Abstract

Mycotoxin production by aflatoxin B1 (AFB1) -producing Aspergillus flavus Zt41 and sterigmatocystin (ST) -hyperproducer Aspergillus creber 2663 mold strains on corn and rice starch, both of high purity and nearly identical amylose-amylopectin composition, as the only source of carbon, was studied. Scanning electron microscopy revealed average starch particle sizes of 4.54 ± 0.635 µm and 10.9 ± 2.78 µm, corresponding to surface area to volume ratios of 127 1/µm for rice starch and 0.49 1/µm for corn starch. Thus, a 2.5-fold difference in particle size correlated to a larger, 259-fold difference in surface area. To allow starch, a water-absorbing powder, to be used as a sole food source for Aspergillus strains, a special glass bead system was applied. AFB1 production of A. flavus Zt41 was determined to be 437.6 ± 128.4 ng/g and 90.0 ± 44.8 ng/g on rice and corn starch, respectively, while corresponding ST production levels by A. creber 2663 were 72.8 ± 10.0 µg/g and 26.8 ± 11.6 µg/g, indicating 3–fivefold higher mycotoxin levels on rice starch than on corn starch as sole carbon and energy sources.

Key points

• A glass bead system ensuring the flow of air when studying powders was developed.

• AFB1 and ST production of A. flavus and A. creber on rice and corn starches were studied.

• 3–fivefold higher mycotoxin levels on rice starch than on corn starch were detected.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Aflatoxins (AFs), though natural substances, are among the presently known most carcinogenic compounds. These most important mycotoxins are produced mainly by numerous species from the genus Aspergillus (Rank et al. 2011). These fungi can contaminate cereals before harvest on the fields or during storage in storehouses, resulting in substantial economic losses throughout the world (Wilkinson et al. 2004). Aflatoxins can cause acute hepatic failure in humans, as well as in higher vertebrates and poultry (Wogan 1992; Hua et al. 2020).

Sterigmatocystin (ST) is a precursor of AFs in their biosynthesis, first isolated from Aspergillus versicolor in 1954 (Soriano del Castillo 2007). ST is also toxic, mutagenic, and carcinogenic (Kövesi et al. 2021; Zhou et al. 2023; Zingales et al. 2020), although less than aflatoxin B1 (AFB1) (Alonso-Jauregui et al. 2023). The oral LD50 values of ST and AFB1 for male rats are 60–800 and 5.5 mg/kg body weight, respectively (Tabata 2011). ST is produced by some Aspergillus species like A. versicolor, A. nidulans, and A. sydowii, and also by some species of Bipolaris. The major ST-producer among them is A. versicolor (Tabata 2011; Mahata et al. 2022).

According to dozens of studies in the scientific literature (Yu 2012; Schmidt-Heydt et al. 2009, 2010; Marroquin-Cardona et al. 2014; Dövényi-Nagy et al. 2020), the optimal aw for mycotoxin production is at the range of 0.92–0.96 aw, at 27–35 °C. Lv et al. (2019) found that the highest level of AFB1 was produced by Aspergillus flavus on rice at 0.96 aw and 33 °C after 2 weeks. Bernaldez et al. (2017) studied mycotoxin production on corn substance, and found that the maximum AFB1 production was at 30 °C and 0.98 aw (Cotty 1988). In the studies of Casquete et al. (2017), the maximum AFB1 production by A. flavus strains occurred at pH 5.0.

It is well known that the carbon source has a significant impact on AF formation. Simple sugars like maltose or glucose, formed from starches, support AF production (Abdollahi and Buchanan 1981; Buchanan and Lewis 1984; Luchese and Harrigan 1993; Payne and Brown 1998). A relationship between the activity of alpha-amylase and AF production by A. flavus was also reported (Woloshuk et al. 1997). Molds have adapted during their evolution to use starch as carbon and energy sources. Aspergillus strains are highly efficient producers of many extracellular polysaccharide-decomposing enzymes (Mojsov 2016; Hu et al. 2011). These strains are used commercially for the production of amylases, which are in turn used in the starch industry to produce sugars from starch (Van der Maarel et al. 2002). Starch consists of two types of molecules: amylose (linear polymer of D-glucose linked by 1,4 glycosidic linkages) and amylopectin (branched polymer of α-D-glucose units with 1,4–1,6 glycosidic linkages) (Suzuki and Suzuki 2021).

The digestibility of rice starches depends on many factors such as the ratio of amylose and amylopectin (Björck 1996), the crystallinity degree (Chung et al. 2006), and the amylopectin’s molecular structure (Srichuwong and Jane 2007). The digestibility is not related to the percentage of amylopectin, but rather to the size of the side chains (degree of polymerization—DP) that make up the molecule, which for longer chains (DP > 37) results in crystalline cores, making enzymatic hydrolysis more difficult. Better digestibility of amylopectin with short side chains (DP = 6–12) has been reported in several publications (Jane et al. 1997; Magallanes-Cruz et al. 2017). The size and shape of the starch particles are also responsible for the digestibility of starch, as more water is adsorbed on the higher surface area of small starch granules promoting enzymatic digestion.

