Abstract

Urea oxidation reaction (UOR) is a crucial process for the efficiency of urea-based energy conversion technologies, including electrocatalytic water splitting and urea fuel cells. These technologies are considered alternatives to the traditional hydrogen production methods due to lower overpotentials and higher cost-effectiveness. However, sluggish UOR kinetics currently limit the practical applications of these technologies. In this study, we investigated the influence of electrolyte composition and temperature on the performance of Ruddlesden-Popper complex oxides in UOR. Our findings demonstrate that the formation of a carbonate layer at the electrode surface is a critical factor limiting UOR kinetics. This layer is mainly composed of carbonates of alkali metal from the solution and can be eliminated at elevated temperatures due to increased solubility. Specifically, we found that LaSrNi0.5Co0.5O4±δ catalyst exhibited superior electrocatalytic activity (6 mA cm−2 at 1.45 V vs. RHE with loading 100 µg cm−2) operating at 60 °C in 5 M KOH. Moreover, changing the solution to cesium hydroxide, we were able to avoid the creation of a non-conductive layer due to higher solubility of the cesium carbonate, thus stabilizing the catalytic reaction.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Electrochemical water splitting is a critical process for producing green hydrogen [1,2,3], which is essential for various technologies, including proton-exchange membrane fuel cells (PEMFs). However, the high cost of electrolytic hydrogen production remains a significant challenge [4, 5]. Thermodynamic voltage for water splitting is 1.23 V at 298 K. However, over 1.8 V is needed to drive this process at a practical current density due to high overpotentials of both cathodic (hydrogen evolution reaction, HER) and anodic (oxygen evolution reaction, OER) reactions.

One promising approach to reduce energy consumption in electrolysis is to shift the anodic reaction from oxygen evolution to a reaction with a less positive redox potential, such as urea electrooxidation (UOR). UOR is an attractive option because it occurs at relatively low anodic potentials and produces inorganic products, including nitrogen, carbonates, and water [6,7,8,9]. Furthermore, effective UOR can provide a means to eliminate urea as an environmental hazard.

UOR is thermodynamically favorable, as the standard electrode potential of the reaction.

is equal to 0.37 V vs. reversible hydrogen electrode (RHE) [6]. This value offers great prospects for reducing cell voltage and hence energy costs for hydrogen production. However, urea oxidation reaction typically occurs at large overpotentials (E > 1.2 V vs. RHE) [9]. Therefore, new efficient catalysts for UOR are urgently needed.

