Abstract

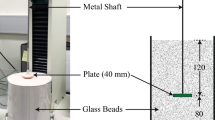

Predicting the force exerted on an object as it penetrates a granular medium is of interest in engineering, locomotive, and geotechnical applications. Current models of granular drag, however, vary widely in applicability and parameterization, and the physical origin of the granular resistive force itself is a subject of debate. Here we perform constant speed penetration experiments, combined with calibrated, large-scale molecular dynamics simulations, at velocities up to 2 m/s to test the effect of impact velocity on the depth dependent ‘hydrostatic’ drag force. We discover that the evolution of the granular flow field around an intruder regulates the presence of depth dependent drag forces. In addition, we find that the observed linear depth dependence is commensurate with the mass of flowing grains. These results suggest that, as the impact speed increases beyond the quasistatic regime, the depth dependent drag term becomes intertwined with inertial effects.

Graphic abstract

Similar content being viewed by others

References

Viswanathan, K., Mahato, A., Murthy, T.G., Koziara, T., Chandrasekar, S.: Kinematic flow patterns in slow deformation of a dense granular material. Granul. Matter. 17, 553 (2015)

Goldman, D.I., Umbanhowar, P.: Granular impact and the critical packing state. Phys. Rev. E 77, 021308 (2008)

Umbanhowar, P., Goldman, D.I.: Granular impact and the critical packing state. Phys. Rev. E 82, 010301 (2010)

Aguilar, J., Goldman, D.I.: Robophysical study of jum** dynamics on granular media. Nat. Phys. 12, 278 (2016)

Katsuragi, H., Durian, D.J.: Unified force law for granular impact cratering. Nat. Phys. 3, 420 (2007)

Feng, Y., Blumenfeld, R., Liu, C.: Support of modified Archimedes’ law theory in granular media. Soft Matter 15, 3008 (2019)

Clark, A.H., Kondic, L., Behringer, R.P.: Particle scale dynamics in granular impact. Phys. Rev. Lett. 109, 238302 (2012)

Kang, W., Feng, Y., Liu, C., Blumenfeld, R.: Archimedes’ law explains penetration of solids into granular media. Nat. Commun. 9, 1101 (2018)

Albert, R., Pfeifer, M.A., Barabási, A.-L., Schiffer, P.: Slow drag in a granular medium. Phys. Rev. Lett. 82, 205 (1999)

Brzinski, T.A., Mayor, P., Durian, D.J.: Depth-dependent resistance of granular media to vertical penetration. Phys. Rev. Lett. 111, 168002 (2013)

Seguin, A., Bertho, Y., Martinez, F., Crassous, J., Gondret, P.: Experimental velocity fields and forces for a cylinder penetrating into a granular medium. Phys. Rev. E 87, 012201 (2013)

Hamm, E., Tapia, F., Melo, F.: Dynamics of shear bands in a dense granular material forced by a slowly moving rigid body. Phys. Rev. E 84, 041304 (2011)

Tapia, F., Espíndola, D., Hamm, E., Melo, F.: Effect of packing fraction on shear band formation in a granular material forced by a penetrometer. Phys. Rev. E 87, 014201 (2013)

Murthy, T.G., Gnanamanickam, E., Chandrasekar, S.: Deformation field in indentation of a granular ensemble. Phys. Rev. E 85, 061306 (2012)

Gravish, N., Umbanhowar, P.B., Goldman, D.I.: Force and flow transition in plowed granular media. Phys. Rev. Lett. 105, 128301 (2010)

Gravish, N., Umbanhowar, P.B., Goldman, D.I.: Force and flow at the onset of drag in plowed granular media. Phys. Rev. E 89, 042202 (2014)

Kobayakawa, M., Miyai, S., Tsuji, T., Tanaka, T.: Local dilation and compaction of granular materials induced by plate drag. Phys. Rev. E 98, 052907 (2018)

Stukowski, A.: Visualization and analysis of atomistic simulation data with OVITO-the Open Visualization Tool. Modelling Simul. Mater. Sci. Eng. 18, 015012 (2010)