For toxicology studies, it is essential to perform animal feeding trials with higher-than-normal toxin concentrations. For this purpose, the best way to produce toxins is the inoculation of a substrate with the toxin-producing molds under laboratory conditions. Synthetic media support minimal toxin production (1 to 60 µg AFB1 per g medium), whereas maximum yields (700 to 900 µg AFB1 per g medium) could be observed on autoclaved wheat, rice, cottonseed, and corn (Detroy et al. 1971). On solid rice substrate, more than 1 mg/g AFB1 production was obtained in 5 days at 28 °C (Shotwell et al. 1966). Another favored substrate for toxin production is corn grit. According to Epstein et al. (1970), A. flavus produced 72 µg/g AFs on corn at 28 °C after 2 days. Winn and Lane (1978) found 35 µg/g AFB1 on cracked corn at 25 °C and 70 µg/g at 30 °C. These data suggest that the AF yield of aspergilli on rice is around ten-fold higher than that on corn.

As for the production of ST on corn or rice substrate, only limited data are available. Lepom and Kloss (1988) tested nineteen A. versicolor strains for their production of ST. All isolates were able to produce ST at different levels on a cracked corn substrate, and 53% of the isolates produced more than 500 µg/g of ST. A. nidulans produced only 10.4 µg/g ST, while obtained yields for A. versicolor 22333, 22332, 22334, and flour-mill isolate 2380 were 186.2, 157.4, 9.3, and 12.3 µg/g, respectively, while the best ST producer strain was flour-mill isolate A. creber 2663, with 277.1 µg/g ST production on corn grit (Dobolyi et al. 2021). ST production on rice substrate is submitted by Hajjar et al. (1989), who found that A. nidulans produced 4.6–32.6 µg/g rice, although A. nidulans is not the best ST-producing Aspergillus sp. (Dobolyi et al. 2021). The amounts of the ST produced by A. creber on rice reached 100–150 µg/g at pH levels around 6 at 30 °C and up to 400 µg/g at the optimal temperature of 26 °C (non-published data).

As seen in the scientific literature, there is approximately a tenfold yield difference between corn and rice substrates for AF and ST production, although yields strongly depend on mold species, strains, and environmental conditions of production. During our preliminary experiments, we also established that the AFB1 and ST-producing mold strains grown on rice produce larger amounts of mycotoxins than in the case of corn. For animal feeding trials, 7.59 µg/g ST concentration could be obtained with A. creber in larger quantities of corn grit (Balogh et al. 2019), while on rice 84.39 µg/g ST could be achieved (non-published data), and the ten-fold difference could be observed under the same conditions with the same mold strain.

Our studies aimed to find the reason behind the phenomenon that mycotoxin production by aspergilli on the rice substrate is much higher than on corn. For this purpose, we used our recently isolated AFB1 and ST-producing Aspergillus strains (A. flavus Zt41 and the first extreme ST-producer A. creber 2663 strains in Hungary (Dobolyi et al. 2013, 2021)) with high toxin production ability. To eliminate the complex organic substrates present in corn and rice grains, high-purity corn and rice starches were used as sole carbon and energy sources. Therefore, it was not necessary to include complex purification of the extract, e.g., by liquid–liquid separation using centrifugal partition chromatography (Endre et al. 2019) or application of more selective detection mode, e.g., high-resolution mass spectrometry in the determination of target compounds. In the choice of culture conditions, the objective was to create appropriate environmental conditions for toxin production, to design a culturing system that best mimics the conditions under which molds grow on corn and rice grains.

Liu et al. (2016) investigated the factors that influence the accumulation of AFB1 in seeds. A strong relationship between nutrients and AFB1 production was found in different cereal grains. Different nutrients have different effects on A. flavus growth and mycotoxin production. In the case of lipid-free seeds, AFB1 production significantly decreased. In addition to lipids, other nutrients in the substrate also play a pivotal role in AFB1 biosynthesis and mycelium growth (Liu et al. 2016). Glass beads as a solid support have shown utility not only in plating cell cultures and colony growth (Worthington et al. 2001; Prusokas et al. 2021), but also in the cultivation of filamentous fungi (Bottcher and Conn, 1942; Nguyen et al. 2005; Droce et al. 2013; Ali et al. 2016) showing advantages to both agar plate cultures and liquid cultures.

Taking these aspects into account, the paper fills a notable gap in the literature, particularly concerning the differential production of aflatoxin and sterigmatocystin by Aspergillus species on corn and rice substrates. To this aim a novel approach has been taken by culturing aflatoxin and sterigmatocystin-producing strains of Aspergillus on glass beads coated with corn and rice starches, simulating the natural growth environment of molds on grains. By applying this novel system, the effect of other compounds and nutrients (for example, soluble sugars, lipids, amino acids, etc.) than starch in the seeds on mycotoxin production can be eliminated.

Materials and methods

Chemicals

Corn starch and rice starch used for the AF and ST production studies were purchased from Sigma-Aldrich (Merck Life Science Kft., Budapest, Hungary). The ratio of amylose to amylopectin in corn starch is 27:73 w/w% (Sigma), while rice contains slightly less, 23% amylose (https://www.sigmaaldrich.com/HU/en/product/sial/s4126). All chemicals used in the study were of analytical grade.

Experimental strains

A. flavus Zt41 (NCAIM F.01021) with good AFB1-producing ability was obtained from corn (2009, Baranya County, Hungary); A. creber 2663 (NCAIM F.01020) was isolated from a flour mill in Hungary in 2016 and has an outstanding ST-producing capability (Dobolyi et al. 2021). The strains were stored at − 80 °C in 20% glycerol until use.

