Abstract

High-performance thin-layer chromatography (HPTLC) is a cost-effective method for the separation of small molecules, such as active pharmaceutically ingredients. The method can be used without sophisticated equipment. For example, the detection and quantification of colored compounds on an HPTLC plate can be performed with a CCD camera. For noncolored compounds, a new dip** solution for the generation of chemiluminescence on an HPTLC plates is presented. In combination with a charge-coupled diode (CCD) camera, this can be used as a universal detection system. The efficiency of this new staining reagent is demonstrated by the detection of trimethoprim and sulfamethoxazole from a fixed-dose combination in a ratio of 1:5.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

An advantage of high-performance thin-layer chromatography (HPTLC) is that several universal detection systems are available. Colored compounds can be detected directly on the plate with the eyes. Compounds absorbing only light below 400 nm can be visualized by adding a fluorescent dye to the layer that mostly absorbs light at 254 nm. When the plate is illuminated with light of 254 nm, visible fluorescence is induced around 550 nm. If a sample zone covers the dye, it quenches the fluorescence so that the zone is visible as a dark band. Compounds that do not absorb light at 254 nm wavelength remain invisible. Substances with native fluorescence can be often detected by eye when the plate is illuminated with light at 366 nm.

If all these visualizing methods are not applicable, compounds on HPTLC plates can be visualized without destruction by exposing the layer to iodine vapor. Lipophilic sample zones accumulate iodine reversibly. The zones become visible as brown bands on an almost white background, which are sufficiently stable for a photo. The method is unsuitable for densitometric measurements.

Water is another universal detection reagent for lipophilic compounds. The plate is dipped in water for 1 s, then wiped with a window wiper and placed on a black background. The wetted plate is translucent, except where the lipophilic zones are located. Here, the plate is not sufficiently wetted to let the black color of the background pass through. As a result, the plate shows white zones on a grey background [1]. The method is also unsuitable for densitometric measurements.

The combination of the antibiotics trimethoprim and sulfamethoxazole as a fixed-dose combination in the ratio of 1:5 is known as cotrimoxazole and is used here as an example of an HPTLC separation. A method for quantifying both compounds in tablets by diode-array detection (DAD)–HPTLC was recently published [2]. The purpose of this work is to establish a new chemiluminescence-based method for the visualization of compounds on HPTLC plates.

2 Experimental

2.1 Chemicals, preparation of standards, and application on the HPTLC plate

All the chemicals used were of analytical reagent grade. bis(2,4,6-Trichlorophenyl)oxalate (TCPO) and H2O2 were obtained from Fluka (Buchs, Switzerland). Trimethoprim was from Sigma Aldrich (Steinheim, Germany) and sulfamethoxazole was purchased from Sigma Chemicals (St. Louis, MO). Both standards have a purity of ≥ 99.5%. trans-Resveratrol with a purity of ≥ 98% as well as methanol, ethyl acetate, n-butyl acetate, and cyclopentyl methyl ether (CPME) were purchased from Carl Roth GmbH + Co. KG (Karlsruhe, Germany). Aluminum foil silica gel 60 F254 plates (1.05554) with a fluorescent dye were from Merck (Darmstadt, Germany).

Standard solutions (St) were prepared by weighing the standards in different amounts (trimethoprim 1.608 mg) and sulfamethoxazole (11.529 mg) using an Orion Cahn® C-33 microbalance from Environmental Instruments (Beverly, MA). The standards were dissolved in 10 mL of methanol. The final standard solution (St1) was prepared by mixing 300 µL of each standard solution (St) and then adding 600 µL of methanol. The final concentrations in St1 was 40.2 ng/µL for trimethoprim and for 288.255 ng/µL for sulfamethoxazole.

Standard solutions (St) were spotted band-wise over 7 mm on predeveloped plates (predeveloped with methanol–water (8:2, V/V) using an automatic TLC Sampler (ATS 4) from CAMAG (Muttenz, Switzerland) equipped with a 25-µL syringe. Bands were spotted at a distance of 10 mm from the bottom plate edge and at a distance of 5 mm from the plate edges.

2.2 Separation conditions

Silica gel 60 F254 plates (10 cm × 10 cm) were developed at 22 °C and 35% relative humidity in a vertical develo** chamber (twin-trough glass chamber) at vapor saturation (20 min) to a distance of 50 mm (calculated from the point of application) with the solvent CPME–methanol–water (7.6:2:0.4, V/V).

2.3 Chemiluminescence, apparatus, and evaluation

Chemiluminescence can easily be induced by oxidation of diaryl ethanedioates. The compound TCPO is often used for this reaction because it is quickly oxidized by H2O2 [3,4,5,6,7,8]. In the presence of trans-resveratrol, the reaction energy can be transferred to this fluorescing compound, which emits light while relaxing from its excited state [4].

