Abstract

In this study, we show how electrochemically mediated bioconversion can greatly increase the co-production of 1,3-propanediol and organic acids from glycerol in an industrial bioprocess using a Clostridum pasteurianum mutant. Remarkably, an enhanced butyrate formation was observed due to a weakened butanol pathway of the mutant. This allowed the strain to have a higher ATP generation for an enhanced growth, higher glycerol consumption and PDO production. The PDO titer reached as high as 120.67 g/L at a cathodic current of -400 mA, which is 33% higher than that without electricity, with a concurrent increase of butyric acid by 80%. To fully recover the increased PDO and organic acids, a novel downstream process combining thin film evaporation of PDO and esterification of organic acids with ethanol was developed. This enables the efficient co-production of PDO, ethyl acetate and ethyl butyrate with a high overall carbon use of 87%.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The commercial bio-production of 1,3-propanediol (PDO) is one of the most prominent achievements of industrial biotechnology in the last two decades. It is achieved by integrating advances in strain engineering (metabolic engineering and synthetic biology) and bioprocess engineering, especially regarding downstream processing which presents great challenges because of the high boiling point of PDO and the necessity of removing the salts and fermentation byproducts [12, Esterification process for the production of ethyl acetate and ethyl butyrate The retentate from the thin film evaporator containing the most part of glycerol and all the sodium salt of organic acids was mixed with anhydrous ethanol at a mass ratio of 1: 1.5, and the pH of the mixture was adjusted to 0.5 by adding excessive H2SO4. Esterification reaction of acetic and butyric acids with ethanol was then carried out at 70 °C in a similar reaction system (2 L) as described by [22]. Subsequently, ethanol, ethyl acetate and ethyl butyrate were together evaporated from the esterified broth at a heating temperature of 70 °C and a vacuum pressure of 200 mbar in a rotary evaporator. After the targeted temperature was reached, 0.5 mL sample was withdrawn every 30 min for analyzing the reaction conversion of acetic acid and butyric acid. All the results shown are averages with standard deviations of experiments conducted in triplicates. The substrate and products in the fed-batch fermentation experiments and the ethyl ester of organic acids (ethyl acetate and ethyl butyrate) were quantified using high-performance liquid chromatography (HPLC, Kontron Instruments, Switzerland) with an Aminex HPX-87H 300 mm × 7.8 mm column (Bio-Rad Laboratories, USA) as the separation column at an operation temperature of 30 °C. The eluent for the HPLC detection was 0.1% trifluoroacetate and the flow rate was maintained at 0.6 mL/min. The detection of organic acids was assessed by a UV detector (Shimadzu, Japan) at a wavelength of 210 nm. The detection of alcohols and ethyl esters were assessed by a differential refractometer RI-detector (Kontron Instruments, Switzerland). The specific growth rate (μ in h−1), volumetric productivity of PDO (QPDO, in g/L/h), glycerol consumption rate (Qglycerol, in g/L.h), production yield (PDO/glycerol, g/g), carbon recovery (CR) and reducing equivalent balance (NADHR) in the fermentation process were determined as described by [22]. The ATP yield of biomass (YATP, g/mol) was calculated from Eq. 1 as described by [19], where i is the accumulated fermentation products (mol), and X is the accumulated biomass (g) in the fed-batch fermentation. The content as weight fraction in percentage (wt%) of each component (C) in each purification step was calculated from Eq. 2, where c is the concentration (g/L) determined by HPLC, d the dilution factor, v the volume (L) and w the weight (g) of the sample taken for analysis. The conversion of acetic acid (XHAc) or butyric acid (XHBu) in the esterification process was calculated using Eq. 3, where C0 is the initial concentration (g/L) of acetic acid or butyric acid detected by HPLC; Ce is the concentration of acetic acid or butyric acid after esterification.Analytical methods and calculations