To prepare the inoculum for the experiments, the mold strains were spread onto PDA (Potato Dextrose Agar, VWR) plates. The plates were incubated at room temperature for 7 days, in the dark. Suspensions of molds were prepared with sterile water with a Potter homogenizer. The final concentrations were set to 109 conidiospore/mL.

Sterigmatocystin production of A. creber 2663 and aflatoxin B1 production of A. flavus Zt41 on corn and rice starches mounted on glass beads

Into 100 mL glass flasks with screw-tops, 40 g of glass beads with diameters of 2 mm were placed and sterilized by autoclaving. To the flasks, 5 g of rice or corn starch and 3 mL of minimal medium ((NH4)2SO4 1.25 g, KH2PO4 0.5 g, MgSO4 × 7 H2O 0.5 g in 1000 mL distilled water, pH = 4.8) sterilized by filtration were added, and were mixed with a sterile spoon until the starch suspension covered the glass beads evenly.

The pH was 6.0 at the beginning of the experiment, and each setup was sampled periodically during the 3-week incubation. The fifth samples were used for the determination of pH at the end of the cultivation period. Distilled water was added to the flasks and the final pH values were measured as 4.85 and 5.20 for A. creber on rice and corn starch, respectively, and 5.64 and 5.56 for A. flavus on rice and corn starch, respectively.

Then, 500 µl of A. creber 2663 or A. flavus Zt41 suspension prepared as described before was pipetted into each flask in 5–5 parallels, respectively. The flasks were incubated at 26 °C in the dark for 3 weeks. The conditions of cultivation and mycotoxin production were set according to preliminary experiments for mycotoxin production optimisation (non-published data), though from the article’s point of view, it was only necessary to provide the same conditions for both starch setups.

Quantification of sterigmatocystin and aflatoxin B1 by high performance liquid chromatography

After 3 weeks of incubation, to each flask, 20 mL methanol was added and the whole content of the flask was transferred into a Stomacher bag and pulsified for 45 s in a Pulsifier (Microgen Bioproducts Ltd., Camberley, UK). After 24 h in the dark, the bags were pulsified again for 45 s to finish the extraction. The liquid parts were transferred into 50 mL plastic Falcon tubes and centrifuged at 20 °C, for 10 min, at 3000 rpm. The supernatants were stored at − 20 °C until analysis. Control (blank) samples were extracted, derivatised (AFB1), and analyzed in the same way as for the real samples to determine matrix interferences.

For analytical determination of ST and AFB1 by HPLC with reverse phase chromatography, a modular Shimadzu LC-10AD VP HPLC system (Shimadzu Europa GmbH, Duisburg, Germany) was used, equipped with an SPD-10AVP UV–VIS detector (254 nm) and an RF-20A fluorescence detector for ST and AFB1, respectively. ST was detected by its UV absorption. AFB1 was detected by induced fluorescence.

ST analysis has been performed on a Purospher STAR Rp18e 5 µm 125 × 4 mm column (Merck, Darmstadt, Germany). Five microliters of the methanolic extracts were directly injected into the HPLC system mentioned above. The flow rate of 0.5 mL/min was applied during the separation. Initial eluent composition was 40% of water and 60% of methanol, which was held for 1 min; then, methanol content gradually increased to 80% at 9 min, stayed at this rate for 16 min, and finally decreased to the starting value. External calibration with standard solutions of ST was carried out in the range between 0.010 and 20.0 µg/mL.

AFB1 measurement required derivatisation prior to HPLC-FLD analysis. Dried residues, obtained from 1 mL of each extract were resuspended in 0.4 mL of hexane, and 0.1 mL of trifluoroacetic acid (TFA) was added to form the corresponding derivative at 60 °C for 15 min. Next 0.4 mL of water:acetonitrile (9:1) was added, they were mixed, and the lower (aqueous) phase was collected. Three microliters was injected into HPLC system equipped with a Prodigy C18 150 × 4.6 mm 5 µm column (Phenomenex, Torrance, CA, USA) and fluorescence detector. Isocratic chromatographic separation was applied using an eluent (65:35) containing water and a mixture of methanol:acetonitrile (1:1, v/v%) at a flow rate of 1 mL/min. Fluorescence detection wavelengths of 350 nm and 430 nm were used for the excitation and emission, respectively. Calibration curves were recorded with derivatised AFB1 solutions containing the toxin at levels of 1.25, 2.5, 5, 10, 20, 50, 100, and 200 ng/mL. If the level of the sample was out of the range of the calibration curve, it was tenfold diluted.

Calibration curves, obtained from HPLC peak areas at the corresponding retention times, had excellent linear calibration characteristics for both analytes. The Determination Coefficient values (R2) of calibration curves ranged between 0.998 and 1.000, whereas the slopes were 18.3 and 146.5 for AFB1 and ST, respectively. The limits of detection (LODs), defined as analyte concentrations corresponding to the signal-to-noise ratio of 3:1 or greater, were determined with standard solutions. LODs were found to be 1.25 and 10 ng/mL for AFB1 and ST, respectively. Thus, using derivatisation and fluorescence detection mode for AFB1 allowed an order of magnitude improvement in the LOD compared to UV detection (10 ng/mL), in our previous works (Kosztik et al. 2020; Bata-Vidács et al. 2020). The same improved LODs were obtained in spiked liquid matrices extracted from blank samples, indicating no matrix effect under the experimental conditions applied.