To perform chemiluminescence in HPTLC, the dry plate was dipped in a chemiluminescence solution for four seconds. This solution was prepared by dissolving 100 mg TCPO in 35 mL ethyl acetate. The amount of 1 mL H2O2 (35%) was shaken vigorously together with this solution for 1 min. Then, 14 mL of the trans-resveratrol solution (10 mg trans-resveratrol, dissolved in 100 mL of ethyl acetate), was added. The mixture is suitable for chemiluminescence measurements within 1 h.

After dip**, the wet plate was dried slightly until no more light reflection could be seen on the surface. For chemiluminescence, a sensitive CCD camera (model: Celvin® S) from Biostep company (Jahnsdorf, Germany) was used. The measurement time was 4 min with no pixel binning. The highest light intensity in the measured picture was set to J0. All other measured light intensities (J) were divided by this value. To reduce noise, 30 diodes per track were averaged as a single densitogram. The reflectance (R) was calculated using expression (1). For evaluations, the self-written program ImageTLC in PureBasic (Ver. 6.14) was used.

2.4 Spectral measurements from plate

A TIDAS TLC S700 system from J&M (Aalen, Germany) with a reflection attachment consisting of three rows of optical fibers was used for the spectral measurements on the plate. It has a wavelength resolution of 0.8 nm and a spatial resolution on the plate of 100 µm, manufactured by the TransMIT Centre for Fibre Optics and Industrial Laser Applications (Gießen, Germany). The middle row was used for detection, and the other two rows were connected to a deuterium lamp (for ultraviolet measurements) and a 365-nm LED for fluorescence measurements. The measurement time for a single spectrum in the wavelength range from 190 to 1000 nm was 25 ms. After measuring J and J0, the wavelengths-dependant reflectance (R) was calculated according to the following equation:

J is the intensity of light reflected and/or scattered from a sample track, and J0 is the intensity of light reflected and/or scattered from a blank track.

The raw data of the measurement were evaluated using expression (2), the function of the extended Kubelka–Munk equation [1, 9, 10]:

k: backscattering factor (0 ≤ k ≤ 1), a: absorption coefficient, J0: reflected light intensity measured from a neat plate part, and J: reflected light intensity measured from a sample track.

The factors k and l adjust Eq. (2) to special measurement conditions. For example, in trace analysis, not too much light is absorbed by the analyte and almost all of the illuminated light is reflected by the plate surface. This is taken into account by setting the backscattering factor k in Eq. (2) to 1, leading to Eq. (4) [1, 9, 10]:

3 Results and discussion

3.1 TCPO chemiluminescence on plate

The most effective type of chemiluminescence is the reaction of active oxalates, such as bis(2,4,6-trichlorophenyl) oxalate (TCPO), with hydrogen peroxide as an oxidant. It has been suggested that cyclic peroxides are formed in this reaction and that their thermal decomposition generates excited species that can transfer their energy to various externally added fluorescent activators, which emit light from their excited states [11,12,13]. For example, the mixture of TCPO and H2O2 in nonpolar solvents, such as ethyl acetate or n-butyl acetate, in the presence of trans-resveratrol shows a bright luminescence on an HPTLC plate [4]. Analyte zones can be identified by light suppression.

Figure 1 shows a silica gel 60 F254 plate on which trimethoprim and sulfamethoxazole were separated using the solvent CPME–methanol–water (7.6:2:0.4, V/V). Trimethoprim shows an RF value of 0.22 and sulfamethoxazole of 0.77. After drying, the plate was dipped for four seconds in a mixture of TCPO, H2O2 and trans-resveratrol dissolved in ethyl acetate. The plate was then immediately measured for 4 min using a very light-sensitive camera with a signal resolution of 16 bits.

A 16-bit image taken within 4 min of a 10 cm × 10 cm silica gel 60 F254 plate, which was dipped in a TCPO chemiluminescence solution. The application zone and the bands of trimethoprim (with amounts from 402 to 804 ng) and sulfamethoxazole bands (with amounts from 2882 to 5764 ng) are shown from bottom to top. The plate was developed with the solvent CPME–methanol–water (7.6:2:0.4, V/V). Volumes of 20, 18, 18, 10, 18, 20, 10, 20, and 20 µL (from left to right) were applied

In Fig. 2, the signals of the measured 16-bit image of Fig. 1 were converted to reflectance values according to Eq. (1). The value of J0 was taken from the pixel with the highest measured intensity, which is around 65,000 counts. The reflectance densitogram on the left shows a track where 804 ng trimethoprim and 5764 ng sulfamethoxazole are separated, resulting in reflectance value of R = 0.360 for sulfamethoxazole and R = 0.4667 for trimethoprim. In the dark zone of sulfamethoxazole, for example, a light intensity of 23,400 counts is measured.