Analysis of fermentation products and ethyl esters by HPLC

Calculations

Results and discussion

Glycerol fermentation pattern and genomic analysis of C. pasteurianum G8

Iron concentration has been reported to have strong effects on the pattern of glycerol fermentation by C. pasteurianum [6, 7]. Therefore, we first examined the effects of iron concentration (1, 10 and 100 mg/L FeSO4·7H2O) on the growth, PDO production and by-product distribution of the mutant C. pasteurianum G8 in batch-fermentations of pure glycerol before evaluating the effects of CEF on the strain. Table 1 summarizes the results from these fermentations at 24 h or when glycerol was completely consumed. When 1 mg/L FeSO4·7H2O (iron limitation) was supplemented in the medium, cell growth and glycerol consumption were remarkably lower than those under the other two iron concentrations (iron excess). As a result, the initial glycerol was completely consumed under iron excess conditions, but 28.96 ± 1.26 g/L of the glycerol remained under iron limitation conditions. No butanol was produced by C. pasteurianum G8 in all the batch fermentations with limited or excess iron. To maintain redox homeostasis, the production of PDO becomes the dominant sink for NADH regeneration of the strain regardless of the applied iron concentration in the medium. Maximum production of PDO (38.51 ± 2.35 g/L, 4.81 ± 0.30 g/L/h) occurred with 100 mg/L FeSO4·7H2O owing to the fast growth of the strain and high product selectivity to PDO of C. pasteurianum G8 under this condition. On the contrary, the strain C. pasteurianum DSMZ 525 produced 12.91 g/L butanol and only 6.09 g/L PDO from glycerol under 10 mg/L FeSO4·7H2O, demonstrating its high product selectivity to butanol.

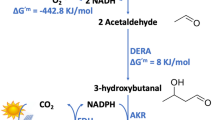

To better understand the special traits of our new mutant, the genome of C. pasteurianum G8 was sequenced. The assembling results showed that its genome size is 4.19 Mbp with a GC content of 29.8%. The number of coding sequences and RNAs are 4,049 and 82, respectively, which belong to 275 subsystems according to the RAST annotation of gene functions. Important genes associated with glycerol anaerobic metabolism and PDO synthesis were identified and compared to those in the most studied butanol-producing C. pasteurianum DSMZ 525 (NCBI, GCA_000330945.1). As summarized in Table S1, the number of genes encoding butanol dehydrogenase in C. pasteurianum G8 is significantly less than that in the 525 strain (2 in G8 vs. 4 in 525). Butanol dehydrogenase is responsible for the last step of butanol formation from butyraldehyde (Fig. 1). The reduction in the genes for this group of enzymes may lead to the decreased capacity of C. pasteurianum G8 for butanol production. Moreover, we found that there is only one gene encoding the butyryl-CoA dehydrogenase (bcd) in C. pasteurianum G8 (2 in 525). In anaerobic bacteria, bcd and the electron transferring flavoprotein (Etf) together form the BCdH-ETF complex, which catalyzes the reduction of crotonyl-CoA to butyryl-CoA by consuming two NADH within a flavin-based electron bifurcating process [4]. The reduction of the gene encoding butyryl-CoA dehydrogenase in C. pasteurianum G8 is likely to weaken the bifurcation process catalyzed by the BCdH-ETF complex, which further reduces the carbon flux towards butanol production. In fact, the NADHR which only considers the reduction of crotonyl-CoA to butyryl-CoA by the 2, 4-dienoyl-CoA reductase with one NADH consumption, was close to 100% in most of the batch fermentations (Fig. 1 and Table 1). This also indicates that the bifurcation pathway is weak or not active in C. pasteurianum G8. In contrast to the reduction in genes for butanol bioconversion, there are two genes encoding 1,3-PDO dehydrogenase in C. pasteurianum G8, whereas only one was found in C. pasteurianum DSMZ 525 (dhaT1 of G8, 99.91%; and dhaT2 of G8, 90.92% identical to dhaT of DSMZ 525). The presence of double genes for the enzyme 1,3-PDO dehydrogenase also suggests their likely importance in achieving high product selectivity to 1,3-PDO by C. pasteurianum G8.