Nickel and its various oxide compounds are highly catalytically active in UOR [10,11,12,13,18, 19]. Catalysts consist of trimetallic nickel–cobalt–iron layered triple hydroxide nanosheets showed promising results for UOR catalysis in alkaline solutions [20]. The authors used a hydrothermal route to grow catalysts on nickel foam as a support to obtain catalyst with high surface area. In this regard, the role of Fe (III) ions in increasing the catalytic activity of nickel-based catalysts for UOR should be specifically noted [Surface area analysis Nitrogen adsorption analysis was performed with a Quantachrome Instruments NOVA 2000 high-speed surface area analyzer at 77 K. Before the measurements, the samples were degassed in a dynamic vacuum for at least 6 h at 200 °C. The specific surface area was calculated using the Brunauer-Emmett-Teller (BET) method from the nitrogen adsorption data in the relative pressure range (P/P0) from 0.05 to 0.30. Electrochemical measurements were performed in a standard PTFE three-electrode cell (cell volume was 120 mL for KOH solution and 24 mL for CsOH solution) using a Metrohm Autolab PGSTAT302N potentiostat equipped with a linear scan generator module. A glassy carbon (GC) rotating disk electrode (1600 rpm) with Sgeom = 0.07069 cm2 was used as a working electrode. A glassy carbon plate was used for XPS and SEM analysis. Before experiments, the surface of glassy carbon was polished with a 0.05 μm Al2O3 slurry on a polishing cloth, rinsed with distilled water several times, and finally dried under an N2 stream. Oxide powders were deposited onto GC disk electrodes as thin films. For this, an appropriate amount of catalysts powder has been added to a water/isopropanol solution (4:1 by volume), which contained 0.06 wt % Na-substituted Nafion (Sigma–Aldrich) to reach a weight ratio of ∼1 g Nafion to 1 g catalyst. The resulting mixture was sonicated for 60 min to obtain a homogeneous ink. To deposit a uniform catalyst layer, two portions (2 μL two times) of the ink were subsequently drop-cast onto the GC disk electrode using a micropipette with intermediate drying under a weak N2 gas stream. The total catalyst loading was always 100 μg·cm−2. The electrolyte was either 5 M KOH (Sigma–Aldrich) or 6 M CsOH (ChemCraft). The temperature of the solution was adjusted at a constant value in the interval 20–60 °C by a water-cooled thermostatic bath UED WBE-1S (Russia). The temperature control accuracy was 0.3 °C. A platinum wire was used as a counter electrode. Electrode potentials were set and measured against a mercury-mercuric oxide (Hg/HgO) reference electrode filled with the same alkali solution. All potentials reported in the present paper were recalculated into the RHE scale via the equation: E(RHE) = E(Hg/HgO in 5 M KOH) + 0.879 V for the experiments in 5 M KOH and E(RHE) = E(Hg/HgO in 6 M CsOH) + 0.936 V for the experiments in 6 M CsOH. Urea electrooxidation was studied in a solution containing 0.5 M CO(NH2)2 in 5.0 M KOH. The dependence of specific conductivity of potassium hydroxide solutions on their concentration has a maximum of 0.3 wt. KOH, which approximately corresponds to 4.5 M solution. The choice of alkaline solutions is due to the fact that namely such solutions are used in industry [30]. Urea (extra pure) was purchased from ChemCraft (Russia) and used without additional purification. Before the voltammetric measurements, the solution was deaerated by bubbling argon (extra pure) for 30 min. The UOR kinetics were investigated under both potentiodynamic and potentiostatic conditions. Cyclic voltammograms were recorded at a scan rate of 10 mV·s−1 starting from the open-circuit potential. In order to determine the stability of prepared catalysts, potentiostatic current transients were recorded at potentials of urea oxidation. X-ray photoelectron spectroscopy (XPS) experiments were performed using PHI 500 VersaProbe II spectrometers with spherical mirror analyzers. Al Kα monochromatic x-ray source with 1486.6 eV x-ray energy was utilized. Pressure in the analysis chamber was in the range of 10−6–10−7 Pa. Sample after electrolysis was thoroughly washed with deionized water before XPS investigation. Survey spectra were recorded with a 1.0 eV step size, while high-resolution spectra were recorded with a 0.1 eV step size. High-resolution XPS spectra were processed to obtain atomic concentrations. The procedure of spectra quantifications that are commonly used in analyzing data from X-ray spectroscopy was applied. Photoelectron backgrounds were subtracted from the high-resolution spectra using Shirley function approximation. The resulting spectra were used for element quantifications. All the spectra were calibrated to the same C1s binding energy position of 285.0 eV.Electrochemical measurements

X-ray photoelectron spectroscopy

Results and discussions

Structure of electrocatalysts: The composition of near-electrode layers

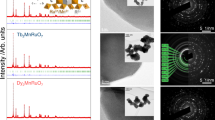

The synthesized mixed oxides with RP structure were analyzed using powder X-ray diffraction (XRD), which showed that all the materials are phase-pure and crystallize in a tetragonal cell with space group I/4mmm (Fig. 1) and coincide well with the standard PXRD pattern JCPDS #01-075-5726. Lattice parameters and atomic positions were calculated using Rietveld refinement and are given in Table S1 and Tables S4–S6, respectively. The substitution of B-positions by the different atoms do not lead to a change in the space group but provide only the difference in lattice parameters (Table S1). We used a modified ultrasonic spray pyrolysis method [25, 31] for the synthesis, which includes adding sorbitol into the solution of nitrates and using O3 as an oxidizer. The oxidation of sorbitol in an ozone atmosphere results in the formation of hollow spheres with a large number of pores (Figs. S1–S3), which leads to an increase in the true surface area from ~8 [31] to ~16 m2/g as shown by BET analysis (Table S1). An increase in the true surface area leads to an enlargement in the number of available electrochemically active centers, which in turn accelerates the rate of urea oxidation reaction.

EDX analysis was conducted to confirm the homogeneity of prepared catalysts. EDX spectra revealed the average cationic composition of prepared RP phases in agreement with the theoretical stoichiometry (Table S2). The distribution of metal cations over the surface of particles is uniform (Figs. S4–S6).