A 16-bit chemiluminescence image of a trimethoprim and sulfamethoxazole separation, taken from a 10 cm × 10 cm silica gel 60 F254 plate and evaluated in reflectance. The reflectance densitogram of track five is shown on the left. Volumes of 20, 18, 18, 10, 18, 20, 10, 20, and 20 µL (from left to right) were applied

It can also be seen that the baseline between the two peaks is not flat and that reflectance values less than one are measured on the sides of the plate. This is probably caused by the evaporation of the volatile solvent ethyl acetate, because without solvent the chemiluminescence reaction does not take place. This is a real disadvantage of the method and can be partly compensated by substituting ethyl acetate with the less volatile solvent n-butyl acetate.

The same sample solution was applied on tracks 2, 3, and 5. Scanning of the tracks with a DAD scanner at 286 nm and evaluation according to Eq. (4) results in a relative standard deviation of 2.91% for trimethoprim and 3.59% for sulfamethoxazole. The corresponding standard deviations for these three tracks, measured in chemiluminescence, are 4.76% for trimethoprim and 4.61% for sulfamethoxazole. Despite the additional dip** step, these values are only slightly higher than those of the DAD scanner.

3.2 Light suppressing process in TCPO chemiluminescence

There are three possible mechanisms of light suppression. One obvious light suppression mechanism is that the analyte simply absorbs light. Drying the plate increases the analyte concentration on the plate surface, because the analyte migrates to the plate surface due to the evaporation of the mobile phase. The light emitted from the plate layer must pass through this zone and the light can be absorbed. According to the Lambert–Beer law, this type of light suppression should show a nonlinear dependence between the reflectance and the analyte concentration in the layer.

A second possible process of light reduction in an analyte zone is that the soaking volume of the layer is reduced by the presence of the analyte alone. With this “space effect,” less chemiluminescence solution in a zone leads to a reduction in light emission. A third possible mechanism of light reduction in an analyte zone is that the analytes interfere or react with the compounds of the chemiluminescent reagent in the form of a competitive reaction, thus reducing the emitted light intensity.

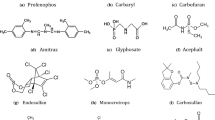

In Fig. 1, the application zone is clearly visible as a band of light suppression. This zone is probably reduced in its thickness during the spaying process. Light absorption cannot be responsible for this chemiluminescence quenching, because a scan in the wavelength range of 200 to 400 nm reveals that no analyte is present. Figure 3 shows the densitogram of the chemiluminescence evaluation in combination with the DAD densitogram as well as the structure of both compounds. The application signal at 5 mm is visible in the chemiluminescence densitogram but not in the DAD densitogram measured at 286 nm. The “space effect” discussed above is probably responsible for this light suppression, because a reduction in the thickness of the application zone reduces the amount of chemiluminescence solution in the band compared with the surrounding area.

Densitograms of a trimethoprim (left) and sulfamethoxazole (right) separation (track five in Figs. 1 and 2), measured as chemiluminescence (blue line) and as DAD data at 286 nm (red line), evaluated according to Eq. (4). The application signal at 5 mm separation distance is only visible in the chemiluminescence densitogram. Separated are 804 ng trimethoprim and 5764 ng sulfamethoxazole

Figure 4 shows the calibration graphs of sulfamethoxazole in the range from 30 to 5800 ng, evaluated according to Eq. (4). The plate was first developed and scanned using a DAD scanner. The red line in Fig. 4 shows the DAD evaluation at 286 nm. After scanning, the plate was dipped in the chemiluminescence solution and measured for 4 min. The blue line shows the chemiluminescence evaluation according to Eq. (4), resulting in a linear calibration graph. In contrast, the DAD measurement is better approximated with a polymeric function. This is not surprising, as the evaluation of light in solution and on plate is mostly a nonlinear matter [1]. From Fig. 4, it can be concluded that the light suppression of the sulfamethoxazole bands is probably caused by the “space effect” and not by light absorption.

Figure 5 shows the calibration graphs of trimethoprim in the range from 4 to 800 ng, evaluated according to Eq. (4). Due to lower amounts of the compound compared with the sulfamethoxazole evaluation, the DAD data at 286 nm (red line) show an almost linear dependence on the amount of trimethoprim in the separated band.

