeration tank. As a general consideration, the model exhibits good fitting of the observed data over the five years of reference. It owns to be highlighted that an average SRT value of 55 days was set as constant input in the model. Such a constrain might result in model deficiency for the representation of the dynamic operation of such a complex and large WWTP.

Modelled vs observed monthly average values, years 2015–2019. One-year steady-state simulation (with 2015 yearly average conditions) was run in order to achieve steady-state conditions, prior to the dynamic simulation a) Ammonia, Nitrate and soluble COD concentrations in Cuodiodepur WWTP effluent b) VSS concentration in aeration tank

Comparison between model and ODT results

Figure 5 shows the profile of the AORMAX(20 °C) registered by the ODT over the period April-December 2019 (measured under non-limiting conditions of ammonium and DO and normalised for temperature), together with the chloride concentration observed in the nitrification tank. Temperature is also reported in Fig. 5, for the sake of completeness. Since chloride is a conservative indicator of the industrial activity, it can be clearly observed the drop in its concentration during the three holiday breaks: the first at the end of April, the second in August, and the third between the end of October and the beginning of November.

These interruptions are characterised by a first drop in the industrial load followed by a subsequent increase, as clearly profiled by the chloride concentration. The effect of such fluctuation as well as temperature variations on nitrifying biological activity have been registerd by the ODT. Over the three holiday breaks, a negative correlation is clearly observed only in the first event occurred in April–May, whereas such a correlation is less evident in the subsequent two events. A speculation of the possible reasons behind these evidences is provided. In April, the AORMAX(20 °C) clearly reaches a first peak in correspondence of the first decrease in industrial activity, highlighting the inhibitory nature of the load entering this system. Indeed, the highest AORMAX(20 °C) values (ca. 15–20 mgN_NH4+L−1 h−1) are reached with the lowest industrial loads (Fig. 5).In August, the industrial activity is paused, and the influent load is dramatically reduced to the sole municipal contribution. The ODT monitoring of nitrifying activity is also paused during August due to regular maintenance activities occurring in the WWTP making data set not available. As the industrial activity starts again in September, chloride concentration rises back to the levels registered in June-July. Indeed, the AORMAX(20 °C) remains at moderate values of 6 ± 1 mgN_NH4+L−1 h−1. During the October–November holiday break, the load decreases and then increases slightly, but does not return to the values registered at the beginning of October. This is probably due to the heavy rainfall occurred during November and December 2019 and confirmed by data of the regional weather service Consorzio Lamma that registered the period as the most rainy since 1955. The strong precipiation events generated an increase in the domestic influent flow rate and, in fact, a dilution of the industrial load and a concomitant drop in temperature, whereas the ammonium load remained high (Fig. 5 and 7). In the same period, higher AORMAX(20 °C) is observed compared to previous months (June to September), suggesting that the lower (diluted) chloride concentration alleviated the inhibition effect. Further monitoring of the nitrification rates is recommended during the holiday breaks to improve the consistency of the correlation hypothesis between industrial load and AORMAX.

Figure 6 shows the modelled AORMAX versus the AORMAX observed by the ODT expressed as a monthly average value with its relative standard deviation over the period April-December 2019. Modell AORMAX has been calculated by the actual AOR observed in each aeration tanks, corrected for non-limiting oxygen and ammonium conditions, according to the actual DO and ammonium concentration in each tanks. The maximum values of modelled AORs are straightfarwardly comparable with the maximum observed AORs (maximum deviation of 30%), during April-June, when a lower inhibition on nitrifying biomass is assumed as explained above. On the contrary, in the months with significant industrial activity, the model returns a higher AORMAX compared to the ODT. This finding is in line with the assumption that an actual inhibition occurs in that period and that such an inhibition is not included in the model.