Plimpton, S.: Fast parallel algorithms for short-range molecular dynamics. J. Comput. Phys. 117, 1 (1995)

Silbert, L.E., Ertaş, D., Grest, G.S., Halsey, T.C., Levine, D., Plimpton, S.J.: Granular flow down an inclined plane: Bagnold scaling and rheology. Phys. Rev. E 64, 051302 (2001)

Silbert, L.E., Ertaş, D., Grest, G.S., Halsey, T.C., Levine, D.: Geometry of frictionless and frictional sphere packings. Phys. Rev. E 65, 031304 (2002)

Horabik, J., Molenda, M.: Parameters and contact models for DEM simulations of agricultural granular materials: A review. Biosyst. Eng. 147, 206 (2016)

Zhang, H.P., Makse, H.A.: Jamming transition in emulsions and granular materials. Phys. Rev. E 72, 011301 (2005)

Forterre, Y., Pouliquen, O.: Flows of dense granular media. Annu. Rev. Fluid Mech. 40, 1 (2008)

Singh, A., Magnanimo, V., Saitoh, K., Luding, S.: The role of gravity or pressure and contact stiffness in granular rheology. New J. Phys. 17, 043028 (2015)

Koval, G., Roux, J.-N., Corfdir, A., Chevoir, F.M.C.: Annular shear of cohesionless granular materials: From the inertial to quasistatic regime. Phys. Rev. E 79, 021306 (2009)

Clark, A.H., Kondic, L., Behringer, R.P.: Steady flow dynamics during granular impact. Phys. Rev. E 93, 050901 (2016)

da Cruz, F., Emam, S., Prochnow, M., Roux, J.-N., Chevoir, F.M.C.: Rheophysics of dense granular materials: discrete simulation of plane shear flows. Phys. Rev. E 72, 021309 (2005)

Hurley, R.C., Andrade, J.E.: Friction in inertial granular flows: competition between dilation and grain-scale dissipation rates. Granular Matter 17, 287 (2015)

Acknowledgements

I extend sincere gratitude to my advisor, Heinrich M. Jaeger, for his support. I thank Kieran Murphy, Melody Lim, Abhinendra Singh, and Endao Han for their invaluable discussions, and I am very grateful to Paul Umbanhowar for the generous use of his glass beads throughout this project. This work was supported by the Center for Hierarchical Materials Design (CHiMaD), which is supported by the National Institute of Standards and Technology, US Department of Commerce, under financial assistance award 70NANB14H012, and by the Army Research Office under Grant Number W911NF-19-1-0245.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The author declares that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendices

Appendix 1: Depth dependence

In Fig. 15, we calculate the depth dependent force extracted via linear fit in the relatively low speed penetration simulations (\(v_0 = 40\) cm/s) and explicitly probe the dependence of \(F_z\) on gravity. We follow the functional form proposed by Brzinski III et al., as described in Sect. 1: \(F_z = \alpha \mu \rho _g g D^2 z\), where \(\alpha\) was found to be approximately \(\sim 20-30\) [5, 10].

The fitted values of \(\alpha\) are \(35 \pm 5\), and do not vary strongly with gravity. These values are nearly within error of those reported by Brzinski III et al., without accounting for disparities in packing fraction and friction. Strength is further lent to this agreement due to the difference in experimental procedure: where Brzinski III et al. measured the depth dependent force in static conditions, we extract ours from penetration at speeds slightly higher than the quasistatic limit, as evidenced by the peak at low z in Fig. 15 [10].

Appendix 2: Inertial number

To investigate the flow characteristics below the rod surface more quantitatively, in Fig. 16 we plot vertical profiles of \(\dot{\gamma }\), \(v_z\) and \(\phi\), averaged in a cylinder of diameter 2/3D (Fig. 16), at the same \(\widetilde{t}\). This area, highlighted in Fig. 16right, was chosen to avoid the areas of high shear around the edge of the intruder.