Electron microscopy

A few beads from the rice and corn starch setups at the end of the incubation period were used for electron microscopic studies. The pictures were taken by Evo 40 Zeiss electron microscope (Carl Zeiss SMT Evo Series—SEM Technology, Oberkochen, Germany) at the microscope laboratory of the HUN-REN Hungarian Research Network, Budapest, Hungary. The diameters of the starch granules were determined by the AnalySIS Pro 3.2 software (Soft Imaging System GmbH, Münster, Germany).

Results

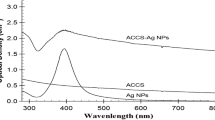

The AFB1 and ST production of A. flavus and A. creber, respectively, on corn and rice starches were studied to determine whether rice starch is a better substrate for toxin production than corn starch, the same way as rice grain is a tenfold better substrate than corn for this purpose. To properly grow mold capable of producing toxins, a suitable model system using glass beads was developed. The physical and morphological characteristics of corn and rice starches and the mycelial growth on the starch granules mounted on glass beads were studied by scanning electron microscopy.

Particle size measurements for rice and corn starch

The particle size distributions of rice and corn starches were determined from scanning electron microscopy images (Fig. 1). Diameters of a hundred particles of rice and corn starch were measured; and averages, deviations, surfaces, and volumes were calculated. The size distribution is shown in Fig. 2, and other parameters determined are presented in Table 1. According to the results, average particle sizes were 10.9 ± 2.78 µm and 4.54 ± 0.635 µm for corn for rice starch, respectively. These results are similar to the findings of Ali et al. (2016), who reported that the size of the granules varied from 5.2 to 5.9 µm and 11.4–12.0 µm for rice and corn starches, respectively, and also with other studies on rice (Gonzalez and Perez 2002; Simi and Abraham 2008) and corn (Jobling 2004) starches. The morphology of starch granules may be attributed to the physiology and biological origin of the plant and also to the biochemistry of the amyloplast. The amylose and amylopectin ratios might also influence the shape and size of starch particles (Kaur et al. 2007). Structure affects the enzymatic digestibility of starches (Biliaderis 1991). Corn and rice starches showed significant differences regarding morphological and physico-chemical properties. The particle size of corn starch is higher on average compared to the granule sizes of rice starches (Dobolyi et al. 2013).

Mold growth on corn and rice starches mounted on glass beads

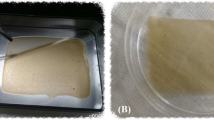

A special system was developed with glass beads that can be used with water-absorbing powdery substrates as starch in experiments that model mold growth on the surface of grain pieces, to ensure the free flow of air and the place for mycelial growth between the grains. Glass beads with diameters of 2 mm were chosen to provide similar parameters as corn grit or rice. The starches were mounted on the surface of the beads with adequate amounts of water. The inoculated molds could grow mycelia and even sporulate on the surface as they would on grain grit particles (Figs. 3 and 4).

Sterigmatocystin production of A. creber 2663 and aflatoxin B1 production of A. flavus Zt41 on corn and rice starches mounted on glass beads

To determine whether rice starch is a better substrate for toxin production than corn starch, rice and corn starches were mounted on glass beads, and the flasks were inoculated with AFB1 producer A. flavus Zt41 or ST producer A. creber 2663. After 3 weeks of incubation at 26 °C in the dark, both molds on both starches showed good growth and sporulation (Fig. 5).

Mycotoxin production in the cultured aspergilli was determined by high performance liquid chromatography (HPLC) using detection by ultraviolet (UV) absorbance of ST and emitted fluorescence of AFB1 derivatised with trifluoroacetic acid (TFA) to form a fluorescent hemiacetal derivative of its terminal fused dihydrofurane ring. Standard chromatograms for ST and AFB1 are shown in Figs. 6 and 7. As blank samples did not contain matrix components, where the target components (ST and AFB1) appear in the chromatograms, quantitation was readily based on instrumental (external) calibration with standard solutions.

Chromatograms of samples analyzed for sterigmatocystin (ST), extracted blank starch matrix (purple line), and that of containing ST (black line). The upper chromatogram was measured for rice (A) and the lower for the corn starch matrix (B). Chromatograms were recorded by using UV–VIS detection mode at wavelength 254 nm

Chromatograms of samples analyzed for aflatoxin B1 (AFB1), extracted blank starch matrix (purple line), and that of containing AFB1 (black line). The upper chromatogram was measured for rice (A) and the lower for corn (B) starch matrix. Chromatograms were recorded by using fluorescence detection mode at wavelengths 350 nm and 430 nm for excitation and emission, respectively

AFB1 production of A. flavus Zt41 was found to be 437.6 ± 128.4 ng/g and 90.0 ± 44.8 ng/g on rice and corn starch substrates, respectively. A. creber 2663 produced 72.8 ± 10.0 µg/g and 26.8 ± 11.6 µg/g ST on rice and corn starch substrates, respectively. A five-fold difference can be observed for AF production between rice and corn starches, and 3 times higher ST production was found on rice starch substrate compared to corn starch.