Figure 7 shows the MNC and its standard deviation, the inlet nitrogen load and the outlet ammonium concentration. The increase in biological activity recorded at the end of April is not reflected in a higher ammonium removal efficiency, already the highest achievable, given the affinity of the ammonia oxidising biomass for the ammonium substrate (Ks = 0.7 mgN_NH4+L−1). According to the incoming N load, the minimum capacity required for complete removal of incoming nitrogen under maximum load conditions is approximately 3 tonN d−1.

During April-June period, the plant has significant residual treatment capacity (up to 16 tonN d−1). In accordance with plant operators, a reduction in the DO set-point, typically ranging around 2.5–3 mgL−1, was considered as a cost-effective measure since nitrification efficiency can be achieved even at lower DO levels. A modell-based analysis was conducted in order to evaluate the effect of a DO set-point reduction in the aeration tank and supported the plant decision to reduce DO set-point in the oxidation tanks. An average lowering of 12% for the last semester of year 2019 (avg. 2.2 mgO2L−1) was achieved compared to the DO set-point of previous year (avg. 2.5 mgO2L−1).

Figure 7 also shows that during the months characterised by intense industrial activity and lower temperature (October–November), the MNC dereases significantly down to values close to the total nitrogen load entering the plant. Might the MNC be lower than the incoming load, ammonium would accumulate in the effluent and possible AOB washout would occur. According to personal communication with plant operators, occasional events of fast and sudden nitrification inhibition occur in the plant and are likely related to new chemicals adopted by the tanneries. A further advantage brought by the novel integrated approach is that it offers a real-time snapshot of the nitrification stability and residual capacity and can support plant operators during accidental loss of nitrification activity. If nitrification activity loss are promptly detected, operational strategies such as flowrate recirculation increase or DO setpoint regulation can be adopted in order to limit possible events of ammonia accumulation. Inexpensive simulations can be integrated as support tool to select the most suitable action according to the case-specific requirements.

For future development of the work, it is suggested to include an inhibition function for the chloride concentration, in order to be able to simulate also the dynamic inhibition experienced by the AOB biomass in Cuoiodepur WWTP. Besides, a dynamic modell response based on weekly or even daily average values is also considered to be a valuable upgrade of the current modell.

Conclusions

In the present work, a new and powerful decision support tool, based on the integration of a real-time ODT and plant-wide modelling, is presented. The knowledge derived from the information provided by online monitoring of ammonium removal rates and a well-developed model promotes rational use of energy resources while ensuring high quality effluent over time, despite the numerous load fluctuations that characterise many large wastewater treatment plants.

The ODT monitoring shed light on process instability, during critical periods of the year linked to fluctuations in industrial activity. The research work clearly shows an inhibition of the nitrifying biomass, which is subject to high loads of salinity and recalcitrant compounds such as tannins. Despite this near-permanent inhibition, the wastewater plant has a residual treatment capacity that allows the removal of ammonium even during periods of strong inhibition. The information provided by the ODT were consistent with model results, when inhibition was less relevant. The model showed good fitting with the selected observed plant parameters, allowing for scenario simulations towards plant energy optimisation. Future developments of the work are intended to provide further AORMAX monitoring data and include a nitrification inhibition function for the chloride in the model, in order to be able to simulate also the dynamic inhibition experienced by the AOB biomass in Cuoiodepur WWTP and increase the prediction capacity of the model.

Data Availability

Enquiries about data availability should be directed to the authors.

Change history

22 July 2022

Missing Open Access funding information has been added in the Funding Note.

References

Badoer S, Miana P, Della Sala S, Marchiori G, Tandoi V, Di Pippo F (2015) Nitrifying bacterial biomass and nitrification activity evaluated by FISH and an automatic on-line instrument at full-scale Fusina (Venice, Italy) WWTP. Environ Sci Pollut Res 22:19786–19792. https://doi.org/10.1007/s11356-015-5140-0

Ficara E Rocco A, Rozzi A (2000) Determination of nitrification kinetics by the ANITA-DOstat biosensor