Elecrocatalytic activity in UOR

Urea electrooxidation starts at potentials higher than 1.23 V vs. RHE (Fig. 2a), that is, at potentials where oxygen evolution is thermodynamically feasible. However, due to kinetic limitations, oxygen evolution occurs at a noticeable rate only at E > 1.45 V (Fig. 2b). The UOR currents are observed on polarization curves at potentials 1.25–1.5 V.

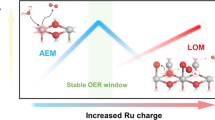

Electrocatalytic activity of RP oxides in UOR decreases in the following sequence: LaSrNi0.5Co0.5O4 (LSNC) > LaSrCo0.5Fe0.5O4 (LSCF) > LaSrNi0.5Fe0.5O4 (LSNF). This can be seen from the first voltammetric scans presented in Fig. 2a. This sequence is opposite to that observed for catalytic activity in the OER (Fig. 2b) and their Tafel slopes 69.98, 68.18, and 68.18 mV for LSNF, LSCF, and LSNC, respectively [31]. In contrast to OER, the LSNF anode is the least active in UOR. This can be explained by the formation of a thicker blocking layer at the LSNF catalyst surface due to faster UOR initial kinetics. The UOR in this condition is self-inhibiting, which is why the most catalytically active samples show a faster decrease of electrocatalytic activity due to passivation by layers of carbonates.

Indeed, the LSNF sample demonstrates the sharpest drop in current from 0.4 to 0.03 mA cm−2 within a few minutes after the imposition of a constant urea oxidation potential (Fig. 3). As we have recently demonstrated [31], RP structures with nickel and iron atoms in the B-position have the highest activity in OER due to the formation of extremely active mixed Ni-Fe hydroxide layer [24, 25, 32]. Fast electron transfer LSNF is responsible for the rapid formation of carbonates layer at potentials of UOR, which in turn leads to a more efficient blocking of the catalytically active surface.

UOR currents are high in the first several seconds when the solution containing urea is brought into contact with the electrode (Fig. 3). After that, a drastic decrease in anodic currents is observed. As discussed in the literature [28], this is due to the blocking of the active electrode surface by carbonates forming during urea oxidation in a solution of potassium hydroxide. It is known that the solubility of potassium carbonate sharply decreases with increasing alkali concentration [33, 34]. In addition, one cannot exclude the possibility of insoluble strontium carbonate formation at the electrode surface. The formation of an insoluble layer covering the active material is confirmed by our scanning electron microscopy (SEM) images of the electrode surface before and after electrolysis in a 5 M solution of KOH-containing urea (Fig. S7).

X-ray photoelectron spectroscopy (XPS) study was carried out after electrolysis for 2 h in 5.0 M KOH. It revealed that iron group metal ions are concentrated in the surface layers of the anode. Species in an oxidation state +3 (Fig. S8) are formed at the electrode surface at the potentials of urea oxidation, which suggests its catalytic activity towards oxygen evolution and urea oxidation [7, 28]. However, the concentration of strontium atoms in the near-electrode layer decreases almost 4 times after electrolysis (Table S3), which indicates the unlikely formation of strontium carbonate on the surface during electrolysis. Previous detailed investigations of the near-electrode region of RP oxides after anodic polarization in aqueous solutions revealed an amorphous layer with a thickness of 10–20 nm [24, 32]. Both the composition and structure of this layer significantly affect the electrocatalytic properties of RP oxides [26].

Blocking of the electrode surface with a non-conductive layer results in a gradual decrease in UOR currents from cycle to cycle when scanning the electrode potential in the anodic region (Fig. 4) observed for all the studied electrodes.

Several approaches can be suggested to prevent the formation of sparingly soluble carbonates at the electrode surface in the course of urea oxidation. One can use alkaline solutions, in which the solubility of carbonates is higher. According to ref. [33], the solubility of cesium carbonate in concentrated CsOH solution reaches 1 mol L−1. In addition, one can increase the temperature of the solution, since the solubility of carbonates increases with increasing temperature. Therefore, at the next step, we performed measurements of electrochemical urea oxidation on RP oxides in CsOH solution and at elevated temperatures.