Discussion

In our study, we aimed to determine whether the use of high-purity corn and rice starch as the only source of carbon and energy could replicate the large differences in AFB1 and ST production yields observed in corn and rice grains. The developed novel glass bead system effectively simulated the surface-volume ratio parameter range of rice and partially of corn seeds. The surface of the glass beads was coated with starch, and the model molds (A. flavus Zt41 and A. creber 2663) were able to weave them richly with their mycelial fibers. Electron microscopy images depicted the starch-degrading activity of the mold strains and the process of spore formation. Analytical studies on pure starch substrates also confirmed the empirical fact that mycotoxin production in rice is well above that in corn. A fivefold difference in AFB1 and a three-fold difference in ST production were detected for rice and corn starches. This means that the difference between the toxin production on rice and corn grains is present for rice and corn starches as well. The difference may be due to the different degradability of the different starches, such as the level of the available substrate, maltose, and glucose. The amylose-to-amylopectin ratio has a role in the enzymatic digestibility of a given starch, but this was found to be only a few percent different in in vitro digestibility studies comparing external low-amylose vax rice varieties (You et al. 2014). Since the amylose content of the corn and rice starches used in the experiment was similar, this difference cannot be the main reason for the observed pronounced difference in toxin production. This difference suggests a diversity in metabolic activity, probably due to the ability of Aspergillus strains to uptake more metabolizable glucose and maltose from rice starch.

In electron microscopy analysis of starches, we found that rice starch granules are half the diameter of corn starch granules, and thus the surface area to volume ratio for rice starch is more than two and a half times that of corn starch, which can greatly enhance the effectiveness of amylases The smaller size of rice starch granules compared to corn starch provides a larger surface area for the same amount of starch, making nutrients more accessible to molds. A higher degree of hydrolysis of rice starch compared to other starches is mentioned in several publications (Fuwa et al. 1977; Snow and O’Dea 1981), because rice starch with smaller granules has a higher specific surface area, increasing the efficiency of enzymatic hydrolysis.

The increase in hydrolytic activity measured for cellulose with increasing specific surface area is a good analogy for the different degradability of corn and rice starch. Yeh et al. (2010) studied how particle size affected the enzymatic hydrolysis of cellulose. By milling technique, two different types of cellulose were obtained: one with a diameter of about 0.8 µm and a second batch with 2.6 µm. The production rate of cellobiose and glucose increased at least fivefold for the starch with the smaller granules, which the authors explained by the larger specific surface area due to the smaller size.

Considering that the amylose-amylopectin ratios of the starches tested were similar (Garc et al. 2015), and existing literature data suggest that this feature is unlikely to cause such a difference in in vitro digestibility (Jane et al. 1997; Magallanes-Cruz et al. 2017), it is probable that the variance in surface area-to-volume ratio is one of the primary explanations for the higher mycotoxin production on the rice substrate. The developed glass bead system may also be suitable for studying the environmental parameters of metabolites produced by other molds.

Data availability

The authors declare that the data supporting the findings of the study are available in the study. If raw data files are required, they are available upon reasonable request from the corresponding author.

References

Abdollahi A, Buchanan RL (1981) Regulation of aflatoxin biosynthesis: induction of aflatoxin production by various carbohydrates. J Food Sci 46(2):633–635. https://doi.org/10.1111/j.1365-2621.1981.tb04928.x

Ali A, Wani TA, Wani IA, Masoodi FA (2016) Comparative study of the physico-chemical properties of rice and corn starches grown in Indian temperate climate. J Saudi Soc Agric Sci 15:75–82. https://doi.org/10.1016/j.jssas.2014.04.002

Alonso-Jauregui M, López de Cerain A, Azqueta A, Rodriguez-Garraus A, Gil AG, González-Peñas E, Vettorazzi A (2023) In vivo genotoxicity and toxicity assessment of sterigmatocystin individually and in mixture with aflatoxin B1. Toxins 15(8):491. https://doi.org/10.3390/toxins15080491

Balogh K, Kövesi B, Zándoki E, Sz K, Zs A, Erdélyi M, Cs D, Bata-Vidács I, Inotai K, Szekeres A, Mézes M, Kukolya J (2019) Effect of sterigmatocystin or aflatoxin contaminated feed on lipid peroxidation and glutathione redox system and expression of glutathione redox system regulatory genes in broiler chicken. Antioxidants 8(7):201. https://doi.org/10.3390/antiox8070201

Bata-Vidács I, Kosztik J, Mörtl M, Székács A, Kukolya J (2020) Aflatoxin B1 and sterigmatocystin binding potential of non-Lactobacillus LAB strains. Toxins 12(12):799. https://doi.org/10.3390/toxins12120799

Bernaldez V, Cordoba JJ, Magan N, Peromingo B, Rodriguez A (2017) The influence of ecophysiological factors on growth, aflR, gene expression and aflatoxin B1 production by a type strain of Aspergillus flavus. LWT - Food Sci Technol 83:283–291. https://doi.org/10.1016/j.lwt.2017.05.030

Biliaderis CG (1991) The structure and interactions of starch with food constituents. Can J Physiol Pharmacol 69:60–78. https://doi.org/10.1139/y91-011

Björck I (1996) Starch: Nutritional aspects. In: Eliasson AC (ed) Carbohydrates in food. Marcel Dekker, New York, pp 505–553

Bottcher EJ, Conn HJ (1942) A medium for the rapid cultivation of soil actinomycetes. J Bacteriol 44:137. https://doi.org/10.1128/jb.44.1.137-137.1942

Buchanan RL, Lewis DF (1984) Regulation of aflatoxin biosynthesis: effect of glucose on activities of various glycolytic enzymes. Appl Environ Microbiol 48:306–310. https://doi.org/10.1128/aem.48.2.306-310.1984

