Abstract

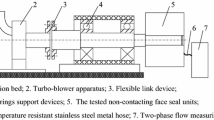

The porous elastic dam** metal mesh material (metal fiber) is considered as a joint seal. The features of this type of turbine seals and requirements to their application are presented. Data of the experimental studies and already created seal designs are given.

Similar content being viewed by others

References

Remizov, A.E., Vyatkov, V.V., and Lebedev, V.V., Improvement of Gas-Dynamic Efficiency of GTE Gas Turbine Stages at the Design Stage, Izv. Vuz. Av. Tekhnika, 2016, vol. 59, no. 4, pp. 106–110 [Russian Aeronautics (Engl. Transl.), 2016, vol. 59, no. 4, pp. 559–564].

Mamaev, B. I. and Ryabov, V.K., A Technique for the Gas Dynamic Calculation of the Cooled Multistage Turbine Performance, Izv. Vuz. Av. Tekhnika, 2015, vol. 58, no. 1, pp. 50–55 [Russian Aeronautics (Engl. Transl.), 2015, vol. 58, no. 1, pp. 62–70].

Belousov, A.I. and Parovai, F.V., Problems of Engine Sealing with the Use of MR Material, Izv. Vuz. Av. Tekhnika, 2001, vol. 44, no. 1, pp. 71–73 [Russian Aeronautics (Engl. Transl.), 2001, vol. 44, no. 1, pp. 105–108].

Kharitonov, N.P., Krotikov, V.A., and Ostrovskii, V.V., Organosilikatnye kompozitsii (Organosilicate Compositions), Leningrad: Nauka, 1980.

Borisov, V.A., Markin, M.I., Mikhailov, N.I., and Zakharov, Yu.P., USSR Inventor’s Certificate no. 1181359. Byul. Izobr., 2005, no. 34, MPK F01D 11/00, 9/02.

Borisov, V.A., Parovai, F.V., and Kuklev, V.E., Investigation and Development of Seals Made of MR Material for Connections of the Base Members, Tezisy dokladov 5go Vsesoyuznogo nauchno-tekhnicheskogo soveshchaniya po uplotnitel’noi tekhnike, (Proc. 5th All-Union Scientific-Technical Conf. of Sealing Technology), Sumy: Izd-vo Sumskogo Politekhn. In-ta, 1988, pp. 40–41.

Bogacheva, A.V., Pnevmaticheskie elementy sistem avtomaticheskogo upravleniya (Pneumatic Elements of Automatic Control Systems), Moscow: Mashinostroenie, 1966.

Borisov, V.A., Vysokotemperaturnye uplotneniya stykov detalei turbin aviatsionnykh gazoturbinnykh dvigatelei (High-Temperature Seals for Joints of Aircraft Gas-Turbine Engine Turbine Members), Available from VINITI, Samara, 1994, no. 1551, p. 35.

Author information

Authors and Affiliations

Corresponding author

Additional information

Russian Text © The Author(s), 2019, published in Izvestiya Vysshikh Uchebnykh Zavedenii, Aviatsionnaya Tekhnika, 2019, No. 2, pp. 89–94.

About this article

Cite this article

Belousov, A.I., Borisov, V.A. & Parovai, F.V. Research and Development of the Joint Seals for Gas Turbine Engine High-Temperature Turbine Stator Units. Russ. Aeronaut. 62, 267–273 (2019). https://doi.org/10.3103/S1068799819020132

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1068799819020132