Urea electrooxidation in CsOH solution

In contrast to KOH solutions, UOR currents in 6.0 M CsOH did not decrease in the course of long-term cycling of electrode potential, but instead increased from cycle to cycle (Fig. 5a).

Potentiostatic current transients show a slower decrease in CsOH solutions (Fig. 5b) more indicative of diffusion limitations than of irreversible passivation by carbonates in KOH media. Only a slight decrease from 1 to 0.7 mA cm−2 in anodic current is observed in the first minutes after the onset of urea oxidation. Based on these data, one can conclude that the degree of electrode blocking by insoluble oxidation products in CsOH solution is much smaller than that in KOH solutions at the same temperature. This assumption was confirmed by SEM images of LaSrCo0.5Fe0.5O4 after long-term oxidation of urea (Fig. 6). Indeed, no noticeable blocking layer of carbonates is observed after electrolysis in CsOH, while in the case of KOH, it is clearly visible (Fig. S7). The sample after electrolysis in CsOH media retains its morphology, which confirms that it is not covered by a layer of carbonates.

Thus, our experiments on urea electrooxidation in KOH and CsOH solutions clearly show that the main cause of the suppression of urea oxidation current is the blocking of the electrode surface by alkali metal carbonates. Cesium hydroxide solution, in which cesium carbonate is quite soluble, is appropriate for urea oxidation. However, cesium compounds are rather scarce and expensive, which forces us to look for other ways to prevent the blocking of the electrode surface by the products of urea electrooxidation.

UOR in KOH solutions at higher temperatures

According to ref. [34], solubility of K2CO3 in 5 M KOH (23.06 wt. %) is equal to 28.5% at 313.15 K and 35.0% at 353.15 K, i.e., it increases with temperature. Based on this, we attempted to oxidize urea in potassium hydroxide solutions at elevated temperatures. As expected, UOR currents are decreasing over the time of electrolysis at higher temperatures but current density at the 50th cycle at 60 °C stabilized at a value close to that in the 1st cycle at 30 °C (Fig. 7a). Moreover, the current at a temperature of 60 °C remains much higher than the current at lower temperatures for a long period of time (Fig. 7b). The effect of temperature is the same for both LaSrCo0.5Ni0.5O4 and LaSrCo0.5Fe0.5O4 catalysts.

Conclusions

Our results show that electrooxidation of urea on Ruddlesden-Popper oxide phases LaSrM11−xM2xO4±δ (M1, M2–Fe, Co, Ni) allows to reduce the overpotential for hydrogen electrolytic production, which is a promising result. However, UOR is self-inhibiting due to the formation of a layer of non-conductive insoluble carbonates at the electrode surface.

The catalytic activity of Ruddlesden-Popper oxides towards urea oxidation in potassium hydroxide solutions follows a decreasing sequence of LSCF > LSNC > LSNF, which is contrary to their catalytic activity in OER. Apparently, the fast oxidation of urea molecules occurring on the LSNF anode in the first seconds of electrolysis leads to the effective blocking of its surface by insoluble carbonates. However, we discovered that blocking of the anode surface by insoluble products of urea electrooxidation is significantly reduced in cesium hydroxide solutions. This is explained by the relatively high solubility of cesium carbonate, which leads to more stable characteristics of the LSCF and LSNC anodes during cycling. At temperatures exceeding 60 °C, promising stability of urea oxidation is observed in potassium hydroxide solutions because of the increase in potassium carbonate solubility. This gives hope that with further optimization, UOR on RP compounds will approach the conditions for industrial production of hydrogen by the electrochemical method.

Data availability

The data presented in this study are available on request from the corresponding author.

References

Li X, Zhao L, Yu J, Liu X, Zhang X, Liu H, Zhou W (2020) Water splitting: from electrode to green energy system. Nano-Micro Letters 12:131

Terlouw T, T., Ch. Bauer, Ch., R. McKenna, R., M. Mazzotti, M. (2022) Large-scale hydrogen production via water electrolysis: a techno-economic and environmental assessment. Energy Environ Sci 15:3583–3602

Lee JE, Jeon K-J, Show PL, Jung SC, Choi YJ, Rhee GH, Lin KY, Park YK (2022) Mini review on H2 production from electrochemical water splitting according to special nanostructured morphology of electrocatalysts. Fuel 308