Flow profiles averaged within an cylinder of radius 2/3 D aligned with the intruder axis. Each profile is taken at \(\widetilde{t} = 1.0\). a Shear strain rate \(\dot{\gamma }\) as a function of distance from the rod surface. b Vertical grain velocity profile. c Local packing density under the rod surface

The \(\dot{\gamma }\) and \(v_z\) profiles show clear exponential behavior that extends several D away from the intruder surface, consistent with the experiments of Seguin et al. [11] (Fig. 16 a and b). Additionally, the local packing density in this inner cylinder is lowered by about 3 percentage points near the intruder surface, independent of \(v_0\) (Fig. 10c). The dilation region ends uniformly at \(\sim D\) away from the rod, very close to the mean lengthscale \(\lambda _{vz} = 0.98 D \pm 0.15\) which is independent of \(v_0\) and was extracted via exponential fit from the \(v_z\) profile. Under these conditions, there is no evidence of an underlying jammed structure or stagnant zone such as those suggested by Aguilar and Goldman [4] or Kang et al. [8].

The flow characteristics in the area directly below the rod are regular and proportional to \(v_0\), and do not exhibit an obvious signature of a transition between inertial and quasistatic behaviors. However, the region of most violent shear — and the highest degree of inertial flow — is contained in the flow around the bottom edge of the rod (as can be seen in Fig. 10a). To investigate the possibility of a force transition signature in the area of peak flow, the value of \(\dot{\gamma }\), \(\phi\) and the grain pressure at \(r=R\) are averaged and recorded as a function of intruder depth. We use the grain pressure and shear strain rate to calculate the inertial number I, given by:

where P is the pressure and \(d_g\) is the diameter of a grain [24, 25]. The inertial number is used to compare the timescale associated with deformation of the material, given by \(\dot{\gamma }\), with the rearrangement time under a pressure P [24]. Small values of \(I \le 0.01\) correspond to quasistatic flow, whereas \(I \ge 0.1\) delimits the collisional regime and the presence of inertial effects [24, 26].

a Change in packing fraction in the region near the edge of the rod as a function of \(\widetilde{t}\) in a co-moving frame. b Inertial number of the flow in the same region. c I versus \(\phi _{\mathrm {edge}}\) for a range of values of g and D, plotted with a linear fit. Inset: \(\phi _{\mathrm {edge}}\) plotted against I for only the simulations calibrated with the experimental data

In Fig. 17b, we plot the inertial number at the edge of the rod as a function of \(\widetilde{t}\), and Fig. 17a is the change in packing fraction at the edge of the rod, \(\phi _{\mathrm {edge}}-\phi _0\). There is scatter, but some observations can be drawn. Our general results for the inertial number are consistent with I as measured empirically by Clark et al. [27]. Clark et al. calculated the inertial number for a circular intruder impacting a system of disks, finding that \(I \sim 0.09\) in the area directly below the intruder for impact speeds below 6 m/s.

When \(\widetilde{t}=1\), the rates of change of both I and \(\phi _{\mathrm {edge}}-\phi _0\) increase markedly. In addition, when \(\widetilde{t}<1\), \(\phi _{\mathrm {edge}}\) is increasing (and I decreasing), albeit at a more gradual rate. This may be indicative of the hybrid nature of the flow as a function of depth: the gradual trends in I and \(\phi _{\mathrm {edge}}\), especially for higher \(v_0\), reflect that the flow is operating in increasing ambient pressure conditions, so that there is some bleeding between the ‘inertial,’ high \(v_0\) regime, and the later quasistatic behavior. Nonetheless, it seems that we are able to draw the conclusion, from Fig. 17a and b, that the gradual change of ambient static granular conditions is not sufficient to explain the bend in I and \(\phi _{\mathrm {edge}}\) at \(\widetilde{t}=1\).