Apart from the PDO and butanol biosynthesis, another interesting finding is that C. pasteurianum G8 lacks the gene encoding the putative 2-hydroxyacid dehydrogenase with a similar function to D-lactate dehydrogenase [11], compared to C. pasteurianum DSMZ 525. In addition, large deletions on the genes encoding L-lactate dehydrogenase were also identified in the G8 strain (length of 742 bp for ldh1, and 190 bp for ldh2 in G8; length of 944 bp for ldh1, and 842 bp for ldh2 in 525). Both the absence and deletion of lactate dehydrogenase-related genes are expected to negatively affect the production of lactate. Indeed, almost no lactate (< 0.5 g/L) was produced by C. pasteurianum G8 in all the batch fermentations (Table 1). As a “back-up” pathway for stabilizing the internal redox balance, especially when the ferredoxin-dependent conversion steps are reduced (Fig. 1), lactate production was found to be 75 times higher under iron limitation than iron excess by C. pasteurianum DSMZ 525 in the previous study [7]. It is likely that the weakened pathway to lactate in C. pasteurianum G8 failed to make up the pyruvate metabolism under iron limitation condition and, therefore, resulted in pyruvate accumulation and reduced glycerol consumption. Considering the fact that 100 mg/L FeSO4·7H2O led to the best 1,3-PDO production in terms of final titer, overall productivity and yield from glycerol, it was chosen to be the reference condition for the subsequent CEF experiments.

Electricity-aided fed-batch fermentations with C. pasteurianum G8

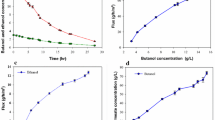

In total, four fed-batch fermentations using pure glycerol as substrate with continuous feeding (20–40 g/L/h with 50 wt% glycerol) under different cathodic currents (0, − 200, − 400 and − 600 mA) were performed. For all experiments, the electrode was started 2 h after inoculation (OD600 reached 2–3) and continued until the end of the fermentation. As shown in Fig. 2 and Table 2, the butyrate production of strain G8 was significantly enhanced with increasing intensity of the cathodic current. The butyrate concentration increased from 14.37 g/L at 0 mA, to 18.84 g/L at − 200 mA, and further to 25.89 g/L at − 400 mA. On the contrary, acetate production decreased from 24.01 g/L at 0 mA, to 20.72 g/L at -200 mA, and further to 19.45 g/L at − 400 mA, respectively. At − 600 mA the butyrate production was slightly reduced to 20.62 g/L, but a small amount of butanol production (1.23 g/L) also occurred at this current density. These results are strictly opposite to those reported by [2, 5], where butyrate production decreased significantly in the CEFs with C. pasteurianum DSMZ 525. When the intracellular NADH/NAD+ ratio increased in CEF, a metabolic shift was triggered towards the more efficient NADH-consuming production of butanol (Fig. 1), leading to less carbon flow to the butyrate production. Butanol production (net NADH-neutral) was used as the main solution for the fast regulation of intracellular redox balance as well as for ATP supply in the CEFs with the 525 strains.

On the contrary, the weakened butanol pathway in C. pasteurianum G8 is probably not efficient enough to fast regulate the increased NADH/NAD+ ratio in CEF. As an alternative, the combination of butyrate and PDO production becomes the most efficient way for balancing NADH/NAD+ ratio as well as maintaining a high energy supply in C. pasteurianum G8. As shown in Fig. 1, the NADH production yield from glycerol through the acetate pathway in C. pasteurianum is 2 mol NADH/mol glycerol, whereas this value decreases to 1 mol NADH/mol glycerol through the butyrate pathway. Moreover, when the BCdH-ETF is involved in the conversion of crotonyl-CoA to butyryl-CoA, the NADH production yield from glycerol through the butyrate pathway will be further reduced to 0.5 mol NADH/mol glycerol [4, 7]. Under a high NADH/NAD+ ratio induced by the cathodic current, butyrate production with a lower NADH-producing efficiency was therefore enhanced in CEF. Calculations for the NADH recovery also reveal that other than electrons from glycerol, extra electrons were supplied to the strain for PDO production during the CEFs (All NADHR in CEF were higher than that in the control fermentation, Table 2). However, the PDO yield from glycerol in all the CEFs with extra electron supply were still lower than that in the control fermentation due to the higher carbon loss of glycerol for butyrate production than acetate production.