Ball M, Weeda M (2016) The hydrogen economy—vision or reality? In Compendium of Hydrogen Energy. Hydrogen Use, Safety and the Hydrogen Economy 4:237–266

Sojoudi A, Sefidan A, Alam K, Saha S (2021) Hydrogen production via electrolysis: mathematical modeling approach. Bioenergy Res Technol 157–193

Boggs B, King R, Botte G (2009) Urea electrolysis: direct hydrogen production from urine. Chem Commun 32:4859–4861

Forslund R, Mefford J, Hardin W, Alexander C, Johnston K, Stevenson K (2016) Nanostructured LaNiO3 perovskite electrocatalysts for enhanced urea oxidation. ACS Catal 6:5044–5051

King R, Botte G (2011) Investigation of multi-metal catalysts for stable hydrogen production via urea electrolysis. J Power Sources 196:9579–9584

Forslund R, Hardin W, Rong X, Abakumov A, Filimonov D, Alexander C, Mefford J, Iyer H, Kolpak A, Johnston K, Stevenson J (2018) Exceptional electrocatalytic oxygen evolution via tunable charge transfer interactions in La0.5Sr1.5Ni1−xFexO4±δ Ruddlesden-Popper oxides. Natur Commun 9:3150

Ma Y, Ma Ch, Wang Y, Wang K (2022) Advanced nickel-based catalysts for urea oxidation reaction: challenges and developments. Catalysts 12:337

Li J, Wang Sh, Chang J, Feng L (2022) A review of Ni based powder catalyst for urea oxidation in assisting water splitting reaction. Advanced Powder Materials 3:100030

Wang D, Yan W, Vijapur S, Botte G (2012) Enhanced electrocatalytic oxidation of urea based on nickel hydroxide nanoribbons. J Power Sources 217:498–502

Liang Y, Liu Q, Asiri A, Sun X (2015) Enhanced electrooxidation of urea using NiMoO4·xH2O nanosheet arrays on Ni foam as anode. Electrochim Acta 153:456–460

Tong Y, Chen P, Zhang M, Zhou T, Zhang L, Chu W, Wu Ch, **e Y (2018) Oxygen vacancies confined in nickel molybdenum oxide porous nanosheets for promoted electrocatalytic urea oxidation. ACS Catal 8:1–7

Yan W, Wang D, Botte G (2012) Nickel and cobalt bimetallic hydroxide catalysts for urea electro-oxidation. Electrochim Acta 61:25–30

Zeng M, Wu J, Li Zh, Wu H, Wang J, Wang H, He L, Yang X (2019) Interlayer effect in NiCo layered double hydroxide for promoted electrocatalytic urea oxidation. ACS Sustainable Chem Eng 7:4777–4783

Lu Sh, Hummel M, Gu Zh, Wang Y, Wang K, Pathak R, Zhou Y, Jia H, Qi X, Zhao X, Xu B, Liu X (2021) Highly efficient urea oxidation via nesting nano-nickel oxide in eggshell membrane-derived carbon. ACS Sustainable Chem Eng 9:1703–1713

Hefnawy M, Fadlallah S, El-Sherif R, Medany Sh (2022) Synergistic effect of Cu-doped NiO for enhancing urea electrooxidation: comparative electrochemical and DFT studies. J Alloys Compd 896:162857

Yang X, Zhang H, Xu W, Yu B, Liu Y, Wu Z (2022) A do** element improving the properties of catalysis: in situ Raman spectroscopy insights into Mn-doped NiMn layered double hydroxide for the urea oxidation reaction. Catal Sci Technol 12:4471–4485

Patil K, Babar P, Bae H, Jo E, Jang JS, Bhoite P, Kolekar S, Kim JH (2022) Enhanced electrocatalytic activity of a layered triple hydroxide (LTH) by modulating the electronic structure and active sites for efficient and stable urea electrolysis. Sustain En Fuels 6:474–483

**e J, Liu W, Lei F, Zhang X, Qu H, Gao L, Hao P, Tang B, **e Y (2018) Iron-incorporated α-Ni(OH)2 hierarchical nanosheet arrays for electrocatalytic urea oxidation. Chem Eur J 24:18408–18412

Das G, Tesfaye R, Won Y, Yoon H (2017) NiO-Fe2O3 based graphene aerogel as urea electrooxidation catalyst. Electrochim Acta 237:171–176