Granular rheology experiments and simulations under simple flow configurations have shown that I and \(\phi\) are related in the following way:

where \(\phi _{\mathrm {ini}}\) is the initial packing fraction and m is a constant, usually given as 0.6 and 0.2, respectively, for glass spheres in three dimensions [24, 28, 29]. To compare, we plot \(\phi\) and I in Fig. 17, c. The best fit line is given by \(\phi = 0.57-0.35I\), plotted in black in Fig. 17c, and is remarkably close to the prediction from granular rheology — especially for such irregular and dynamic flow conditions. Interestingly, \(\phi _{\mathrm {ini}}\) is much smaller than both the initial packing fraction of the system, 0.61, and the predicted dilation threshold, \(\phi _c \sim 0.60\) [16]. However, Kobayakawa et al. have observed in their simulations of horizontal drag that the packing density within a shear band, \(\phi _s\) can be lower than \(\phi _c\), and they find that \(\phi _s = 0.58\) to 0.59 in their simulations [17]. The average packing fraction in the center of the rod, away from the edge, as plotted in Fig. 16c, indicates that \(\phi _s\) for this system is near 0.58, agreeing well with Kobayakawa et al.

The linearity of Fig. 17c, indicates that the flow around the rod surface is regular and well captured by existing models; in other words, there is not a discontinuity in flow at the transition between velocity and depth dependent regimes. Though there are signatures of the transition in I and \(\phi _{\mathrm {edge}}\) at \(\widetilde{t}=1\), it would seem that this is due to additional actors in the system that influence the flow but do not disturb it. To explain the force regime transition, then, we must look elsewhere.

Appendix 3: Vertical velocity transition

a Vertical velocity profile of width \(2r_g\) taken radially from the rod surface for \(R=1\). Near the rod, at \(r \rightarrow R\), grains are entrained in the motion of the rod and move downwards. Away from the shaft, the grain velocity \(v_z\) becomes positive, indicating an upwelling of grains, and then decays as it travels in the bulk. b Maximum vertical grain velocity in the profiles shown in a, normalized by a factor proportional to \(v_0\) and the characteristic velocity, \(\sqrt{gD}\) (unnormalized in inset). The lowest speed does not collapse as well as \(v_0>40\) cm/s, indicating a minimum fluidization speed. c) and d The same collapse for different values of D, g and \(v_0\), for \(v_0 > 40\) cm/s. The sharp decrease in maximum vertical grain velocity at \(\widetilde{t}=1\) correlates with the activity of the uppermost layer of grains

Figure 18 relates the time dependent transition identified in Fig. 13 for grains above the rod position, to the characteristics of the vertical velocity of grains parallel with the rod surface. In Fig. 18, the vertical velocity profile in a plane parallel with the rod surface is plotted as a function of r. The vertical velocity reaches a peak \(\sim 1.5-2.0 R\) from the rod shaft, and then decays into the bulk.

Plotting the maximum vertical velocity in this plane as a function of \(\widetilde{t}\) (Fig. 18b) mirrors, to a certain extent, the packing fraction collapse shown in Fig. 13e. By normalizing the maximum upward velocity at the rod surface — which may be assumed to characterize the strength of the flow field in this plane, given the similar profile structures in Fig. 16, a — by the product of \(v_0\) and the gravity-scaled velocity \(\sqrt{gD}\), we are able to achieve a serviceable collapse that is particularly successful at the faster impact speeds tested. Although not immediately clear, the quantity \(\sqrt{v_0\left( gD \right) ^{1/2}}\) could represent the geometric mean of the two principal velocity scales in the system at this point of critical juncture, a mixing of the two spatial regimes: the area directly below the intruder, dominated by the impact speed \(v_0\), and the volume of grains above the rod surface that is governed by the gravitational velocity scale \(\sqrt{gD}\). Nonetheless, the maximum upward velocity, and with it the magnitude of the entire velocity profile at the rod surface, decreases dramatically at \(\widetilde{t}=1\). Because the transition from high to low upward velocity is much sharper and less foreshadowed than the vertical velocity crossover at \(\widetilde{t}=1\) in Fig. 12 or the averaged velocities in Fig. 13, it could be that the vertical velocity profile of the grains parallel with the rod surface is responding to the conditions imposed by the grains above — and not causing the transition itself.

Rights and permissions

About this article

Cite this article

Roth, L.K. Constant speed penetration into granular materials: drag forces from the quasistatic to inertial regime. Granular Matter 23, 54 (2021). https://doi.org/10.1007/s10035-021-01106-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10035-021-01106-5