Surprisingly, the total glycerol consumptions by the strain G8 in all the CEFs were higher than that in the control experiment, which also resulted in a higher PDO titer in the CEFs (Table 2). The final PDO concentration increased from 90.55 g/L at 0 mA, to 103.01 g/L at -200 mA, and further to 120.67 g/L at − 400 mA. This could be due to the increased ATP production in CEFs for higher biomass formation. Especially, the YATP at -400 mA reached 10.41 gbiomass/molATP, which was 62% higher than that achieved in the control fermentation. Since the theoretical YATP is reported as 8.5 gbiomass/molATP [19], a YATP higher than this value indicates that, apart from substrate-level phosphorylation, more ATP could be formed through electron transport phosphorylation [8]. It is reported that the menaquinone-dependent proton-translocating enzyme Hydrogenase-1 in C. pasteurianum is able to translocate a pair of protons outside the cell membrane with concomitant consumption of H2 present outside the cell membrane, which contributes to ATP synthesis by a proton-translocating ATPase [14]. It is highly possible that the abiotically produced hydrogen by the electrode at -400 mA improved hydrogen uptake of the strain, which also enhanced the ATP generation from electron transport phosphorylation.

Further increase of the cathodic current to − 600 mA did not result in a higher glycerol consumption and PDO production. Instead, PDO titer decreased to 102.07 g/L with a lower NADH recovery of 104.95% as compared to those with lower current intensities (NADHR: 109.90% at − 200 mA and 109.49% at − 400 mA, Table 2). It is assumed that the strain might suffer some stress and growth inhibition after being exposed to the high current intensities at − 600 mA for some time, which negatively affected the fermentation performance. It can be seen that the cells completely entered the stationary phase after 15 h fermentation at − 600 mA (Fig. 2D), whereas slow growth (µ = 0.025 h−1) was maintained until the end of the fermentation at − 400 mA (Fig. 2C). Moreover, according to the whole genome sequencing results, the butanol pathway is weakened but intact in C. pasteurianum G8. When the strain suffers from severe stress, such as exposure to an initial glycerol concentration over 120 g/L, butanol will be forced to be produced as a way for stress relief [22]. The small amount of butanol production (1.23 g/L) only occurred at -600 mA further confirmed the possible growth inhibition induced by the high current intensity. Apart from the biomass formation, the lower extra electron acceptance by the strain at − 600 mA could also be the reason for the reduced PDO production. Either the growth inhibition or the increased utilization of bifurcation conversion from crotonyl-CoA to butyryl-CoA under high current intensity could lead to a reduced extra electron uptake ability of the strain. Nevertheless, these results from CEFs of C. pasteurianum G8 give the first example to demonstrate the potential use of electro-fermentation in an industrial biological process.

DSP for the co-production of PDO, ethyl acetate and ethyl butyrate

The unique regulation pattern of C. pasteurianum G8 in the CEF at − 400 mA resulted in a marked increase of PDO titer by more than 33% and reached a final PDO titer of 120.67 g/L, which is the highest PDO production level ever reported by natural PDO producers so far. The increased total products concentration in CEF (PDO + acids: 166.10 g/L at − 400 mA vs. 128.93 g/L in control) is also expected to reduce the energy consumption for water evaporation in the DSP. However, CEF did not result in a higher PDO yield from glycerol by C. pasteurianum G8. Instead, more acids were produced (acetate + butyrate: 45.34 g/L at − 400 mA vs. 38.38 g/L in control) and a lower PDO yield (0.49 g/g at − 400 mA vs. 0.51 g/g in control) were reached in CEF. To increase the process economy of bio-PDO production by CEF, the acids should be well separated and recovered as co-products of PDO in the DSP to avoid significant carbon loss of glycerol in the whole production process.