Tran Q, Yoon S, Park B, Yoon H (2018) CeO2-modified LaNi0.6Fe0.4O3 perovskite and MWCNT nanocomposite for electrocatalytic oxidation and detection of urea. J Electroanal Chem 818:76–83

Lopez P, Chung D, Rui X, Zheng H, He H, Martins P, Strmcnik D, Stamenkovich D, Zapol P, Mitchell J, Klie R, Markovich N (2021) Dynamically stable active sites from surface evolution of perovskite materials during the oxygen evolution reaction. J Am Chem Soc 143:2741–2750

Porokhin S, Nikitina V, Aksyonov D, Filimonov D, Pazhetnov E, Mikheev I, Abakumov A (2021) Mixed-cation perovskite La0.6Ca0.4Fe0.7Ni0.3O2.9 as a stable and efficient catalyst for the oxygen evolution reaction. ACS Catal 11:8338–8348

Wang X, Li J-P, Duan Y, Li J, Wang H, Yang X, Gong M (2022) Electrochemical urea oxidation in different environment: from mechanism to devices. ChemCatChem 14(13):e202101906. https://doi.org/10.1002/cctc.202101906

Baker D, Lundgren C (2019) Expansion of the urea electrocatalytic oxidation window by adsorbed nickel ions. J Appl Electrochem 49:883–893

Tewari A, Sambhy V, Urquidi Macdonald M, Sen A (2006) Quantification of carbon dioxide poisoning in air breathing alkaline fuel cells. J Power Sources 153(1):1–10

Muhammed NK, Alex C, Jana R, Datta A, John NS (2022) Remarkable COx tolerance of Ni3+ active species in a Ni2O3 catalyst for sustained electrochemical urea oxidation. Journal of Materials Chemistry A 10(8):4209–4221

Le Bideau D, Mandin P, Benbouzid M, Kim M, Sellier M (2019) Review of necessary thermophysical properties and their sensivities with local temperature and electrolyte mass fraction for alkaline water electrolysis multiphysics modelling. Int J Hydrogen Energy 44(10):4553–4569

Sinitsyn P, Kuznetsov V, Filatova E, Levchenko S (2022) Ruddlesden-Popper oxides LaSrM11−xM2xO4±δ (M1, M2—Fe Co, Ni) synthesized by the spray-pyrolysis method as promising electrocatalysts for oxygen evolution reaction. Energies 15(21):8315

Friebel D, Louie M, Bajdich M, Sanwald K, Cai Yu, Wise A, Cheng M, Sokaras D, Weng T-C, Alonso-Mori R, Davis R, Bargar J, Nørskov J, Nilsson A, Bell A (2015) Identification of highly active Fe sites in (Ni, Fe)OOH for electrocatalytic water splitting. J Am Chem Soc 137:1305–1313

Lang A, Sukava A (1958) The system KOH–K2CO3–H2O at low temperatures: I. Phase equilibria Can J Chem 36:1064–1069

Yang N, Du H, Wang Sh, Zheng Sh, Zhang Y (2023) Solubility data for the KOH−K2CO3−K3VO4−H2O system at (313.15 and 353.15) K. J Chem Eng Data 58(3):677–681

Acknowledgements

The authors express their acknowledgements to AICF (Skoltech, Russia) for granting access to SEM facilities.

Funding

This research was funded by the Russian Science Foundation grant number 21-13-00419.

Author information

Authors and Affiliations

Contributions

P.A.S. guided synthesis, collected SEM images, and SEM EDX map**. E.M.A. synthesized the samples and collected XRD data. S.S.I. collected the electrochemical data. E.M.P. collected and analyzed XSP spectra. M.A.V. collected BET data. V.A.N. and V.V.K. guided electrochemical experiments. S.V.L. formulated the problem. P.A.S., V.A.N., V.V.K., and S.V.L. prepared the manuscript. All authors revised this manuscript.

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Sinitsyn, P.A., Atoian, E.M., Ivchenko, S.S. et al. Stable electrochemical urea oxidation on Ruddlesden–Popper oxide catalysts. J Solid State Electrochem 28, 1799–1807 (2024). https://doi.org/10.1007/s10008-024-05814-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10008-024-05814-9