Casquete R, Benito MJ, Cordoba MG, Ruiz-Moyano S, Martin A (2017) The growth and aflatoxin production of Aspergillus flavus strains on a cheese model system are influenced by physicochemical factors. J Dairy Sci 100:6987–6996. https://doi.org/10.3168/jds.2017-12865

Chung HJ, Lim HS, Lim ST (2006) Effect of partial gelatinization and retrogradation on the enzymatic digestion of waxy rice starch. J Cereal Sci 43:353–359. https://doi.org/10.1016/j.jcs.2005.12.001

Cotty P (1988) Aflatoxin and sclerotial production by Aspergillus flavus: influence of pH. Phytopathol 78:1250–1253. https://doi.org/10.1094/Phyto-78-1250

Detroy RW, Lillehoj EB, Ciegler A (1971) Aflatoxin and related compounds. In: Ciegler A, Kadis S, Ajl SJ (eds) Microbial toxins, 6th edn. Academic Press Inc, New York, pp 3–178

Dobolyi C, Sebők F, Varga J, Kocsubé S, Szigeti G, Baranyi N, Szécsi Á, Tóth B, Varga M, Kriszt B, Szoboszlay S, Krifaton C, Kukolya J (2013) Occurrence of aflatoxin producing Aspergillus flavus isolates in maize kernel in Hungary. Acta Aliment 42:451–459. https://doi.org/10.1556/AAlim.42.2013.3.18

Dobolyi C, Inotai K, Bata-Vidács I, Sárkány D, Csernus O, Kocsubé S, Tóth B, Szekeres A, Kukolya J (2021) Isolation and characterisation of sterigmatocystin producing Aspergillus isolates from Hungarian flour-mills. Acta Aliment 50(2):247–258. https://doi.org/10.1556/066.2020.00326

Dövényi-Nagy T, Rácz C, Molnár K, Bakó K, Szláma Z, Jóźwiak Á, Farkas Z, Pócsi I, Dobos AC (2020) Pre-harvest modelling and mitigation of aflatoxins in maize in a changing climatic environment—a review. Toxins 12(12):768. https://doi.org/10.3390/toxins12120768

Droce A, Sørensen JL, Giese H, Sondergaard TE (2013) Glass bead cultivation of fungi: combining the best of liquid and agar media. J Microbiol Meth 94:343–346. https://doi.org/10.1016/j.mimet.2013.07.005

Endre G, Hegedüs Z, Turbat A, Škrbić B, Vágvölgyi C, Szekeres A (2019) Separation and purification of aflatoxins by centrifugal partition chromatography. Toxins 11(6):309. https://doi.org/10.3390/toxins11060309

Epstein E, Steinberg MP, Nelson AI, Wei LS (1970) Aflatoxin production as affected by environmental conditions. J Food Sci 35:389–391. https://doi.org/10.1111/j.1365-2621.1970.tb00939.x

Fuwa H, Nakajima M, Hamada A, Glover DV (1977) Comparative susceptibility to amylases of starches from different plant species and several single endosperm mutants and their double-mutant combinations with opaque-2 inbred Oh43 maize. Cereal Chem 54:230–237. https://doi.org/10.3177/jnsv.24.437

Garc NL, Fam L, Accorso NBD, Goyanes S (2015) Eco-friendly polymer nanocomposites. Springer, India 17–77. https://doi.org/10.1007/978-81-322-2473-0

Gonzalez Z, Perez E (2002) Effect of acetylation on some properties of rice starch. Starch/starke 54:148–154. https://doi.org/10.1002/1521-379X(200204)54:3/4%3c148::AID-STAR148%3e3.0.CO;2-N

Hajjar JD, Bennett JW, Bhatnagar D, Bahu R (1989) Sterigmatocystin production by laboratory strains of Aspergillus nidulans. Mycol Res 93(4):548–551. https://doi.org/10.1016/S0953-7562(89)80052-8

Hu HL, Van den Brink J, Gruben BS, Wösten HAB, Gu J-D, de Vries RP (2011) Improved enzyme production by co-cultivation of Aspergillus niger and Aspergillus oryzae and with other fungi. Int Biodeterior Biodegradation 65:248–252. https://doi.org/10.1016/j.ibiod.2010.11.008

Hua Z, Liu R, Chen Y, Liu G, Li C, Li C, Song Y, Cao Z, Li W, Li W, Lu C, Liu Y (2020) Contamination of aflatoxins induces severe hepatotoxicity through multiple mechanisms. Front Pharmaco 11:605823. https://doi.org/10.3389/fphar.2020.605823

Jane J, Wong KS, McPherson AE (1997) Branch-structure difference in starches of A- and B-type X-ray patterns revealed by their Naegeli dextrins. Carbohydr Res 300:219–227. https://doi.org/10.1016/S0008-6215(97)00056-6

Jobling S (2004) Improving starch for food and industrial applications. Curr Opin Plant Biol 7:210–218. https://doi.org/10.1016/j.pbi.2003.12.001

Kaur L, Singh J, Mccarthy OJ, Singh H (2007) Physico-chemical, rheological and structural properties of fractionated potato starches. J Food Eng 82:383–394. https://doi.org/10.1016/j.jfoodeng.2007.02.059

Kosztik J, Mörtl M, Székács A, Kukolya J, Bata-Vidács I (2020) Aflatoxin B1 and sterigmatocystin binding potential of lactobacilli. Toxins 12(12):756. https://doi.org/10.3390/toxins12120756