Here, a novel DSP which can achieve the efficient co-production of PDO and ethyl ester of organic acids is presented (Fig. S1). After ultrafiltration to remove biomass and evaporation to remove water, the concentrated broth containing PDO, glycerol, medium salts and sodium salt of organic acids is fed to a thin film evaporator for the direct distillation of PDO. It is expected that most part of PDO and some part of the glycerol are collected as distillate. This distillate without the contamination of PDO esters and free acids can be directly fed to a distillation column for the separation of PDO and glycerol. In this way, only 4 steps are needed for obtaining the fiber-grade PDO, which is highly efficient. On the other hand, most part of the glycerol and all the inorganic and organic acid salts are collected as residue from the thin film evaporation. The continuous flow of glycerol generated by the inner scrapper of the thin film evaporator is expected to prevent the precipitation of salts during the distillation process. Since PDO has been separated and the esterification reactivity of organic acids to glycerol is significantly lower than that to PDO [22], the residue can be mixed with ethanol instead of methanol for the removal of inorganic salts and for the efficient production of ethyl acetate and ethyl butyrate (Fig. S2). Finally, the residual glycerol after separating the ethanol and ethyl esters can be directly recycled to the next DSP as a heavy solvent again.

Thin film evaporation for the continuous distillation of PDO

To fulfill the designed DSP, a successful thin film evaporation process for continuous PDO distillation is necessary. To achieve a high PDO yield in the distillate and at the same time retain most of the glycerol in the residue for efficient salts suspension, the heating temperature for the thin film evaporation should be closed to the boiling point of glycerol and significantly higher than the boiling point of PDO at a specific vacuum pressure. Fig. S3 shows the boiling points of PDO and glycerol predicted by Aspen plus using the NRTL model under different pressures. As the pressure drops, the difference of boiling point between PDO and glycerol is also getting smaller and smaller. In particular, a pressure lower than 1 mbar may result in a similar distillation proportion of the two compounds, which leads to insufficient glycerol in the residue for suspending all the inorganic and organic acids salts. In a batch distillation experiment for separating PDO from glycerol using a rotary evaporator [21], a heating temperature of 140 °C, and a vacuum pressure of 20 mbar (Boiling point of PDO at 20 mbar: 115 °C) were efficient enough for recovering more than 95% PDO with very low glycerol evaporation (< 5%). However, these conditions are not able to achieve a high product yield in the continuous PDO distillation process due to the low retention time (heating time) of the feed in the thin film evaporator. A heating temperature significantly higher than the boiling point of PDO is needed in the thin film evaporation process. Therefore, to achieve a low glycerol evaporation but a high PDO yield in the distillate, a vacuum pressure of 2 mbar (PDO boiling point: 75 °C; glycerol boiling point: 132 °C) and a heating temperature of 135 °C were chosen to test the thin film evaporation. Another issue that needs to be considered before carrying out the experiment is the glycerol content in the concentrated broth. Previous studies have shown that 20 wt% glycerol was not enough for suspending all the inorganic salts and sodium acid salts during the batch distillation of PDO [21]. To ensure the continuous outflow of residue from the thin film evaporator without significant salt crystallization, glycerol content in the ultra-filtrated broth was adjusted to 10 wt%, which resulted in a concentrated broth containing more than 40 wt% glycerol after water evaporation.