The nonlinear behavior of trimethoprim after chemiluminescence treatment is interesting. The suppression of the chemiluminescence signals increases disproportionately with increasing trimethoprim concentration in the band. It can be speculated that the disproportionate increase in trimethoprim signals is caused by more than a single mechanism for light suppression. It is known from the literature that the oxidation of trimethoprim either by dip** in nitric acid [14] or by contact with oxygen in combination with 24 h daylight irradiation [15] results in a bright fluorescence. Trimethoprim is a compound that can be easily oxidized. The H2O2-containing chemiluminescence solution probably oxidizes trimethoprim under H2O2 consumption, so that we have a second mechanism in addition to the “space effect” that suppresses chemiluminescence in the band.

4 Conclusions

A mixture of TCPO, H2O2 and trans-resveratrol is a suitable reagent to induce light emission from an HPTLC plate. Sample zones can be identified as zones of suppressed chemiluminescence. The suppression mechanism is probably not based on light absorption but on a simple “space effect,” when molecules located in the sample zone reduce the uptake volume of the chemiluminescence reagent, resulting in lower light emissions. This mechanism suggests that the new chemiluminescence solution can be used as a universal detection system for visualizing separated compounds on an HPTLC plate.

Abbreviations

- HPTLC:

-

High-performance thin-layer chromatography

- CCD:

-

Charge-coupled diode

- DAD:

-

Diode-array detection

- CPME:

-

Cyclopentyl methyl ether

- TCPO:

-

bis(2,4,6-Trichlorophenyl)oxalate

References

Spangenberg B, Poole CF, Weins C (2010) Quantitative thin-layer chromatography: a practical survey. Springer, Berlin

Spangenberg B (2024) Quality control in pharmaceutical analysis by diode-array thin-layer chromatography: quantification of trimethoprim and sulfamethoxazole as a case study. J Planar Chromatogr—Mod TLC. https://link.springer.com/content/pdf/10.1007/s00764-023-00276-7.pdf

Spangenberg B (2011) A new way of using chemiluminescence in thin-layer chromatography. J Planar Chromatogr 24:357–359

Lotz A, Milz B, Spangenberg B (2015) A new and sensitive TLC method to measure trans-resveratrol in red wine. J Liq Chromatogr Relat Technol 38:1104–1108

Spangenberg B (2015) Two-dimensional thin-layer chromatography of polyaromatic hydrocarbons measured by absorption, fluorescence, and chemiluminescence. J Planar Chromatogr 28:139–143

Humpert D, Milz B, Lotz A, Spangenberg B (2016) Thin-layer chromatographic separation and in situ chemiluminescence of phenolic compounds. J Planar Chromatogr 29:318–322

Lotz A, Habermehl P, Spangenberg B (2017) A new and highly sensitive TLC method to measure hypericin using chemiluminescence. J Liq Chromatogr Relat Technol 40:287–291

Milz B, Minar YA, Spangenberg B (2018) Quantification of astaxanthin in salmons by chemiluminescence and absorption after TLC separation. J Liq Chromatogr Relat Technol 41:358–361

Spangenberg B, Klein KF (2000) Fibre optical scanning with high resolution in thin-layer chromatography. J Chromatogr A 898:265–269

Spangenberg B (2006) Does the Kubelka–Munk Theory describe TLC evaluations correctly? J Planar Chromatogr 19:332–341

Hadd AG, Seeber A, Birks JW (2000) Kinetics of two pathways in peroxyoxalate chemiluminescence. J Org Chem 65:2675–2683

Stevani CV, Silva SM, Baader WJ (2000) Studies on the mechanism of the excitation step in peroxyoxalate chemiluminescence. Eur J Org Chem 24:4037–4046

Wu N, Huie CW (1994) Factors influencing peroxyoxalate chemiluminescence detection in thin-layer chromatography. J Planar Chromatogr 7:88–94

Schlöbe R, Thijssen HHW (1982) Quantitative thin-layer chromatography of trimethoprim and tetroxoprim using fluorescence densitometry. J Chromatogr 230:212–215

Sigel CW, Grace ME (1973) A new fluorescence assay of trimethoprim and metabolites using quantitative thin-layer chromatography. J Chromatogr A 80:111–116. https://doi.org/10.1016/S0021-9673(01)85355-3

Acknowledgements

The authors express their appreciation to Merck-Company (Darmstadt, Germany) for kind support.

Funding

Open Access funding enabled and organized by Projekt DEAL.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The author declares that he has no conflict of interest.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Spangenberg, B. A new universal detection system for high-performance thin-layer chromatography plates using chemiluminescence. JPC-J Planar Chromat 36, 465–470 (2023). https://doi.org/10.1007/s00764-024-00286-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00764-024-00286-z