Kövesi B, Sz K, Zs A, Zándoki E, Erdélyi M, Mézes M, Balogh K (2021) Individual and combined effects of aflatoxin B1 and sterigmatocystin on lipid peroxidation and glutathione redox system of common carp liver. Toxins 13(2):109. https://doi.org/10.3390/toxins13020109

Lepom P, Kloss H (1988) Production of sterigmatocystin by Aspergillus versicolor isolated from roughage. Mycopathologia 101:25–29. https://doi.org/10.1007/BF00455665

Liu J, Sun L, Zhang N, Zhang J, Guo J, Li C, Rajput SA, Qi D (2016) Effects of nutrients in substrates of different grains on aflatoxin B1 production by Aspergillus flavus. Biomed Res Int 10 https://doi.org/10.1155/2016/7232858 (Article ID 7232858)

Luchese RH, Harrigan WF (1993) Biosynthesis of aflatoxin - the role of nutritional factors. J Appl Bacteriol 74:5–14. https://doi.org/10.1111/j.1365-2672.1993.tb02989.x

Lv C, ** J, Wang P, Dai X, Liu Y, Zheng M, **ng F (2019) Interaction of water activity and temperature on the growth, gene expression and aflatoxin production by Aspergillus flavus on paddy and polished rice. Food Chem 293:472–478. https://doi.org/10.1016/j.foodchem.2019.05.009

Magallanes-Cruz PA, Flores-Silva PC, Bello-Perez LA (2017) Starch structure influences its digestibility: a review. J Food Sci 82:2016–2023. https://doi.org/10.1111/1750-3841.13809

Mahata PK, Dass RS, Gunti L, Thorat PA (2022) First report on the metabolic characterization of Sterigmatocystin production by select Aspergillus species from the Nidulantes section in Foeniculum vulgare. Front Microbiol 13:958424. https://doi.org/10.3389/fmicb.2022.958424

Marroquin-Cardona AG, Johnson NM, Phillips TD, Hayes AW (2014) Mycotoxins in a changing global environment - a review. Food Chem Toxicol 69:220–230. https://doi.org/10.1016/j.fct.2014.04.025

Mojsov KD (2016) Aspergillus enzymes for food industries. In: Gupta VK (ed) New and future developments in microbial biotechnology and bioengineering. Elsevier, pp 215–222. https://doi.org/10.1016/b978-0-444-63505-1.00033-6

Nguyen L, Kalachova L, Novotna J, Holub M, Kofronova O, Benada O, Thompson C, Weiser J (2005) Cultivation system using glass beads immersed in liquid medium facilitates studies of Streptomyces differentiation. Appl Environ Microbiol 71:2848–2852. https://doi.org/10.1128/AEM.71.6.2848-2852.2005

Payne GA, Brown MP (1998) Genetics and physiology of aflatoxin biosynthesis. Annu Rev Phytopathol 36:329–362. https://doi.org/10.1146/annurev.phyto.36.1.329

Prusokas A, Hawkins M, Nieduszynski CA, Retkute R (2021) The effectiveness of glass beads for plating cell cultures. Phys Rev E 103:052410. https://doi.org/10.1103/PhysRevE.103.052410

Rank C, Nielsen KF, Larsen TO, Varga J, Samson RBA, Frisvad JS (2011) Distribution of sterigmatocystin in filamentous fungi. Fungal Biol 115:406–420. https://doi.org/10.1016/j.funbio.2011.02.013

Schmidt-Heydt M, Abdel-Hadi A, Magan N, Geisen R (2009) Complex regulation of the aflatoxin biosynthesis gene cluster of Aspergillus flavus in relation to various combinations of water activity and temperature. Int J Food Microbiol 135:231–237. https://doi.org/10.1016/j.ijfoodmicro.2009.07.026

Schmidt-Heydt M, Rufer CE, Abdel-Hadi A, Magan N, Geisen R (2010) The production of aflatoxin B1 or G1 by Aspergillus parasiticus at various combinations of temperature and water activity is related to the ratio of aflS to aflR expression. Mycotoxin Res 26:241–246. https://doi.org/10.1007/s12550-010-0062-7

Shotwell OL, Hesseltine CW, Stubblefield RD, Sorenson WG (1966) Production of aflatoxin on rice. Appl Microbiol 14(3):425–428. https://doi.org/10.1128/am.14.3.425-428.1966

Simi CK, Abraham TE (2008) Physicochemical rheological and thermal properties of Njavara rice (Oryza sativa) starch. J Agric Food Chem 56:12105–12113. https://doi.org/10.1021/jf802572r

Snow P, O’Dea K (1981) Factors affecting the rate of hydrolysis of starch in food. Amer J Clin Nutr 34(12):2721–2727. https://doi.org/10.1093/ajcn/34.12.2721

Soriano del Castillo JM (2007) Micotoxinas en alimentos. Spain: Ediciones Díaz de Santos, ISBN: 978–84–7978–808–7. https://www.editdiazdesantos.com/wwwdat/pdf/9788479788087.pdf

Srichuwong S, Jane J (2007) Physicochemical properties of starch affected by molecular composition and structure: a review. Food Sci Biotechnol 16(5): 663–674. https://koreascience.kr/article/JAKO200735822355808.pdf

Suzuki R, Suzuki E (2021) The branched structure and properties of starch - determined from studies on branching enzymes. Glycoforum 24(3):A7. https://doi.org/10.32285/glycoforum.24A7