As shown in Table 3 and Fig. 3, the continuous PDO distillation by using the thin film evaporator was successfully performed. The collected distillate contained a very high purity of PDO and glycerol without any contamination of free acids or PDO esters (Table 3, content 5). A very high PDO yield more than 96% was achieved. Surprisingly, the recovery of glycerol in the distillate was also very high (41.64 wt%) even when the heating temperature was only 3 °C higher than the boiling point of glycerol. This could be due to the fluctuation of vacuum pressure from 1–3 mbar during thin film evaporation. Nevertheless, the remaining glycerol in the residue (49.01 wt%) was still enough to suspend all the salts and a continuous outflow of residue was observed throughout the whole evaporation process (Fig. 3A). However, when a concentrated broth only containing 20 wt% glycerol was fed to the thin film evaporator, a large amount of crystallized salts were precipitated at the bottom (Fig. 3B), and the process was stopped due to the blockage of the residue outlet. Apart from the glycerol content, we also tested whether the pH of the concentrated broth will affect the thin film evaporation of PDO. Figure 3C shows the retentions of sodium acetate and sodium butyrate in the residue of thin film evaporation. It can be seen that 100% acids retention was only achieved under pH12 (actual pH: 11.58). As the pH decreased, more acids were evaporated and contaminated the PDO product in the distillate. In a previous study done by our group, a heating temperature of 180 °C at 20 mbar resulted in 8.5% and 8.4% evaporation of acetic acid and butyric acid, respectively, even when the pH of the concentrated broth was adjusted to 12 [21] Although a higher vacuum pressure is expected to reduce the glycerol evaporation, it also requires a higher heating temperature for recovering most of the PDO, which may also result in the liberation of free acids from the sodium acid salts. To avoid any possible formation of PDO ester impurities in the final distillation step, thin film evaporation under high pH (11–12) and low heating temperature (< 140 °C) is therefore required.

Continuous PDO distillation from concentrated fermentation broth by thin film evaporation operating at a heating temperature of 135 °C, a vacuum pressure of 1–3 mbar, and a feed rate of 10–15 mL/min. A Continuous outlet flow of the residue was achieved when the feed was containing 40 wt% glycerol; B Significant precipitation of salts in the outlet flow of the residue was observed when the feed was only containing 20 wt% glycerol; C Retentions of sodium acetate and sodium butyrate in the residue from the thin film evaporation under different pH

Esterification of organic acids with ethanol in the fermentation broth

Table 3 (content 6) shows the components of the residue from successful thin film evaporation. It can be seen that the PDO content (2.90 wt%) was significantly lower than the total acids content (25.97 wt%). Therefore, the influence of PDO on the esterification selectivity of acids to ethanol can be ignored. Moreover, an ethanol: residue ratio of 1.5: 1 (w/w) was found to be enough for the complete crystallization of inorganic salts. This is probably due to the reduced solubility of inorganic salts in the residue without PDO and their lower solubility in ethanol than in methanol. In the previous studies done by our group, the heterogeneous catalyst Amberlyst-15 was used for the esterification between acids and methanol [22], because more PDO ester impurities will be formed when using H2SO4 as catalyst. In fact, the homogeneous catalyst H2SO4 is more frequently used for esterification reactions in the industry due to its strong catalytic activity and dehydration ability. If H2SO4 were used in our esterification process, it can not only act as a catalyst, but also an acidification agent for the sodium acid salts and a dehydration agent for the produced water. The absence of PDO in the residue from thin film evaporation allows the use of H2SO4 as a catalyst, which is expected to result in a faster conversion rate of acid esters than that with Amberlyst-15.