Fiocchi N, Ficara E, Bonelli S, Canziani R, Ciappelloni F, Mariani S, Pirani M, Ratini P, Mazouni D, Harmand J (2008) Automatic set-point titration for monitoring nitrification in SBRs. Water Sci Technol 58:331–336. https://doi.org/10.2166/wst.2008.387

Gernaey AK, Petersen B, Ottoy JP, Vanrolleghem P (2001) Activated sludge monitoring with combined respirometric-titrimetric measurements. Water Res 35:1280–1294. https://doi.org/10.1016/S0043-1354(00)00366-3

Hauduc H, Johnson B, Bott C, Ward M, Takács I (2017) Incorporating sulfur and relevant reactions into a general plantwide and sewer model. IFAC-PapersOnLine 50:3935–3940. https://doi.org/10.1016/j.ifacol.2017.08.141

Lubello C, Caffaz S, Gori R, Munz G (2009) A modified activated sludge model to estimate solids production at low and high solids retention time. Water Res 43:4539–4548. https://doi.org/10.1016/j.watres.2009.08.001

Mannucci A, Caretti C, Ducci I, Lubello C, Gori R, Coppini E, Munz G (2020) Ammonia Oxidizing Bacteria (AOB) kinetic parameters estimated using the actual maximum ammonia oxidation rate. Int Biodeterior Biodegrad. https://doi.org/10.1016/j.ibiod.2019.104876

Mora M (2014) Characterization of S-Oxidizing biomass through respirometric techniques under anoxic and aerobic conditions 192

Mora M, López LR, Lafuente J, Pérez J, Kleerebezem R, van Loosdrecht MCM, Gamisans X, Gabriel D (2016) Respirometric characterization of aerobic sulfide, thiosulfate and elemental sulfur oxidation by S-oxidizing biomass. Water Res 89:282–292. https://doi.org/10.1016/j.watres.2015.11.061

Moussa MS, Sumanasekera DU, Ibrahim SH, Lubberding HJ, Hooijmans CM, Gijzen HJ, Van Loosdrecht MCM (2006) Long term effects of salt on activity, population structure and floc characteristics in enriched bacterial cultures of nitrifiers. Water Res 40:1377–1388. https://doi.org/10.1016/j.watres.2006.01.029

Munz G, Gori R, Cammilli L, Lubello C (2008) Characterization of tannery wastewater and biomass in a membrane bioreactor using respirometric analysis. Biores Technol 99:8612–8618. https://doi.org/10.1016/j.biortech.2008.04.004

Munz G, Lubello C, Oleszkiewicz JA (2011) Modeling the decay of ammonium oxidizing bacteria. Water Res 45:557–564. https://doi.org/10.1016/j.watres.2010.09.022

Szpyrkowicz L, Kaul SN (2004) Biochemical removal of nitrogen from tannery wastewater: Performance and stability of a full-scale plant. J Chem Technol Biotechnol 79:879–888. https://doi.org/10.1002/jctb.1064

Yuan Z, Olsson G, Cardell-Oliver R, van Schagen K, Marchi A, Deletic A, Urich C, Rauch W, Liu Y, Jiang G (2019) Sweating the assets – The role of instrumentation, control and automation in urban water systems. Water Res 155:381–402. https://doi.org/10.1016/j.watres.2019.02.034

Acknowledgements

This work has been supported by financial contribution from Consorzio Cuoiodepur S.p.A., the Ente Cassa di Risparmio di Firenze (CORE project) and the European Union’s Horizon 2020 research and innovation programme (Recycles project, grant agreement No. 872053).

Funding

Open access funding provided by Università degli Studi di Firenze within the CRUI-CARE Agreement.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The manuscript has no associated data. The authors declaire that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Polizzi, C., Falcioni, S., Mannucci, A. et al. Integrating online differential titrimetry and dynamic modelling as innovative energy saving strategy in a large industrial WWTP. Clean Techn Environ Policy 24, 1771–1780 (2022). https://doi.org/10.1007/s10098-022-02285-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10098-022-02285-2