Tabata S (2011) Yeasts and molds - mycotoxins: aflatoxins and related compounds. In: Fuquay JW (ed) Encyclopedia of dairy sciences, 2nd edn. Academic Press, San Diego, CA, USA, pp 801–811

Van der Maarel MJEC, Van der Veen B, Uitdehaag JCM, Leemhuis H, Dijkhuizen L (2002) Properties and applications of starch-converting enzymes of the α-amylase family. J Biotechnol 94:137–155. https://doi.org/10.1016/s0168-1656(01)00407-2

Wilkinson HH, Ramaswamy A, Sung CS, Keller NP (2004) Increased conidiation associated with progression along the sterigmatocystin biosynthetic pathway. Mycology 96:1190–1198. https://doi.org/10.1080/15572536.2005.11832867

Winn RT, Lane GT (1978) Aflatoxin production on high moisture corn and sorghum with a limited incubation. J Dairy Sci 61(6):762–764. https://doi.org/10.3168/jds.S0022-0302(78)83645-5

Wogan GN (1992) Aflatoxins as risk for hepatocellular carcinoma in humans. Cancer Res 52(7 Suppl.): 2114–2118. PMID: 1311989. https://aacrjournals.org/cancerres/article/52/7_Supplement/2114s/498652/Aflatoxins-as-Risk-Factors-for-Hepatocellular

Woloshuk CP, Cavaletto JR, Cleveland TE (1997) Inducers of aflatoxin biosynthesis from colonized maize kernels are generated by an amylase activity from Aspergillus flavus. Phytopathol 87:164–169. https://doi.org/10.1094/PHYTO.1997.87.2.164

Worthington M, Luo R, Pelo J (2001) Copacabana method for spreading E. coli and yeast colonies. Biotechniques 30(4):738. https://doi.org/10.2144/01304bm05

Yeh A-I, Huang Y-C, Chen SH (2010) Effect of particle size on the rate of enzymatic hydrolysis of cellulose. Carbohydr Polym 79:192–199. https://doi.org/10.1016/j.carbpol.2009.07.049

You SY, Lim ST, Lee JH, Chung HJ (2014) Impact of molecular and crystalline structures on in vitro digestibility of waxy rice starches. Carbohydr Polym 112:729–735. https://doi.org/10.1016/j.carbpol.2014.06.065

Yu J (2012) Current understanding on aflatoxin biosynthesis and future perspective in reducing aflatoxin contamination. Toxins 4(11):1024–1057. https://doi.org/10.3390/toxins4111024

Zhou Y, Hu L, Zhou G, Luo Y, Liu R (2023) Sterigmatocystin induced cytotoxicity and disturbed lipid metabolism. J Agric Food Res 14:100673. https://doi.org/10.1016/j.jafr.2023.100673

Zingales V, Fernández-Franzón M, Ruiz M-J (2020) Sterigmatocystin: occurrence, toxicity and molecular mechanisms of action - a review. Food Chem Toxicol 146:111802. https://doi.org/10.1016/j.fct.2020.111802

Acknowledgements

The authors would like to thank László Szabó for the electron microscopic studies at the laboratory of the HUN-REN Hungarian Research Network, Budapest, Hungary.

Funding

Open access funding provided by Eszterhazy Karoly Catholic University. This work was funded by the Hungarian National Research, Development and Innovation Office within the National Competitiveness and Excellence Programs NVKP-16–1-2016–0009, 2020–1.1.2-PIACI-KFI-2021–00300, TKP2021-NVA-22, and 2022–2.1.1-NL-2022–00006 “Development of the Agrotechnology National Laboratory” (Grant agreement NKFIH-3524–1/2022) supported from the National Research, Development and Innovation Fund by the Hungarian Ministry of Culture and Innovation. Ildikó Bata-Vidács and Judit Kosztik are supported by the Lendület Program (award no. 96049) of the Hungarian Academy of Sciences and the Hungarian Research Network. In addition, funding was provided by projects OTKA K116631 and OTKA K115690, by the Hungarian Ministry of Technology and Industry project KEHOP-3.2.1–15-2021–00037, as well as Flagship Research Groups Programme of the Hungarian University of Agriculture and Life Sciences.

Author information

Authors and Affiliations

Contributions

Conceptualization: J.K.; methodology: K.I., I.B.-V., Á.T., and Ju.K.; formal analysis: K.I., I.B.-V., Á.T., Ju.K., A.S., M.V., I.N., Ist.N., M.M., Cs.D., and A.Sz.; investigation: K.I., I.B.-V., Á.T., Ju.K., A.S., M.V., I.N., Ist.N., M.M., Cs.D., and A.Sz.; data curation: K.I., I.B.-V., M.M., and J.K.; writing—original draft preparation: K.I., I.B.-V., and J.K.; writing—review and editing: M.M., A.S., A.Sz., and J.K.; visualization: K.I. and I.B.-V.; supervision: J.K.; project administration: I.B.-V.; funding acquisition: J.K. and A.Sz. All authors have read and agreed to the published version of the manuscript.

Corresponding author

Ethics declarations

Ethical approval

This article does not contain any studies with human participants or animals performed by any of the authors.

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Inotai, K., Bata-Vidács, I., Tóth, Á. et al. Glass bead system to study mycotoxin production of Aspergillus spp. on corn and rice starches. Appl Microbiol Biotechnol 108, 348 (2024). https://doi.org/10.1007/s00253-024-13190-7

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00253-024-13190-7