Based on the above assumption, residue from the thin film evaporation was mixed with anhydrous ethanol (1.5 times the weight of the residue), and subsequently acidified to pH0.5 by adding 96% H2SO4. Since homogeneous catalyst was used, the reaction was directly carried out at 70 °C without removing the crystallized inorganic salts. As shown in Fig. 4 and Table 3 (content 7), H2SO4 exhibited a very strong catalytic activity for the esterification between organic acids and ethanol. More than 50% acetic acid and butyric acid were converted to their corresponding ethyl ester products only after the acidification to pH 0.5. Finally, 6.47 wt% ethyl acetate and 6.69 wt% ethyl butyrate were simultaneously produced after 1 h reaction, representing a very high esterification yield of 96% for acetic acid, and 94% for butyric acid, respectively. After salt removal by centrifugation, ethanol and ethyl esters were separated from glycerol by using a rotary evaporator, resulting in an ethanol solution containing 9.22 wt% ethyl acetate and 8.9 wt% ethyl butyrate (Table 3, content 9). In this scenario, the total carbon recovery (carbon from PDO, acetic and butyric acids) from the CEF fermentation broth is more than 87%, which is 21% higher than the case when PDO is recovered as a single product. It should be noted that more than 10% ethyl acetate and 13% ethyl butyrate were lost in the salt pellet after centrifugation (Table 3, content 8). This led to a reduction of overall process recovery (in ethyl ester form) from 86% (before centrifugation) to 78% (after centrifugation) for acetic acid, and from 80 to 70% for butyric acid. To improve the recovery yield of ethyl esters, the salts pellet can be washed with a small amount of anhydrous ethanol for several times to recover the esters as much as possible. Theoretically more than 90% of the acids can be separated and recovered in ethyl ester form from the CEF fermentation broth if the lost acids in the dead volume (stuck in the inner wall of the thin film evaporator and in the salts pellet) is not considered.

Conclusions

In this study, the effect of CEFs on the PDO production from glycerol by a low-butanol-producing mutant C. pasteurianum G8 was investigated. A significantly higher butyrate formation and YATP were induced by the cathodic current, resulting in an enhanced biomass formation, and therefore higher glycerol consumption and PDO production. The highest product titer reached 166.10 g/L (120.67 g/L PDO + 45.43 g/L acids) in the CEF at -400 mA. Finally, co-production of PDO and ethyl esters from the CEFs broth was successfully achieved by a novel DSP integrated with a thin film evaporation process and an esterification process.

Data availability

The data that support the findings of this study are available from the corresponding author upon reasonable request.

References

Aziz RK, Bartels D, Best AA et al (2008) The RAST server: rapid annotations using subsystems technology. BMC Genom 9:75

Arbter P, Sabra W, Utesch T, Hong Y, Zeng AP (2021) Metabolomic and kinetic investigations on the electricity-aided production of butanol by Clostridium pasteurianum strains. Eng Life Sci 21:181–195

Arbter P, Widderich N, Utesch T, Hong Y, Zeng AP (2022) Control of redox potential in a novel continuous bioelectrochemical system led to remarkable metabolic and energetic responses of Clostridium pasteurianum grown on glycerol. Microb Cell Fact 21(1):1–8

Buckel W, Thauer RK (2013) Energy conservation via electron bifurcating ferredoxin reduction and proton/Na+ translocating ferredoxin oxidation. Biochim Biophys Acta 1827:94–113

Choi O, Kim T, Woo HM, Um Y (2014) Electricity-driven metabolic shift through direct electron uptake by electroactive heterotroph Clostridium pasteurianum. Sci Rep 4:6961

Gallardo R, Alves M, Rodrigues LR (2016) Influence of nutritional and operational parameters on the production of butanol or 1,3-propanediol from glycerol by a mutant Clostridium pasteurianum. New Biotechnol 34:59–67

Groeger C, Wang W, Sabra W, Utesch T, Zeng AP (2017) Metabolic and proteomic analyses of product selectivity and redox regulation in Clostridium pasteurianum grown on glycerol under varied iron availability. Microb Cell Fact 16:64

Hackmann TJ, Firkins JL (2015) Electron transport phosphorylation in rumen butyrivibrios: unprecedented ATP yield for glucose fermentation to butyrate. Front Microbiol 6:622

Kaeding T, DaLuz J, Kube J, Zeng AP (2015) Integrated study of fermentation and downstream processing in a miniplant significantly improved the microbial 1,3-propanediol production from raw glycerol. Bioprocess Biosyst Eng 38:575–586

Li Z, Yan L, Zhou J, Wang X, Sun Y, **u ZL (2019) Two-step salting-out extraction of 1, 3-propanediol, butyric acid and acetic acid from fermentation broths. Sep Purif Technol 209:246–253

Matelska D, Shabalin IG, Jabłońska J, Domagalski MJ, Kutner J, Ginalski K, Minor W (2018) Classification, substrate specificity and structural features of D-2-hydroxy acid dehydrogenases: 2HADH knowledgebase. BMC Evol Biol 18:199

Nakamura CE, Whited GM (2003) Metabolic engineering for the microbial production of 1,3-propanediol. Curr Opin Biotech 14:454–459

Song Z, Sun Y, Wei B, **u Z (2013) Two-step salting-out extraction of 1,3-propanediol and lactic acid from the fermentation broth of Klebsiella pneumonia on biodiesel-derived crude glycerol. Eng Life Sci 13:487–495

Sabra W, Wang W, Surandram S, Groeger C, Zeng AP (2016) Fermentation of mixed substrates by Clostridium pasteurianum and its physiological, metabolic and proteomic characterizations. Microb Cell Fact 15:114

Sun YQ, Shen JT, Yan L, Zhou JJ, Jiang LL, Chen Y, Yuan JL, Feng EM, **u ZL (2018) Advances in bioconversion of glycerol to 1,3-propanediol: prospects and challenges. Process Biochem 71:134–146

Utesch T, Zeng AP (2018) A novel all-in-one electrolysis electrode and bioreactor enable better study of electrochemical effects and electricity-aided bioprocesses. Eng Life Sci 18:600–610

Utesch T, Sabra W, Prescher C, Baur J, Arbter P, Zeng AP (2019) Enhanced electron transfer of different mediators for strictly opposite shifting of metabolism in Clostridium pasteurianum grown on glycerol in a new electrochemical bioreactor. Biotechnol Bioeng 116:1627–1643

**u ZL, Zeng AP (2008) Present state and perspective of downstream processing of biologically produced 1,3-propanediol and 2,3-butanediol. Appl Microbiol Biotechnol 78:917–926

Zeng AP (1996) Pathway and kinetic analysis of 1,3-propanediol production from glycerol fermentation by Clostridium butyricum. Bioprocess Eng 14:169–175

Zeng AP (2019) New bioproduction systems for chemicals and fuels: needs and new development. Biotechnol Adv 37:508–518

Zhang C, Sharma S, Wang W, Zeng AP (2021) A novel downstream process for highly pure 1,3-propanediol from an efficient fed-batch fermentation of raw glycerol by Clostridium pasteurianum. Eng Life Sci 21:351–363

Zhang C, Sharma S, Ma C, Zeng AP (2022) Strain evolution and novel downstream processing with integrated catalysis enable highly efficient co-production of 1,3-propanediol and organic acid esters from crude glycerol. Biotechnol Bioeng 199:1450–1466

Acknowledgements

We thank Shubhang Sharma for assistance in carrying out some of the experiments for DSP, Dr. Wei Wang and Anna Grote for support in the sample analysis.

Author information

Authors and Affiliations

Contributions

CZ: Conceptualization; methodology; validation; formal analysis; investigation; data curation; writing—original draft; review & editing; visualization. PT: Conceptualization; Methodology; validation; investigation. APZ: Conceptualization; supervision; writing—review & editing; funding acquisition.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zhang, C., Traitrongsat, P. & Zeng, AP. Electrochemically mediated bioconversion and integrated purification greatly enhanced co-production of 1,3-propanediol and organic acids from glycerol in an industrial bioprocess. Bioprocess Biosyst Eng 46, 565–575 (2023). https://doi.org/10.1007/s00449-022-02841-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00449-022-02841-6